transmission MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 11 of 1865

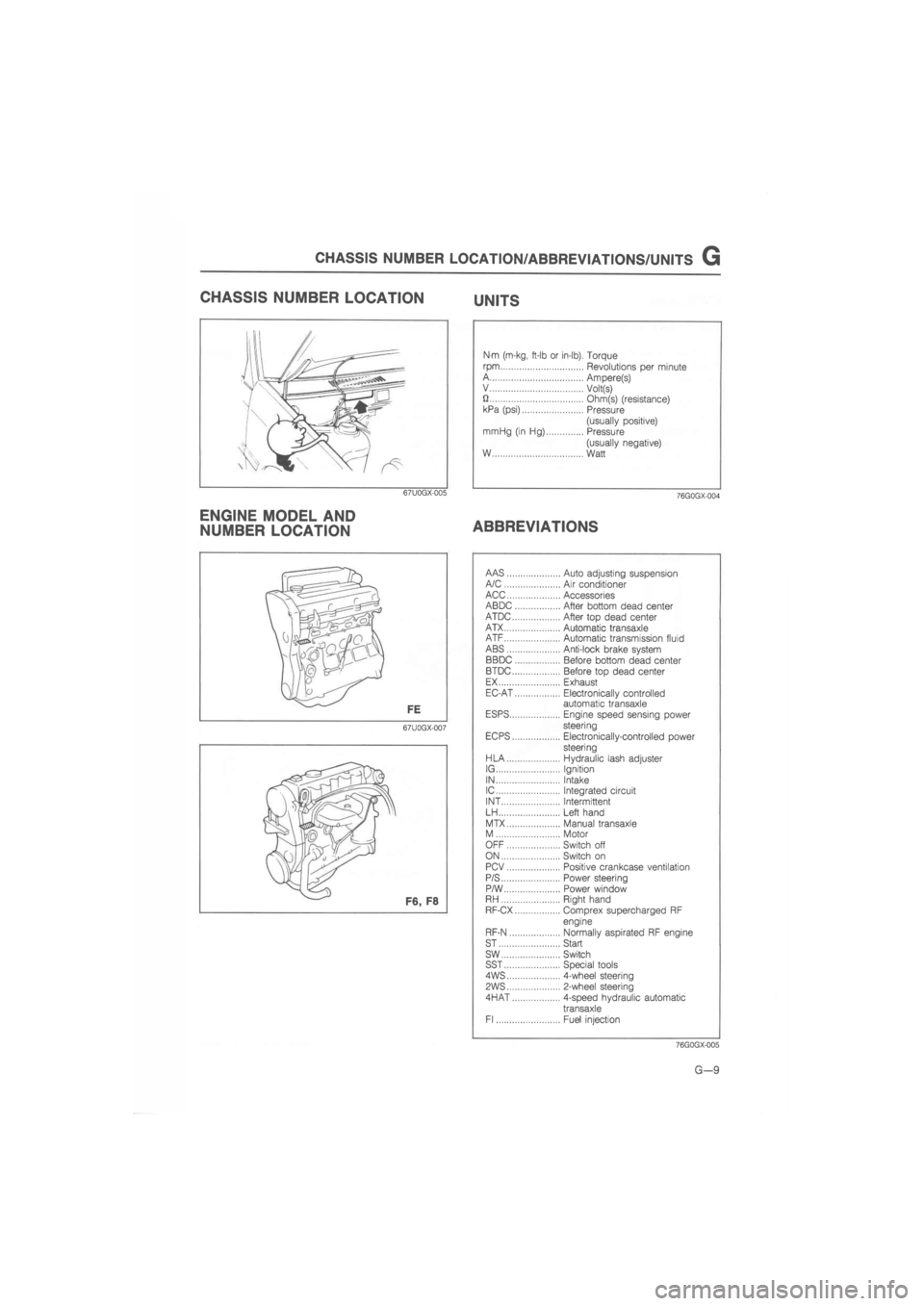

CHASSIS NUMBER LOCATION/ABBREVIATIONS/UNITS G

CHASSIS NUMBER LOCATION UNITS

67U0GX-005

ENGINE MODEL AND

NUMBER LOCATION

Nm (m-kg, ft-lb or in-lb). Torque

rpm Revolutions per minute A Ampere(s) V Volt(s) U Ohm(s) (resistance) kPa (psi) Pressure

(usually positive) mrriHg (in Hg) Pressure

(usually negative) W Watt

76G0GX-004

ABBREVIATIONS

67U0GX-007

AAS Auto adjusting suspension A/C Air conditioner ACC Accessories ABDC After bottom dead center ATDC After top dead center ATX Automatic transaxle ATF Automatic transmission fluid ABS Anti-lock brake system BBDC Before bottom dead center BTDC Before top dead center EX Exhaust EC-AT Electronically controlled automatic transaxle ESPS Engine speed sensing power steering EC PS Electronically-controlled power steering HLA Hydraulic lash adjuster IG Ignition IN Intake IC Integrated circuit INT Intermittent LH Left hand

MTX Manual transaxle M Motor OFF Switch off ON Switch on PCV Positive crankcase ventilation P/S Power steering P/W Power window RH Right hand RF-CX Comprex supercharged RF

engine

RF-N Normally aspirated RF engine ST Start sw Switch SST Special tools 4WS 4-wheel steering

PWS 2-wheel steering

4HAT 4-speed hydraulic automatic

transaxle Fl Fuel injection

76GQGX-005

G—9

Page 129 of 1865

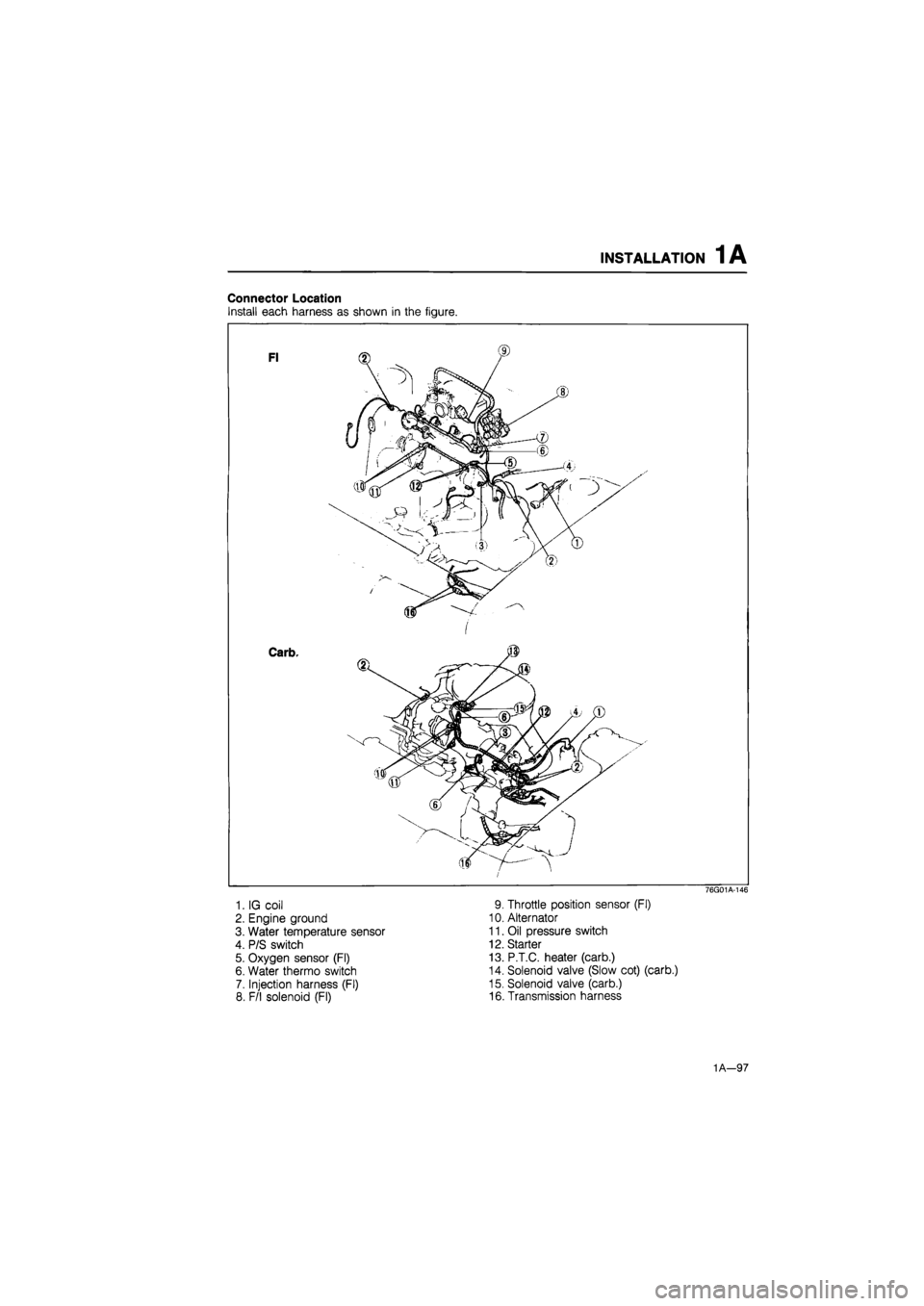

INSTALLATION 1A

Connector Location

Install each harness as shown in the figure.

1. IG coil

2. Engine ground

3. Water temperature sensor

4. P/S switch

5. Oxygen sensor (Fl)

6. Water thermo switch

7. Injection harness (Fl)

8. F/l solenoid (Fl)

76G01A-146

9. Throttle position sensor (Fl)

10. Alternator

11. Oil pressure switch

12. Starter

13. P.T.C. heater (carb.)

14. Solenoid valve (Slow cot) (carb.)

15. Solenoid valve (carb.)

16. Transmission harness

1A—97

Page 210 of 1865

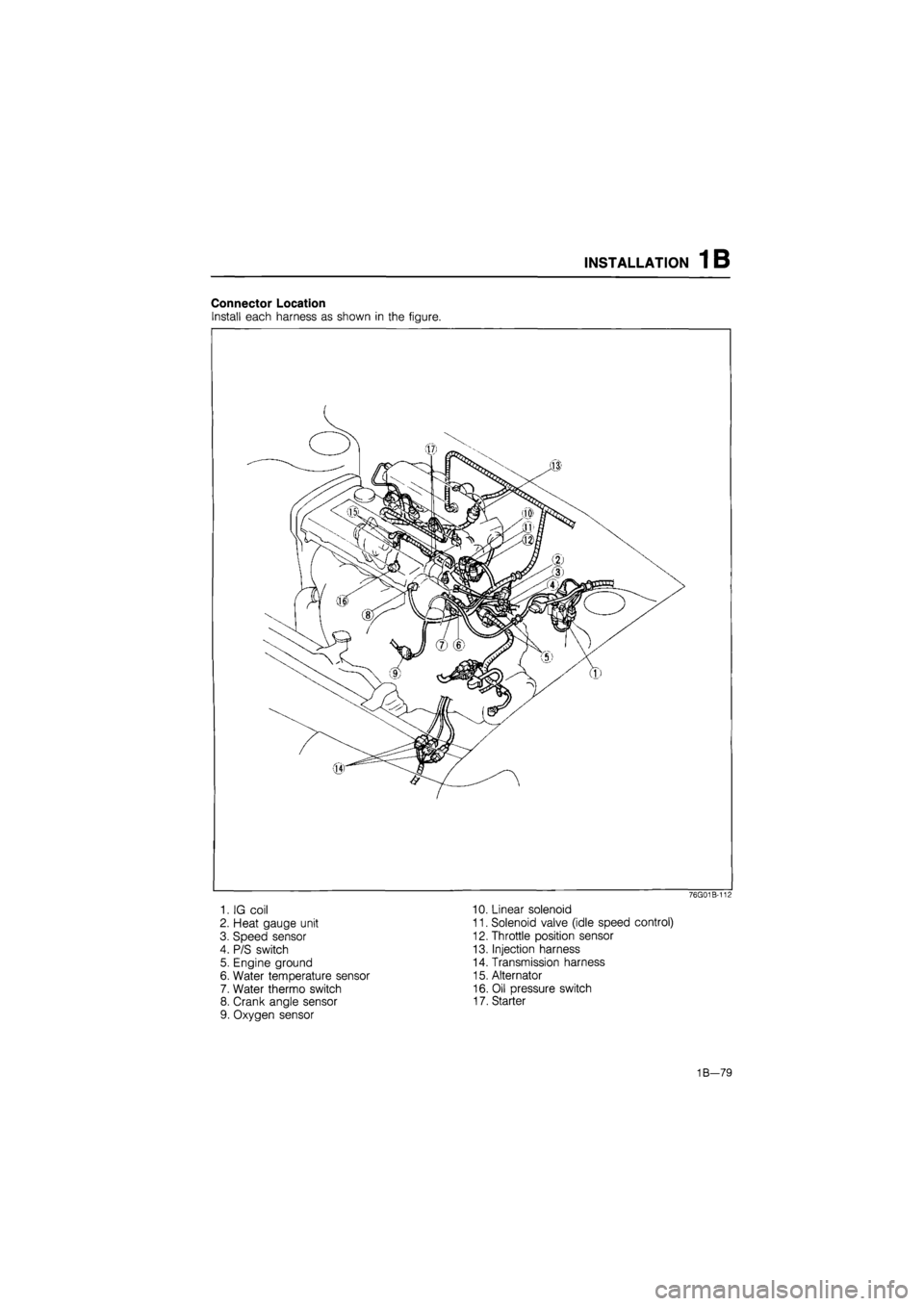

INSTALLATION 1B

Connector Location

Install each harness as shown in the figure.

76G01B-112

1. IG coil 10. Linear solenoid

2. Heat gauge unit 11. Solenoid valve (idle speed control)

3. Speed sensor 12. Throttle position sensor

4. P/S switch 13. Injection harness

5. Engine ground 14. Transmission harness

6. Water temperature sensor 15. Alternator

7. Water thermo switch 16. Oil pressure switch

8. Crank angle sensor 17. Starter

9. Oxygen sensor

1B-79

Page 398 of 1865

FUEL SYSTEM 4A

76G04A-040

76G04A-041

Clearance

® J t'YCL ® J

V hi /®

'-v

76G04A-042

Fast Idle Opening

FE and F8 (General, ECE, Hong Kong, and Sin-

gapore)

Adjustment of fast idle opening is normally un-

necessary.

But if it is necessary, adjust it as shown.

1. Before adjustment, let the carburetor set at 25WC

(77°F) for at least 1 hour.

2. Check that the center of the cam lever aligns with

the mark (25°) on the fast idle cam.

3. If not as specified, adjust it by turning the adjust

screw.

4. Measure the throttle valve clearance between the

throttle valve and wall with a wire gage.

Specification

Spec. General, ECE, Hong Kong,

and Singapore

Transmission MTX ATX

Clearance mm (in) 0.48—0.64

(0.019-0.025)

0.56—0.72 (0.022-0.028)

5. If not as specified, adjust it by turning the fast idle

adjust screw.

Unloader System

Only FE and F8 (General, ECE, Hong Kong, and

Singapore)

1. Open the primary throttle valve fully.

2. Measure the choke valve clearance.

Clearance-

1.68—2.14 mm (0.066—0.084 in)

3. If not as specified, adjust it by bending tab A.

Slow Fuel Cut Solenoid Valve

1. Start the engine, and run it at idle.

2. Disconnect the connector of the carburetor.

3. Check that the engine stops.

4. If the engine does not stop, replace the slow fuel

cut solenoid valve.

76G04A-043

4A-33

Page 442 of 1865

IDLE-UP CONTROL SYSTEM 4A

Troubleshooting

Note

Make the system inspection first. If no problem is found, continue with the next inspec-

tion of the Troubleshooting. (Refer to page 4A—70.)

\\ Possible cause

\ Page

£ O

S in c o

£ O **

in

0) ** (0 o

o **

s <0

o ** c o o •o d>

£ O **

S (0 o E a>

X 1-<,

£ O

S w £ O

a> > a >

u o c 0) o

c 3

O ** C o

c o s o a> a (0 c

c a E o o

® TJ w <0 4> DC

0) a » c cs IL

a> (0

o

£ C

i « a <

a. 3 a>

Engine

i

terminal

E a>

s. CO

Symptom

Section

15 Section 15 4A—95 4A—93 Section

15 4A—77 4A—86— 4A—91 4A—77

Checking order 3 4 5 6 7 8 2 9 1

76G04A-152

'Engine control unit terminal Check the following terminal voltages

Transmission Terminal

MTX A, C, D, H, Q, R

ATX I, 2B, 2C, 2D, 2E, 2H, 2M

System Inspection

1. Warm up the engine and run it at idle.

2. Connect a jumper wire to the carburetor connec-

tor terminal wire (YW) and ground.

3. Connect a tachometer to the engine.

4. Turn all accessories off.

5. Verify that the engine speed is within specification.

Engine speed: 900—950 rpm (MTX)

Engine speed: 1,000—1,050 rpm

(ATX; in N range)

6. Disconnect the tachometer.

76G04A-153

Idle-up Solenoid Valve

1. Turn all accessories OFF and turn the ignition

switch ON.

2. Disconnect the idle-up solenoid valve connector.

3. Ground the carburetor connector terminal wire

(YW) using with a jumper wire.

4. Check the rod is drawn into the valve.

5. Replace if necessary.

U

76G04A-154

4A-77

Page 553 of 1865

CONTROL SYSTEM 4B

Replacement

1. Disconnect the negative battery cable.

2. Remove the front console covers (right and left).

3. Disconnect the connectors from the control unit.

4. Replace the control unit.

NEUTRAL SWITCH

Inspection

1. Disconnect the neutral switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Transmission Continuity

In neutral No

In other ranges Yes

4. After checking, connect the switch connector.

Note

Refer to section 7A for replacement of the

neutral switch.

CLUTCH SWITCH

Inspection

1. Disconnect the clutch switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Pedal Continuity

Depressed No

Released Yes

4. After checking, connect the switch connector.

Note

Refer to section 6 for replacement of the

clutch switch.

BRAKE LIGHT SWITCH

Inspection

1. Disconnect the brake light switch connector.

2. Connect an ohmmeter to the switch.

3. Check the continuity of the switch.

Pedal Continuity

Depressed Yes

Released No

4. After checking, connect the switch connector.

Note

Refer to section 11 for replacement of the

brake switch.

4B-91

Page 658 of 1865

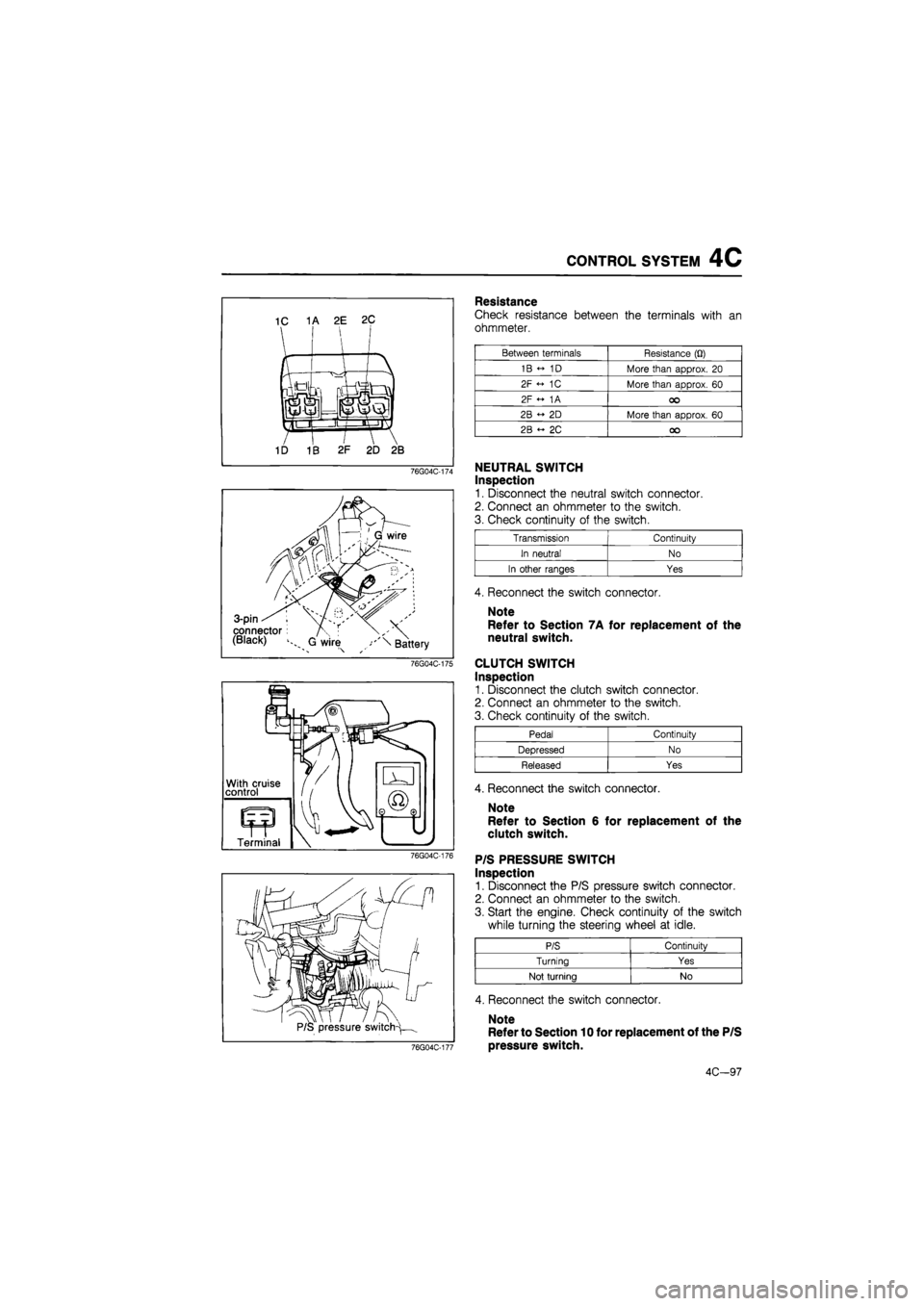

CONTROL SYSTEM 4C

Resistance

Check resistance between the terminals with an

ohmmeter.

Between terminals Resistance (Q)

1B « 1D More than approx. 20

2F <- 1C More than approx. 60

2F « 1A oo

2B « 2D More than approx. 60

2B ~ 2C oo

NEUTRAL SWITCH

Inspection

1. Disconnect the neutral switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Transmission Continuity

In neutral No

In other ranges Yes

4. Reconnect the switch connector.

Note

Refer to Section 7A for replacement of the

neutral switch.

CLUTCH SWITCH

Inspection

1. Disconnect the clutch switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Pedal Continuity

Depressed No

Released Yes

4. Reconnect the switch connector.

Note

Refer to Section 6 for replacement of the

clutch switch.

P/S PRESSURE SWITCH

Inspection

1. Disconnect the P/S pressure switch connector.

2. Connect an ohmmeter to the switch.

3. Start the engine. Check continuity of the switch

while turning the steering wheel at idle.

P/S Continuity

Turning Yes

Not turning No

4. Reconnect the switch connector.

Note

Refer to Section 10 for replacement of the P/S

pressure switch.

4C-97

Page 811 of 1865

TROUBLESHOOTING GUIDE 7A

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Change lever won't Seized change lever ball Replace 7A-58 shift smoothly, or is Seized change control rod joint Replace 7A-58

hard to shift Bent change control rod Replace 7A-58

Too much play in Worn change control rod bushing Replace 7A-58 change lever Weak spring of ball or change lever Replace 7A-58 Worn bushing of ball or change lever Replace 7A—58

Difficult to shift Bent change rod Replace 7A—58

No grease in transmission control Lubricate with grease 7A-58

Insufficient oil Add oil 7A-6

Deterioration of oil quality Replace with oil of 7A-6 specified quality

Wear or play of shift fork or shift rod Replace 7 A—18

Wear of synchronizer ring Replace 7A-27

Wear of synchronizer cone of gear Replace 7A-27

Bed contact of synchronizer ring and cone of Replace 7A-27 gear

Excessive longitudinal play of gears Replace 7A-22

Wear of bearing Adjust or replace 7A—22

Wear of synchronizer key spring Replace 7A-27

Excessive shaft gear bearing preload Adjust 7A-37

Improperly adjusted change guide plate Adjust 7A-20

Won't stay in gear Bent change control rod Replace 7A-58

Worn change control rod bushing Replace 7A-58

Weak change lever ball spring Replace 7A-58

Improperly installed extension bar Tighten 7A-58

Wear of shift fork Replace 7A—22

Wear of clutch hub Replace 7A-27

Worn clutch hub sleeve Replace 7A-27

Worn gear sliding part of both shaft gears Replace 7A-26

Worn gear sliding part of each gear Replace 7A-26

Worn steel sliding groove of control end Replace 7 A—18

Weak spring pressing against steel ball Replace 7A-18

Excessive thrust clearance Replace 7A—33,35

Worn bearing Replace 7A—22

Improperly installed engine mount Tighten 7A—49

Abnormal noise Insufficient oil Add oil 7A-6

Deterioration of oil quality Replace 7A-6

Worn bearing Adjust or replace 7A-22

Worn gear sliding surface of both shaft gears Replace 7A—26

Wear of sliding surfaces of gears Replace 7A-26

Excessive thrust clearance Replace 7A—33,35

Damaged gear teeth Replace with oil of 7A-26

specified quality Foreign material in gears Replace 7A-22

Damaged differential gear, or excessive backlash Adjust or replace 7A—30

76G07A-005

7A-5

Page 852 of 1865

7A ASSEMBLY

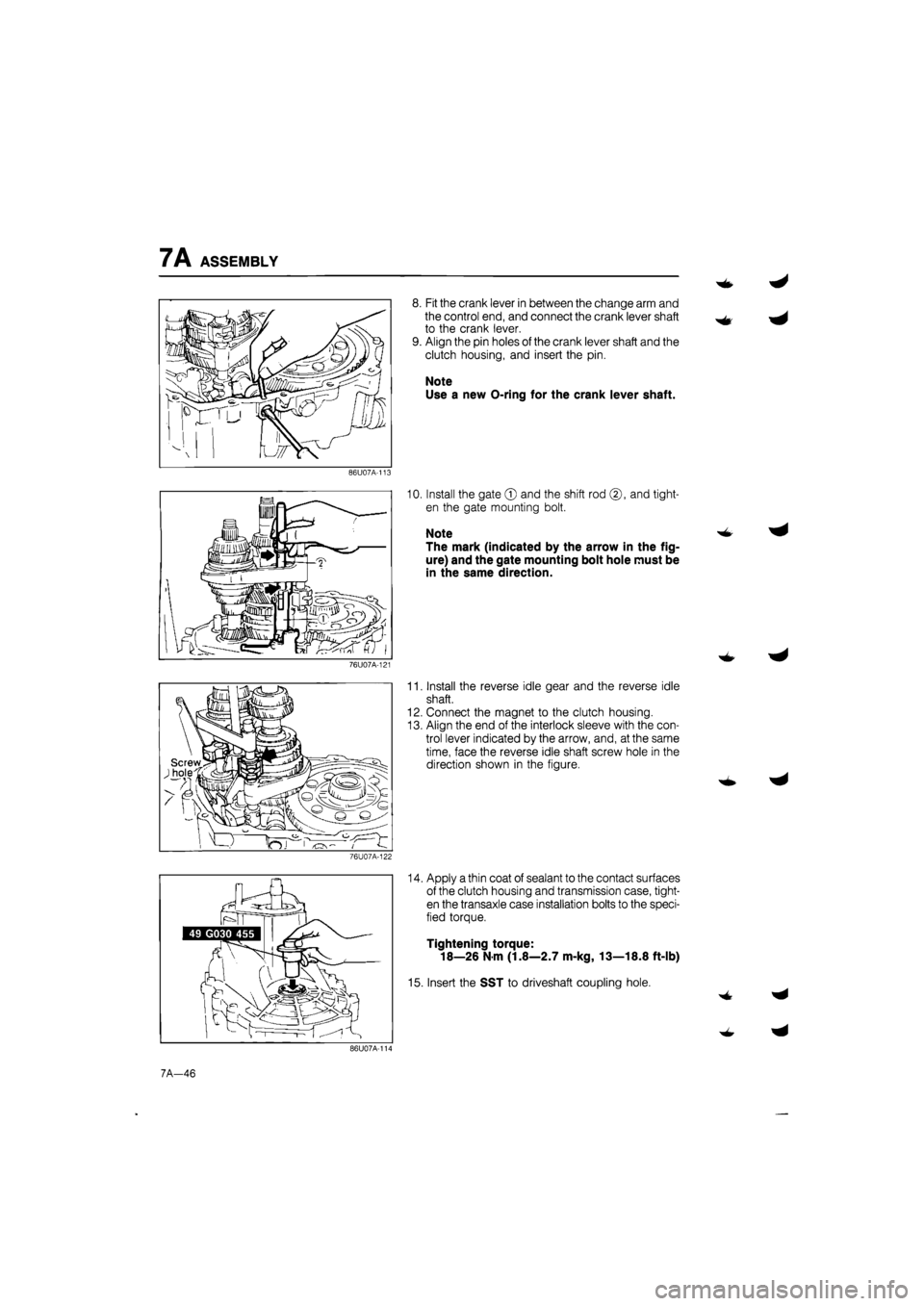

8. Fit the crank lever in between the change arm and

the control end, and connect the crank lever shaft

to the crank lever.

9. Align the pin holes of the crank lever shaft and the

clutch housing, and insert the pin.

Note

Use a new O-ring for the crank lever shaft.

86U07A-113

10. Install the gate © and the shift rod ©, and tight-

en the gate mounting bolt.

Note

The mark (indicated by the arrow in the fig-

ure) and the gate mounting bolt hole must be

in the same direction.

76U07A-121

11. Install the reverse idle gear and the reverse idle

shaft.

12. Connect the magnet to the clutch housing.

13. Align the end of the interlock sleeve with the con-

trol lever indicated by the arrow, and, at the same

time, face the reverse idle shaft screw hole in the

direction shown in the figure.

76U07A-122

14. Apply a thin coat of sealant to the contact surfaces

of the clutch housing and transmission case, tight-

en the transaxle case installation bolts to the speci-

fied torque.

Tightening torque:

18—26 N m (1.8—2.7 m-kg, 13—18.8 ft-lb)

15. Insert the SST to driveshaft coupling hole.

7A-46

Page 868 of 1865

7B OUTLINE

OUTLINE

SPECIFICATIONS

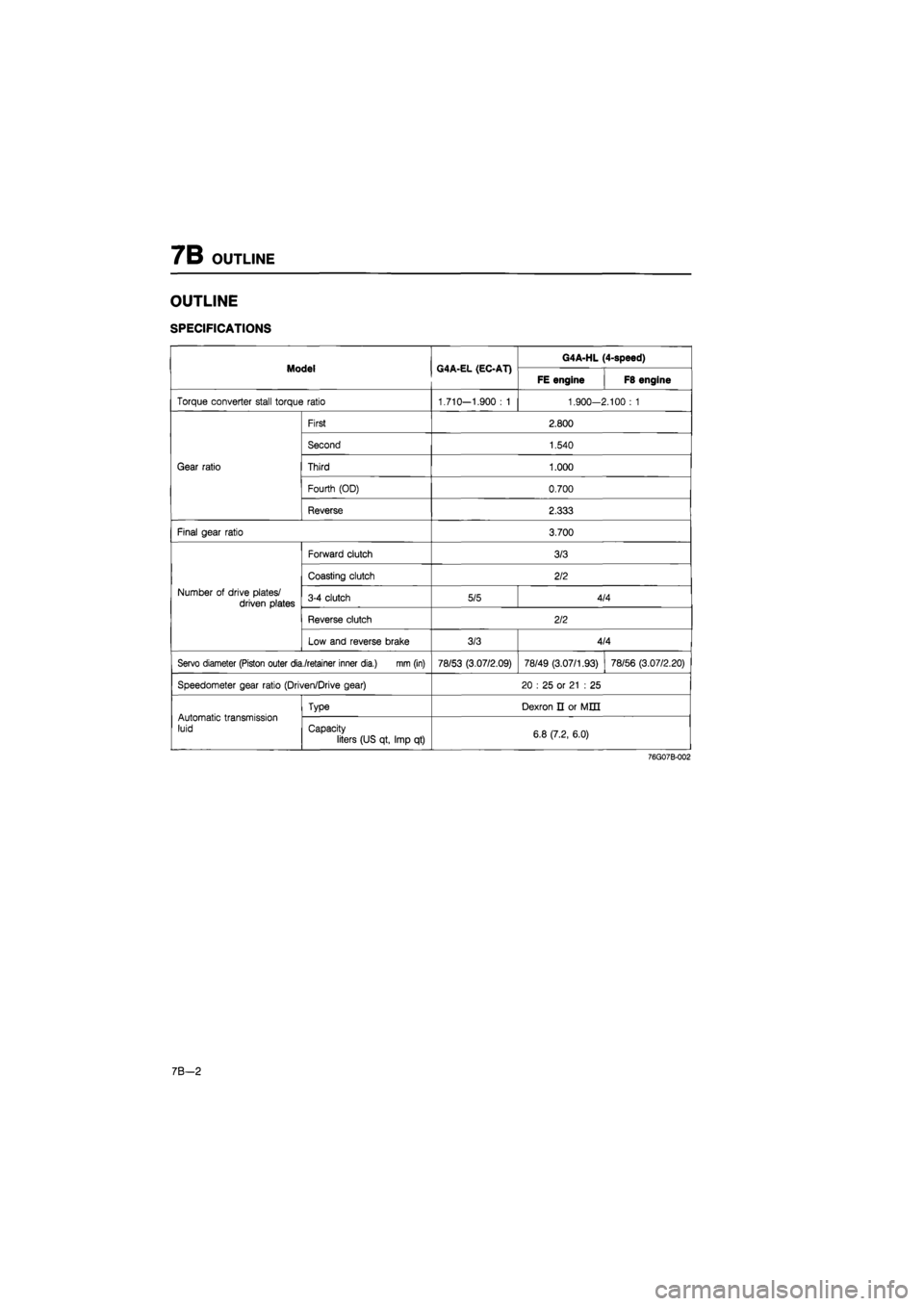

Model G4A-EL (EC-AT) G4A-HL (4-speed) Model G4A-EL (EC-AT)

FE engine F8 engine

Torque converter stall torque ratio 1.710—1.900

: 1

1.900-2.100

: 1

Gear ratio

First 2.800

Gear ratio

Second 1.540

Gear ratio Third 1.000 Gear ratio

Fourth (OD) 0.700

Gear ratio

Reverse 2.333

Final gear ratio 3.700

Number

of

drive plates/ driven plates

Forward clutch 3/3

Number

of

drive plates/ driven plates

Coasting clutch 2/2

Number

of

drive plates/ driven plates 3-4 clutch 5/5 4/4 Number

of

drive plates/ driven plates

Reverse clutch 2/2

Number

of

drive plates/ driven plates

Low and reverse brake 3/3 4/4

Servo diameter (Piston outer dia./retainer inner dia.) mm (in) 78/53 (3.07/2.09) 78/49 (3.07/1.93) 78/56 (3.07/2.20)

Speedometer gear ratio (Driven/Drive gear) 20

: 25 or

21

: 25

Automatic transmission luid

Type Dexron

n or

MED

Automatic transmission luid Capacity

liters (US qt, Imp

qt)

6.8 (7.2, 6.0)

76G07B-002

7 B—2