lock MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 282 of 1865

1 C ASSEMBLY (CYLINDER BLOCK)

86U01X-133

76G01C-162

76G01C-163

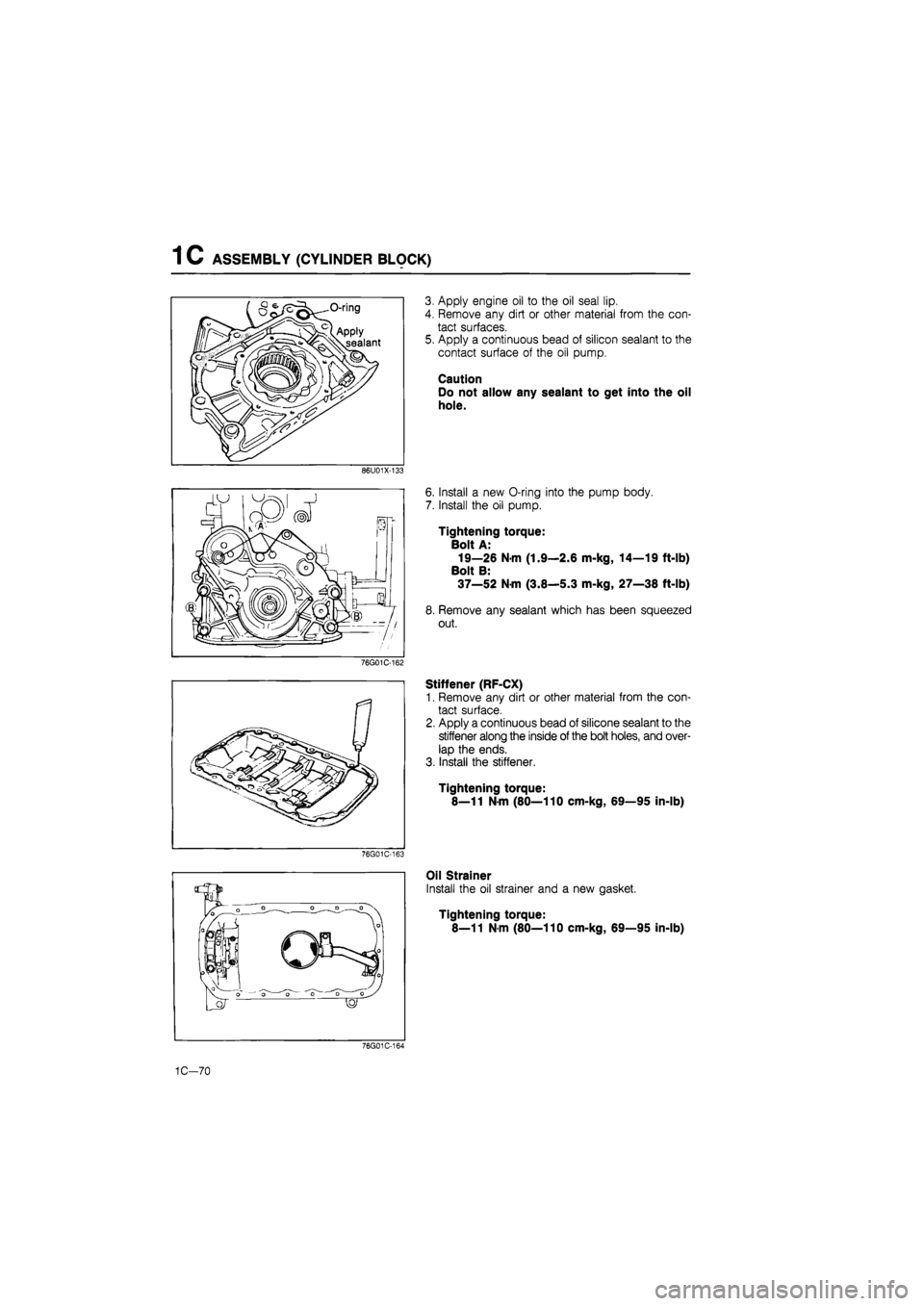

3. Apply engine oil to the oil seal lip.

4. Remove any dirt or other material from the con-

tact surfaces.

5. Apply a continuous bead of silicon sealant to the

contact surface of the oil pump.

Caution

Do not allow any sealant to get into the oil

hole.

6. Install a new O-ring into the pump body.

7. Install the oil pump.

Tightening torque:

Bolt A:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B:

37—52 Nfli (3.8—5.3 m-kg, 27—38 ft-lb)

8. Remove any sealant which has been squeezed

out.

Stiffener (RF-CX)

1. Remove any dirt or other material from the con-

tact surface.

2. Apply a continuous bead of silicone sealant to the

stiffener along the inside of the bolt holes, and over-

lap the ends.

3. Install the stiffener.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Oil Strainer

Install the oil strainer and a new gasket.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

76G01C-171

1C-70

Page 283 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

76G01C-165

76G01C-166

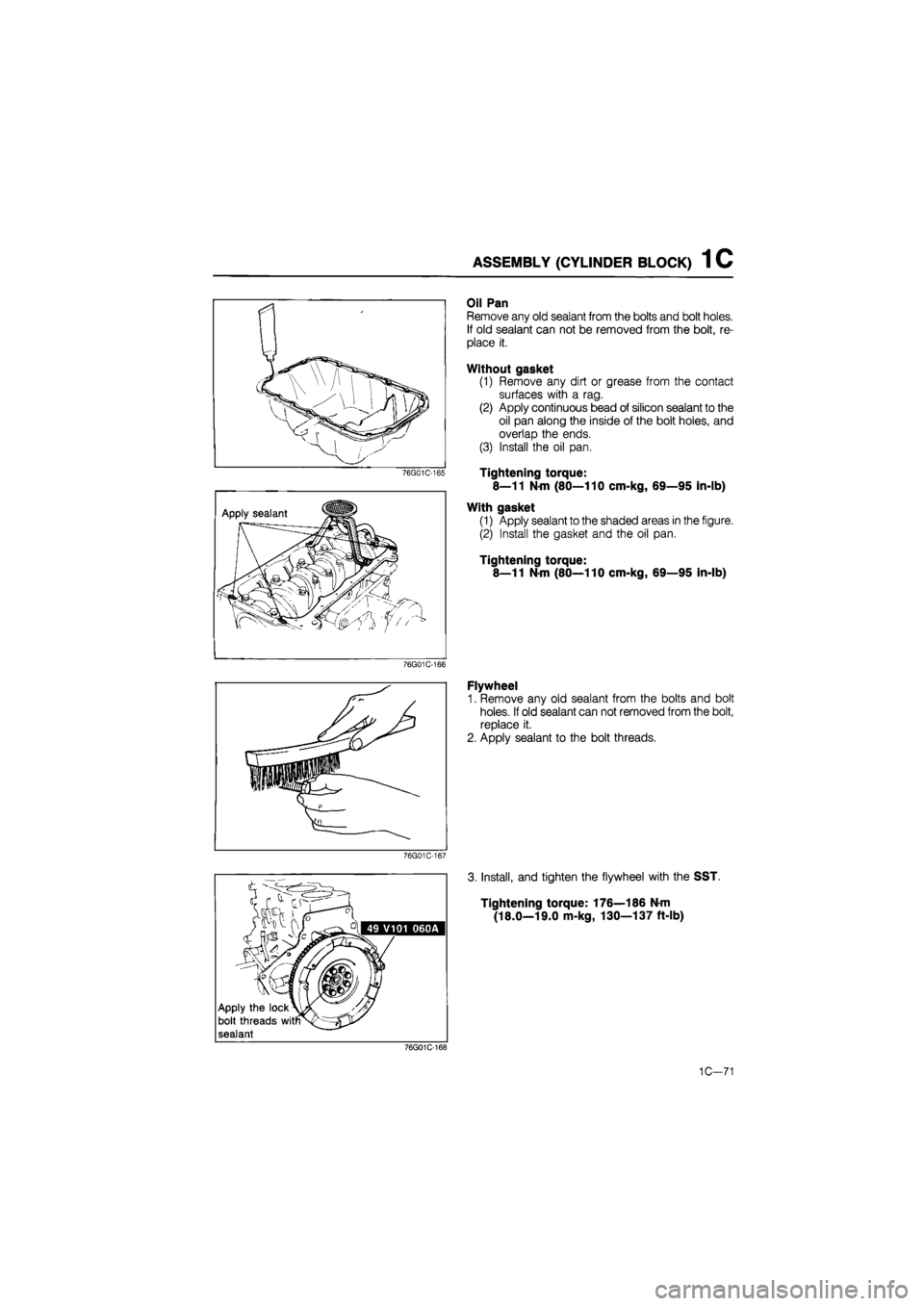

Oil Pan

Remove any old sealant from the bolts and bolt holes.

If old sealant can not be removed from the bolt, re-

place it.

Without gasket

(1) Remove any dirt or grease from the contact

surfaces with a rag.

(2) Apply continuous bead of silicon sealant to the

oil pan along the inside of the bolt holes, and

overlap the ends.

(3) Install the oil pan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

With gasket

(1) Apply sealant to the shaded areas in the figure.

(2) Install the gasket and the oil pan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Flywheel

1. Remove any old sealant from the bolts and bolt

holes. If old sealant can not removed from the bolt,

replace it.

2. Apply sealant to the bolt threads.

76G01C-167

Apply the lock

bolt threads

sealant

3. Install, and tighten the flywheel with the SST.

Tightening torque: 176—186 N-m

(18.0—19.0 m-kg, 130—137 ft-lb)

76G01C-172

1C—71

Page 284 of 1865

1 C ASSEMBLY (CYLINDER BLOCK)

Clutch Disc and Clutch Cover

Install the clutch disc and clutch cover using the SST.

(Refer to Section 6.)

Tightening torque:

18—26 Nm (1.8—2.7 m-kg, 13—20 ft-lb)

76G01C-169

Timing Belt Pulley

1. Install the timing belt pulley with the semicircular

(woodruff) key.

Tightening torque:

179—193 Nm (18.3—19.7 m-kg,

132—142 ft-lb)

4BG01B-180

2. Release the ring gear brake, turn the flywheel,

move the No.

1

piston to the top position, and then

turn it approximately 45° in the forward direction.

Caution

This is to prevent damage to the pistons and

valves when the cylinder head is installed.

4BG01B-181

1C—72

Page 286 of 1865

1 C ASSEMBLY (CYLINDER

BLOCK)

76G01C-170

Adjusting

disc

Tappet -

Apply engine oil

4BG01B-150

4BG01B-182

Apply engine oil

1.

Cylinder head bolt

below head length

Valve and Valve Spring

1. Install the lower spring seat.

2. Apply molybdenum disulphide grease to the valve

stem.

3. Install the valve.

4. Install the valve springs and the upper spring seat.

5. Compress the valve spring with the SST; then in-

stall the valve keepers.

6. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Tappet and Adjusting Disc

1. Apply engine oil to the tappets.

2. Install the tappets in the hole.

3. Install the adjusting discs.

Cylinder Head

1. Thoroughly remove all dirt and grease from the top

of the cylinder block with a rag.

2. Place the new cylinder head gasket in position.

3. Remove any dirt or grease from the bottom sur-

face of the cylinder head.

4. Place the cylinder head in position.

5. Measure the length of the cylinder head bolt be-

low the head. If the length exceeds the maximum,

replace the bolt.

Length: 113.2—113.8 mm (4.457—4.480 in)

Maximum: 114.5 mm (4.508 in)

76G01C-171

1C-74

Page 287 of 1865

ASSEMBLY (CYLINDER

BLOCK)

1 C

6. Apply engine oil to the cylinder head bolts.

7. Tighten the cylinder head bolts.

(1) Tighten the bolts to the specified torque, in or-

der shown in the figure.

Tightening torque:

29 Nm (3.0 m-kg, 22 ft-lb)

4BG01B184

(2)Make paint marks on the bolt heads, as shown

in the figure.

(3)With the paint marks as a reference point, turn

the cylinder head bolts another 90°

(90°—105°) in the tightening direction. Tight-

en them in the order.

(4)Then tighten them once again 90°

(90°—105°) in the tightening order.

Caution

Be absolutely sure to tighten all bolts in the

order.

4BG01 B-185

Camshaft

1. Apply engine oil to the camshaft and journal part

of the cylinder head.

2. Set the seal cap.

3. Apply a coat of sealant (1016 77 739) to the area

shown in the figure.

4. Install the camshaft so that the key groove faces

directly upward.

4BG01 B-186

5. Install the camshaft caps according to the number

and

^

mark,

and loosely tighten the camshaft cap

nuts.

76G01C-172

1C—75

Page 294 of 1865

1C ASSEMBLY (TIMING BELT)

Rear Camshaft Pulley

1. Install the rear camshaft pulley.

2. Hold the camshaft with a wrench (29 mm, 1.14 in)

and tighten to the specification.

Tightening torque:

55—65 Nm (5.6—6.6 m-kg, 41—48 ft-lb)

76G01C-189

Camshaft Pulley

1. Connect the camshaft pulley onto the camshaft with

the semicircular (woodruff) key.

4BG01B-200

2. Hold the camshaft with a wrench (29 mm, 1.14 in),

tighten the camshaft pulley lock bolt.

Tightening torque:

55—65 Nm (5.6—6.6 m-kg, 41—48 ft-lb)

3. Align the mark on the camshaft pulley with the mark

on the seal plate.

76G01C-190

Injection Pump Pulley

1. Install the injection pump pulley with the semicir-

cular (woodruff) key to the injection pump shaft.

2. Rotate the injection pump pulley until the timing

marks are aligned.

3. Affix the injection pump pulley to the bracket us-

ing two bolts (35—40 mm, 1.4—1.6 in).

4. Tighten the lock nut.

Tightening torque:

59—69 N-m (6.0—7.0 m-kg, 43—51 ft-lb)

1C-82

Page 296 of 1865

1C ASSEMBLY (TIMING BELT)

jf^iLJF'

76G01C-194

Timing marks

Timing marks

76G01C-195

76G01C-196

4. Install the idler pulley.

Tightening torque:

37—52 N

m

(3.8—5.3 m-kg, 27—38 ft-lb)

5. Remove the two affixing bolts from the injection

pump pulley.

6. Loosen the tensioner lock bolt.

7. Turn the crankshaft twice in the direction of rota-

tion (clockwise).

Caution

Do not rotate in reverse direction.

8. Check that each timing mark is correctly aligned.

If not aligned, remove the timing belt. Repeat step

2-9.

9. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52

N m

(3.8—5.3 m-kg, 27—38 ft-lb)

10. Check the timing belt tension.

If the tension is not correct, loosen the tensioner

lock bolt and repeat step 6—9, or replace the ten-

sioner spring.

Standard deflection:

9.0—11.5 mm (0.35—0.45 in)

/98 N (10 kg, 22 lb)

Caution

Be sure not to apply tension other than that

of the tensioner spring.

76G01C-197

1C-84

Page 300 of 1865

1 C ASSEMBLY (AUXILIARY PARTS)

76G01C-205

76G01C-206

76G01C-207

o e-

Oil Cooler Assembly

1. Clean the contact surfaces of the cylinder block

and oil filter assembly.

2. Install new O-rings, and apply a coat of engine oil.

3. Install the oil cooler assembly.

Tightening torque:

Bolt A: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

4. Connect the water hose.

Oil Filter

1. Install the oil filter cover.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Apply a coat of engine oil to the filter rubber seal.

3. Install the oil filter until the rubber seal contacts the

oil cooler by hand. Then tighten it a 7/6 turn fur-

ther with a band type wrench.

Alternator

1. Install the alternator.

Tightening torque:

Bolt A: 19—26 N m

(1.9—2.6 m-kg, 14—19 ft-lb)

Bolt B: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

2. Install the alternator drive belt, and adjust the belt

deflection. (Refer to page 1C—7)

76G01C-208

1C—88

expert22 ajia http://rutracker.org

Page 306 of 1865

1C INSTALLATION

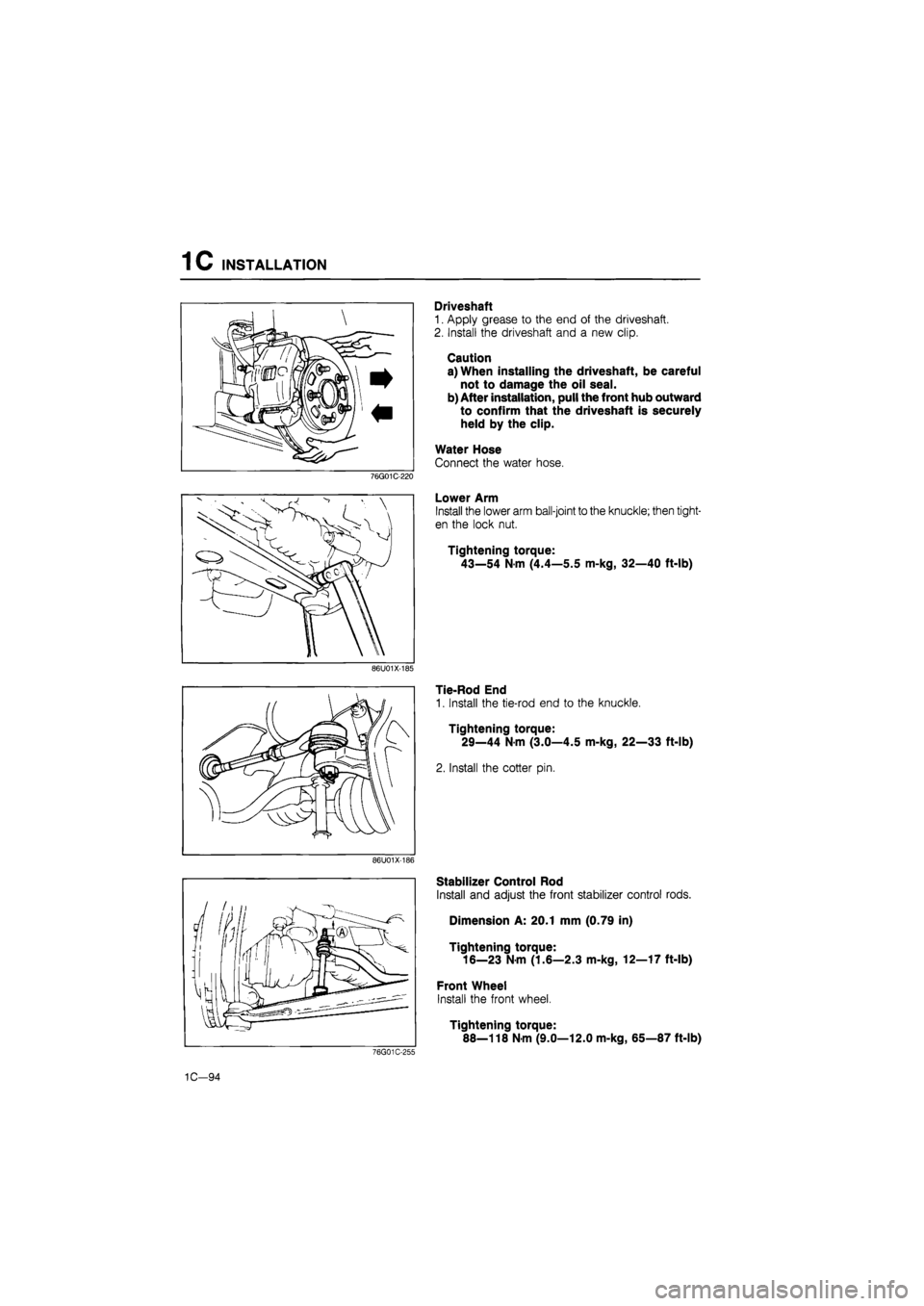

Driveshaft

1. Apply grease to the end of the driveshaft.

2. Install the driveshaft and a new clip.

Caution

a) When installing the driveshaft, be careful

not to damage the oil seal.

b) After installation, pull the front hub outward

to confirm that the driveshaft is securely

held by the clip.

Water Hose

Connect the water hose.

76G01C-220

Lower Arm

Install the lower arm ball-joint to the knuckle; then tight-

en the lock nut.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

86U01X-185

Tie-Rod End

1. Install the tie-rod end to the knuckle.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

2. Install the cotter pin.

86U01X-186

76G01C-255

Stabilizer Control Rod

Install and adjust the front stabilizer control rods.

Dimension A: 20.1 mm (0.79 in)

Tightening torque: 16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

Front Wheel

Install the front wheel.

Tightening torque:

88—118 N-m (9.0—12.0 m-kg, 65—87 ft-lb)

1C—94

Page 319 of 1865

2A OIL PAN

4BG02X-037

76G02A-013

76G02A-014

(SOHC)

1. Remove the oil pan mounting bolts.

2. Insert a scraper or a suitable tool between the oil

pan and the stiffener or the cylinder block to sep-

arate them.

3. Remove the oil pan.

Caution

Do not bend the oil pan when prying loose.

INSPECTION

Check the following points. Repair or replace if

necessary.

1. Cracks, deformation, damage

2. Damaged drain plug threads

INSTALLATION

Install in the reverse order of removal referring to the

installation note.

Installation Note

Stiffener (FE 8-valve...only ECE, 12-valve)

1. Remove any dirt or other material from the con-

tact surface.

2. Apply silicon sealant to the stiffener around inside

of the bolt holes and overlap the ends.

3. Install the stiffener.

Tightening torque:

7—12 Nm (70—120 cm-kg, 61—104 in-lb)

Oil pan

1. Apply silicon sealant to the oil pan around inside

of the bolt holes and overlap the ends.

2. Install the oil pan.

Tightening torque:

7—12 Nm (70—120 cm-kg, 61—104 in-lb)

Caution (DOHC)

Oil pan projection and recession from the end

of the cylinder block must not be more than

1.5 mm (0.06 in).

2A—8