lock MAZDA 626 1987 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 213 of 1865

ENGINE

(DIESEL)

OUTLINE 1C— 2

STRUCTURAL VIEW 1C— 2

SPECIFICATIONS 1C— 3

TROUBLESHOOTING GUIDE 1C— 3

TUNE-UP PROCEDURE 1C— 5

ON-VEHICLE INSPECTION 1C—10

COMPRESSION 1C—10

ON-VEHICLE MAINTENANCE 1C—11

TIMING BELT 1C—11

CYLINDER HEAD 1C—16

VALVE SEAL 1C—24

REMOVAL 1C—31

DISASSEMBLY 1C—34

AUXILIARY PARTS 1C—34

TIMING BELT 1C—36

INJECTION PUMP 1C—39

CYLINDER HEAD 1C—40

CYLINDER BLOCK 1C—43

INSPECTION AND REPAIR 1C—47

ASSEMBLY 1C—62

CYLINDER BLOCK 1C—62

CYLINDER HEAD 1C—73

INJECTION PUMP 1C—78

TIMING BELT 1C—81

AUXILIARY PARTS 1C—87

INSTALLATION 1C—91

TRANSAXLE ASSEMBLY 1C—91

ENGINE INSTALLATION 1C—92 76G01C-001

Page 219 of 1865

TUNE-UP PROCEDURE 1C

P/S oil pump Checking point

B

Vacuum/^ i V pumpf o ) y ®

v Rear \ camshaft

J

pulley

A-—mP

P/S oil pump \ L^

76G01C-009

Drive Belt

1. Check the drive belt for wear, cracks, or fraying.

Replace if necessary.

2. Check the drive belt deflection by applying moder-

ate pressure (98 N, 10 kg, 22 lb) midway between

the pulleys.

Alternator

Deflection mm (in)

New 8.0-10.0 (0.31-0.39)

Used 9.0—11.0 (0.35—0.43)

If necessary, loosen the idler lock nut and adjust

the belt deflection by turning the adjust bolt.

Tightening torque:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

Vacuum pump and P/S oil pump

Deflection mm (in)

Vacuum

pump

New 7.5-8.5 (0.30-0.33) Vacuum

pump Used 8.5-9.5 (0 33-0.37)

P/S oil pump

New 6.5-7.5 (0.26-0 30) P/S oil pump Used 7.0-8.0 (0.28—0.31)

If necessary, adjust the belt deflection as follows.

(1) Loosen the vacuum pump bolts ©and (§).

(2) Lever the vacuum pump outward and apply

tension to the belt.

(3)Tighten the adjust bolt

Tightening torque:

19—26

N

m (1.9—2.6 m-kg, 14—19 ft-lb)

(4)Tighten the mounting bolt

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)

A/C compressor

Deflection mm (in)

New 8.5—9.5 (0.33—0.37)

Used 9.5-10.5 (0.37-0.41)

If necessary, loosen the idler lock nut and adjust

the belt deflection by turning the adjust bolt.

Tightening torque:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

1C-7

Page 220 of 1865

1C TUNE-UP PROCEDURE

Comprex supercharger

Deflection mm (in)

New 4 0-6.0 (0.16—0.23)

Used 8.0-10 0 (0 31-0.39)

If necessary, loosen the idler lock nut and adjust

the belt deflection by turning the adjust bolt.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

76G01C-011

o

INJECTION TIMING

1. Disconnect the negative battery cable.

2. Release the CSD using the screw driver.

3. Remove the cover on the clutch housing.

4. Turn the flywheel and set the indicator at ATDC.

5. Disconnect the injection pipes from the injection

pump.

76G04D-008

6. Remove the hydraulic head plug from the injec-

tion pump.

7. Mount the SST into the plug hole on the hydraulic

head so the tip of the dial gauge pointer touches

the plunger end of the pump and the dial gauge

indicates approx. 2.0 mm (0.08 in).

76G04D-009

8. Turn the crankshaft slowly counterclockwise to

30-50° BTDC.

9. Make sure the dial indicator pointer no longer

moves by slightly turning the crankshaft.

10. Set the dial gauge scale to Zero at the pointer.

76G04D-010

1C-8

Page 221 of 1865

TUNE-UP PROCEDURE 1C

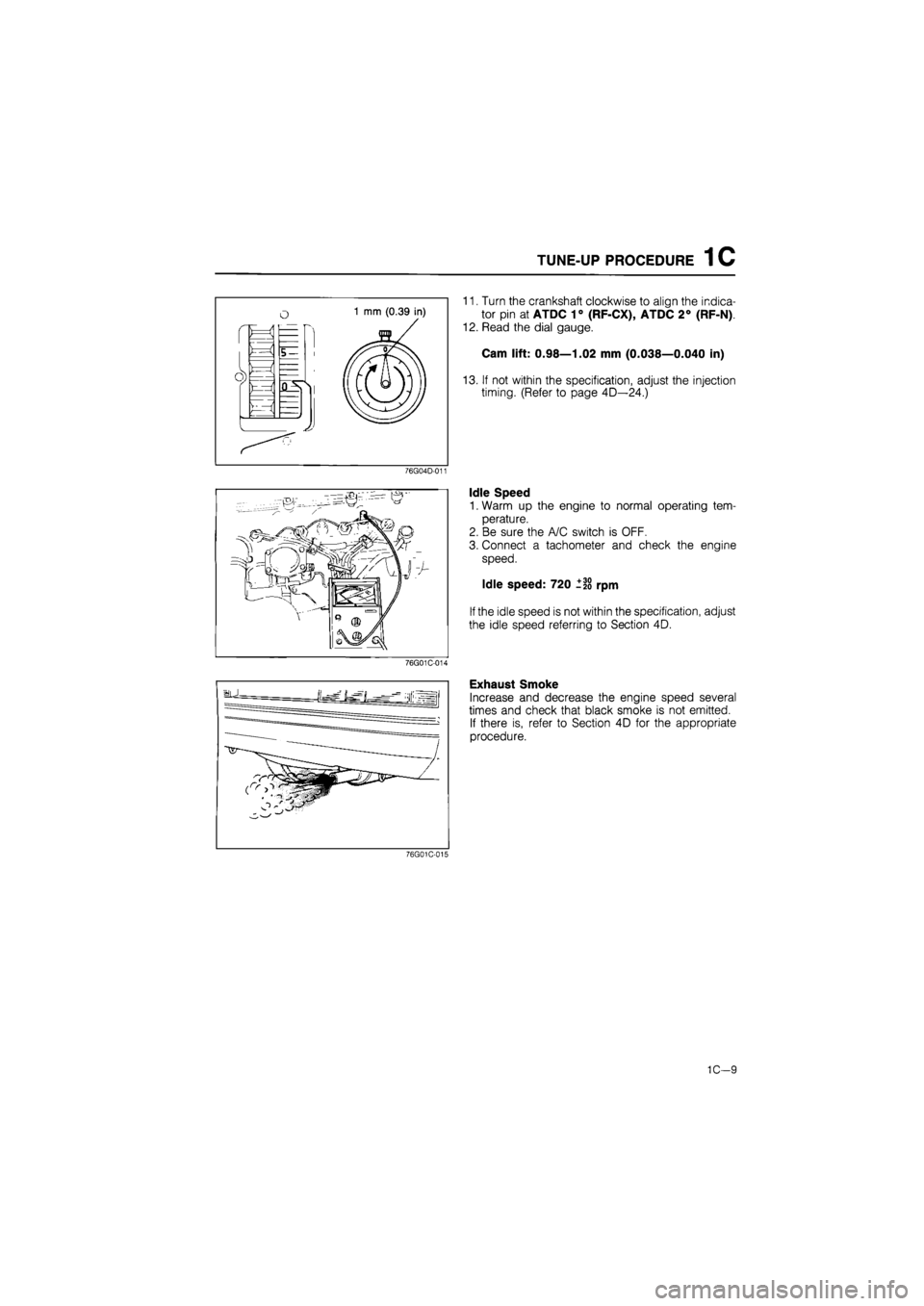

11. Turn the crankshaft clockwise to align the indica-

tor pin at ATDC 1° (RF-CX), ATDC 2° (RF-N)

12. Read the dial gauge.

Cam lift: 0.98—1.02 mm (0.038—0.040 in)

13. If not within the specification, adjust the injection

timing. (Refer to page 4D—24.)

76G04D-011

Idle Speed

1. Warm up the engine to normal operating tem-

perature.

2. Be sure the A/C switch is OFF.

3. Connect a tachometer and check the engine

speed.

Idle speed: 720 ±20 rpm

If the idle speed is not within the specification, adjust

the idle speed referring to Section 4D.

76G01C-014

Exhaust Smoke

Increase and decrease the engine speed several

times and check that black smoke is not emitted.

If there is, refer to Section 4D for the appropriate

procedure.

76G01C-015

1C—9

Page 224 of 1865

1 C ON-VEHICLE MAINTENANCE (TIMING BELT)

76G01C-020

76G01C-238

Kww

76G01C-021

Removal note

Timing belt

1. Aligh the timing marks of each pulleys.

2. Affix the injection pump pulley to the bracket us-

ing two bolts (35—40 mm, 1.4—1.6 in).

Caution

a) Do not turn in the reverse direction of en-

gine revolution.

b) After removing the timing belt, do not ro-

tate the crankshaft pulley or camshaft

pulley.

3. Make the forward direction arrow on the timing belt.

Note

Direction arrow is to reassemble the timing

belt in the same direction.

4. Loosen the timing belt tensioner bolt.

5. Shift the tensioner outwards as far as possible, and

temporarily tighten it.

6. Suspend the engine with chain block on the front

engine hanger.

7. Remove the No.3 engine mount.

8. Remove the timing belt.

Caution

Do not allow any oil or grease on the timing

belt.

Inspection and Repair

Inspect the following parts. (Refer to page 1C—60,

61).

1. Timing belt

2. Timing belt tensioner and spring

3. Timing belt idler pulley

4. Timing belt pulley

76G01C-022

1C—12

Page 226 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 C

2. Install the timing belt tensioner and spring.

3. Temporarily secure the tensioner with it shifted

outwards.

63G01D-330

4. Install the timing belt.

Caution

a) The timing belt must be reinstalled in the

same direction of previous rotation, if it is

to be reused.

b) Be sure that there is no oil, grease, or dirt

on the timing belt.

76G01C-024

Install the idler pulley.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27-38 ft-lb)

Remove the affixing bolts from the injection pulley.

76G01C-025

7. Loosen the tensioner lock bolt.

8. Turn the crankshaft twice in the direction of rota-

tion (clockwise).

Caution

Do not rotate reverse direction.

9. Check that each timing mark is correcty aligned.

If not aligned, remove the timing belt. Repeat step

1-8.

76G01C-030

1C-14

Page 227 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 C

76G01C-027

76G01C-028

76G01C-029

Checking

point

Idler pulley

Crankshaft pulley zQi A/C

Checking point compressor

76G01C-030

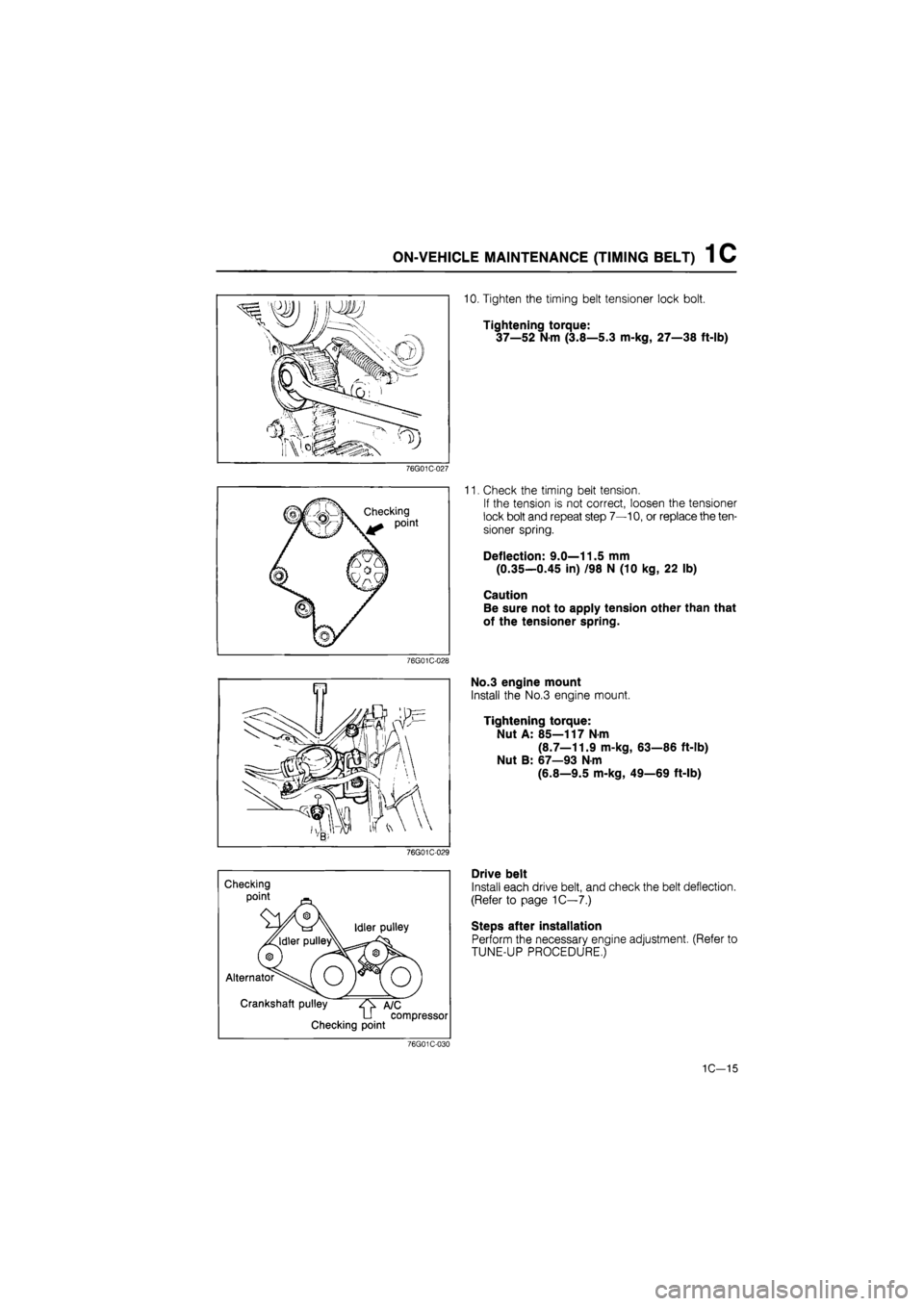

10. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)

11. Check the timing belt tension.

If the tension is not correct, loosen the tensioner

lock bolt and repeat step 7—10, or replace the ten-

sioner spring.

Deflection: 9.0—11.5 mm

(0.35—0.45 in) /98 N (10 kg, 22 lb)

Caution

Be sure not to apply tension other than that

of the tensioner spring.

No.3 engine mount

Install the No.3 engine mount.

Tightening torque:

Nut A: 85—117 N-m

(8.7—11.9 m-kg, 63—86 ft-lb)

Nut B: 67—93 N-m

(6.8—9.5 m-kg, 49—69 ft-lb)

Drive belt

Install each drive belt, and check the belt deflection.

(Refer to page 1C—7.)

Steps after installation

Perform the necessary engine adjustment. (Refer to

TUNE-UP PROCEDURE,)

1C-15

Page 229 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

Removal note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep fire and open flame away from the fuel

area.

Plug the disconnected hoses to avoid fuel leakage.

76G01C-033

2. Hold the camshaft with a wrench (29 mm, 1.14 in)

and loosen the camshaft pulley lock bolt.

Caution

Do not damage the cylinder head edge with

the wrench.

4BG01B-044

3. Separate the camshaft pulley from the camshaft

with the SST.

Caution

Do not hit the camshaft pulley with a hammer.

Rear camshaft pulley

Remove the rear camshaft pulley in the same man-

ner used for camshaft pulley.

76G01C-044

1C—17

Page 230 of 1865

1 C ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

76G01C-241

76G01C-035

69G01A-031

Injection pump pulley

1. Put two bolts of 35—40 mm (1.4—1.6 in) length

into the arms of the injection pump pulley and af-

fix them in the threaded hole of the injection pump

bracket.

2. Loosen the injection pump pulley lock bolt.

3. Separate the injection pump pulley from the injec-

tion pump shaft with the SST.

Cylinder head bolt

Loosen the cylinder head bolts in two or three steps,

and in the order shown in the figure.

Disassembly of Cylinder Head

Refer to page 1C—40.

Inspection of Cylinder Head

Refer to page 1C—47.

Assembly of Cylinder Head

Refer to page 1C—73.

76G01C-048

1C-18

Page 232 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

76G01C-037

Apply engine oil

/

Cylinder head bolt

below head length

76G01C-038

(8) (4; D (5)

® ®

76G01C-039

3m-kg

(21.7ft-lb

Installation

Cylinder head

1. Throughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt and grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

6. Apply engine oil to the threads and the seat face

of the cylinder head bolts.

7. Tighten the cylinder head bolts.

(1) Tighten the bolts to the specified torque, in the

order shown in the figure.

Tightening torque:

29 N-m (3.0 m-kg, 22 ft-lb)

(2) Make paint marks on the bolt heads, as shown

in the figure.

(3) With the paint marks as a reference point, turn

the cylinder head bolts another 90°

(90°—105°) in the tightening direction. Tight-

en them in the order.

(4) Then tighten them once again 90°

(90°—105°) in the tightening order.

Caution

Be absolutely sure that the bolts are tightened

in the proper order.

76G01C-044

1C—20