MAZDA MODEL TRIBUTE 2011 Owners Manual (in English)

Manufacturer: MAZDA, Model Year: 2011, Model line: MODEL TRIBUTE, Model: MAZDA MODEL TRIBUTE 2011Pages: 320, PDF Size: 2.08 MB

Page 231 of 320

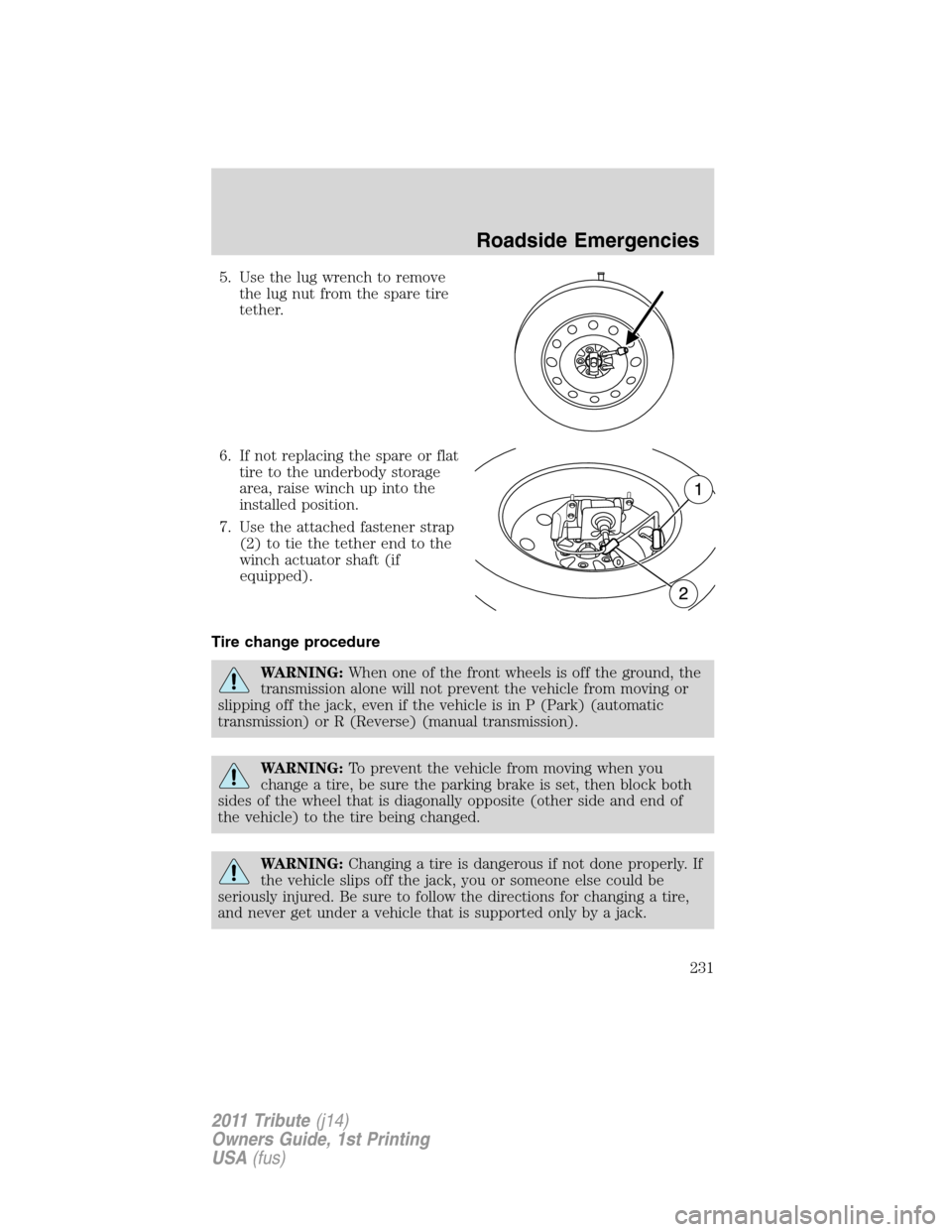

5. Use the lug wrench to remove

the lug nut from the spare tire

tether.

6. If not replacing the spare or flat

tire to the underbody storage

area, raise winch up into the

installed position.

7. Use the attached fastener strap

(2) to tie the tether end to the

winch actuator shaft (if

equipped).

Tire change procedure

WARNING:When one of the front wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the vehicle is in P (Park) (automatic

transmission) or R (Reverse) (manual transmission).

WARNING:To prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block both

sides of the wheel that is diagonally opposite (other side and end of

the vehicle) to the tire being changed.

WARNING:Changing a tire is dangerous if not done properly. If

the vehicle slips off the jack, you or someone else could be

seriously injured. Be sure to follow the directions for changing a tire,

and never get under a vehicle that is supported only by a jack.

Roadside Emergencies

231

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 232 of 320

WARNING:Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack or changing the

wheel.

Note:Passengers should not remain in the vehicle when the vehicle is

being jacked.

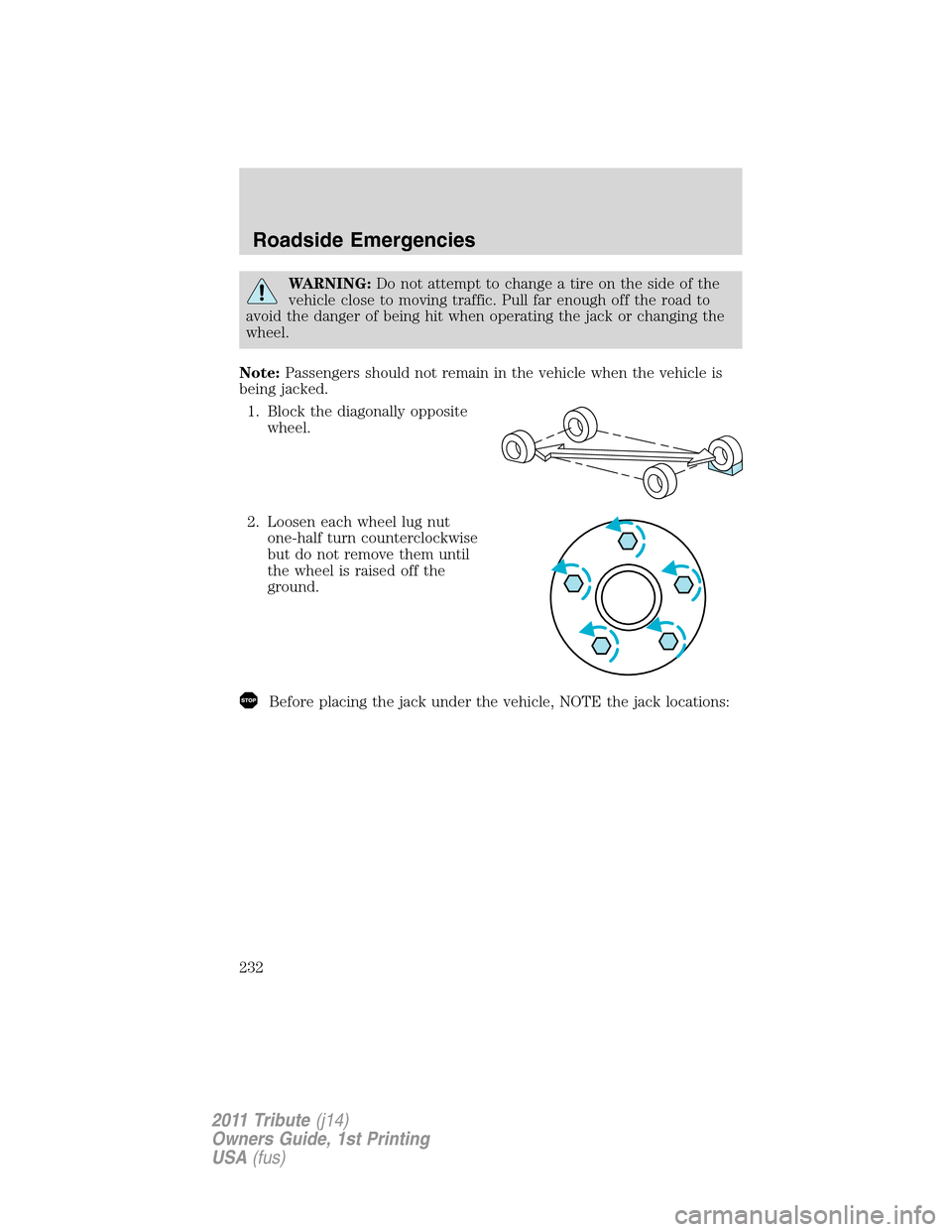

1. Block the diagonally opposite

wheel.

2. Loosen each wheel lug nut

one-half turn counterclockwise

but do not remove them until

the wheel is raised off the

ground.

Before placing the jack under the vehicle, NOTE the jack locations:

Roadside Emergencies

232

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 233 of 320

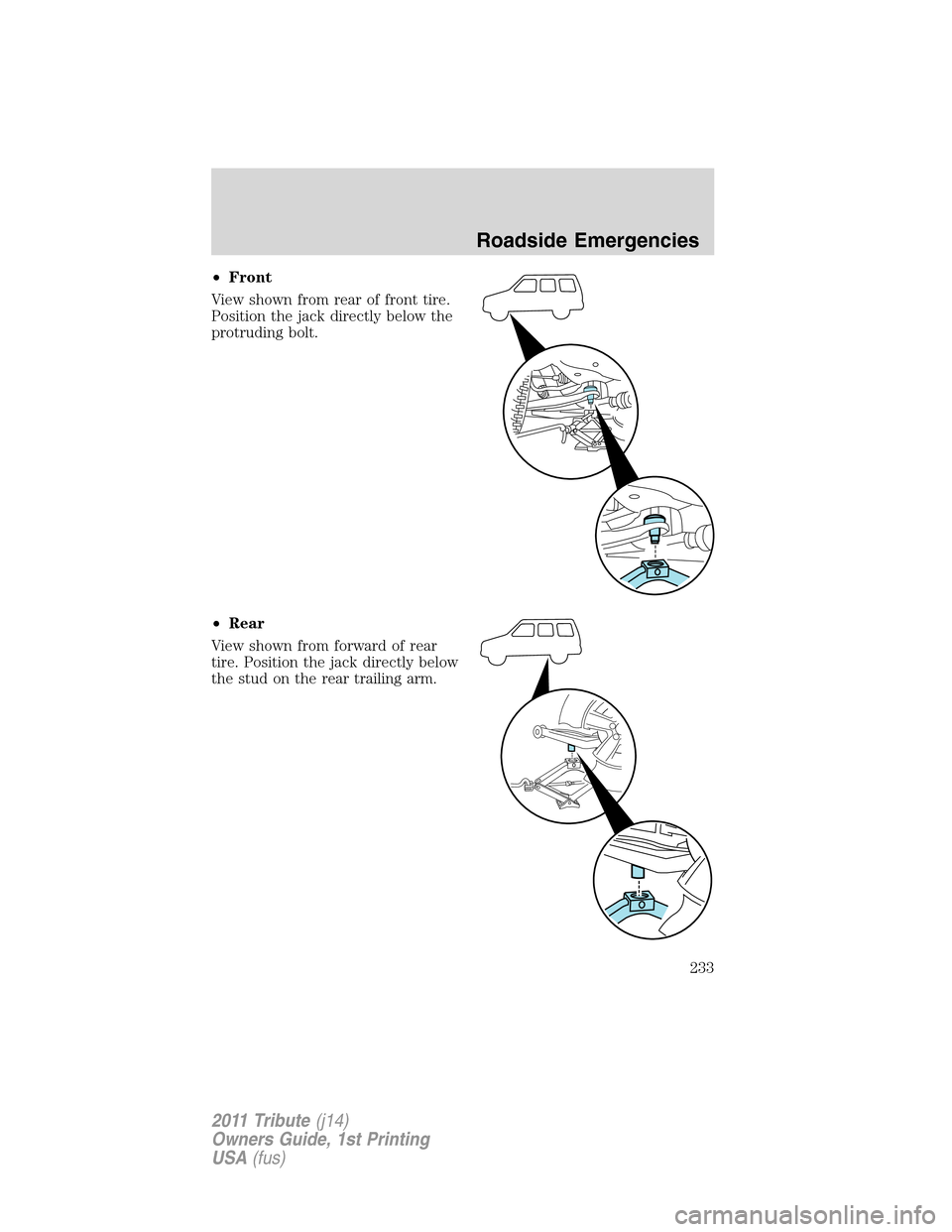

•Front

View shown from rear of front tire.

Position the jack directly below the

protruding bolt.

•Rear

View shown from forward of rear

tire. Position the jack directly below

the stud on the rear trailing arm.

Roadside Emergencies

233

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 234 of 320

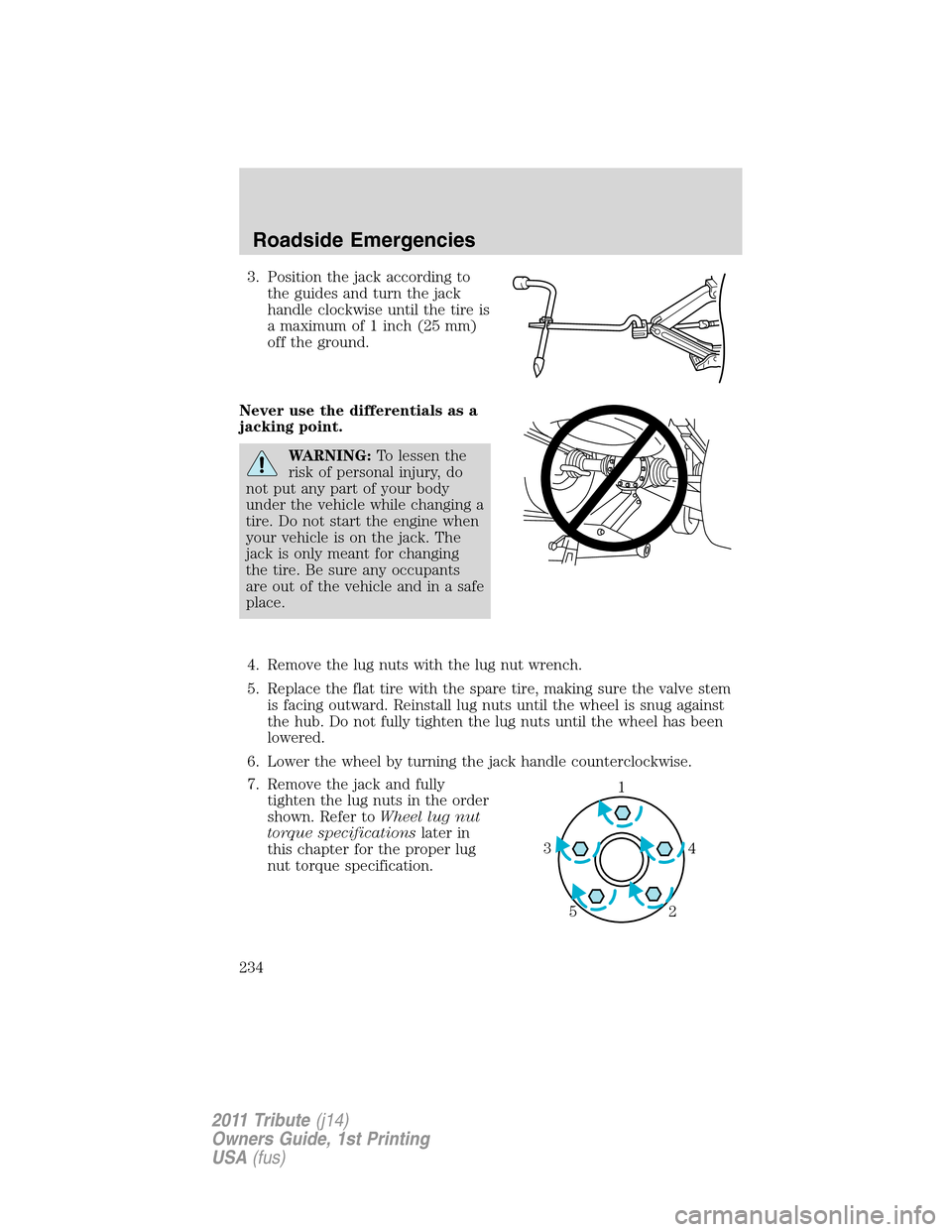

3. Position the jack according to

the guides and turn the jack

handle clockwise until the tire is

a maximum of 1 inch (25 mm)

off the ground.

Never use the differentials as a

jacking point.

WARNING:To lessen the

risk of personal injury, do

not put any part of your body

under the vehicle while changing a

tire. Do not start the engine when

your vehicle is on the jack. The

jack is only meant for changing

the tire. Be sure any occupants

are out of the vehicle and in a safe

place.

4. Remove the lug nuts with the lug nut wrench.

5. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward. Reinstall lug nuts until the wheel is snug against

the hub. Do not fully tighten the lug nuts until the wheel has been

lowered.

6. Lower the wheel by turning the jack handle counterclockwise.

7. Remove the jack and fully

tighten the lug nuts in the order

shown. Refer toWheel lug nut

torque specificationslater in

this chapter for the proper lug

nut torque specification.

1

4 3

2 5

Roadside Emergencies

234

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 235 of 320

Stowing the jack and tools

•Make sure the jack is fully

lowered.

•Reclip the tools onto the jack

making sure that the tools are

fully contained by the clips as

shown.

•Reinstall the jack in the pocket

with the left side first, then snap

the right side down.

•Ensure that the hold-strap

contains the jack and tools before snapping the buckle.

•Ensure that the jack and tools are oriented as illustrated.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

If you are stowing a tire that requires reattaching it to the

vehicle with a tether, perform these steps first, then proceed with

the steps following.

1. Place tire on end with valve

stem facing rearward, away

from vehicle.

2. Place tether into bolt holes in

wheel and attach lug nut using

lug wrench.

3. Lay the tire on the ground with the valve stem facing down. If your

vehicle is equipped with aluminum wheels, remove the wheel center

cap.

4. Slide the wheel partially under the vehicle and install the retainer

through the center of the wheel.

5. Turn the jack handle clockwise until the tire is raised to its original

position underneath the vehicle. The effort to turn the jack handle

increases significantly as the tire contacts the frame. The spare tire

Roadside Emergencies

235

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 236 of 320

carrier will ratchet when the tire is in the fully stowed position. The

spare tire carrier has a built-in ratchet feature that will not allow you

to overtighten. If the spare tire carrier ratchets with very little effort,

take the vehicle to your authorized Mazda dealer for assistance at

your earliest convenience. If your vehicle is equipped with a trailer

hitch, guide the tire with one hand; keep the rear of the tire tilted

down until the tire clears the bumper.

6. Check that the tire lies flat against the frame assembly. Push against

the tire to make sure it is tightly seated under the vehicle. Loosen

and retighten, if necessary. (Make sure that the tire does not contact

the bumper.)

WARNING:Failure to stow the spare tire may result in the

failure of the winch cable and the loss of the spare tire. A loose

tire on the highway is a very dangerous object to other people on the

road. Check to be sure the tire is firmly mounted; go to an authorized

dealer to have it re-mounted if you have any doubt about spare tire

security.

7. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months), or at any time that the spare tire is

disturbed through service of other components.

WHEEL LUG NUT TORQUE SPECIFICATIONS

Retighten the lug nuts to the specified torque at 500 miles (800 km)

after any wheel disturbance (tire rotation, changing a flat tire, wheel

removal, etc.).

Bolt size Wheel lug nut torque*

ft-lb N•m

M12 x 1.5 100 135

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Mazda recommended replacement fasteners.

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Ensure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

Roadside Emergencies

236

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 237 of 320

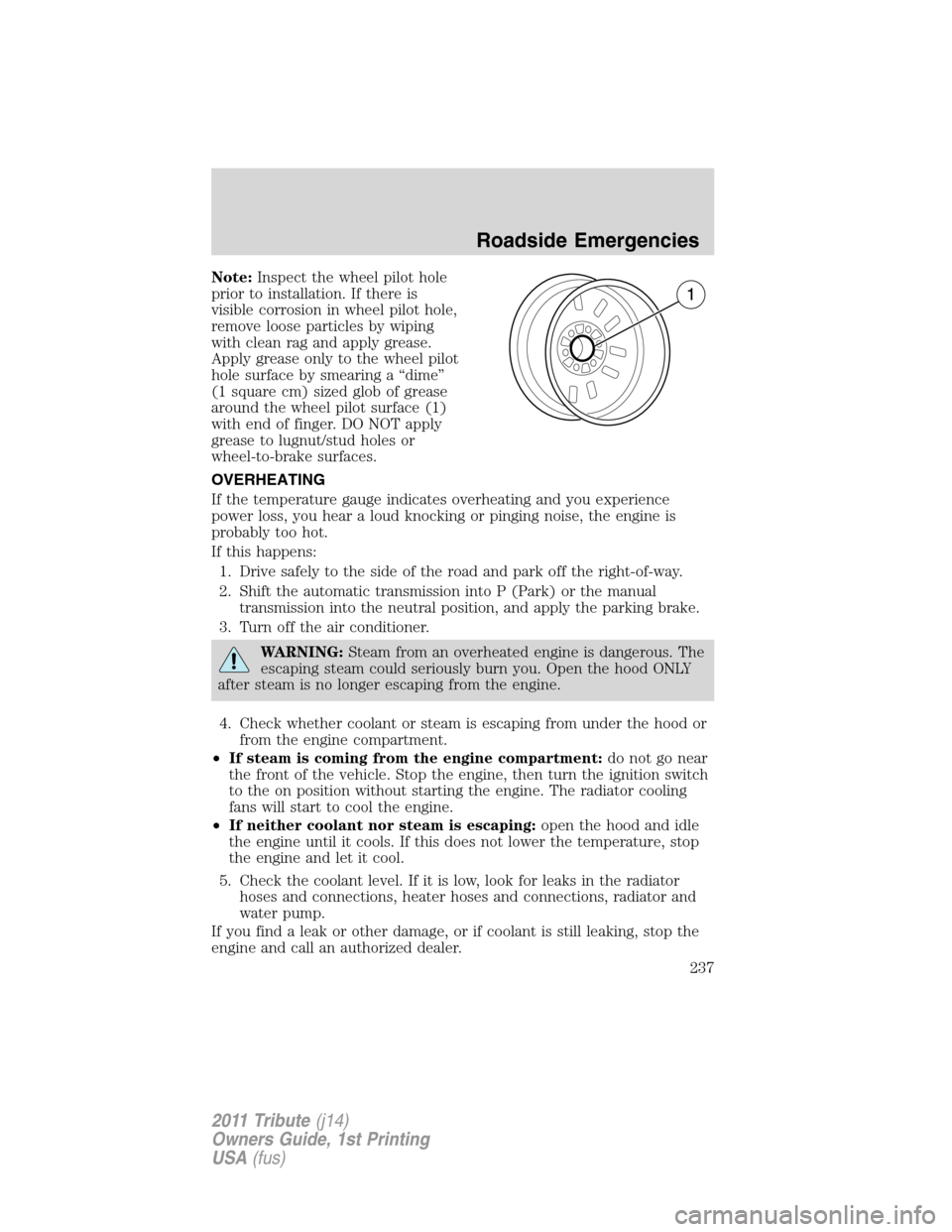

Note:Inspect the wheel pilot hole

prior to installation. If there is

visible corrosion in wheel pilot hole,

remove loose particles by wiping

with clean rag and apply grease.

Apply grease only to the wheel pilot

hole surface by smearing a “dime”

(1 square cm) sized glob of grease

around the wheel pilot surface (1)

with end of finger. DO NOT apply

grease to lugnut/stud holes or

wheel-to-brake surfaces.

OVERHEATING

If the temperature gauge indicates overheating and you experience

power loss, you hear a loud knocking or pinging noise, the engine is

probably too hot.

If this happens:

1. Drive safely to the side of the road and park off the right-of-way.

2. Shift the automatic transmission into P (Park) or the manual

transmission into the neutral position, and apply the parking brake.

3. Turn off the air conditioner.

WARNING:Steam from an overheated engine is dangerous. The

escaping steam could seriously burn you. Open the hood ONLY

after steam is no longer escaping from the engine.

4. Check whether coolant or steam is escaping from under the hood or

from the engine compartment.

•If steam is coming from the engine compartment:do not go near

the front of the vehicle. Stop the engine, then turn the ignition switch

to the on position without starting the engine. The radiator cooling

fans will start to cool the engine.

•If neither coolant nor steam is escaping:open the hood and idle

the engine until it cools. If this does not lower the temperature, stop

the engine and let it cool.

5. Check the coolant level. If it is low, look for leaks in the radiator

hoses and connections, heater hoses and connections, radiator and

water pump.

If you find a leak or other damage, or if coolant is still leaking, stop the

engine and call an authorized dealer.

Roadside Emergencies

237

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 238 of 320

WARNING:When the engine and radiator are hot, scalding

coolant and steam may shoot out under pressure and cause

serious injury. Do not remove the cooling system cap when the engine

and radiator are hot.

SeeAdding engine coolantin theMaintenance and Specifications

section. If you find no problems, the engine is cool and no leaks are

obvious, carefully add coolant as required.

Note:If the engine continues to overheat or frequently overheats, have

the cooling system inspected. The engine could be seriously damaged

unless repairs are made.

RUNNING OUT OF FUEL

If you have run out of fuel and need to refill the vehicle with a portable

fuel container, seeRunning out of fuelin theMaintenance and

Specificationschapter for proper fuel filling method using a portable

fuel container and the included fuel filler funnel.Do notinsert the

nozzle of portable fuel containers or any type of aftermarket funnels into

the Easy Fuel™ “no cap” fuel system as it can be damaged. You must

use the included funnel in such circumstances.

WARNING:Do not insert the nozzle of portable fuel containers

or aftermarket funnels into the Easy Fuel™ system. This could

damage the fuel system and its seal, and may cause fuel to run onto

the ground instead of filling the tank, all of which could result in

serious personal injury.

JUMP STARTING

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

Roadside Emergencies

238

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 239 of 320

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other

moving parts.

4. Check all battery terminals and remove any excessive corrosion

before you attach the battery cables. Ensure that vent caps are tight

and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

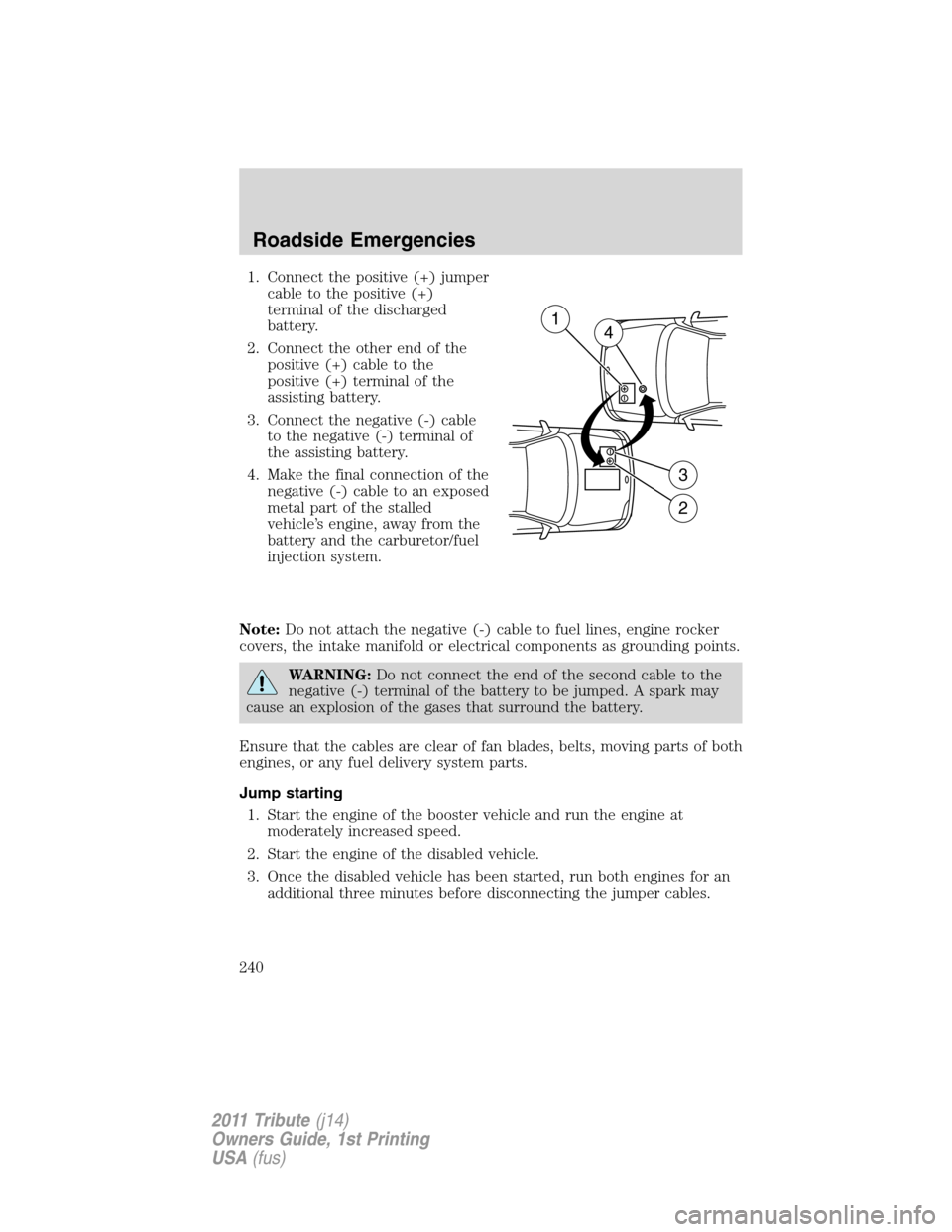

Note:In the illustration, the vehicle on the bottom is used to designate

the assisting (boosting) battery.

Roadside Emergencies

239

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)

Page 240 of 320

1. Connect the positive (+) jumper

cable to the positive (+)

terminal of the discharged

battery.

2. Connect the other end of the

positive (+) cable to the

positive (+) terminal of the

assisting battery.

3. Connect the negative (-) cable

to the negative (-) terminal of

the assisting battery.

4. Make the final connection of the

negative (-) cable to an exposed

metal part of the stalled

vehicle’s engine, away from the

battery and the carburetor/fuel

injection system.

Note:Do not attach the negative (-) cable to fuel lines, engine rocker

covers, the intake manifold or electrical components as grounding points.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

Ensure that the cables are clear of fan blades, belts, moving parts of both

engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–

+–

2

3

14

Roadside Emergencies

240

2011 Tribute(j14)

Owners Guide, 1st Printing

USA(fus)