tire size MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 37 of 1865

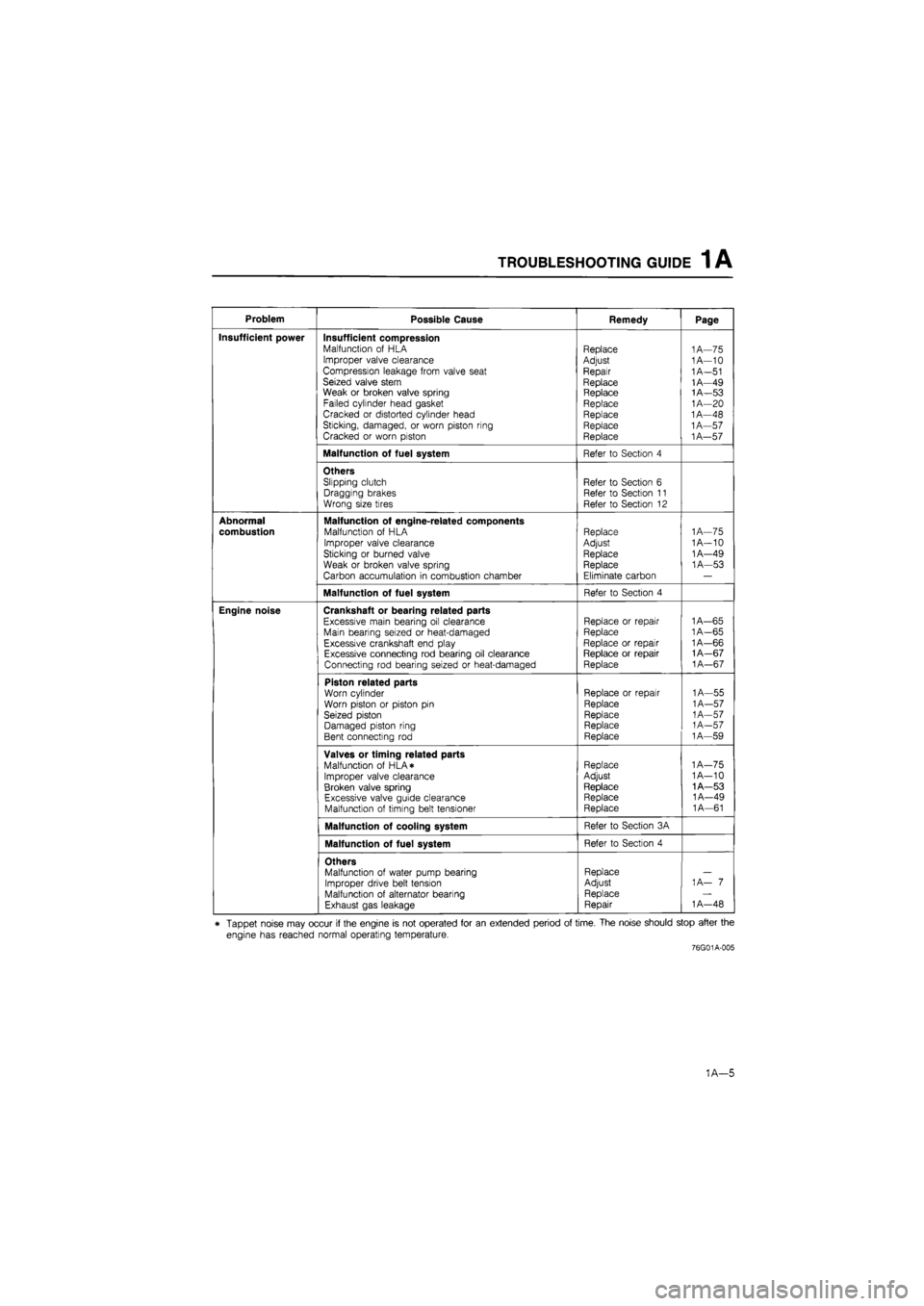

TROUBLESHOOTING GUIDE 1 A

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Malfunction of HLA Improper valve clearance Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Replace

Adjust

Repair

Replace Replace Replace Replace Replace Replace

1A—75 1A—10

1

A—51 1A—49 1A—53

1

A—20 1A—48 1A—57

1

A—57

Malfunction of fuel system Refer to Section 4

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal

combustion

Malfunction of engine-related components Malfunction of HLA

Improper valve clearance Sticking or burned valve

Weak or broken valve spring Carbon accumulation in combustion chamber

Replace Adjust Replace Replace

Eliminate carbon

1

A—75 1A—10 1A—49 1A—53

Malfunction of fuel system Refer to Section 4

Engine noise Crankshaft or bearing related parts

Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1A—65

1

A—65 1A—66 1A—67

1

A—67

Piston related parts Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair

Replace

Replace Replace Replace

1A—55

1

A—57

1

A—57

1

A—57 1A—59

Valves or timing related parts Malfunction of HLA* Improper valve clearance Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Replace Adjust

Replace Replace Replace

1A—75 1A—10 1A—53 1A—49 1A—61

Malfunction of cooling system Refer to Section 3A

Malfunction of fuel system Refer to Section 4

Others Malfunction of water pump bearing Improper drive belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1 A— 7

1

A—48

* Tappet noise may occur if the engine is not operated for an extended period of time. The noise should stop after the

engine has reached normal operating temperature.

76G01A-005

1A—5

Page 89 of 1865

INSPECTION AND REPAIR 1A

76G01A-068

Piston

1. Inspect the outer circumferences of all pistons for

seizure or scoring. Replace if necessary.

2. Measure the outer diameter of each piston at a right

angle (90°) to the piston pin, 18 mm (0.709 in)

below the oil ring land lower edge.

Piston diameter mm (in)

Size Diameter

LU

OO LL LL Standard 85.944-85.964 (3.3836-3.3844)

LU

OO LL LL 0.25 (0.010) oversize 86.194-86.214 (3.3935-3.3942)

LU

OO LL LL

0.50 (0.020) oversize 86 444-86.464 (3.4033-3.4041)

F6

Standard 80 944-80.964 (3.1868-3.1876)

F6

0.25 (0.010) oversize 81.194-81.214 (3.1966-3.1974)

F6 0.50 (0.020) oversize 81.444-81.464 (3.2065-3.2072) F6

0.75 (0.030) oversize 81.694-81.714 (3.2163-3.2171)

F6

1.00 (0.039) oversize 81.944-81.964 (3.2261-3,2269)

3. Check the piston to cylinder clearance.

ClGdrsncG1

0.036—0.075 mm (0.0014—0.0030 in)

Maximum: 0.15 mm (0.0059 in)

4. If the clearance exceeds the maximum, replace the

piston or rebore the cylinders to fit oversize pistons.

Caution

If the piston is replaced, replace the piston

rings also.

76G01A-130

Piston and Piston Ring

1. Measure the piston ring to ring land clearance

around the entire circumference using a new pis-

ton ring.

Clearance (Top and Second):

0.03—0.07 mm (0.001—0.003 in)

Maximum: 0.15 mm (0.006 in)

2. If the clearance exceeds the maximum, replace the

piston.

69G01A-125

1A—57

Page 135 of 1865

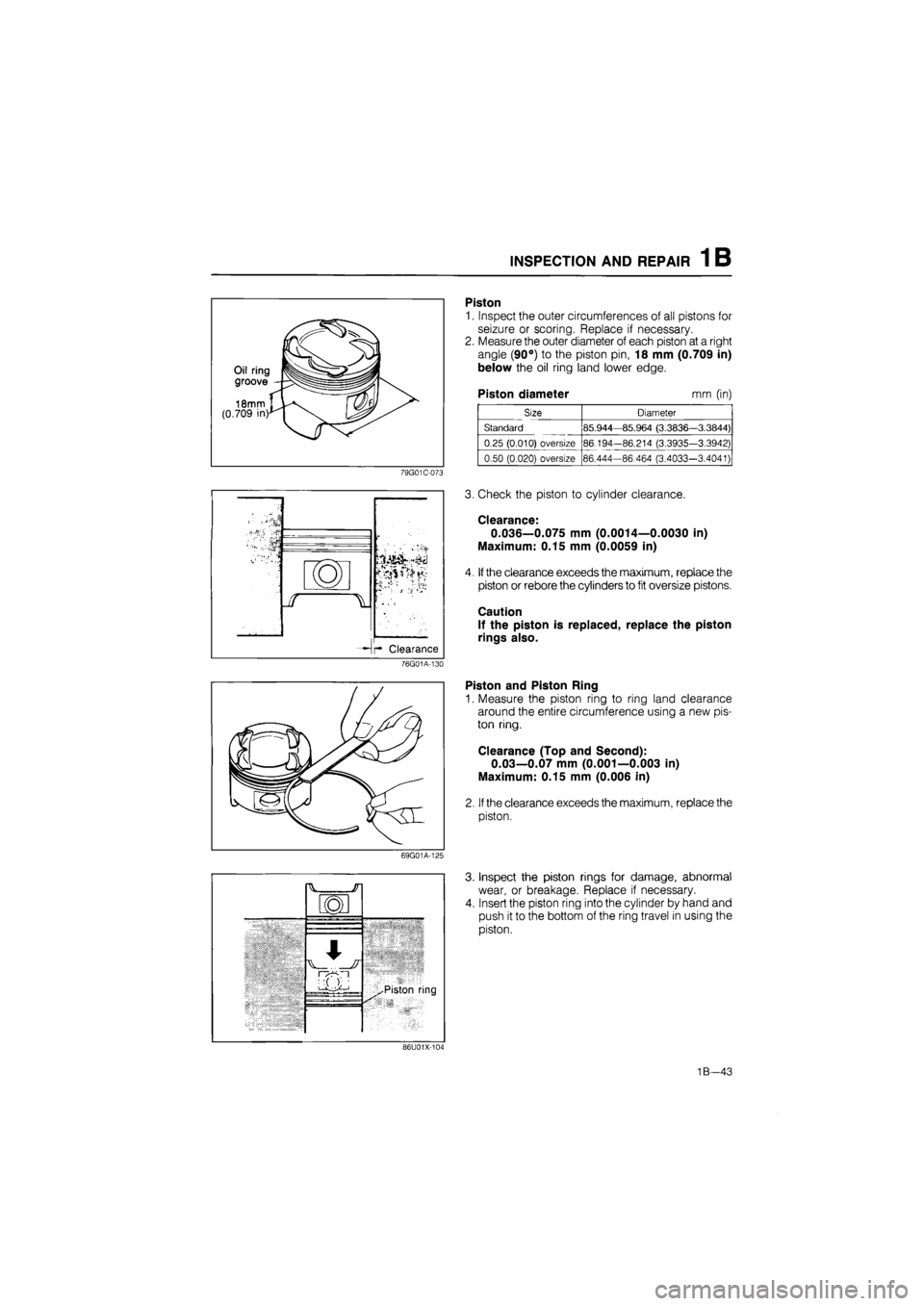

TROUBLESHOOTING GUIDE 1 B

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Malfunction of HLA Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Replace Repair

Replace

Replace Replace Replace Replace Replace

1B—60 1B—37 1B—35 1B—38 1B-16 1B—34 1B—43 1B—43

Malfunction of fuel system Refer to Section 4C

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal combustion Malfunction of engine-related components Malfunction of HLA Sticking or burned valve

Weak or broken valve spring Carbon accumulation in combustion chamber

Replace Replace Replace

Eliminate carbon

1B-60

1B-35

1B—38

Malfunction of fuel system Refer to Section 4C

Engine noise Crankshaft or bearing related parts

Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1B-51 1B—51 1B—52 1B—53 1B—53

Piston related parts

Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair

Replace

Replace Replace Replace

1B—41 1B-44 1B—43 1B—43 1B-44

Valves or timing related parts Malfunction of HLA* Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Replace Replace Replace Replace

1B-60 1B—38 1B—35 1B—47

Malfunction of cooling system Refer to Section 3A

Malfunction of fuel system Refer to Section 4C

Others Malfunction of water pump bearing Improper drive belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1B— 6

1B—34

* Tappet noise may occur if the engine is not operated for an extended period of time. The noise should stop after the engine has reached normal operating temperature. 76G01B-004

1B—4

Page 174 of 1865

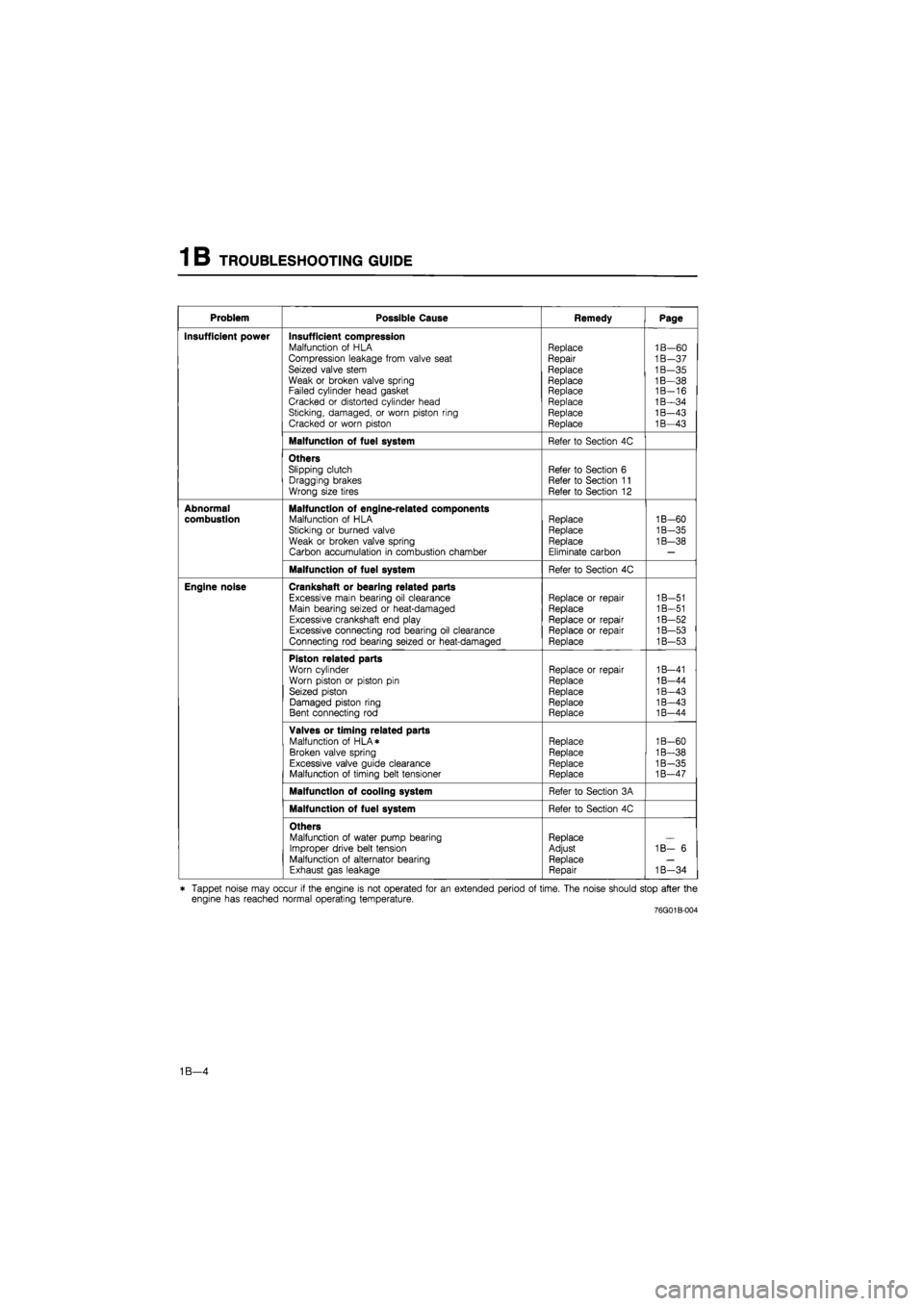

INSPECTION AND REPAIR 1 B

Oil ring

groove

18mm IJUv. (0.709 in)*"! ^

79G01C-073

r Clearance

76G01A-130

69G01A-125

HV JT

101

^^Piston ring

vAv n^-n

iXXi ^^Piston ring ^^Piston ring

Piston

1. Inspect the outer circumferences of all pistons for

seizure or scoring. Replace if necessary.

2. Measure the outer diameter of each piston at a right

angle (90°) to the piston pin, 18 mm (0.709 in)

below the oil ring land lower edge.

Piston diameter mm (in)

Size Diameter

Standard 85.944—85.964 (3.3836—3.3844)

0.25 (0.010) oversize 86.194-86.214 (3.3935-3.3942)

0.50 (0.020) oversize 86.444-86.464 (3.4033-3.4041)

3. Check the piston to cylinder clearance.

Clearance:

0.036—0.075 mm (0.0014—0.0030 in)

Maximum: 0.15 mm (0.0059 in)

4. If the clearance exceeds the maximum, replace the

piston or rebore the cylinders to fit oversize pistons.

Caution

If the piston is replaced, replace the piston

rings also.

Piston and Piston Ring

1. Measure the piston ring to ring land clearance

around the entire circumference using a new pis-

ton ring.

Clearance (Top and Second):

0.03—0.07 mm (0.001—0.003 in)

Maximum: 0.15 mm (0.006 in)

2. If the clearance exceeds the maximum, replace the

piston.

Inspect the piston rings for damage, abnormal

wear, or breakage. Replace if necessary.

Insert the piston ring into the cylinder by hand and

push it to the bottom of the ring travel in using the

piston.

86U01X-101

1B—43

Page 216 of 1865

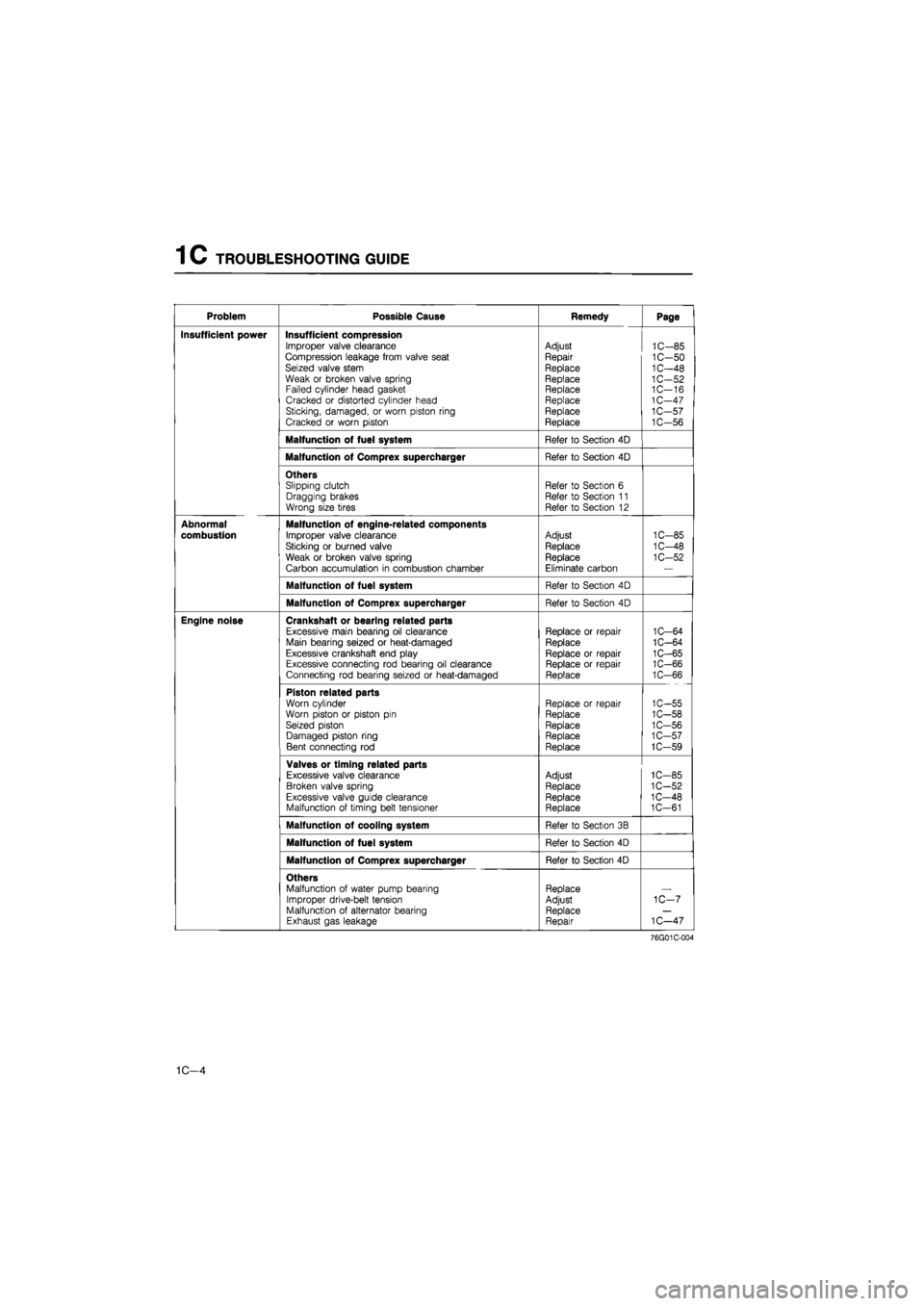

1 C TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Improper valve clearance Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Adjust

Repair

Replace Replace Replace Replace Replace Replace

1C-85 1C-50 1C-48 1C-52 1C—16 1C-47 1C-57 1C-56

Malfunction of fuel system Refer to Section 4D

Malfunction of Comprex supercharger Refer to Section 4D

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal

combustion

Malfunction of engine-related components

Improper valve clearance

Sticking or burned valve

Weak or broken valve spring

Carbon accumulation in combustion chamber

Adjust

Replace

Replace Eliminate carbon

1C-85

1C-48

1C-52

Malfunction of fuel system Refer to Section 4D

Malfunction of Comprex supercharger Refer to Section 4D

Engine noise Crankshaft or bearing related parts Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1C-64 1C-64 1C-65 1C-66 1C-66

Piston related parts Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair Replace

Replace Replace Replace

1C-55 1C-58 1C-56 1C-57 1C-59

Valves or timing related parts Excessive valve clearance Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Adjust Replace Replace Replace

1C-85 1C-52 1C-48 1C-61

Malfunction of cooling system Refer to Section 3B

Malfunction of fuel system Refer to Section 4D

Malfunction of Comprex supercharger Refer to Section 4D

Others Malfunction of water pump bearing Improper drive-belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1C-7

1C—47

76G01C-004

1C—4

Page 269 of 1865

INSPECTION AND REPAIR 1C

-Clearance

3. Check the piston to cylinder clearance.

Clearance-

0.032—0.050 mm (0.0013—0.0020 in)

Maximum: 0.15 mm (0.0059 in)

4. If the clearance exceeds the maximum, replace the

piston or rebore the cylinders to fit oversize pistons.

Note

If the piston is replaced, replace the piston

rings also.

76G01C-134

69G01A-125

Piston and Piston Ring

1. Measure the piston ring to ring land clearance

around the entire circumference using a new pis-

ton ring.

Clearance (Top)

RF-CX: 0.18—0.22 mm (0.0071—0.0087 in)

RF-N : 0.05—0.09 mm (0.0020—0.0035 in)

Clearance (Second):

0.04—0.08 mm (0.0016—0.0031 in)

Maximum: 0.2 mm (0.008 in)

2.

If

the clearance exceeds the maximum, replace the

piston.

3. Inspect the piston rings for damage, abnormal

wear, or breakage. Replace if necessary.

4. Insert the piston ring into the cylinder by hand and

push it to the bottom of the ring travel in using the

piston.

86U01X-104

5. Measure each piston ring end gap with a feeler

gauge. Replace if necessary.

End gap (Top and second)

RF-CX: 0.20—0.35 mm (0.008—0.014 in)

RF-N : 0.20—0.40 mm (0.008—0.016 in)

End gap (Oil rail):

0.20—0.40 mm (0.008—0.016 in)

Maximum: 1.0 mm (0.039 in)

76G01C-144

1C-57

Page 846 of 1865

7A ASSEMBLY

11. Install the SST.

76G07A-039

76G07A-040

76G07A-041

Thickness (Differential)

mm

(in)

0.10 (0.004) 0.70 (0.026)

0.15 (0.006) 0.75 (0.028)

0.20 (0.008) 0.80 (0.030)

0.25 (0.010) 0.85 (0.032)

0.30 (0.012) 0.90 (0.034)

0.35 (0.014) 0.95 (0.036)

0.40 (0.016) 1.00 (0.038)

0.45 (0.018) 1.05 (0.040)

0.50 (0.020) 1.10 (0.042)

0.60 (0.022) 1.15 (0.044)

0.65 (0.024) 1.20 (0.046)

12. Adjust the selector with the SST until the specified

preload is obtained.

Preload:

0.5 N-m (5 cm-kg, 4.3 in-lb)

13. Use a feeler gauge to measure the gap in the selec-

tor for the differential.

Note

Measure the gap around the entire circumfer-

ence of the selector

76G07A-042

14. Add 0.15 mm (0.0059 in) to the measured clear-

ance and select the combination of shims whose

thickness added is nearest higher than that valve.

See the table for available shim sizes.

Example: 0.32 mm (0.013 in)

0.32 mm (0.013 in) + 0.15 mm (0.006 in) =

0.47 mm (0.019 in).

So the nearest shim (on the thick side) to 0.47

mm (0.019 in) is 0.50 mm (0.020 in).

Note

Use a maximum of two shims.

15. Remove the SST and transaxle case.

16. Remove the primary shaft assembly and the

differential.

17. Remove the bearing outer races.

7A—40

Page 900 of 1865

7B TROUBLESHOOTING (G4A-EL)

STEP 7 (ROAD TEST)

This step is performed to inspect for problems at the various ranges. If these tests show any problems,

adjust or replace by referring to the electronic system component or mechanical sections.

Caution

Perform the test at normal ATF operating temperature (50—80°C, 122—176°F).

D Range Test

Shift point, shift pattern, and shift shock

1. Shift the selector lever to D range and select the Power mode.

2. Accelerate the vehicle with half and full throttle valve opening.

Note

Throttle sensor voltage of the EC-AT Tester represents the throttle valve opening.

3. Check that 1-2, 2-3 and 3-OD up-shifts and downshifts and lock-up are obtained. The shift points

must be as shown in the D range (Power) shift diagram.

Note

a) Drum speed (rpm) of the EC-AT Tester represents the shift point.

b) Vehicle speed of the EC-AT Tester and speedometer and vehicle speed on a chassis

roller may not meet the specified shift pattern because of tire size. Therefore, check

the shift points with the Drum speed.

c) There is no lock-up when the coolant temperature is below 72°C (162°F).

d) There is no overdrive when the cruise control is operating and there is a 3 km/h (1.9

mph) difference between the pre-set cruise speed and vehicle speed, or set or resume

switch is ON.

e) There is no lock-up when the brake pedal is depressed.

4. Check the up-shifts for shift shock or slippage in the same manner.

5. While driving in OD, shift the selector lever to S range and check that 4-3 downshift immediately

occurs, then decelerate and check that engine braking effect is felt in only 3rd gear.

7B—34

Page 919 of 1865

TROUBLESHOOTING (G4A-HL) 7B

STEP 5 (ROAD TEST)

This step is performed to inspect for problems at the various ranges.

If

these tests show any problems,

adjust or replace by referring to the mechanical sections.

Perform the test at normal ATF operating temperature (50—80°C, 122—176°F).

D Range Test

Shift point, shift pattern, and shift shock

1. Shift the selector lever to D range and depress the OD OFF switch.

2. Accelerate the vehicle with half (4/8) and full (8/8) throttle valve opening.

3. Check that 1-2, 2-3 and 3-OD up-shifts and downshifts and lock-up are obtained. The shift points

must be as shown in the D range shift diagram.

Note

a) Vehicle speed on a chassis roller may not meet the specified shift diagram because of

tire size.

b) There is no lock-up or OD when the coolant temperature is below 72°C (162°F), and when

the OD OFF switch is depressed.

4. Check the up and down shifts for shift shock or slippage.

5. While driving in 3rd (50—60 km/h, 31—37 mph) shift the selector lever to 2 range and check that

3-2 downshift immediately occurs, then decelerate and check that engine braking effect is felt in

2nd gear.

D range shift diagram

FE engine

Caution

8/8 n

-OD

0 20(12) 40(25) 60(37) 80(50) 100(63) 120(74) 140(87)

Vehicle speed km/h (mph)

76GC7B-057

7B—53

Page 921 of 1865

TROUBLESHOOTING (G4A-HL) 7B

1 Range Test

Shift pattern

1. Shift the selector lever to 1 range.

2. Accelerate the vehicle with half (4/8) and full (8/8) throttle valve opening.

3. Check that the 1-2 up- and down-shifts are obtained and that no 3rd gear, no OD, and no lock-up

are obtained. The shift points must be as shown in the 1 range shift diagram.

Note

Vehicle speed on a chassis roller may not meet the specified shift diagram because of tire

size.

4. Check the up and down-shifts for shift shock or slippage.

5. Drive in 1st gear then decelerate and check that engine braking effect is felt.

1 range shift diagram

FE engine

8/8-1 i

7/8-

6/8-2

2 CT>

I 4/8-a> a. o a> 3/8-

o

2/8-

1/8-

20 40 60 80 (25) (37) (50)

Vehicle speed km/h (mph)

80 100 120 140 (63) (74) (87) (12)

76G07B-059

7B—55