ECU MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 519 of 1865

FUEL SYSTEM 4B

REPLACEMENT

Caution

a) Before performing the following procedure,

release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire

(Refer to page 4B—45).

b)When servicing the fuel system, keep

sparks, cigarettes, and open flames away

from the fuel.

76G04B-077

86U04A-101

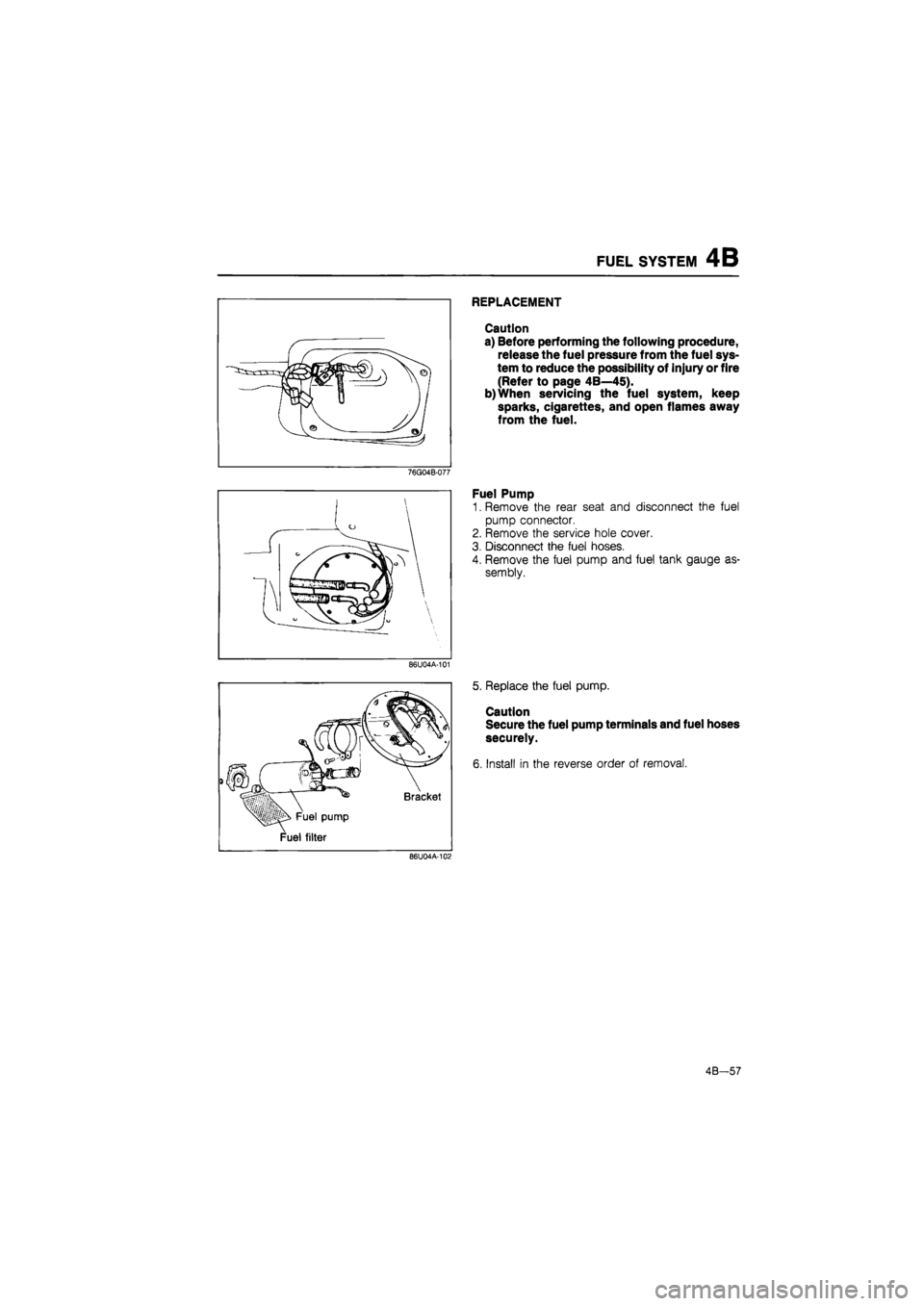

M Fuel pump

Fuel filter

Bracket

86U04A-102

Fuel Pump

1. Remove the rear seat and disconnect the fuel

pump connector.

2. Remove the service hole cover.

3. Disconnect the fuel hoses.

4. Remove the fuel pump and fuel tank gauge as-

sembly.

5. Replace the fuel pump.

Caution

Secure the fuel pump terminals and fuel hoses

securely.

6. Install in the reverse order of removal.

4B—57

Page 522 of 1865

4B FUEL SYSTEM

Pressure Regulator

1. Disconnect the vacuum hose and fuel return hose.

2. Remove the pressure regulator.

3. Install in the reverse order of removal.

Tightening torque:

8—11 N-m (0.8—1.1 m-kg, 69—95 in-lb)

76G04B-084

Pulsation Damper

1. Loosen the pulsation damper and remove it.

2. Install in the reverse order of removal.

76G04B-085

^-Fuel hose

ML*? ^-Fuel pump

^silntank filter

ti* e

76G04B-086

h

tS

Is o

Sjfbj

Fuel Filter

Low pressure side

Refer to page 4B—57.

86U04A-116

High pressure side

The fuel filter must be replaced at the intervals out-

lined in the maintenance schedule.

Warning

Always work away from sparks or open

flames.

1. Disconnect the fuel hoses from the fuel filter.

2. Remove the fuel filter and the bracket.

3. Install a new filter and the bracket.

4. Connect the fuel hoses.

Note

When installing the filter, push the fuel hoses

fully onto the fuel filter and secure the hoses

with spring clamps.

4B-60

Page 599 of 1865

4C INTAKE AIR SYSTEM

Installation Note

Water hose spring clamps

Face the clamp end as shown in the figure.

Gasket

Use new gaskets at the intake manifold, dynamic

chamber, and throttle body.

86U04A-056

• . v 1

Engine 1 Ml' ' •-

hanger ^ •

• i::£?^Solenoid valve bracket

Air cleaner. r^I. ^jUvW;

Th V

Ground harnesses

Make sure that the ground harnesses are tightened

securely at the following positions.

(1) Air cleaner upper case

(2) Solenoid valve braket

(3) Engine hanger

76G04C-062

Solenoid valve connectors

Connect the solenoid valve connectors at the posi-

tions shown in the figure.

76G04C-063

Inspection after installation

1. After completing installation, fill up the engine with

the specified engine coolant.

2. Warm up the engine and run it at idle.

3. Check for any vacuum, coolant, or fuel leaks.

76G04C-064

4C-38

Page 621 of 1865

4C FUEL SYSTEM

BW B

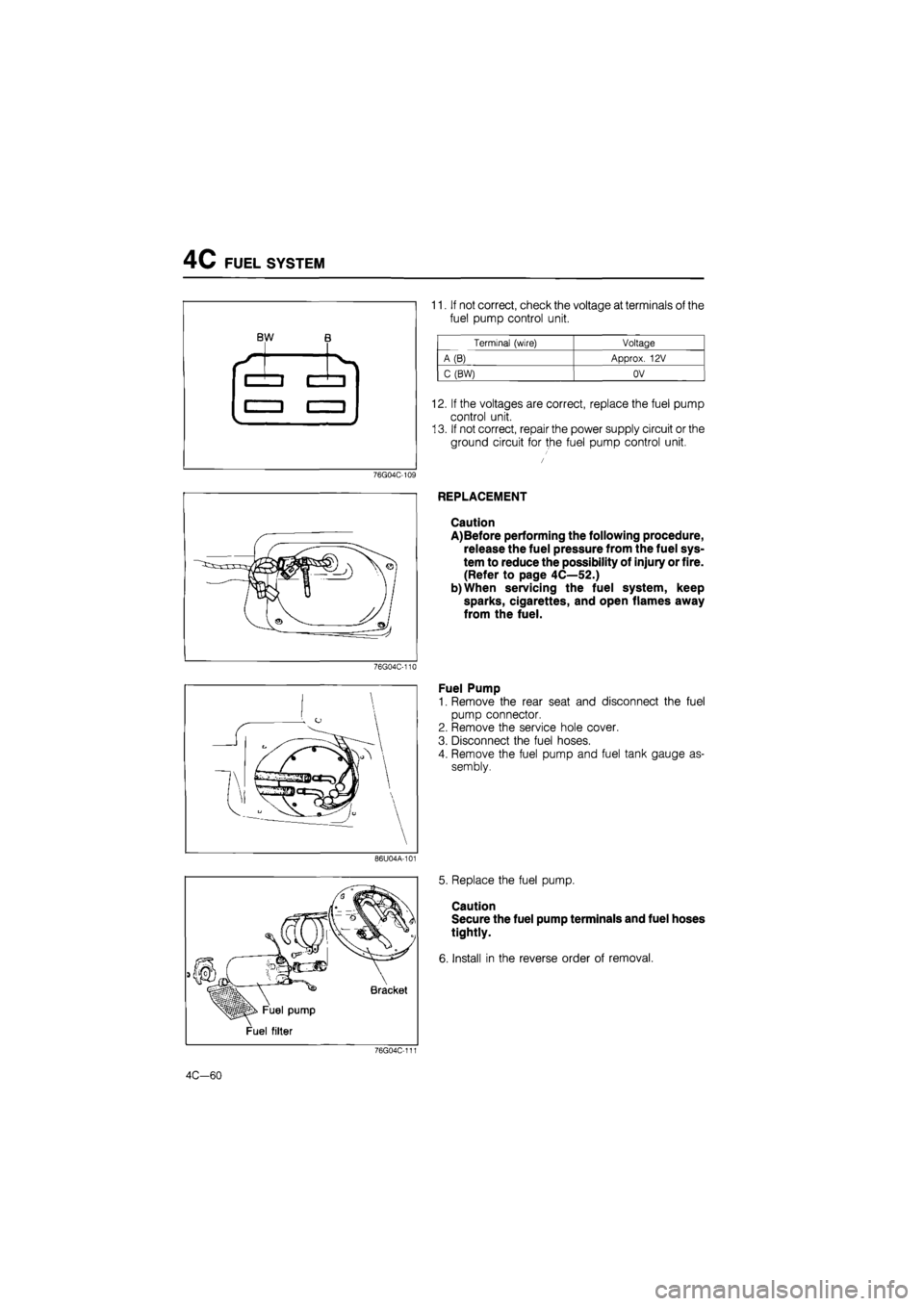

11. If not correct, check the voltage at terminals of the

fuel pump control unit.

76G04C-109

76G04C-110

86U04A-101

Fuel pump

Fuel filter

Bracket

76G04C-111

Terminal (wire) Voltage

A(B) Approx. 12V

C (BW) OV

12. If the voltages are correct, replace the fuel pump

control unit.

13. If not correct, repair the power supply circuit or the

ground circuit for the fuel pump control unit.

REPLACEMENT

Caution

A)Before performing the following procedure,

release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire.

(Refer to page 4C—52.)

b)When servicing the fuel system, keep

sparks, cigarettes, and open flames away

from the fuel.

Fuel Pump

1. Remove the rear seat and disconnect the fuel

pump connector.

2. Remove the service hole cover.

3. Disconnect the fuel hoses.

4. Remove the fuel pump and fuel tank gauge as-

sembly.

5. Replace the fuel pump.

Caution

Secure the fuel pump terminals and fuel hoses

tightly.

6. Install in the reverse order of removal.

4C—60

Page 625 of 1865

4C FUEL SYSTEM

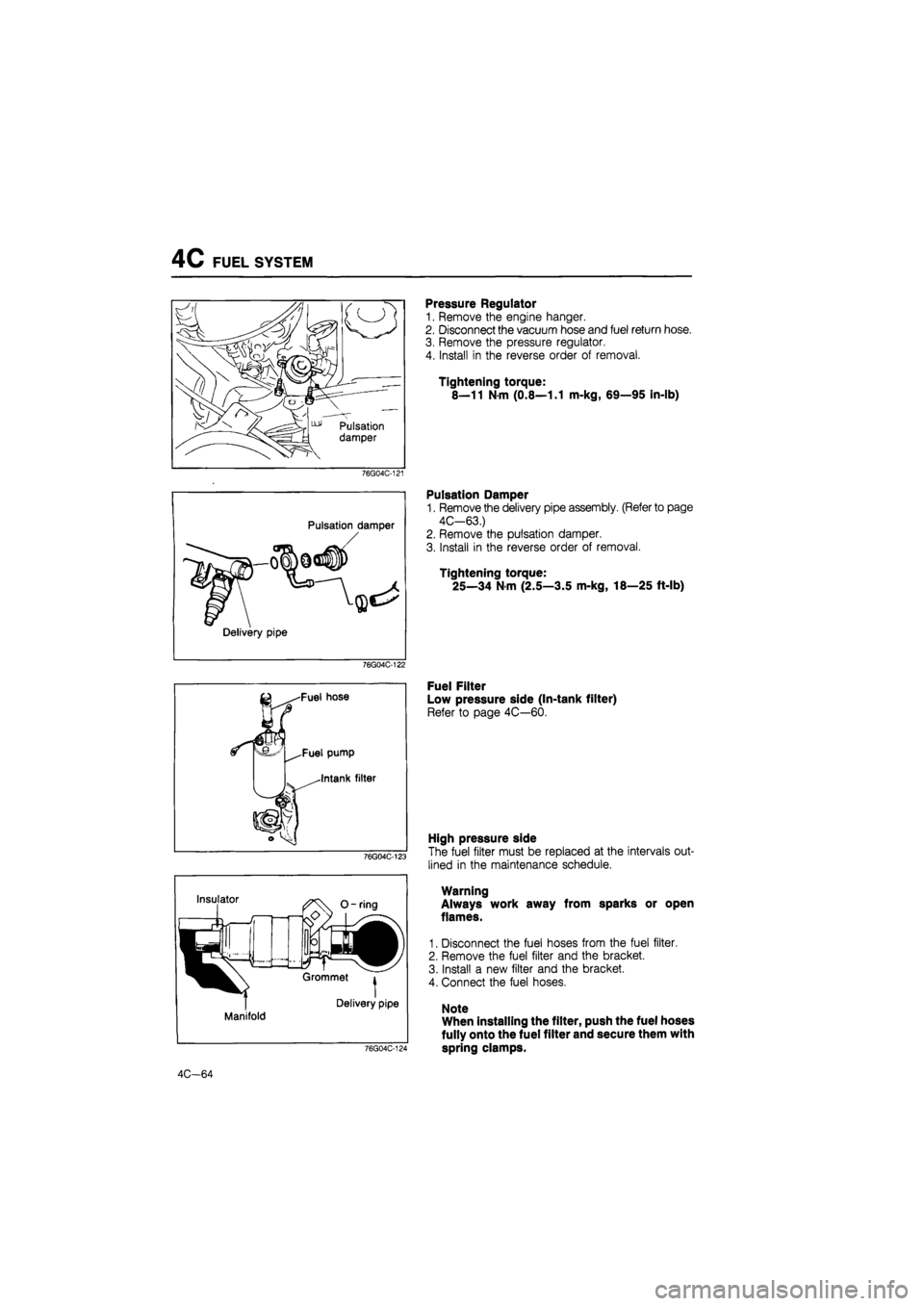

^ Pulsation

damper

76G04C-121

Pulsation damper

—

Delivery pipe

76G04C-122

Fuel hose

,Fuel pump

-Intank filter

76G04C-123

Insulator

f f r—

/ 0 DM

•

II r

O - ring

Grommet

Manifold

Delivery pipe

Pressure Regulator

1. Remove the engine hanger.

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the pressure regulator.

4. Install in the reverse order of removal.

Tightening torque:

8—11 Nm (0.8—1.1 m-kg, 69—95 in-lb)

Pulsation Damper

1. Remove the delivery pipe assembly. (Refer to page

4C-63.)

2. Remove the pulsation damper.

3. Install in the reverse order of removal.

Tightening torque:

25—34 N m (2.5—3.5 m-kg, 18—25 ft-lb)

Fuel Filter

Low pressure side (In-tank filter)

Refer to page 4C—60.

76G04C-124

High pressure side

The fuel filter must be replaced at the intervals out-

lined in the maintenance schedule.

Warning

Always work away from sparks or open

flames.

1. Disconnect the fuel hoses from the fuel filter.

2. Remove the fuel filter and the bracket.

3. Install a new filter and the bracket.

4. Connect the fuel hoses.

Note

When installing the filter, push the fuel hoses

fully onto the fuel filter and secure them with

spring clamps.

4C-64

Page 741 of 1865

ALTERNATOR 5

Stopper spring

Rear bearing

86U05X-026

86U05X-027

86U05X-028

.

',

; i

(S) -^jJSTjT^/

ASSEMBLY

Assemble in the reverse order of disassembly, refer-

ring to assembly note.

Assembly Note

Stopper spring installation

1. Fit the stopper spring into the eccentric groove of

the rear bearing circumference.

2. Check that the protruding part of the spring is fitted

into the deepest part of the groove.

Front bracket and rotor

When assembling the front bracket and rotor, tight-

en the locknut to the specified torque.

Tightening torque:

49—88 N-m (5—9 m-kg, 36—65 ft-lb)

Brush lifting

1. Before assembly, use a finger to hold the brushes

into the brush holder; then pass a wire

(

mm,

40—50 mm, 00.08 in, 1.6—2.0 in) through the

hole shown in the figure.

2. Secure the brushes in position.

Note

Be sure to remove wire after assembly is com-

pleted.

Rear bearing installation

1. Heat the rear bracket.

2. Press the rear bearing into the rear bracket.

3. Check that the rotor turns easily.

4BG05X-054

5-35

Page 797 of 1865

CLUTCH RELEASE CYLINDER

INSTALLATION

1. Install the clutch master cylinder.

2. Tighten the mounting nuts.

Tightening torque:

19—26 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

3. Tighten the clutch pipe flare nut securely with the

SST.

Tightening torque:

13—22 N m (1.3—2.2 m-kg, 9—16 ft-lb)

76G06X-021 4. Install the ABS relay box. (LHD)

After installation

1. Perform air bleeding. (Refer to page 6—14.)

2. Verify that there is no leakage.

3. Perform a road test.

CLUTCH RELEASE CYLINDER

86U06X-019

6-11

Page 800 of 1865

6 AIR BLEEDING

76U06X-031

4. Install the following parts:

(1) Push rod

(2) Boot

INSTALLATION

1. Install the release cylinder.

2. Tighten the installation bolts.

Tightening torque:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

3. Tighten the clutch pipe flare nut securely with the

SST

Tightening torque:

13—22 N-m (1.3—2.2 m-kg, 9—16 ft-lb)

After installation

1. Perform air bleeding.

2. Verify that there is no leakage from the hydraulic

circuit.

3. Perform a road test.

49 0259 770B

AIR BLEEDING

The clutch hydraulic system must be bled to remove

air that entered when the pipes were disconnected.

This bleeding is done as described below.

Note

a) The fluid in the reserve tank must be main-

tained at the 3/4 level or higher during air

bleeding.

b) Use only the specified fluid type. (Refer to

page 6—3)

c) Be careful not to spill clutch fluid onto a

painted surface.

1. Remove the bleeder cap, and attach a vinyl hose

to the bleeder screw.

2. Place the other end of the vinyl tube in a glass con-

tainer of the appropriate capacity.

3. Slowly pump the clutch pedal several times by

hand.

4. While the clutch pedal is depressed, loosen the

bleeder screw to let fluid and air escape.

Then close the bleeder screw.

5. Repeat step 3 and 4 until no more air bubbles are

in the fluid.

6. Check for correct clutch operation.

86U06X-027

86U06X-028

49 0259 770B

76G06X-023

6—14

expert22 ajia http://rutracker.org

Page 814 of 1865

7A ON-VEHICLE MAINTENANCE

86U07A-012

86U07A-013

86U07A-014

8. Tap the new oil seal into the transaxle case with

the SST.

Note

a) Tap in until the oil seal installer contacts the

case.

b)Coat the oil seal lip with transaxle oil.

9. Replace the driveshaft end clip with a new one.

Insert the clip with the gap at the top of the groove.

10. Install the driveshaft as follows:

(1) Pull the front hub outward, then

fit

the driveshaft

into the transaxle.

(2) Insert the driveshaft into the transaxle by push-

ing on the wheel hub assembly.

Note

a) Be careful not to damage the oil seal.

b) After installation is finished, pull the front

hub slowly outward to check that the

driveshaft is held securely by the clip.

11. Install the lower arm ball-joint to the knuckle, and

tighten the clinch bolt.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

12. Install the tie-rod end and new cotter pin.

Tightening torque:

29—44 N m (3.0—4.5 m-kg, 22—33 ft-lb)

86U07A-015

7 A—8

Page 861 of 1865

INSTALLATION 7A

14. Install the clutch release cylinder.

Tightening torque: 19—26 N-m

(1.9—2.6 m-kg, 14—19 ft-lb)

76G07A-060

15. Install the gusset plates.

Tightening torque: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

76G07A-061

16. Replace the clips at the end of the driveshafts and

joint shaft with new ones.

17. Install the joint shaft and right driveshaft as follows:

(1) Install and tighten the reamer bolts (A); then in-

stall and tighten the standard bolts (§).

Tightening torque:

® :7—10 N-m

(70—100 cm-kg, 43—61 in-lb)

(B) :42—62 Nm

(4.3—6.3 m-kg, 31—46 ft-lb)

76G07A-062

(2) Remove the SST and insert the shaft into the

transaxle.

(3) Pull the front hub outward and connect the

driveshaft to the joint shaft.

(4) Push the joint at the differential side to secure-

ly connect the driveshaft to the joint shaft.

Note

a) After installation, pull the front hub outward

to confirm that the driveshaft doesn't come

out.

b)Do not damage the oil seal.

86U07A-219

7A-55