heater MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 11 of 1708

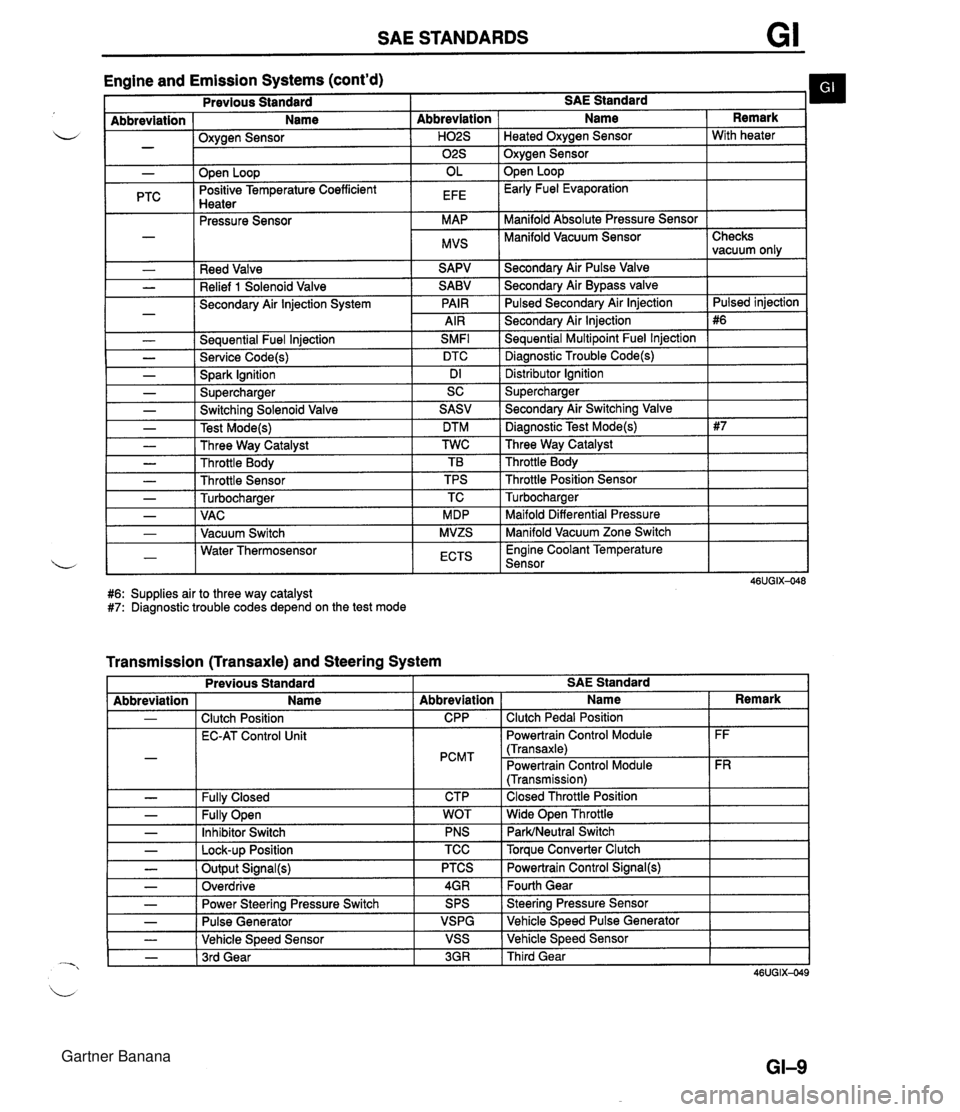

SAE STANDARDS Engine and Emission Systems (cont'd) I Previous Standard I SAE Standard b I - Abbreviation ( Name I Oxvaen Sensor - .w- - I I ." I 02s I Oxygen Sensor I - PTC Reed Valve Relief 1 Solenoid Valve Secondary Air lnjection System - Seauential Fuel lniection SMFl L - Service Code(s) DTC - Spark Ignition Dl - Supercharger SC Abbreviation I Name Open Loop Positive Temperature Coefficient Hnatar Secondarv Air Pulse Valve Remark . .--.-. Pressure Sensor Secondary Air Bypass valve Pulsed Secondarv Air lniection H02S I Heated Oxvaen Sensor I With heater OL EFE Secondary Air lnjection Sequential Multipoint Fuel lnjection Diagnostic Trouble Code(s) Open Loop Early Fuel Evaporation MAP MVS Distributor lgnition Supercharger Manifold Absolute Pressure Sensor Manifold Vacuum Sensor I - - - - - - Checks vacuum only Pulsed iniection - Switching Solenoid Valve Test Mode(s) Three Way Catalyst Throttle Body Throttle Sensor Turbocharaer .. Maifold Differential Pressure Manifold Vacuum Zone Switch , - I - 1 VAC I MDP 1-1 Water Thermosensor L - I Vacuum Switch I ECTS I Engine Coolant Temperature Sensor I SASV DTM TWC TB TPS TC MVZS #6: Supplies air to three way catalyst #7: Diagnostic trouble codes depend on the test mode - Secondary Air Switching Valve Diagnostic Test Mode(s) Three Way Catalyst Throttle Body Throttle Position Sensor Turbocharaer Transmission (Transaxle) and Steering System L - - Previous Standard I I I I Abbreviation - - - SAE Standard Fully Open Inhibitor Switch - I Lock-up Position - - Name Clutch Position EC-AT Control Unit Fullv Closed Abbreviation CPP PCMT CTP TCC I Torque Converter Clutch - - - WOT PNS Output Signal(s) Overdrive I Name Clutch Pedal Position Powertrain Control Module (Transaxle) Powertrain Control Module (Transmission) Closed Throttle Position Wide Open Throttle ParWNeutral Switch Power Steering Pressure Switch Pulse Generator Vehicle Speed Sensor - 1 3rd Gear Remark FF FR PTCS 4GR 3GR I Third Gear Powertrain Control Signal(@ Fourth Gear SPS VSPG VSS Steering Pressure Sensor Vehicle Speed Pulse Generator Vehicle Speed Sensor Gartner Banana

Page 12 of 1708

GI SAE STANDARDS Body Electrical System and Heater and Air Conditioner Systems Previous Standard SAE Standard - - Abbreviation I Name I Abbreviation 1 Name Remark 1 VB - - - AIC Switch Air Conditioner 46UGIX-050 #8: System name. Other related names are unchanged. Battery Voltage Coolant Level Sensor Ground Self-Diagnosis System ACS A/C B+ COLS GND OBD Air Conditioning Sensor Air Conditioner d Battery Positive Voltage Coolant Level Sensor Ground On-Board Diagnosis System #8 Gartner Banana

Page 23 of 1708

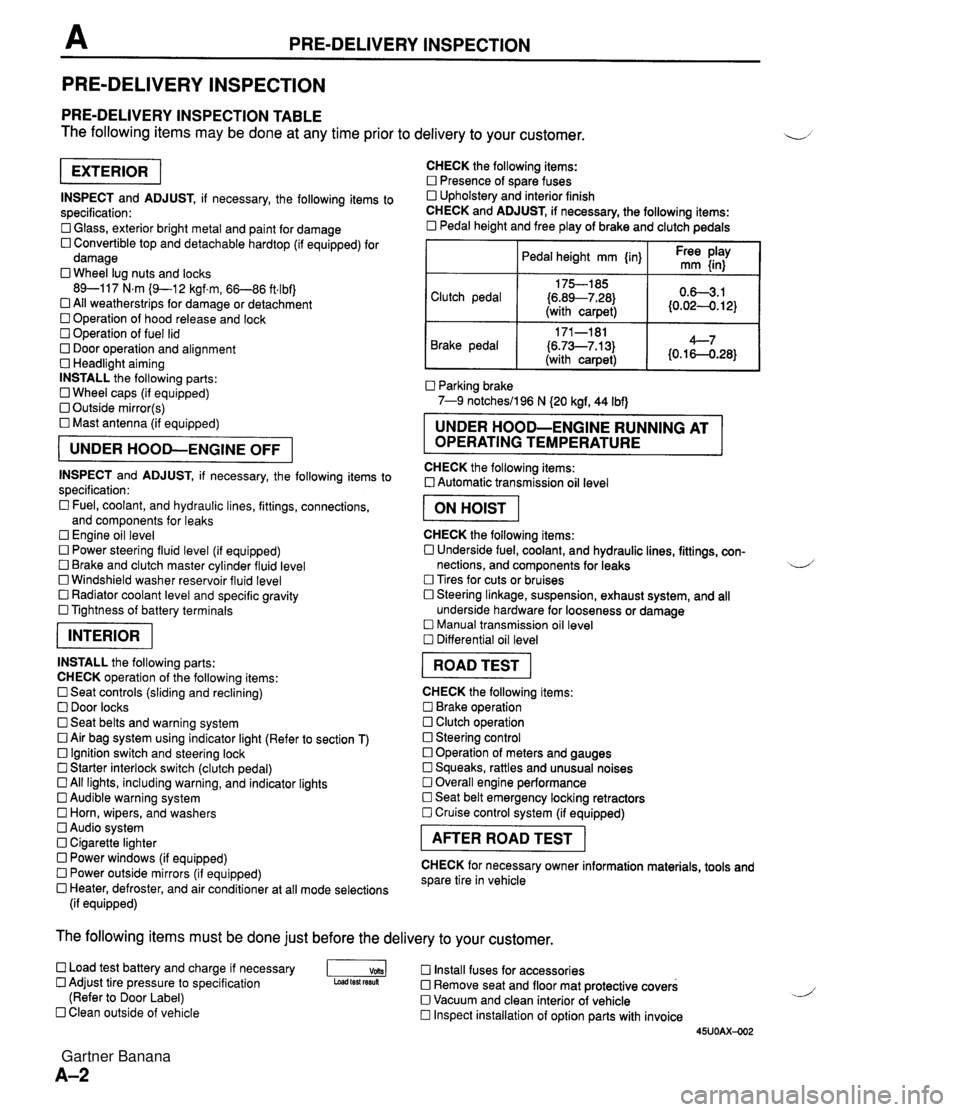

PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION TABLE The following items may be done at any time prior to delivery to your customer. INSPECT and ADJUST, if necessary, the following items to specification: 0 Glass, exterior bright metal and paint for damage 0 Convertible top and detachable hardtop (if equipped) for damage 0 Wheel lug nuts and locks 89-117 N.m (9-1 2 kgf.m, 66-86 ft4bf) 0 All weatherstrips for damage or detachment Operation of hood release and lock Operation of fuel lid 0 Door operation and alignment Headlight aiming INSTALL the following parts: Wheel caps (if equipped) 0 Outside mirror(s) 0 Mast antenna (if equipped) UNDER HOOD-ENGINE OFF INSPECT and ADJUST, if necessary, the following items to specification : Fuel, coolant, and hydraulic lines, fittings, connections, and components for leaks Engine oil level 0 Power steering fluid level (if equipped) Brake and clutch master cylinder fluid level 0 Windshield washer reservoir fluid level 0 Radiator coolant level and specific gravity 0 Tightness of battery terminals pKiq INSTALL the following parts: CHECK operation of the following items: 0 Seat controls (sliding and reclining) 0 Door locks 0 Seat belts and warning system 0 Air bag system using indicator light (Refer to section T) Ignition switch and steering lock 0 Starter interlock switch (clutch pedal) All lights, including warning, and indicator lights 0 Audible warning system 0 Horn, wipers, and washers Audio system 0 Cigarette lighter Power windows (if equipped) 0 Power outside mirrors (if equipped) 0 Heater, defroster, and air conditioner at all mode selections (if equipped) CHECK the following items: Presence of spare fuses 0 Upholstery and interior finish CHECK and ADJUST, if necessary, the following items: 0 Pedal height and free play of brake and clutch pedals I Pedal height mm {in} I Ft: $iy I Clutch pedal {6.89--7.28) (with carpet) Parking brake 7-9 notchesil96 N (20 kgf, 44 Ibf) 0.63.1 (0.024. 12) Brake pedal RUNNING AT OPERATING TEMPERATURE CHECK the following items: 0 Automatic transmission oil level 171-181 (6.73--7.13) (with carpet) I ON HOIST I 4--7 {0.16-0.28} CHECK the following items: 0 Underside fuel, coolant, and hydraulic lines, fittings, con- nections, and components for leaks 4 Tires for cuts or bruises 0 Steering linkage, suspension, exhaust system, and all underside hardware for looseness or damage Manual transmission oil level Differential oil level I ROAD TEST I CHECK the following items: Brake operation Clutch operation 0 Steering control 0 Operation of meters and gauges Squeaks, rattles and unusual noises 0 Overall engine performance Seat belt emergency locking retractors 0 Cruise control system (if equipped) I AFTER ROAD TEST I CHECK for necessary owner information materials, tools and spare tire in vehicle The following items must be done just before the delivery to your customer. 0 Load test battery and charge if necessary -1 Install fuses for accessories Adjust tire pressure to specification Load test fesuk 0 Remove seat and floor mat protective covers (Refer to Door Label) 0 Vacuum and clean interior of vehicle Clean outside of vehicle Inspect installation of option parts with invoice 45UOAX-002 Gartner Banana

Page 67 of 1708

B REMOVAL is connect the hoses shown in the figure. 1. Brake vacuum hose 4. Vacuum hose (Cruise control) 2. Fuel hose 5. Water inlet hose Removal Note . . . . . . . . . . . . . . . . . . below 6. Heater hose 3. Vacuum hose (Purge control) Removal Note Fuel hose Warning Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep sparks and flames away from fuel. Disconnect the fuel hoses. Gartner Banana

Page 305 of 1708

CONTROL SYSTEM SENSOR CONNECTOR EATED OXYGEN Specification Fully closed: 0.1-1.1 V Fully open: 3.14.5V (Verify that the voltage increase is directly d propotioned to the throttle valve opening angle.) 8. Tighten the attaching screws. Tightening torque: 1.6-2.3 N.m (16-24 kgfmm, 14-20 in-lbf} 9. If not adjusted, replace the throttle position sensor. 45UOFX-495 Replacement 1. Turn the ignition switch OFF. 2. Remove the throttle position sensor screws. 3. Remove the throttle position sensor . 4. Replace a new throttle position sensor and adjust it. (Refer to page F-155.) 5. Tighten the throttle position sensor screws. Tightening torque: 1.6-2.3 N.m (16-24 kgf-cm, 14-20 in-lbf} HEATED OXYGEN SENSOR Inspection On-vehicle 1. Warm-up the engine to normal operating temperature and run it at idle. 2. Disconnect the heated oxygen sensor connector. -.-' 3. Measure the voltage at terminal A. 4. If not as specified, check the intake air system, the fuel system and run the on-board diagnosis test. 5. If these system are OK, replace the heated oxygen sen- sor. Specification Heater 1. Disconnect the heated oxygen sensor connector. 2. Measure resistance between terminals C and D. Resistance: Approx. 13R (20°C (68°F)) Engine condition Terminal A 3. Replace the heater if not as specified. Increasing engine speed (V) 0.&1 .O Idle Below 1.0 Replacement 1. Disconnect the heated oxygen sensor connector. 2. Remove the heated oxygen sensor. 3. Install in the reverse order of removal. Decreasing engine speed (V) 0-0.4 Tightening torque: 3049 N-m (3.0-5.0 kgf-m, 22-36 ftlbf) Gartner Banana

Page 814 of 1708

DASHBOARD AND CONSOLE DASHBOARD AND CONSOLE COMPONENTS Removal l Installation 1. Disconnect the negative battery cable. Warning Handling the air bag module improperly can accidently deploy the air bag, which may seri- ously injure you. Read SERVICE WARNINGS, section T, before handling the air bag module. 2. Remove in the order shown in the figure, referring to Removal Note. To remove the dashboard, remove the control wires of the heater unit and blower unit. 3. Install in the reverse order of removal. 1. Ashtray 2. Change lever knob 3. Rear console assembly a. Back plate b. Shift lever boot 7. Speedometer cable 8. Instrument cluster 9. Center louver Removal Note ............. page S-57 10. Center an el assemblv c. Power window switch Removal Note ............. page S-58 d. Cover (Without power window) 1 1. Glove box assembly e. Console lock assembly 12. Passenger-side airbag module (if equipped) 4. Center lower panel assembly Removal 1 Installation ......... section T Removal Note ............. page S-57 13. Hood release knob -1 5. Steering shaft 14. Center hole cover 6. Meter hood assembly 15. Side cover Removal Note ............. page $57 16. Dashboard Gartner Banana

Page 816 of 1708

DASHBOARD AND CONSOLE - / AIRFLOW MODE WIRE I _ -We -_ -, _ - 11 Center panel assembly The clips are where shown. Adjustment Note Airflow mode wire 1. Set the airflow mode control lever to VENT position. 2. Connect and clamp the wire with the shutter lever on the heater unit at its closest point. 3. Move the airflow mode control lever to make sure the wire is securely attached and that it moves the full stroke from DEF to VENT. REC-FRESH wire 1. Set the selector lever to FRESH position. 2. Connect and clamp the wire with the shutter lever on the blower unit at its closest point. 3. Move the REC-FRESH lever to make sure the wire is securely attached and that it moves the full stroke from - REC to FRESH. TEMF - - I 'ERATURE BLEND WIRE 45UOSX-080 Temperature blend wire 1. Set the temperature blend lever to MAX-HOT position. 2. Connect and clamp the wire with the shutter lever on the heater unit all the way to the right. 3. Move the temperature blend lever to make sure the wire is securely attached and that it moves the full stroke from HOT to COLD. Gartner Banana

Page 820 of 1708

FLOOR COVERING FLOOR COVERING COMPONENTS Removal / Installation 1. To remove the cabin carpet, first remove the following: a Seats (Refer to page S-65.) b Dashboard (Refer to page S-56.) c Heater unit (Refer to Section U) d Front side trim, scuff plates, quarter trim, and rear package trim (Refer to page S-59.) e Front seat belts and buckles (Refer to page S-63.) 2. Remove the remaining parts in the order shown in the figure. 3. Install in the reverse order of removal. 1. Rear end mat 2. Foot rest 3. Bracket 4. Cabin carpet Gartner Banana

Page 854 of 1708

OUTLINE T NO type relay I STOP Not in operation (No power supply) ax FLOW I STOP NC type relay NO switch In operation (Power supply) ELECTRICAL SYMBOLS Switches and Relays There is an NC (normally closed) and NO (normally open) indication for switches and relays that shows when no change of operation conditions has occurred. Relay Switch I w FLOW - Other Electrical Symbols - ax STOP FLOW NC switch FLOW STOP I I I I - FUSIBLE LINK e $1 VARIABLE RESISTOR + LIGHT TRANSISTOR HOLDER BOX FUSE 4 RESISTOR 1 T CONDENSER BATTERY 4) MOTOR 8 THERMISTOR SPEAKER I CIGARETTE LIGHTER I HEATER - - BODY GROUND t COIL, SOLENOID + DIODE I 25UOTX-010 Gartner Banana

Page 857 of 1708

T FUSE DESCRIPTION Main Fuse Block The main fuse block is located on the right side of the engine compartment and contains nine fuses and two relays. -1 Fuse Box Fuse block No.1 is located above the dead pedal of the driver side. The fuse box cover shows the speci- fied fuse locations. A circuit breaker is included in the fuse box to protect the heater blower motor circuit. Fuse block No.2 is located to the side of the battery in the trunk compartment. 45UOTX-016 REPLACEMENT Caution Determine and correct the cause of a burnt fuse before replacing it. If the fuse is replaced before doing this, it may burn again. Plate type 1. Disconnect the negative battery cable. 2. Replace the failed fuse with the fuse puller. 3. Reconnect the negative battery cable. Cartridge-type 80A fuse (Black) 1. Disconnect the negative battery cable. 2. Remove the fuse block mounting nuts, and remove the service cover. 3. Remove the fuse installation bolts, and pull out the fuse. 4. Install the new fuse and the fuse installation bolts. 5. Install the main fuse block. 6. Reconnect the negative battery cable. Gartner Banana