differential MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 315 of 1865

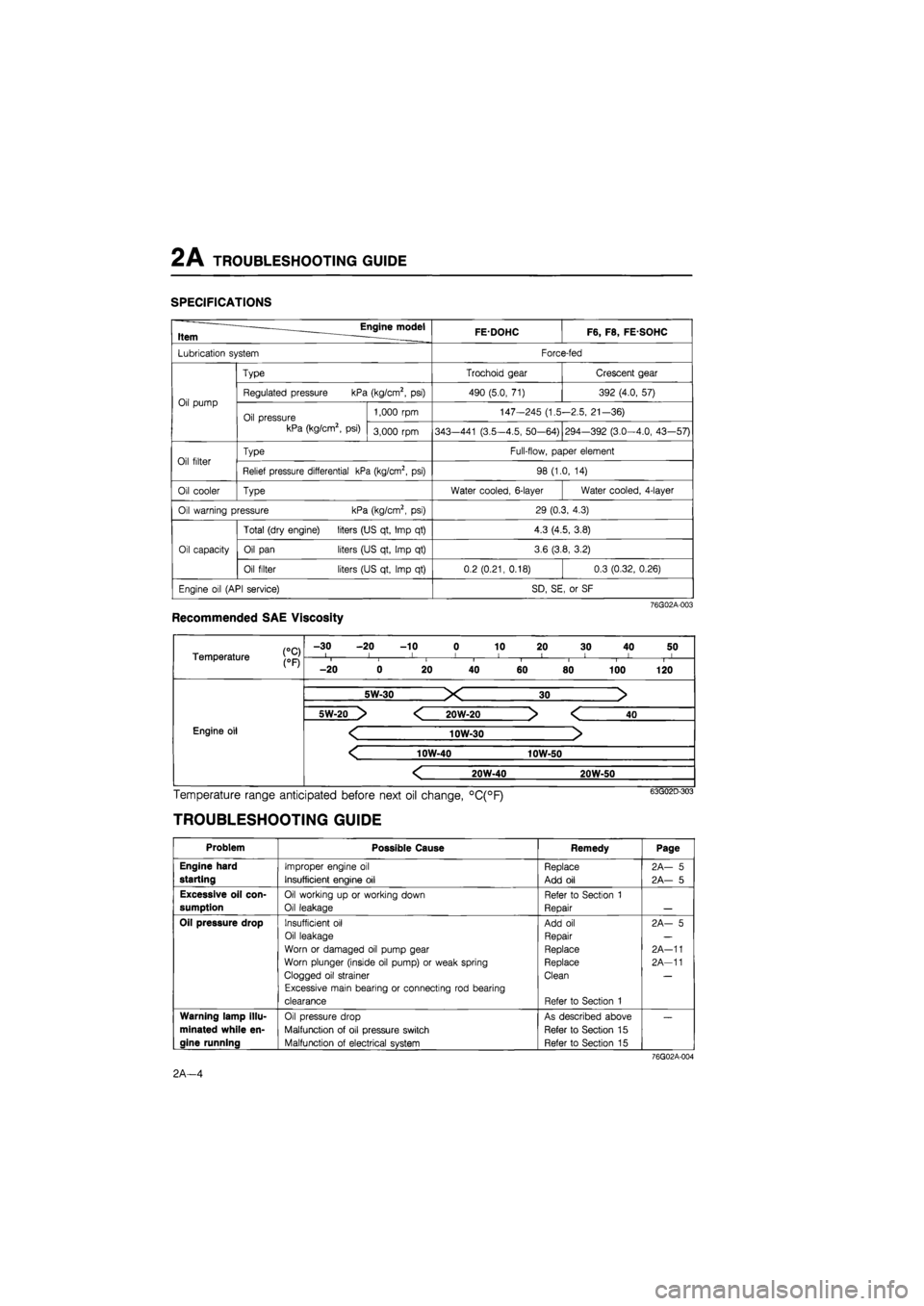

2 A TROUBLESHOOTING GUIDE

SPECIFICATIONS

Engine model Item . FEDOHC F6, F8, FE SOHC

Lubrication system Force-fed

Oil pump

Type Trochoid gear Crescent gear

Oil pump Regulated pressure kPa (kg/cm2, psi) 490 (5.0, 71) 392 (4.0, 57) Oil pump

Oil pressure kPa (kg/cm2, psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pump

Oil pressure kPa (kg/cm2, psi) 3,000 rpm 343—441 (3.5-4.5, 50-64) 294-392 (3.0-4.0, 43—57)

Oil filter Type Full-flow, paper element Oil filter Relief pressure differential kPa (kg/cm2, psi) 98 (1.0, 14)

Oil cooler Type Water cooled, 6-layer Water cooled, 4-layer

Oil warning pressure kPa (kg/cm2, psi) 29 (0.3, 4.3)

Oil capacity

Total (dry engine) liters (US qt, Imp qt) 4.3 (4.5, 3.8)

Oil capacity Oil pan liters (US qt, Imp qt) 3.6 (3.8, 3.2) Oil capacity

Oil filter liters (US qt, Imp qt) 0.2 (0.21, 0.18) 0.3 (0.32, 0.26)

Engine oil (API service) SD, SE, or SF

76G02A-003

Recommended SAE Viscosity

Temperature j0pj

-30 -20 -10 0 10 20 30 40 50 I l I I 1 < ! I I Temperature j0pj i i i i I i 1 1

-20 0 20 40 60 80 100 120

Engine oil Engine oil

5W-30 X 30 >

Engine oil Engine oil

5W-20 > < 20W-20 > < 40

Engine oil < 10W-30 > Engine oil

< 10W-40 10W-50

Engine oil Engine oil

< 20W-40 20W-50

Engine oil

Temperature range anticipated before next oil change, °C(°F)

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine oil

Insufficient engine oil

Replace

Add oil

2A— 5

2A— 5

Excessive oil con-

sumption

Oil working up or working down

Oil leakage

Refer to Section 1

Repair

Oil pressure drop Insufficient oil

Oil leakage

Worn or damaged oil pump gear

Worn plunger (inside oil pump) or weak spring

Clogged oil strainer

Excessive main bearing or connecting rod bearing

clearance

Add oil

Repair

Replace

Replace

Clean

Refer to Section 1

2A- 5

2A-11

2A-11

Warning lamp illu-

minated while en-

gine running

Oil pressure drop

Malfunction of oil pressure switch

Malfunction of electrical system

As described above

Refer to Section 15

Refer to Section 15

76G02A-004

2A—4

Page 327 of 1865

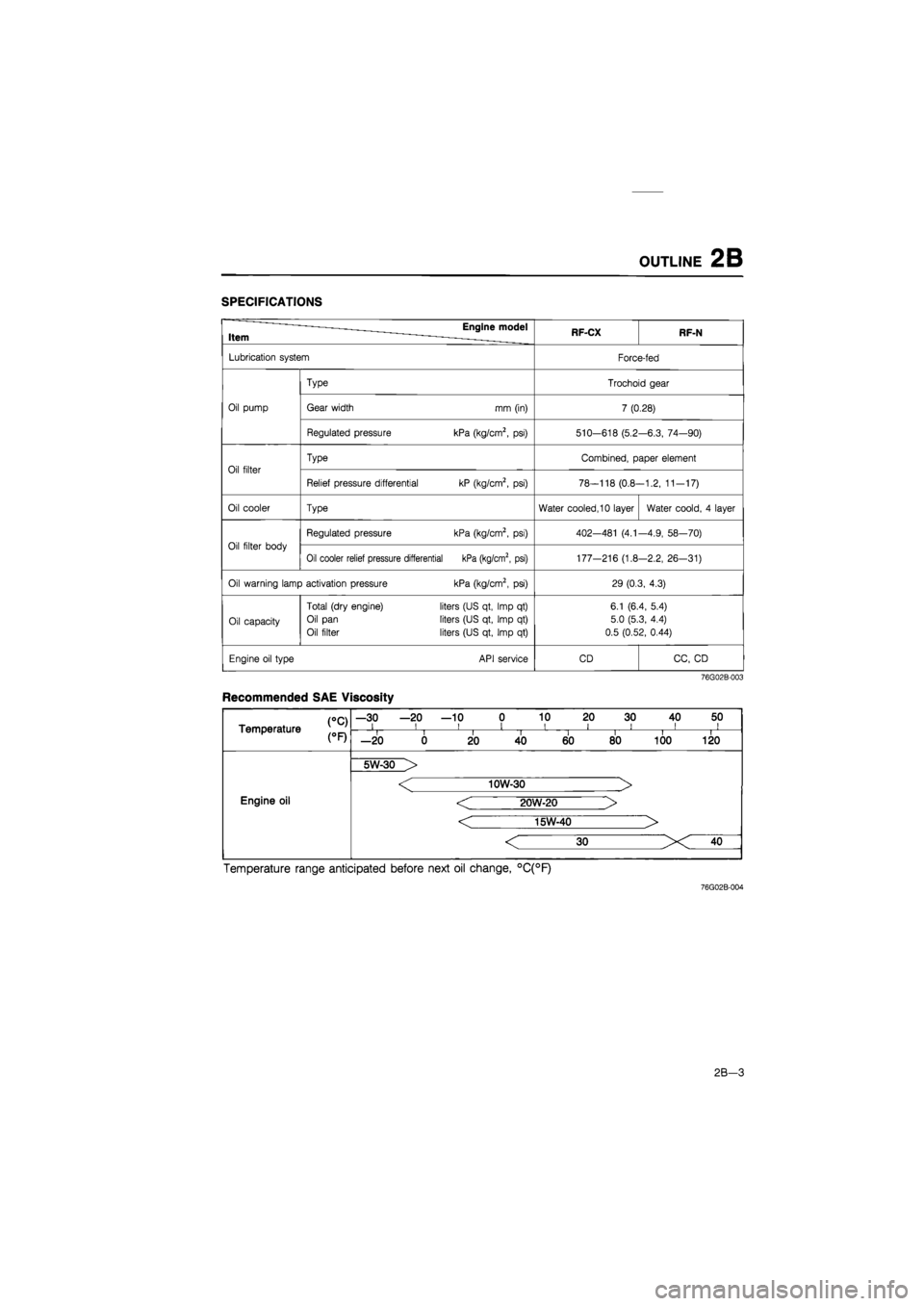

OUTLINE 2B

SPECIFICATIONS

Item Engine model RF-CX RF-N

Lubrication system Force-fed

Type Trochoid gear

Oil pump Gear width mm (in) 7 (0.28)

Regulated pressure kPa (kg/cm2,

psi)

510-618 (5.2 -6.3, 74—90)

Oil filter

Type Combined, paper element

Oil filter

Relief pressure differential kP (kg/cm2,

psi)

78-118 (0.8--1.2, 11-17)

Oil cooler Type Water cooled, 10 layer Water coold,

4

layer

Oil filter body

Regulated pressure kPa (kg/cm2,

psi)

402—481

(4.1

-4.9, 58—70)

Oil filter body

Oil cooler relief pressure differential kPa (kg/cm2, psi) 177-216 (1.8 -2.2, 26-31)

Oil warning lamp activation pressure kPa (kg/cm2,

psi)

29 (0.3, 4.3)

Oil capacity

Total (dry engine)

Oil pan

Oil filter

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

6.1 (6.4, 5.4)

5.0 (5.3, 4.4)

0.5 (0.52, 0.44)

Engine oil type API service CD CC,

CD

76G02B-003

Recommended SAE Viscosity

CC) Temperature

—30 —20 —10 0 10 20 30 40 50 i i i i i i i ii CC) Temperature i i II i i i i —20 0 20 40 60 80 100 120

Engine oil

5W-30 >

Engine oil

< 10W-30 >

< 20W-20 >

< 15W-40 >

Engine oil

Temperature range anticipated before next oil change, °C(°F)

76G02B-004

2B-3

Page 808 of 1865

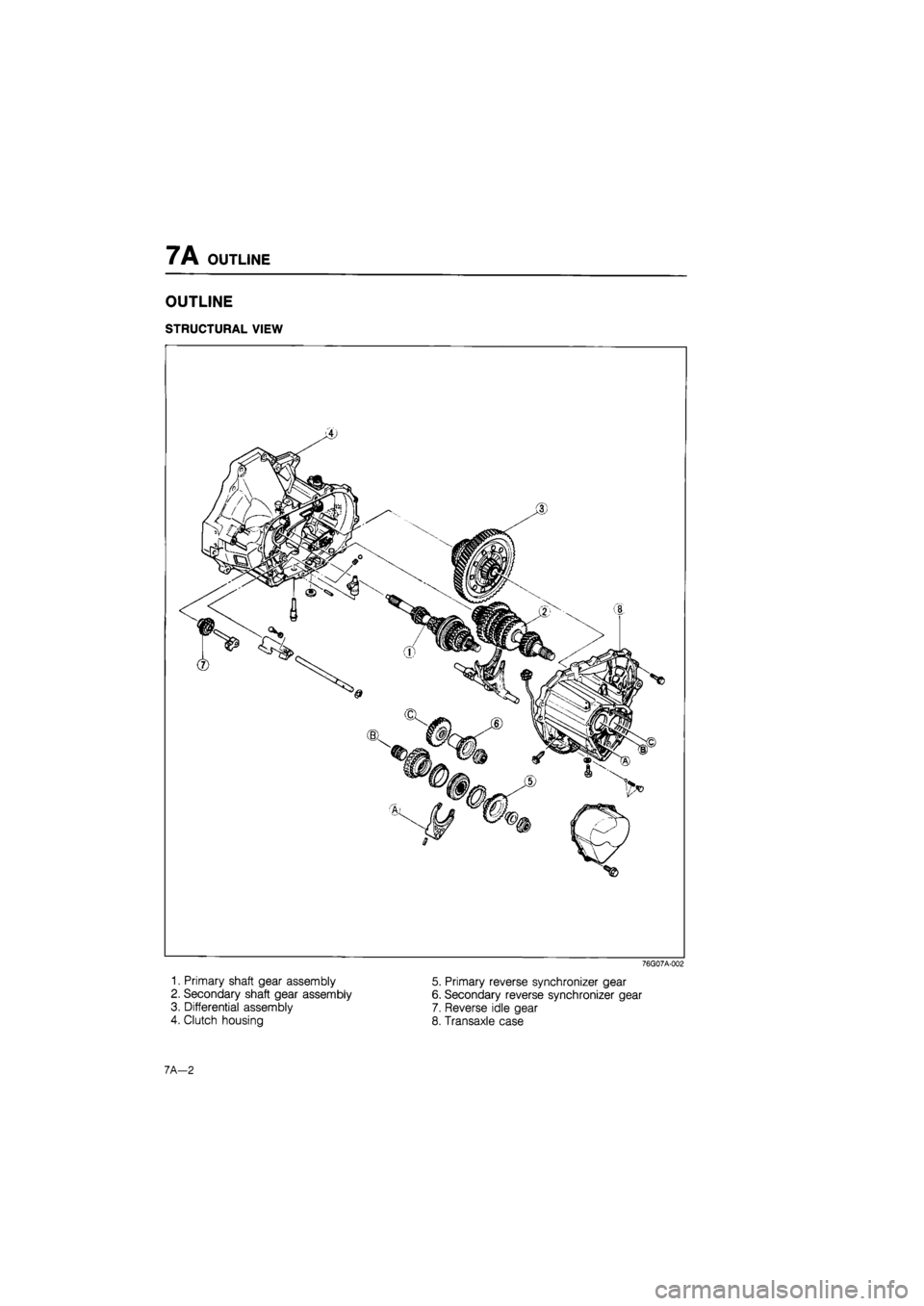

7A OUTLINE

OUTLINE

STRUCTURAL VIEW

76G07A-002

1. Primary shaft gear assembly

2. Secondary shaft gear assembly

3. Differential assembly

4. Clutch housing

5. Primary reverse synchronizer gear

6. Secondary reverse synchronizer gear

7. Reverse idle gear

8. Transaxle case

7A—2

Page 811 of 1865

TROUBLESHOOTING GUIDE 7A

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Change lever won't Seized change lever ball Replace 7A-58 shift smoothly, or is Seized change control rod joint Replace 7A-58

hard to shift Bent change control rod Replace 7A-58

Too much play in Worn change control rod bushing Replace 7A-58 change lever Weak spring of ball or change lever Replace 7A-58 Worn bushing of ball or change lever Replace 7A—58

Difficult to shift Bent change rod Replace 7A—58

No grease in transmission control Lubricate with grease 7A-58

Insufficient oil Add oil 7A-6

Deterioration of oil quality Replace with oil of 7A-6 specified quality

Wear or play of shift fork or shift rod Replace 7 A—18

Wear of synchronizer ring Replace 7A-27

Wear of synchronizer cone of gear Replace 7A-27

Bed contact of synchronizer ring and cone of Replace 7A-27 gear

Excessive longitudinal play of gears Replace 7A-22

Wear of bearing Adjust or replace 7A—22

Wear of synchronizer key spring Replace 7A-27

Excessive shaft gear bearing preload Adjust 7A-37

Improperly adjusted change guide plate Adjust 7A-20

Won't stay in gear Bent change control rod Replace 7A-58

Worn change control rod bushing Replace 7A-58

Weak change lever ball spring Replace 7A-58

Improperly installed extension bar Tighten 7A-58

Wear of shift fork Replace 7A—22

Wear of clutch hub Replace 7A-27

Worn clutch hub sleeve Replace 7A-27

Worn gear sliding part of both shaft gears Replace 7A-26

Worn gear sliding part of each gear Replace 7A-26

Worn steel sliding groove of control end Replace 7 A—18

Weak spring pressing against steel ball Replace 7A-18

Excessive thrust clearance Replace 7A—33,35

Worn bearing Replace 7A—22

Improperly installed engine mount Tighten 7A—49

Abnormal noise Insufficient oil Add oil 7A-6

Deterioration of oil quality Replace 7A-6

Worn bearing Adjust or replace 7A-22

Worn gear sliding surface of both shaft gears Replace 7A—26

Wear of sliding surfaces of gears Replace 7A-26

Excessive thrust clearance Replace 7A—33,35

Damaged gear teeth Replace with oil of 7A-26

specified quality Foreign material in gears Replace 7A-22

Damaged differential gear, or excessive backlash Adjust or replace 7A—30

76G07A-005

7A-5

Page 822 of 1865

7A REMOVAL

19. Install the SST to the differential side gear.

Note

Failure to install the SST may cause the

differential side gears to become misposi-

tioned.

86U07A-027

20. Remove the gusset plates, (except DOHC)

21. Remove the under cover, (except DOHC)

22. Remove the extension bar and the control rod.

76G07A-014

23. Remove the surge tank bracket. (Fl)

24. Remove the starter.

76G07A-015

25. Suspend the engine with the SST.

86U07A-030

7 A-16

Page 824 of 1865

7A DISASSEMBLY

DISASSEMBLY

STEP 1

Disassemble in the sequence shown in the figure referring to disassembly note for the specially marked

parts.

76G07A-016

76G07A-017

24. Crank lever shaft

25. O-ring

26. Crank lever assembly

27. Shift fork and shift rod as-

sembly

28. Steel ball

29. Spring

30. Primary shaft gear as-

sembly

31. Secondary shaft gear as-

sembly

32. Differential assembly

33. Clutch housing

1. Rear cover

2. Lock nut

3. Lock nut

4. Primary reverse synchroniz-

er gear

5. Secondary reverse syn-

chronizer gear

6. Roll pin

7. Shift fork

8. Clutch hub assembly

9. Synchronizer ring

10. 5th gear

11. Gear sleeve

12. Secondary 5th gear

13. Lock bolt

14. Guide bolt

15. Lock bolt, ball and spring

16. Transaxle case

17. Magnet

18. Reverse idle shaft

19. Reverse idle gear

20. Lock bolt

21. Shift rod (5th and reverse)

and clip

22. Gate

23. Pin

7 A—18

Page 827 of 1865

DISASSEMBLY 7 A

Disassembly Note

Bearing outer race (primary shaft)

Remove the bearing outer race with the SST.

86U07A-041

Bearing outer race (secondary shaft)

Remove the bearing outer race by lifting out the fun-

nel and race together.

86U07A-042

Roll pin

Align the groove for removal of the clutch housing

pin with the position of the roll pin, then tap the pin

out using a pin punch.

76G07A-020

Bearing outer race (differential)

Remove the bearing outer race with the SST.

86U07A-044

7A-21

Page 831 of 1865

DISASSEMBLY 7A

STEP 4 (DIFFERENTIAL)

Disassemble in the sequence shown in the figure referring to disassembly note for the specially marked

parts.

Note

a) If the bearing inner races are removed replace them with new ones.

b) Before disassembly, check the backlash of the side gears and pinion gears.

(Refer to page 7A—30)

1. Knock pin

2. Pinion shaft

3. Pinion gear

4. Thrust washer

5. Side gear

6. Thrust washer

7. Side bearing in-

ner race

8. Speedometer

drive gear

9. Side bearing in-

ner race

10. Gear case

76G07A-026

Disassemble Note

Side bearing inner race (side opposite ring gear)

Remove the race from the gear case with the SST.

Caution

Hold the gear case with one hand so that it

does not fall.

76G07A-027

Side bearing inner race (ring gear side)

Remove the race with a combination of parts from

the SST.

86U07A-055

7A-25

Page 834 of 1865

7A INSPECTION

86U07A-058

63U07A-074

63U07A-075

Reverse Idle Gear

1. Worn or damaged bushing.

2. Worn or damaged teeth.

3. Worn or damaged release lever coupling groove.

4. Clearance between sleeve and reverse lever.

Standard: 0.095—0.318 mm (0.004—0.013 in)

Maximum: 0.5 mm (0.020 in)

Clutch Housing, Transaxle Case, Rear Cover,

and Differential Gear Case

Cracks or damage.

Caution

If the clutch housing, transaxle case, or

differential gear case is replaced, adjust the

bearing preload of the shaft gears and the

preload of the differential side bearings.

Bearing

1. Roughness or noise while turning

2. Worn or damaged outer race or rollers

Caution

a) Replace the bearing, the outer race, and the

inner race as a unit.

b)lf the bearing is replaced, adjust the

preload.

Speedometer Driven Gear Assembly

1. Worn or damaged teeth.

2. Worn or damaged O-ring.

Ring Gear Speedometer Drive Gear

Worn or damaged teeth.

Oil Seal

Damaged or worn lip.

63U07A-076

7A—28

Page 835 of 1865

ASSEMBLY 7 A

ASSEMBLY

Note

a) Wash all parts.

b) Apply oil to all friction surfaces.

c) Use new roll pins and retaining rings.

STEP 1 (DIFFERENTIAL)

86U07A-059

Assembly

1. Install the speedometer drive gear and the new

bearing inner race with the SST.

Note

Press to 19,620 N (2,000 kg, 4,400 lb).

2. Install the new bearing inner race with the SST.

Note

Press to 19,620 N (2,000 kg, 4,400 lb).

86U07A-061

7A-29