cruise control MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 14 of 1865

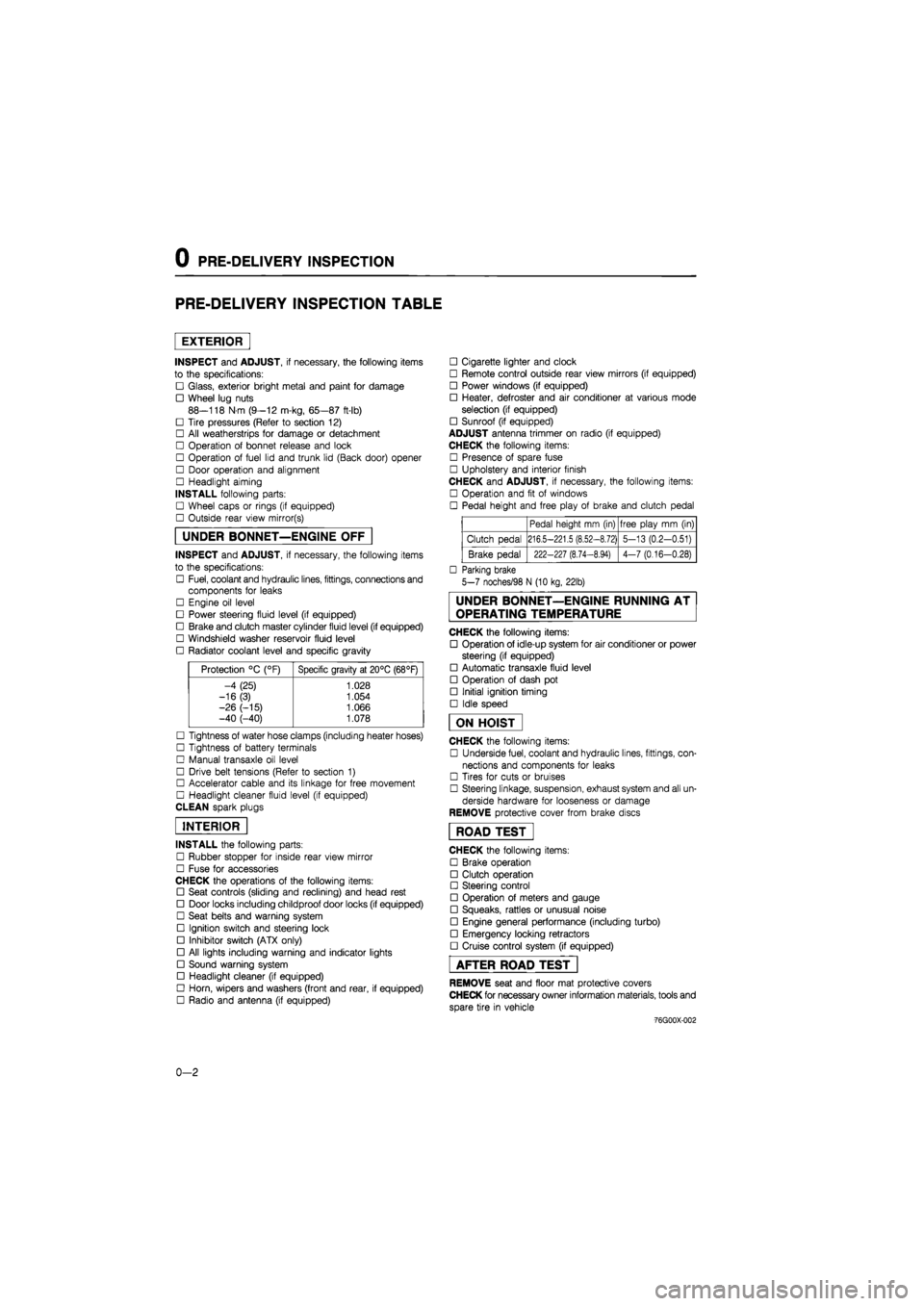

0 PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

EXTERIOR

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Glass, exterior bright metal and paint for damage

• Wheel lug nuts

88—118 N m (9—12 m-kg, 65—87 ft-lb)

• Tire pressures (Refer to section 12)

• All weatherstrips for damage or detachment

• Operation of bonnet release and lock

• Operation of fuel lid and trunk lid (Back door) opener

• Door operation and alignment

• Headlight aiming

INSTALL following parts:

• Wheel caps or rings (if equipped)

• Outside rear view mirror(s)

UNDER BONNET—ENGINE OFF

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

• Engine oil level

• Power steering fluid level (if equipped)

• Brake and clutch master cylinder fluid level (if equipped)

• Windshield washer reservoir fluid level

• Radiator coolant level and specific gravity

Protection °C (°F) Specific gravity at 20°C (68°F)

-4 (25) 1.028

-16(3) 1.054

-26 (-15) 1.066 -40 (-40) 1.078

• Tightness of water hose clamps (including heater hoses)

• Tightness of battery terminals

• Manual transaxle oil level

• Drive belt tensions (Refer to section 1)

• Accelerator cable and its linkage for free movement

• Headlight cleaner fluid level (if equipped)

CLEAN spark plugs

INTERIOR

INSTALL the following parts:

• Rubber stopper for inside rear view mirror

• Fuse for accessories

CHECK the operations of the following items:

• Seat controls (sliding and reclining) and head rest

• Door locks including childproof door locks (if equipped)

• Seat belts and warning system

• Ignition switch and steering lock

• Inhibitor switch (ATX only)

• All lights including warning and indicator lights

• Sound warning system

• Headlight cleaner (if equipped)

• Horn, wipers and washers (front and rear, if equipped)

• Radio and antenna (if equipped)

• Cigarette lighter and clock

• Remote control outside rear view mirrors (if equipped)

• Power windows (if equipped)

• Heater, defroster and air conditioner at various mode

selection (if equipped)

• Sunroof (if equipped)

ADJUST antenna trimmer on radio (if equipped)

CHECK the following items:

• Presence of spare fuse

• Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

• Operation and fit of windows

• Pedal height and free play of brake and clutch pedal

Pedal height mm (in) free play mm (in)

Clutch pedal 216.5-221.5 (8.52-8.72) 5-13 (0.2-0.51)

Brake pedal 222-227 (8.74-8.94) 4-7 (0.16-0.28)

• Parking brake

5-7 noches/98 N (10 kg, 22lb)

UNDER BONNET—ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

• Operation of idle-up system for air conditioner or power

steering (if equipped)

• Automatic transaxle fluid level

• Operation of dash pot

• Initial ignition timing

• Idle speed

ON HOIST

CHECK the following items:

• Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

• Tires for cuts or bruises

• Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

REMOVE protective cover from brake discs

ROAD TEST"

CHECK the following items:

• Brake operation

• Clutch operation

• Steering control

• Operation of meters and gauge

• Squeaks, rattles or unusual noise

• Engine general performance (including turbo)

• Emergency locking retractors

• Cruise control system (if equipped)

AFTER ROAD TEST

REMOVE seat and floor mat protective covers

CHECK for necessary owner information materials, tools and

spare tire in vehicle

-76G00X-002

0-2

Page 867 of 1865

7B

AUTOMATIC TRANSAXLE

(Electronically Controlled and 4-Speed)

OUTLINE 7B— 2

SPECIFICATIONS 7B— 2

COMPONENT LOCATION 7B— 3

STRUCTURAL VIEW 7B— 5

OPERATION OF COMPONENTS 7B— 6

FLUID PASSAGE LOCATION 7B— 9

TROUBLESHOOTING (G4A-EL) 7B— 12

GENERAL NOTE 7B— 12

STEP 1

(WARNING CODE RETRIEVAL) 7B— 15

STEP 2

(PRELIMINARY INSPECTION) 7B— 22

STEP 3 (SIGNAL INSPECTION) 7B— 24

STEP 4 (STALL TEST) 7B— 27

STEP 5 (TIME LAG TEST) 7B— 30

STEP 6 (OIL PRESSURE TEST) 7B— 31

STEP 7 (ROAD TEST) 7B— 34

TROUBLESHOOTING (G4A-HL) 7B— 41

GENERAL NOTE 7B— 41

STEP 1

(PRELIMINARY INSPECTION) 7B— 44

STEP 2 (ELECTRICAL

SYSTEM INSPECTION) 7B— 47

STEP 3 (STALL TEST) 7B— 49

STEP 4 (TIME LAG TEST) 7B- 52

STEP 5 (ROAD TEST) 7B— 53

STEP 6 (OIL PRESSURE TEST) 7B— 58

ELECTRICAL SYSTEM

COMPONENTS 7B— 63

MODE SWITCH (G4A-EL) 7B— 63

HOLD SWITCH (G4A-EL) 7B— 63

OD OFF SWITCH (G4A-HL) 7B— 64

INHIBITOR SWITCH 7B- 65

WATER TEMPERATURE SWITCH 7B— 66

FLUID TEMPERATURE SWITCH

(G4A-EL) 7B— 66

BRAKE LIGHT SWITCH

(G4A-EL) 7B— 66

KICK-DOWN SWITCH (G4A-HL) 7B— 67

PULSE GENERATOR (G4A-EL) 7B- 68

VEHICLE SPEED SENSOR

(G4A-EL) 7B— 68

CRUISE CONTROL SWITCH

(CRUISE CONTROL UNIT) 7B— 68

IDLE SWITCH AND THROTTLE

SENSOR (G4A-EL) 7B— 68

OD RELEASE SOLENOID

VALVE (G4A-HL) 7B— 68

SOLENOID VALVES (G4A-EL) 7B— 69

NO LOAD SIGNAL (G4A-EL) 7B— 69

MODE, AND HOLD INDICATOR

LIGHT (G4A-EL) 7B— 69

OD OFF INDICATOR LIGHT

(G4A-HL) 7B— 69

EC-AT CONTROL UNIT

(G4A-EL) 7B— 69

ON-VEHICLE MAINTENANCE 7B— 71

AUTOMATIC TRANSAXLE

FLUID (ATF) 7B— 71

SELECTOR LEVER 7B— 72

THROTTLE CABLE 7B— 73

CONTROL VALVE BODY 7B— 77

OIL STRAINER 7B— 79

ADJUSTMENT OF 2-4 BRAKE

BAND 78— 80

REPLACEMENT OF

DRIVESHAFT OIL SEAL 7B— 80

OIL COOLER 7B— 81

GOVERNOR (G4A-HL) 7B— 82

REMOVAL 7B— 83

PRECAUTION 7B— 83

DISASSEMBLY 7B— 88

DISASSEMBLY-STEP 1 7B— 88

DISASSEMBLY-STEP 2 7B— 94

DISASSEMBLY-STEP 3 7B— 99

DISASSEMBLY-STEP 4 7B—103

INSPECTION AND REPAIR 7B—107

PRECAUTION 7B—107

TORQUE CONVERTER 7B—107

OIL PUMP 7B—108

CLUTCH ASSEMBLY 7B—113

SMALL SUN GEAR AND

ONE-WAY CLUTCH 7B—122

ONE-WAY CLUTCH AND

CARRIER HUB ASSEMBLY 7B-126

3-4 CLUTCH 7B—128

2-3 ACCUMULATOR 7B—132

GOVERNOR ASSEMBLY

(G4A-HL) 7B-133

LOW AND REVERSE BRAKE 7B—134

2-4 BRAKE BAND 7B—135

BAND SERVO 7B—135

OTHER INSPECTION 7B—135

CONTROL VALVE BODY

(G4A-EL) 7B-136

CONTROL VALVE BODY

(G4A-HL) 7B-155

DIFFERENTIAL 7B—177

OUTPUT GEAR 7B—181

IDLE GEAR 7B—182

BEARING COVER ASSEMBLY 7B—185

BEARING HOUSING 7B—186

ASSEMBLY 7B-187

PRECATION 7B—187

ASSEMBLY-STEP 1 7B—187

ASSEMBLY-STEP 2 7B—197

ASSEMBLY-STEP 3 7B—202

ASSEMBLY-STEP 4 7B—208

INSTALLATION 7B—215

TORQUE SPECIFICATIONS 7B—215

HYDRAULIC CIRCUIT (G4A-EL) 7B—221

HYDRAULIC CIRCUIT (G4A-HL) 7B—239

76G07B-001

Page 869 of 1865

OUTLINE 7B

COMPONENT LOCATION

G4A-EL

76G07B-003

1. Hold indicator light

2. EC-AT control unit

3. Vehicle speed sensor

4. Mode indicator light

5. Cruise control unit

6. Cruise control switch

7. Mode switch

8. Hold switch

9. Water temperature switch

10. Throttle sensor and idle

switch

11. Fluid temperature switch

12. EC-AT

13. Pulse genelator

14. Solenoid valves

15. Inhibitor switch

7B-3

Page 870 of 1865

7B OUTLINE

G4A-HL

1. OD OFF indicator light

2. OD OFF switch

3. Kick-down switch

4. Cruise control unit

5. Cruise control switch

6. Water temperature switch

7. Inhibitor switch

8. OD release solenoid valve

9. Automatic transaxle

76G07B-004

7B—4

Page 884 of 1865

7B TROUBLESHOOTING (G4A-EL)

Retrieval Procedure

1. Locate the service connector.

86U07B-019

76G07B-214

11 IDLFC

5» O | || KICK DOWNS* _ If, DEPRESS

|[BRAKE UORRSW

MNMWE STF *

° M CRUISE CONTROL SW

CDS®> *• PI ^ SPEED DROPS

Gf Aft

•

OO ou

I I

w

6019 HI NOW* XIKI

CO , LTQ

MUX

IN

JAP"

76G07B-016

2. Ground the ground connector of the EC-AT

Tester.

3. Connect the 6-pin connector of the EC-AT Tester

to the service connector.

Note

The service connector is blue-colored con-

nector.

4. Ground the 1 pin service connector.

Note

The service connector is blue-colored con-

nector.

5. Turn the ignition switch ON.

6. Check that "88" flashes on the digital display and

the buzzer sounds for three seconds after turning

the ignition switch ON.

7. If "88" does not flash, check the service connec-

tor wiring.

8. If "88" flashes and the buzzer sounds continuously

for more than 20 seconds, check wiring to 2M ter-

minal of the EC-AT control unit for short-circuit then

replace the EC-AT control unit and repeat steps

3 and 4.

9. Note the code numbers and check for the causes

by referring to the Inspection Procedure shown on

pages 7B—19 to 7B—21, repair as necessary.

Note

After repairs are made, recheck for code num-

bers by performing the "After-repair

procedure."

7B—18

Page 885 of 1865

TROUBLESHOOTING (G4A-EL) 7B

79G07C-068

Drive at 50

km/h

(31

mph)

Kick-down

Stop

the

vehicle

79G07C-069

After-repair Procedure

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery terminal for at least five sec-

onds, then reconnect it.

2. Remove the EC-AT tester if it is connected.

3. Drive the vehicle at 50 km/h (31 mph), then de-

press the accelerator pedal fully to activate kick-

down. Stop the vehicle gradually.

KICK goimsv

BRAKE LIGHTS*

CRUISE CONTROL

C V,. DEPRESS FULL*

Ox

azsa

ORUti rpn

"J

i"

•

rm uu

£ZL ofF

4. Reconnect the EC-AT tester to the 6-pin service

connector.

5. Ground the 1 -pin service connector with a jumper

wire.

6. Turn the ignition switch ON.

7. Check that no code numbers are displayed.

79G07C-070

Inspection Procedure

No. 06 code display (Vehicle speed sensor)

76G07B-017

7B-19

Page 891 of 1865

TROUBLESHOOTING (G4A-EL) 7B

Item Indication Condition Possible cause

BRAKE LIGHT SW ON Brake pedal depressed Brake light switch or

wiring BRAKE LIGHT SW

OFF Brake pedal released

Brake light switch or

wiring

WATER TEMP SW ON Coolant temperature 72°C (162°F) or above Water temp switch or wiring WATER TEMP SW

OFF Coolant temperature lower than 65°C (149°F)

Water temp switch or wiring

ATF TEMP SW ON ATF temperature 150°C (302°F) or above Fluid temperature switch or wiring ATF TEMP SW

OFF ATF temperature lower than 143°C (289°F)

Fluid temperature switch or wiring

CRUISE CONTROL SW Not used — —

Input (Digital display)

THROTTLE SENSOR

EC-AT control unit terminal voltage All the time Throttle sensor, idle switch or wirings

VEHICLE SPEED*

Vehicle speed calculated from speed sensor signal

All the time Vehicle speed sensor, speedometer cable, or wiring

DRUM SPEED* Drum speed All the time Pulse generator or wirings

Output (Light)

1-2 SOLENOID VALVE*

ON

Refer to page 7B—26 solenoid valve operation table

Control unit, 1-2 shift sol., or wiring 1-2 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table

Control unit, 1-2 shift sol., or wiring

2-3 SOLENOID VALVE*

ON Refer to page 7B—26 solenoid valve operation table Control unit, 2-3 shift sol., or wiring 2-3 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table Control unit, 2-3 shift sol., or wiring

3-4 SOLENOID VALVE*

ON

Refer to page 7B—26 solenoid valve operation table

Control unit, 3-4 shift sol., or wiring 3-4 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table

Control unit, 3-4 shift sol., or wiring

LOCK-UP SOLE-NOID VALVE*

ON Lock-up condition Control unit, lock-up sol., or wiring LOCK-UP SOLE-NOID VALVE* OFF Non-lock-up condition

Control unit, lock-up sol., or wiring

HOLD INDICATOR ON Hold mode Control unit, Hold switch, or wiring HOLD INDICATOR OFF Other modes

Control unit, Hold switch, or wiring

MODE INDICATOR ON Power or economy mode Control unit, hold switch, mode switch, or wiring MODE INDICATOR

OFF Hold mode

Control unit, hold switch, mode switch, or wiring

NO LOAD SIGNAL Not used — —

76G07B-028

7B-25

Page 900 of 1865

7B TROUBLESHOOTING (G4A-EL)

STEP 7 (ROAD TEST)

This step is performed to inspect for problems at the various ranges. If these tests show any problems,

adjust or replace by referring to the electronic system component or mechanical sections.

Caution

Perform the test at normal ATF operating temperature (50—80°C, 122—176°F).

D Range Test

Shift point, shift pattern, and shift shock

1. Shift the selector lever to D range and select the Power mode.

2. Accelerate the vehicle with half and full throttle valve opening.

Note

Throttle sensor voltage of the EC-AT Tester represents the throttle valve opening.

3. Check that 1-2, 2-3 and 3-OD up-shifts and downshifts and lock-up are obtained. The shift points

must be as shown in the D range (Power) shift diagram.

Note

a) Drum speed (rpm) of the EC-AT Tester represents the shift point.

b) Vehicle speed of the EC-AT Tester and speedometer and vehicle speed on a chassis

roller may not meet the specified shift pattern because of tire size. Therefore, check

the shift points with the Drum speed.

c) There is no lock-up when the coolant temperature is below 72°C (162°F).

d) There is no overdrive when the cruise control is operating and there is a 3 km/h (1.9

mph) difference between the pre-set cruise speed and vehicle speed, or set or resume

switch is ON.

e) There is no lock-up when the brake pedal is depressed.

4. Check the up-shifts for shift shock or slippage in the same manner.

5. While driving in OD, shift the selector lever to S range and check that 4-3 downshift immediately

occurs, then decelerate and check that engine braking effect is felt in only 3rd gear.

7B—34

Page 913 of 1865

TROUBLESHOOTING (G4A-HL) 7B

STEP 2 (ELECTRICAL SYSTEM INSPECTION)

In this step, the function of the electrical control system (Inhibition of OD and lock-up) is checked. The

electrical control system components should be checked to determine if it functions correctly.

76G07B-048

O/D OFF Switch Inhibition Function

1. Warm up the engine and ATF.

2. Check that the D range, OD, and lock-up is

provided.

3. When driving the vehicle with D range, OD, and

lock-up selected, depress the O/D OFF switch and

check that OD and lock-up is cancelled.

4. If not cancelled, check the O/D OFF switch.

5. Release the O/D OFF switch after completion.

Cruise Control Switch Inhibition Function

1. Drive the vehicle in D range, OD, and lock-up

selected again.

2. Depress the Set switch of the cruise control and

check that OD and lock-up is cancelled.

3. If not cancelled, check the cruise control system.

4. Again drive the vehicle in D range, OD, and

lock-up.

5. Turn the Resume switch of the cruise control and

check that OD and lock-up is cancelled.

6. If not cancelled, check the cruise control system.

76G07B-051

7B—47

Page 934 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

76G07B-079

76G07B-080

76G07B-081

PULSE GENERATOR (G4A-EL)

Inspection

1. Disconnect the pulse generator connector.

2. Check for continuity between the terminals, if

necessary replace the pulse generator.

Resistance: 200—400fl

VEHICLE SPEED SENSOR (G4A-EL)

Inspection of voltage

1. Connect a voltmeter between the 1Q terminal of

the EC-AT control unit and ground as shown.

2. Turn the ignition switch ON.

3. Remove the speedometer cable from the transaxle.

4. Slowly turn the speedometer cable one turn.

5. Check that approx. 4.5V is shown 4 times.

6. If not correct, check the combination meter.

CRUISE CONTROL SWITCH (CRUISE CONTROL

UNIT)

Refer to Section 15.

IDLE SWITCH AND THROTTLE SENSOR

(G4A-EL)

Refer to Section 4A.

OD RELEASE SOLENOID VALVE (G4A-HL)

Inspection of Resistance

1. Disconnect the solenoid valve connector.

2. Check resistance between the terminals.

Resistance: 13—27 ft

3. If not correct, replace the solenoid valve.

76G07B-082

7B-68