air bleeding MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 218 of 1865

1C TUNE-UP PROCEDURE

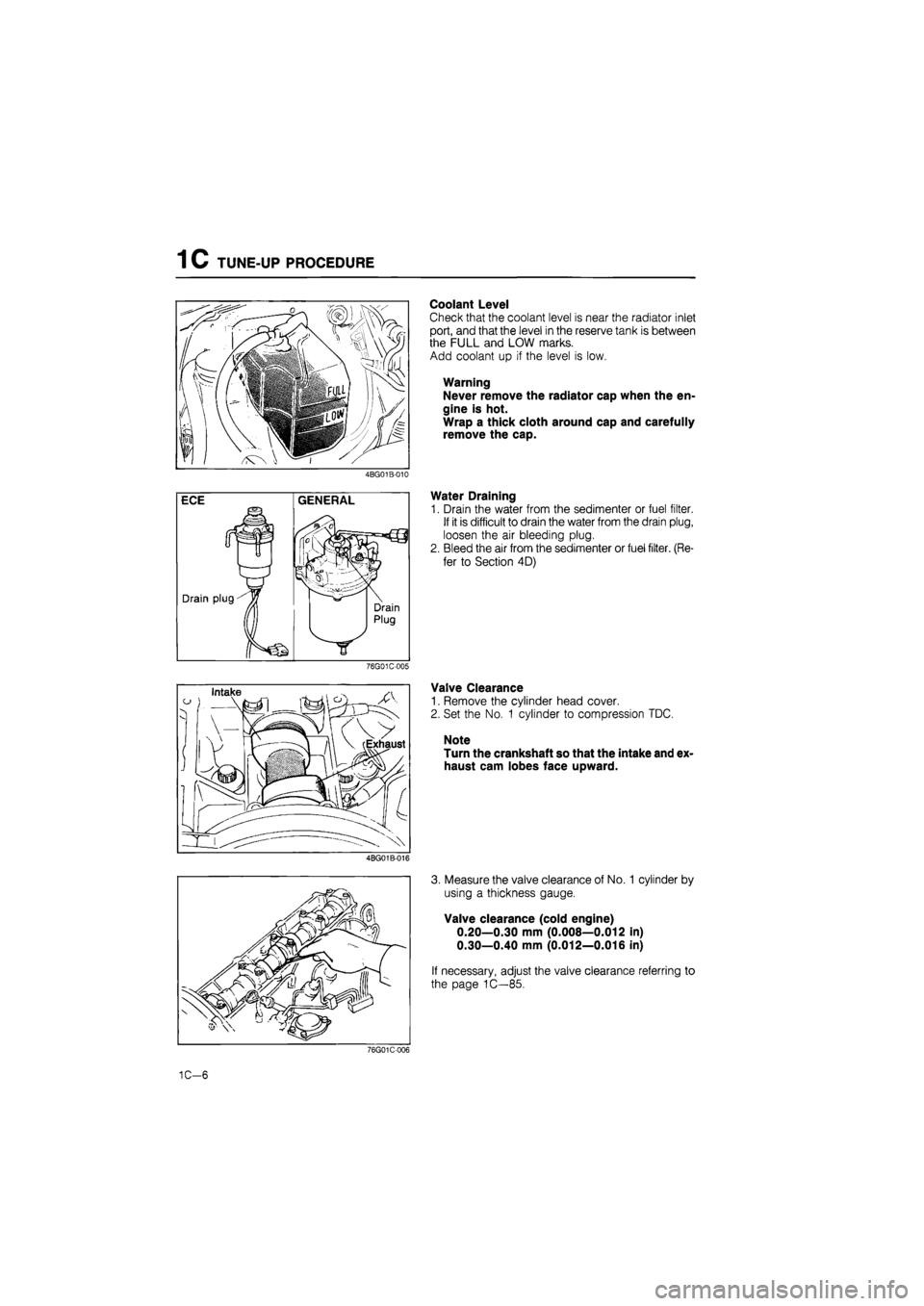

Coolant Level

Check that the coolant level is near the radiator inlet

port, and that the level in the reserve tank is between

the FULL and LOW marks.

Add coolant up if the level is low.

Warning

Never remove the radiator cap when the en-

gine is hot.

Wrap a thick cloth around cap and carefully

remove the cap.

4BG01B-010

Water Draining

1. Drain the water from the sedimenter or fuel filter.

If it is difficult to drain the water from the drain plug,

loosen the air bleeding plug.

2. Bleed the air from the sedimenter or fuel filter. (Re-

fer to Section 4D)

76G01C-005

Valve Clearance

1. Remove the cylinder head cover.

2. Set the No. 1 cylinder to compression TDC.

Note

Turn the crankshaft so that the intake and ex-

haust cam lobes face upward.

4BG01B-016

3. Measure the valve clearance of No. 1 cylinder by

using a thickness gauge.

Valve clearance (cold engine)

0.20—0.30 mm (0.008—0.012 in)

0.30—0.40 mm (0.012—0.016 in)

If necessary, adjust the valve clearance referring to

the page 1C—85.

76G01C-006

1C-6

Page 672 of 1865

4D

FUEL AND EMISSION

CONTROL SYSTEM

(DIESEL)

OUTLINE 4D— 2

SPECIFICATIONS 4D— 2

TROUBLESHOOTING GUIDE 4D— 3

ON-VEHICLE MAINTENANCE 4D— 4

AIR CLEANER ELEMENT 4D— 4

WATER DRAINING 4D— 4

AIR BLEEDING 4D— 4

INJECTION TIMING 4D— 5

IDLE SPEED 4D— 6

EXHAUST SMOKE 4D— 6

INTAKE AIR SYSTEM 4D— 7

STRUCTURAL VIEW 4D— 7

AIR DUCT AND AIR CLEANER 4D— 8

INTAKE MANIFOLD 4D— 9

SUPERCHARGING SYSTEM (RF-CX) 4D-10

TROUBLESHOOTING GUIDE 4D—10

ON-VEHICLE INSPECTION 4D—11

COMPREX SUPERCHARGER 4D—13

STARTING VALVE 4D—15

INTERCOOLER 4D—16

BOOST AIR TEMPERATURE SENSOR 4D—17

EXHAUST SYSTEM 4D—18

STRUCTURAL VIEW 4D—18

EXHAUST MANIFOLD 4D—19

EXHAUST PIPE AND MAIN SILENCER .... 4D—20

FUEL SYSTEM 4D—21

STRUCTURAL VIEW 4D—21

FUEL FILTER 4D—22

SEDIMENTER (GENERAL) 4D—22

WATER LEVEL SENSOR 4D—23

INJECTION PUMP 4D—24

INJECTION NOZZLE 4D—31

FUEL TANK 4D—34

76G04D-001

Page 675 of 1865

4D ON-VEHICLE MAINTENANCE

ON-VEHICLE MAINTENANCE

76G04D-004

AIR CLEANER ELEMENT

Check the air cleaner element for excessive dirt, dam-

age, or oil. Replace if necessary.

Caution

(Wet type)

Do not clean the air cleaner element with com-

pressed air, replace if necessary.

(Dry type)

When cleaning the air cleaner element, blow

dust off from the inside first, then blow off the

outside.

(General)

1. Loosen the drain plug of the sedimenter and let

the water drain. If necessary loosen the air bleed-

ing plug.

2. Bleed air from the sedimenter.

AIR BLEEDING

From Fuel Tank to Fuel Filter

1. Loosen the air bleeding plug of the fuel filter.

2. Pump the priming pump until no air bubbles flow

from the air bleeding plug hole.

3. Depress the priming pump and tighten the air

bleeding plug.

Note

Open only the air bleeding plug of the filter.

From Fuel Filter to Injection Pump

Pump the priming pump until it becomes hard to

pump.

76G04D-007

WATER DRAINING

(ECE)

1. Loosen the drain plug of the fuel filter.

2. Pump the priming pump.

3. Bleed air from the fuel filter.

4D—4

Page 787 of 1865

CLUTCH

OUTLINE 6— 2

STRUCTURAL VIEW 6— 2

SPECIFICATIONS 6— 3

TROUBLESHOOTING GUIDE 6— 3

ON-VEHICLE MAINTENANCE 6— 4

FLUID LEVEL 6— 4

PEDAL HEIGHT 6— 4

PEDAL FREEPLAY 6— 4

CLUTCH PEDAL 6— 5

REMOVAL 6— 5

INSPECTION 6— 6

INSTALLATION 6— 6

ADJUSTMENT 6— 6

CLUTCH MASTER CYLINDER 6— 7

REMOVAL 6— 7

DISASSEMBLY 6—8

INSPECTION 6— 9

ASSEMBLY 6— 9

INSTALLATION 6—11

CLUTCH RELEASE CYLINDER 6—11

REMOVAL 6—12

DISASSEMBLY 6-12

INSPECTION 6—13

ASSEMBLY 6—13

INSTALLATION 6—14

AIR BLEEDING 6—14

CLUTCH AND FLYWHEEL 6—15

REMOVAL 6—15

INSPECTION 6—16

INSTALLATION 6—19

76G06X-001

Page 797 of 1865

CLUTCH RELEASE CYLINDER

INSTALLATION

1. Install the clutch master cylinder.

2. Tighten the mounting nuts.

Tightening torque:

19—26 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

3. Tighten the clutch pipe flare nut securely with the

SST.

Tightening torque:

13—22 N m (1.3—2.2 m-kg, 9—16 ft-lb)

76G06X-021 4. Install the ABS relay box. (LHD)

After installation

1. Perform air bleeding. (Refer to page 6—14.)

2. Verify that there is no leakage.

3. Perform a road test.

CLUTCH RELEASE CYLINDER

86U06X-019

6-11

Page 800 of 1865

6 AIR BLEEDING

76U06X-031

4. Install the following parts:

(1) Push rod

(2) Boot

INSTALLATION

1. Install the release cylinder.

2. Tighten the installation bolts.

Tightening torque:

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

3. Tighten the clutch pipe flare nut securely with the

SST

Tightening torque:

13—22 N-m (1.3—2.2 m-kg, 9—16 ft-lb)

After installation

1. Perform air bleeding.

2. Verify that there is no leakage from the hydraulic

circuit.

3. Perform a road test.

49 0259 770B

AIR BLEEDING

The clutch hydraulic system must be bled to remove

air that entered when the pipes were disconnected.

This bleeding is done as described below.

Note

a) The fluid in the reserve tank must be main-

tained at the 3/4 level or higher during air

bleeding.

b) Use only the specified fluid type. (Refer to

page 6—3)

c) Be careful not to spill clutch fluid onto a

painted surface.

1. Remove the bleeder cap, and attach a vinyl hose

to the bleeder screw.

2. Place the other end of the vinyl tube in a glass con-

tainer of the appropriate capacity.

3. Slowly pump the clutch pedal several times by

hand.

4. While the clutch pedal is depressed, loosen the

bleeder screw to let fluid and air escape.

Then close the bleeder screw.

5. Repeat step 3 and 4 until no more air bubbles are

in the fluid.

6. Check for correct clutch operation.

86U06X-027

86U06X-028

49 0259 770B

76G06X-023

6—14

expert22 ajia http://rutracker.org

Page 1303 of 1865

INSPECTION AND ADJUSTMENT 1 0

INSPECTION AND ADJUSTMENT

BLEEDING OF POWER STEERING SYSTEM

1. Check the fluid level, and add fluid if necessary.

2. Turn the steering wheel fully in both directions 5

times (engine not running).

3. Recheck the fluid level. If the level has lowered,

add fluid, and repeat from step 1.

86U10X-021

4. Start the engine, and run it at idle.

5. Turn the steering wheel fully in both directions 5

times to bleed air from the system.

6. Check that the fluid is not foamy and the fluid lev-

el has not lowered.

If a problem is found, add fluid as necessary and

repeat from step 5.

Note

If bleeding is not done completely, the follow-

ing problems may appear:

• Foamy fluid on level gauge.

• Noise from power steering oil pump.

86U10X-022

10—15

Page 1393 of 1865

11

BRAKING SYSTEM

OUTLINE 11—2

STRUCTURAL VIEW 11—2

SPECIFICATIONS 11— 4

TROUBLESHOOTING GUIDE 11— 5

ON-VEHICLE MAINTENANCE 11—6

BRAKE FLUID LEVEL IN MASTER

CYLINDER RESERVOIR 11— 6

BRAKE HYDRAULIC LINE 11—6

STRUCTURAL VIEW 11—6

ON-VEHICLE INSPECTION OF

BRAKE LINES 11— 8

REMOVAL AND INSTALLATION OF

BRAKE LINES 11— 9

REPLACEMENT OF BRAKE

FLUID 11— 9

AIR BLEEDING 11— 9

BRAKE PEDAL 11—11

ON-VEHICLE INSPECTION 11—11

REMOVAL 11—12

INSPECTION 11—13

INSTALLATION 11—13

MASTER CYLINDER 11—14

REMOVAL 11—15

DISASSEMBLY AND ASSEMBLY

(EXCEPT RHD DOHC TURBO).... 11—14

INSPECTION 11—17

DISASSEMBLY AND ASSEMBLY

(RHD DOHC TURBO) 11—18

INSPECTION 11—21

INSTALLATION 11—22

POWER BRAKE UNIT 11—27

FUNCTION CHECK 11—27

INSPECTION OF CHECK VALVE... 11—29

REMOVAL 11—29

DISASSEMBLY AND ASSEMBLY... 11—30

INSPECTION 11—32

INSTALLATION 11—33

VACUUM PUMP 11—35

ON-VEHICLE INSPECTION 11—35

REMOVAL AND INSTALLATION.... 11—35

DISASSEMBLY AND ASSEMBLY... 11—36

INSPECTION 11—37

DUAL PROPORTIONING VALVE 11—38

FUNCTION CHECK 11—38

REMOVAL AND INSTALLATION.... 11—39

FRONT DISC BRAKE 11—40

SIMPLE INSPECTION OF DISC

PAD WEAR 11—40

REPLACEMENT OF DISC PAD 11—40

REMOVAL 11—42

DISASSEMBLY AND ASSEMBLY... 11—43

INSPECTION 11—44

INSTALLATION 11—45

REAR DISC BRAKE 11—46

SIMPLE INSPECTION OF DISC

PAD WEAR 11—46

REPLACEMENT OF DISC PAD 11—46

REMOVAL 11—49

DISASSEMBLY AND ASSEMBLY... 11—50

INSPECTION 11—54

INSTALLATION 11—55

REAR DRUM BRAKE 11—56

REMOVAL 11—56

DISASSEMBLY AND ASSEMBLY

OF WHEEL CYLINDER 11—59

INSPECTION 11—60

INSTALLATION 11—61

PARKING BRAKE 11—65

ON-VEHICLE MAINTENANCE 11—65

REMOVAL AND INSTALLATION

OF PARKING BRAKE LEVER 11—66

REMOVAL OF PARKING BRAKE

CABLE 11—68

INSTALLATION OF PARKING

BRAKE CABLE 11—69

ANTI-LOCK BRAKE SYSTEM

(ABS) 11—71

STRUCTURAL VIEW 11—71

WIRING DIAGRAM 11—72

TROUBLESHOOTING 11—73

DIAGNOSIS INDICATION MODE ... 11—86

MEMORY CANCEL 11—86

ABS WARNING LIGHT 11—87

RELAY BOX 11—87

WHEEL SPEED SENSOR 11—87

SENSOR ROTOR 11—90

HYDRAULIC UNIT FLUID 11—94

HYDRAULIC UNIT 11—94

CONTROL UNIT CIRCUIT 11—99

76G11X-001

Page 1401 of 1865

BRAKE HYDRAULIC LINE 1 1

REMOVAL AND INSTALLATION OF BRAKE

LINES

1. Loosen or tighten the flare nut with the SST.

Flare nut tightening torque: 13—22 N-m

(1.3—2.2 m-kg, 9—16 ft-lb)

2. When connecting the flexible hose, do not over-

tighten or twist it.

3. After installation:

(1) Check that the hose does not contact other

parts when the vehicle bounces or when the

steering wheel is turned all the way to the right

or left.

(2) Bleed the air from the brake system. (Refer to

page 11—9.)

REPLACEMENT OF BRAKE FLUID

1. Remove the brake fluid from the reservoir with a

suction pump.

2. Fill the reservoir with new, specified brake fluid.

3. Pump out the old brake fluid by loosening the

bleeder screws (one by one) and pumping the

brake pedal. (Refer to page 11—10 for details.)

AIR BLEEDING

Air Bleeding Locations

After the following parts are removed, air bleeding is necessary after installation.

Removed part

Air bleeding location

Removed part Front Rear Removed part

Right side Left side Right side Left side

Master cylinder * * * *

Wheel cylinder or caliper

Front Right side * — — —

Wheel cylinder or caliper

Front Left side — * — —

Wheel cylinder or caliper Rear disc Right side — — * — Wheel cylinder or caliper Rear disc Left side — — — * Wheel cylinder or caliper

Rear drum Right side — — * —

Wheel cylinder or caliper

Rear drum Left side — — — *

Dual proportioning valve * * * *

Hydraulic unit (ABS) * * * *

ABS: Anti-lock Brake System 76GHX-064 *: Indicates where air bleeding is necessary

11—9

Page 1402 of 1865

1 1 BRAKE HYDRAULIC LINE

Procedure

1. Jack up the vehicle and support it with safety

stands.

2. Fill the reservoir with brake fluid. Be sure that it is

at least half full at all times during the air bleeding

process.

Caution

a) Be careful not to spill brake fluid onto a

painted surface.

b)Use only the specified brake fluid. Do not

mix it with any other type.

3. Remove the bleeder cap; then connect one end

of a transparent vinyl tube to the bleeder screw and

place the other end in a receptacle.

4. Have an assistant depress the brake pedal a few

times, and then hold it in the depressed position.

5. Loosen the bleeder screw, drain out the fluid, and

retighten the bleeder.

Note

a) The two people should stay in voice con-

tact with each other.

b) Be sure the pedal remains depressed until

the bleeder is tightened.

86U11X-014

6. Repeat steps 4 and 5 until no more air is dis-

charged.

7. Tighten the bleeder screw, and check that there

is no fluid leakage.

Bleeder screw tightening torque:

6—9 N-m (60—90 cm-kg, 52—78 in-lb)

Caution

Be sure to clean away any spilled fluid with

rags.

8. Add brake fluid to the reservoir up to the speci-

fied level.

11—10