warning lights MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 14 of 1865

0 PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

EXTERIOR

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Glass, exterior bright metal and paint for damage

• Wheel lug nuts

88—118 N m (9—12 m-kg, 65—87 ft-lb)

• Tire pressures (Refer to section 12)

• All weatherstrips for damage or detachment

• Operation of bonnet release and lock

• Operation of fuel lid and trunk lid (Back door) opener

• Door operation and alignment

• Headlight aiming

INSTALL following parts:

• Wheel caps or rings (if equipped)

• Outside rear view mirror(s)

UNDER BONNET—ENGINE OFF

INSPECT and ADJUST, if necessary, the following items

to the specifications:

• Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

• Engine oil level

• Power steering fluid level (if equipped)

• Brake and clutch master cylinder fluid level (if equipped)

• Windshield washer reservoir fluid level

• Radiator coolant level and specific gravity

Protection °C (°F) Specific gravity at 20°C (68°F)

-4 (25) 1.028

-16(3) 1.054

-26 (-15) 1.066 -40 (-40) 1.078

• Tightness of water hose clamps (including heater hoses)

• Tightness of battery terminals

• Manual transaxle oil level

• Drive belt tensions (Refer to section 1)

• Accelerator cable and its linkage for free movement

• Headlight cleaner fluid level (if equipped)

CLEAN spark plugs

INTERIOR

INSTALL the following parts:

• Rubber stopper for inside rear view mirror

• Fuse for accessories

CHECK the operations of the following items:

• Seat controls (sliding and reclining) and head rest

• Door locks including childproof door locks (if equipped)

• Seat belts and warning system

• Ignition switch and steering lock

• Inhibitor switch (ATX only)

• All lights including warning and indicator lights

• Sound warning system

• Headlight cleaner (if equipped)

• Horn, wipers and washers (front and rear, if equipped)

• Radio and antenna (if equipped)

• Cigarette lighter and clock

• Remote control outside rear view mirrors (if equipped)

• Power windows (if equipped)

• Heater, defroster and air conditioner at various mode

selection (if equipped)

• Sunroof (if equipped)

ADJUST antenna trimmer on radio (if equipped)

CHECK the following items:

• Presence of spare fuse

• Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

• Operation and fit of windows

• Pedal height and free play of brake and clutch pedal

Pedal height mm (in) free play mm (in)

Clutch pedal 216.5-221.5 (8.52-8.72) 5-13 (0.2-0.51)

Brake pedal 222-227 (8.74-8.94) 4-7 (0.16-0.28)

• Parking brake

5-7 noches/98 N (10 kg, 22lb)

UNDER BONNET—ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

• Operation of idle-up system for air conditioner or power

steering (if equipped)

• Automatic transaxle fluid level

• Operation of dash pot

• Initial ignition timing

• Idle speed

ON HOIST

CHECK the following items:

• Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

• Tires for cuts or bruises

• Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

REMOVE protective cover from brake discs

ROAD TEST"

CHECK the following items:

• Brake operation

• Clutch operation

• Steering control

• Operation of meters and gauge

• Squeaks, rattles or unusual noise

• Engine general performance (including turbo)

• Emergency locking retractors

• Cruise control system (if equipped)

AFTER ROAD TEST

REMOVE seat and floor mat protective covers

CHECK for necessary owner information materials, tools and

spare tire in vehicle

-76G00X-002

0-2

Page 731 of 1865

ALTERNATOR 5

Warning

Disconnect the nagative battery terminal when disconnect or reconnect B terminal.

TEST 1

1. Disconnect the alternator connector (2-pin).

2. Connect the SST.

4. Connect the red clip of the adapter harness to the battery

(

+

),

and check that the red

lamp and green lamp illuminate.

5. Start the engine and check that both lamps go off.

86U05X-010

TEST 2

1. Connect an ammeter (75A min.) between the wire and the B terminal.

2. Turn all headlights and accessories on, and depress the brake pedal.

3. Start the engine and check that output current is 70A (RF-CX: 75A) or more at

2,500—3,000 rpm of the engine speed.

Caution

Do not ground the B terminal.

76G05X-029

B terminal

5-25

Page 1479 of 1865

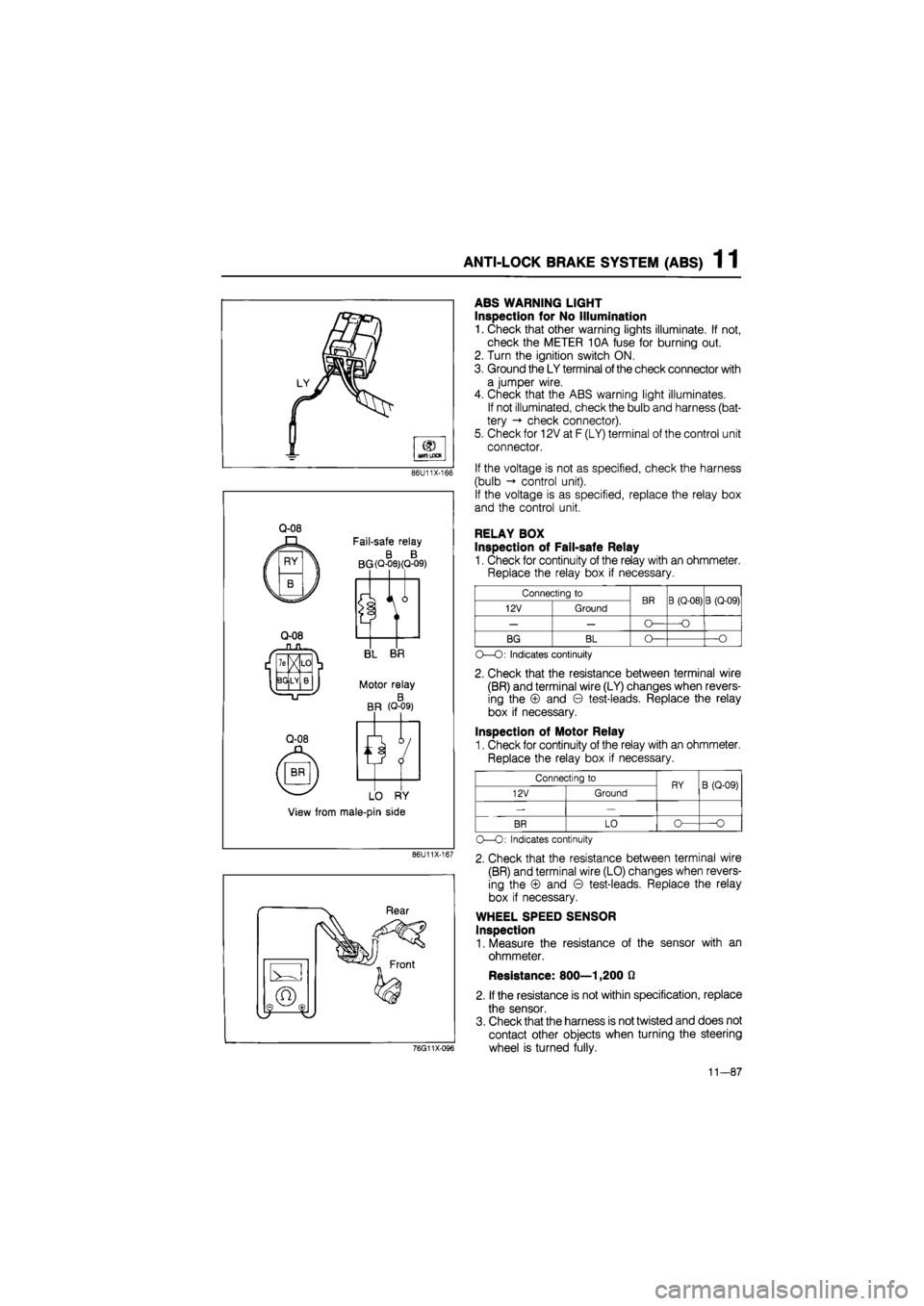

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

86U11X-1C

Q-08

Q-08

Fail-safe relay

B B BG

(Q-08)(Q-09)

V

BL BR

Motor relay

B BR (Q-09)

LO RY

View from male-pin side

86U11X-167

76G11X-096

ABS WARNING LIGHT

Inspection for No Illumination

1. Check that other warning lights illuminate. If not,

check the METER 10A fuse for burning out.

2. Turn the ignition switch ON.

3. Ground the LY terminal

of

the check connector with

a jumper wire.

4. Check that the ABS warning light illuminates.

If not illuminated, check the bulb and harness (bat-

tery -» check connector).

5. Check for 12V at F (LY) terminal of the control unit

connector.

If the voltage is not as specified, check the harness

(bulb control unit).

If the voltage is as specified, replace the relay box

and the control unit.

RELAY BOX

Inspection of Fail-safe Relay

1. Check for continuity of the relay with an ohmmeter.

Replace the relay box if necessary.

Connecting to BR B (Q-08) B (Q-09) 12V Ground BR B (Q-08) B (Q-09)

— — O— —O

BG BL O— —O

O—O: Indicates continuity

2. Check that the resistance between terminal wire

(BR) and terminal wire (LY) changes when revers-

ing the © and © test-leads. Replace the relay

box if necessary.

Inspection of Motor Relay

1. Check for continuity of the relay with an ohmmeter.

Replace the relay box if necessary.

Connecting to RY B (Q-09) 12V Ground RY B (Q-09)

-—

BR LO o— O

O—O: Indicates continuity

2. Check that the resistance between terminal wire

(BR) and terminal wire (LO) changes when revers-

ing the © and © test-leads. Replace the relay

box if necessary.

WHEEL SPEED SENSOR

Inspection

1. Measure the resistance of the sensor with an

ohmmeter.

Resistance: 800—1,200 0

2. If the resistance is not within specification, replace

the sensor.

3. Check that the harness is not twisted and does not

contact other objects when turning the steering

wheel is turned fully.

11-87

Page 1677 of 1865

15 METER

METER

STRUCTURAL VIEW

DIGITAL ELECTRONIC DISPLAY METER

ANALOG DISPLAY METER

76G15X-007

1. Speedometer 5. Warning and indicator lights

2. Tachometer 6. Tripmeter

3. Water temperature gauge 7. Twin tripmeter change switch

4. Fuel gauge 8. Fuel garge scale change switch

15—22

Page 1692 of 1865

WARNING LIGHT AND SENDER 1 5

76G15X-090

Seat Belt Warning Light

76G15X-043

EC-AT Mode Indicator Light

POWER and ECONO indicator lights

do

not

il-

luminate.

NG

Check the hold switch. Refer

to

page 7B—63

NG

Replace the switch.

OK

NG

Check the mode switch. Refer

to

page 7B—63

NG

Replace the switch.

fOK

Replace the bulb

or

repair the harness (Meter

to

mode switch, EC-AT switch

to

control unit).

76G15X-091

76G15X-044

15—37

Page 1693 of 1865

1 5 WARNING AND SENDER

Shift Indicator Light

All shift indicator lights do not Illuminate when ignition switch on. (other warning light are all right.)

Check the voltage

at BY

terminal

of

the inhibitor switch connector with ignition switch

on.

Terminal Voltage

BY 12V

NG

Repair the harness (Fuse box

to

inhibitor switch).

OK

Check the inhibitor switch. Refer

to

page 7B—65

NG

Replace the inhibitor switch. Check the inhibitor switch. Refer

to

page 7B—65 Replace the inhibitor switch.

OK

NG

Check the bulbs

of

the shift indicator lights.

NG

Replace the bulb.

OK

Turn the ignition switch on, and check the voltage

at

each terminal

of

the meter connector with each con-dition.

Terminal Selector lever Voltage

YL (2J) P 12V

RG (1L) R 12V

YR (2L) N 12V

Y(1V) D 12V

YB (1S) 2 12V

YW (1M) 1 12V

NG

Repair the harness (Inhibitor switch

to

meter).

76G15X-087

O/D OFF Indicator Light

OK

Repair the harness (O/D OFF switch

to

ground).

76G15X092

15-38

Page 1698 of 1865

CENTRAL PROCESSING UNIT (CPU) 1 5

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Disconnect the CPU connectors.

3. Release the lock and remove the CPU from the

joint box.

4. Install in the reverse order of removal.

ON-VEHICLE INSPECTION

Note: Check the voltage between "a through

I" terminal and ground.

Check the continuity between "m,

n" terminal and ground.

86U15X-075

Terminal Connecting

to

Measurement condition Measurement value

a Interior light and courtesy lights Any time Approx.

12V

b Batterv Anv time Approx.

12V

c No used

— —

d Ground Anv time OV

e Seat belt warning light Ignition switch

ON

Approx.

12V

f Enaine control unit Enaine runnina Approx.

12V

g Key cylinder illumination light Any time Approx.

12V

i Key reminder switch Insert the key into the cylinder

Pull out the key from the cylinder

Approx.

12V

OV

j Ignition switch (ON) Ignition switch

ON

Ignition switch OFF

or

ACC

Approx.

12V

OV

k Ignition switch (ACC) Ignition switch

ON or

ACC

Ignition switch OFF

Approx.

12V

OV

I Light switch (In the combination switch) Turn the light switch ACC and

ON

Light switch OFF

Approx.

12V

OV

m Seat belt switch Seat belt fastened

Seat belt unfastered

OQ

OO

n Door switch Door closed

Door open

OO

on

76G15X-009

15—43

Page 1854 of 1865

30 TECHNICAL DATA

Body type Specification (W) (BULB TRADE NO)

Item MX-6/Coupe Sedan Hatchback

Brake 1.4

Oil pressure 1.4

Fuel 1.4

Washer level 1.4

Rear 1.4

4WS

— —

1.4 (ECE)

Indicator and warning lights

Door 1.4 Indicator and warning lights Seat belt 1.4 Indicator and warning lights ABS 1.4

Alternator 1.4

High beam 3.4

Turn signal 3.4

O/D OFF 0.8

A/T mode 0.8 (ECE)

A/T position 0.8

Glove compartment light 3.4

Interior lights Interior light 10

Luggage compartment light 5

Motor 4.8

Hazard switch 1.4

Cigar lighter 3.4

Auto cruise main switch 0.5

Illumination lights AAS switch 1.4

Rear defroster switch 1.4

A/T switch 1.4

A/T 3.4

IG switch 1.4

STANDARD BOLT AND NUT TIGHTENING TORQUE

Diameter

mm (in)

Pitch

mm (in)

4T 6T 8T Diameter

mm (in)

Pitch

mm (in) N-m m-kg ft-lb N-m m-kg ft-lb N-m m-kg ft-lb

6 (0.236) 1 (0.039) 4.2-6.2 0.43-0.63 3.1-4.6 6.9-9.8 0.7-1.0 5.0-7.2 7.8-11.8 0.8-1.2 5.8—8.8

8 (0.315) 1.25 (0.049) 9.8—14.7 1.0-1.5 7.2-10.8 16-23 1.6-2.3 12-17 18—26 1.8-2.7 13-20

10 (0.394) 1.25 (0.049) 20-28 2.0—2.9 14-21 31-46 3.2-4.1 23—34 36-54 3.7-5.5 27-40

12 (0.472) 1.5 (0.059) 34—50 3.5-5.1 25-37 55-80 5,6-8.2 41-59 63-93 6.4-9.5 46-69

14 (0.551) 1.5 (0.059)

— — —

75-103 7.7-10.5 56-76 102—137 10-14 75-101

16 (0.630) 1.5 (0.059)

— — —

116-157 12-16 85-116 156-211 16-22 115-156

18 (0.709) 1.5 (0.059)

— — —

167-225 17-23 123-166 221-299 23-31 163—221

20 (0.787) 1.5 (0.059)

— — —

231-314 24-32 171-231 308—417 31-43 227-307

22 (0.866) 1.5 (0.059)

— — —

314—423 32-43 231-312 417—564 43-58 307-416

24 (0.945) 1.5 (0.059)

— — —

475—546 41—56 298—403 536-726 55-74 396-536

30—40