tire type MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 679 of 1865

INTAKE AIR SYSTEM 4D

AIR DUCT AND AIR CLEANER

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

3. Check for air leakage.

1. Tire house cover

2. Air duct

3. Air hose

4. Air cleaner case

5. Air cleaner cover

6. Air cleaner

element

Inspection

Air cleaner

1. Inspect the silencer in the air cleaner cover for

damage.

2. Inspect the air cleaner element for excessive dirt,

damage, or oil. Replace if necessary.

Caution

(Wet type)

Do not clean the air cleaner element with com-

ressed air, replace it if necessary.

(Dry type)

When cleaning the air cleaner element, blow

dust off from the inside first, then blow off the

outside.

Air duct

Inspect the silencer in the air duct for damage. Re-

place if necessary.

76G04D-017

4D—8

Page 1122 of 1865

7C TROUBLESHOOTING

TROUBLESHOOTING

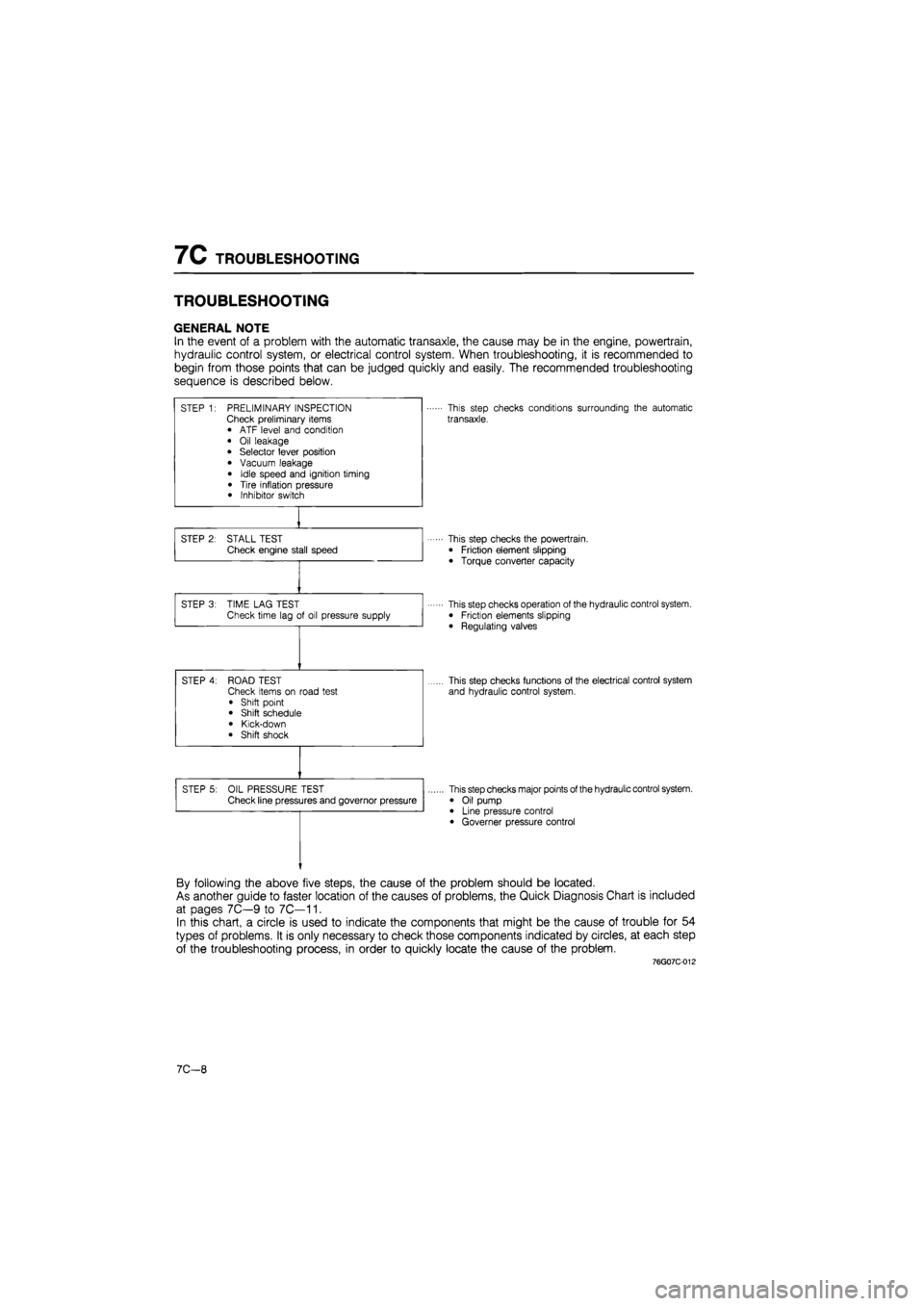

GENERAL NOTE

In the event of a problem with the automatic transaxle, the cause may be in the engine, powertrain,

hydraulic control system, or electrical control system. When troubleshooting, it is recommended to

begin from those points that can be judged quickly and easily. The recommended troubleshooting

sequence is described below.

STEP 1: PRELIMINARY INSPECTION Check preliminary items • ATF level and condition

• Oil leakage • Selector lever position

• Vacuum leakage

• Idle speed and ignition timing

• Tire inflation pressure • Inhibitor switch

This step checks conditions surrounding the automatic

transaxle.

STEP 2: STALL TEST Check engine stall speed This step checks the powertrain.

• Friction element slipping

• Torque converter capacity

STEP 3: TIME LAG TEST Check time lag of oil pressure supply This step checks operation of the hydraulic control system. • Friction elements slipping

• Regulating valves

STEP 4: ROAD TEST Check items on road test

• Shift point • Shift schedule

• Kick-down • Shift shock

This step checks functions of the electrical control system

and hydraulic control system.

STEP 5: OIL PRESSURE TEST Check line pressures and governor pressure This step checks major points of the hydraulic control system.

• Oil pump • Line pressure control • Governer pressure control

By following the above five steps, the cause of the problem should be located.

As another guide to faster location of the causes of problems, the Quick Diagnosis Chart is included

at pages 7C—9 to 7C—11.

In this chart, a circle is used to indicate the components that might be the cause of trouble for 54

types of problems. It is only necessary to check those components indicated by circles, at each step

of the troubleshooting process, in order to quickly locate the cause of the problem.

76G07C-012

7C—8

Page 1296 of 1865

1 0 TROUBLESHOOTING GUIDE

POWER STEERING

Problem Possible cause Remedy Page

Hard steering

Loose

or

damaged belt Low fluid level,

or air in

fluid Leakage

of

fluid

Malfunctioning electrical system* Insufficient oil pump pressure Improperly adjusted wheel alignment Malfunctioning steering gear Linkage ball joint not operating smoothly

Adjust

or

replace Add fluid

or

bleed

air

Repair

or

replace Repair

or

replace Repair

or

replace Refer

to

Section

13

Repair

or

replace Replace

10—12 10-11 10-13 10-87 10-16

10—28,

37

10-18

Poor return

Insufficient tire pressure

Improperly adjusted wheel alignment

Ball-joint not operating smoothly

Steering shaft contacting something

Refer

to

Section

12

Refer

to

Section

13

Replace

Repair

10-20 10-21

Excessive play

Loose gear box housing mounting bolts Worn linkage

or

tie-rod ball joint Worn lower ball joint Worn

or

damaged steering joint Worn rack and pinion gear

Tighten Replace

Refer

to

Section

13

Replace

Replace

10—30

10—18

10—21

10-58,

75

Steering wheel

vibrates

Insufficient tire pressure Damaged

or

unbalanced wheel Improperly adjusted wheel alignment Loose gear box housing mounting bolts Incorrect pinion preload adjustment Worn ball joints

Loose shock absorber mounting Malfunctioning shock absorber

Refer

to

Section

12

Refer

to

Section

13

Refer

to

Section

13

Tighten Adjust

Replace Refer

to

Section

13

Refer

to

Section

13

10-30 10-72,

81

10—18

Steering wheel

pulls

Unevenly worn tires

Incorrect tire pressure

Dragging brake

Improperly adjusted wheel alignment

Refer

to

Section

12

Refer

to

Section

12

Refer

to

Section

11

Refer

to

Section

13 —

Excessively light

steering at high

speed*

Malfunctioning electrical system Repair

or

replace 10-87

*... Only

for

electronically

-

controlled type

76G10X-002

10—8

Page 1299 of 1865

ON-VEHICLE MAINTENANCE 1 0

"{krf

'"""^JlW^M 1

V

^A-X

Power Steering

1.

86U10X-014

86U10X-015

With the vehicle on a hard level surface, move the

steering wheel to put the wheels in the straight

ahead position.

Start the engine and warm the power steering flu-

id to 50—60°C (122—140°F), pull scale.

Attach a pull scale to the outer circumference of

the steering wheel. Then, starting with the wheels

in the straight-ahead position, check the steering

effort required to turn the steering wheel to the left

and to the right.

If the measured value exceeds specification, check

the following: fluid level, air in system, fluid leak-

age at hose or connections, function of oil pump

and gear box, and tire pressure.

Steering wheel effort:

ESPS Type

25—31N (2.6—3.2 kg, 6—7 lb)

ECPS Type

15—23 N (1.7—2.3 kg, 3—5 lb)

4WS Type

25—35N (2.5—3.5 kg, 6—8 lb)

[during one turn of the steering wheel]

Note (4WS)

1)lf not within specification, separate the

transfer shaft from the front steering gear

and check again.

2) If still not within specification, there is a

malfunction of the front steering gear.

3) If the measured value is now within specifi-

cation, check the transfer shaft and rear

steering gear. (Refer to Page 10—45.)

86U10X-016

POWER STEERING FLUID LEVEL

Check the power steering fluid level, and add fluid

to the specified level if necessary.

Caution

Use only the specified power steering fluid.

86U10X-017

10—11

Page 1493 of 1865

1 2 OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

Type

Item Standard Temporary spare (if equipped)

Wheel

Size

5-J

x 13

4-T

x 15

Wheel

Size 5 1/2-JJ

x 14

4-T

x 15

Wheel

Size

6-JJ

x 15

4-T

x 15

Wheel

Off set mm (in) 42 (1.65) 53 (2.09)

Wheel Diameter

of

pitch circle

mm

(in) 114.3 (4.5) Wheel

Material Steel

or

aluminum alloy Steel

Wheel

Number

of

fixing nuts

13 inch-wheel 4

4

or 5

Wheel

Number

of

fixing nuts 14 inch-wheel 5 4

or 5

Wheel

Number

of

fixing nuts 15 inch-wheel 5 4

or 5

Tire

Size

13 inch-wheel

6.45—13—6PR

165 SR13 165/80R13 82S 185/70HR13 185/70R13 85H

T125/70D15

Tire

Size 14 inch-wheel

185/70HR14 185/70R14 87H 185/70R14 88H 185/70VR14

T125/70D15

Tire

Size

15 inch-wheel 195/60R15 86H

195/60VR15

T125/70D15

Tire

Air pressure

kPa (kg/cm2,

psi)

Front 216 (2.2, 31) or 196 (2.0, 28) "See tire labels for application 412(4.2, 60)

Tire

Air pressure

kPa (kg/cm2,

psi) Rear 177 (1.8, 26)

412(4.2, 60)

TROUBLESHOOTING GUIDE 76G12X-001

Problem Possible Cause Remedy Page

Premature tire wear

Incorrect tire pressure Adjust 12-

2

Tire squeal

Incorrect tire pressure Tire deterioration

Adjust ReDlace

12-

2

Road noise or body vibration

Insufficient tire pressure Unbalanced wheel(s) Deformed wheel(s)

or

tire(s) Irregular tire wear

Adjust Adjust Repair

or

replace Reolace

-1

12-

2

12-

5

Steering wheel vibration

Irregular tire wear Right and left tread depths different Deformed

or

unbalanced wheel(s) Deformed tire(s) Unequal tire pressures Loose lug nuts

Replace Replace

Replace

or

adjust Replace Adjust Tiahten

12-

5

12—

2

12-

5

Uneven (one-sided) braking

Unequal tire pressures Adjust 12-

2

Steering wheel doesn't return properly, or pulls to either left or right while vehicle moving on level road surface

Incorrect tire pressure Irregular tire wear (left and right are different) Unequal tire pressures Different types

or

brands

of

tires mixed (right/left) Improperly tightened lug nuts

Adjust Replace Adjust Replace Tighten

12-

2

12—

2

12-

5

General driving in-stability

Unequal tire pressures Deformed

or

unbalanced wheel(s) Loose lug nuts

Adjust Replace

or

adjust Tiahten

12-

2

12-

5

12-

5

Excessive steering wheel play

Loose lug nuts Tighten 12-

5

76G12X-002

12-2

Page 1496 of 1865

WHEELS AND TIRES 1 2

WHEEL BALANCE

If a wheel becomes unbalanced or if a tire is replaced

or repaired, the wheel must once again be balanced

to within specification.

Maximum unbalance (at rim edge): g (oz)

13 inch-wheel 11 (0.39)

14 inch-wheel 10 (0.35)

15 inch-wheel 9 (0.32)

76G12X-005

Balance

weight

Outside

Balance

weight

86U12X-011

Caution

a) Do not use more than two balance weights

on the inner or outer side of the wheel, if

the total weight exceeds 100 g (3.5 oz), re-

balance after moving the tire around on the

rim.

b) Attach the balance weights tightly so that

they do not protrude more than 3 mm (0.12

in) beyond the wheel edge.

c) Select suitable balance weights for steel or

aluminum alloy wheels.

d)Do not use an on-car balancer on ATX

models. Use of this type of balancer may

cause clutch damage.

WHEEL MOUNTING

Tighten the lug nuts to the specified torque in a criss-

cross fashion.

Tightening torque:

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

Caution

a) The wheel-to-hub contact surfaces must be

clean.

b) Never apply oil to the nuts, bolts, or wheels;

doing so might cause looseness or seizure

of the lug nuts.

86U12X-012

SPECIAL NOTE

Regarding wheels and tires:

1. Do not use wheels or tires other than the specified types.

2. Aluminum wheels are easily scratched. When washing them, use a soft cloth, never a wire brush.

If the vehicle is steam cleaned, do not allow boiling water to contact the wheels.

3. If alkaline compounds (such as salt water or road salts), get on aluminum wheels, wash them as

soon as possible to prevent damage. Use only a neutral detergent.

86U12X-013

12-5

Page 1852 of 1865

30 TECHNICAL DATA

12. WHEEL AND TIRE

* ~— - Type

Item ~ ———_____ Standard Temporary spare

(if equipped)

Wheel

Size

5-Jx13

4-T

x 15

Wheel

Size 5 1/2-JJx14 4-T

x 15

Wheel

Size

6JJx15

4-T

x 15

Wheel

Offset

mm (in)

42 (1.65) 53 (2.09)

Wheel Diameter

of

pitch circle

mm

(in) 114.3 (4.5) Wheel

Material Steel

or

aluminum alloy Steel

Wheel

Number

of

fixing nuts

13 inch-wheel 4

4

or 5

Wheel

Number

of

fixing nuts 14 inch-wheel 5 4

or 5

Wheel

Number

of

fixing nuts 15 inch-wheel 5 4

or 5

Tire

Size

13 inch-wheel

6.45-13-6PR 165SR13 165/80R13 82S

185/70HR13 185/70R13 85H

T125/70D15

Tire

Size

14 inch-wheel

185/70HR14 185/70R14 87H 185/70R14 88H 185/70VR14

T125/70D15

Tire

Size

15 inch-wheel 195/60R15 86H 195/60VR15

T125/70D15

Tire

Air pressure kPa (kg/cm2, psi)

Front 216 (2.2, 31)

or

196 (2.0, 28)

Refer to tire labels for applications 412 (4.2, 60)

Tire

Air pressure kPa (kg/cm2, psi) Rear 177 (1.8,

26)

412 (4.2, 60)

Wheel and tire

Runout

mm (in)

Horizontal Steel wheel: 2.5 (0.098), Alminum allov wheel: 2.0 (0.079) max.

Wheel and tire

Runout

mm (in) Vertical 2.0 (0.079) max.

Wheel and tire Unbalance

g

(oz)

13 inch-wheel 11 (0.39) max. Wheel and tire Unbalance

g

(oz) 14 inch-wheel 10 (0.35) max.

Wheel and tire Unbalance

g

(oz) 15 inch-wheel 9 (0.32) max.

13. SUSPENSION

Item Specification

Front suspension

Type Strut

Toe-in

mm

(in) 0 ±

3 (0

±

0

12)

Front wheel alignment Camber angle 0°17' ±

45'

Front wheel alignment Caster angle 1 °13' ±

45'

King pin angle 12C 47'

Maximum front Inner 36°26'33"

steering angle Outer 30°59'15"

Stabilizer Type Torsion

bar

Stabilizer Diameter

mm (in)

20.0 (0.79)

Shock absorbers Standard suspension Oil type Shock absorbers Auto adjust suspension Low-pressure gas sealed type

Identification color Orange Green Light green Pink Brown Purple Gray Blue

Wire diameter

mm (in)

12.5

(0.49)

12.6

(0.49) 12.8 (0.50) 12.9 (0.51) 13.1 (0.52) 13.3 (0.53) 13.6 (0.54) 13.7 (0.54)

Coil springs* Coil inner diameter mm (in) 147.5 (5.8)

Free length

mm

(in) 344 (13.5)

CO <35

362

(14.3)

370

(14.6)

372 (14.6) 365 (14.4) 350 (13.8) 358 (14.1)

Coil number 4.99 5.09 5.31 5.42 5.53 5.46 5.34 5.45

* Refer

to

pages 13—5,6,7

for

coil spring applications

30-38