air condition MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 1029 of 1708

T SRS AIR BAG SYSTEM I Flowchart No.16 I Symptom I Service Code 51 I Possible cause Blown internal fuse in diagnostic module (fault conditions no longer present) 0 Diagnostic module not replaced after service code 13 set and conditions corrected. Intermittent short in air bag deployment circuit. Remedy If repairs were made for a service code 13, replace the diagnostic module. If an intermittent short is sus- pected, inspect the wiring harnesses and connectors for damage. If they are not damaged, wiggle the harnesses and connectors to induce the intermittent short; service code 13 will be set when the fault is induced. Then follow the troubleshooting procedure for service code 13. 36EOTX-143 Gartner Banana

Page 1033 of 1708

Possible cause u 0 Burnt air bag warning light bulb Defective diagnostic module Defective wiring harness Step 1 Carry out "Before Servicing" procedure under GEN- ERAL PROCEDURES, page T-1 60. Air bag system warning light does not illuminate for 6 seconds Flowchart No.1 Step 2 1. Disconnect the diagnostic module connector. 2. Turn the ignition switch to ON. 3. Check the air bag warning light. I Llght condition I Action 1 Symptom 1 Illuminate I Replace diagnostic module (Refer to ~aae T-208) 1 -- I Not illuminate I GO to step 3 J Step 3 1. Remove the instrument cluster. 2. Check the air bag system warning light bulb. I Repair wiring harness (Diagnostic module--Instrument cluster) I Bulb Burnt Action Replace bulb .- Gartner Banana

Page 1034 of 1708

SRS AIR BAG SYSTEM T u Possible cause Poor connection of diagnostic module connector Defective diagnostic module Defective wiring harness Step 1 Carry out "Before Servicing" procedure under GEN- ERAL PROCEDURES, page T-1 60. Air bag warning light remains ON Flowchart No.2 Step 2 1. Verify that the diagnostic module connector is securely connected to the diagnostic module. 2. Verify that the shorting bar is in the fully retracted posi- tion. 3. If the connector and shorting bar are OK, go to step 3. Symptom Step 3 1. Disconnect the diagnostic module connector. 2. Remove the shorting bar from the diagnostic module connector. 3. Check the air bag warning light. Light condition I Action I Illuminate Repair wiring harness (Diagnostic modul~lnstrument duster) I Not illuminate 1 Replace diagnostic module (Refer to Dacie T-208) Gartner Banana

Page 1049 of 1708

T SRS AIR BAG SYSTEM Step 9 1. Disconnect the left D-sensor connector. 2. Check for continuity between terminal B of the left D-sen- sor and ground. il I Continuity I Action I Step 10 Check for continuity between terminal 1 C (BRIG) of the diagnostic module connector and ground. I Continuity Action 1 Yes No I Yes I GO to step 11 Replace D-sensor and then replace diagnos- tic module Replace air bag harness and then replace diagnostic module Step 11 1. Disconnect the right D-sensor connector. 2. Check for continuity between terminal B of the right No D-sensor connectoiand ground. Replace diagnostic module (Refer to page T-208) Continuity Action Replace D-sensor and then replace diagnos- tic module Replace air bag harness and then replace I Flowchart No.15 I Symptom 1 Service Code 51 I Possible cause Blown internal fuse in diagnostic module (fault conditions no longer present) Diagnostic module not replaced after service code 13 set and conditions corrected Intermittent short in air bag deployment circuit Remedy If repairs were made for a service code 13, replace the diagnostic module. If an intermittent short is sus- pected, inspect the wiring harnesses and connectors for damage. If they are not damaged, wiggle the harness and connectors to induce the intermittent short; service code 13 will be set when the fault is induced. Then follow the troubleshooting procedure for service code 13. Gartner Banana

Page 1063 of 1708

Before beginning any service procedure. refer to section T of this manual for I air bag system service warnings and audio antitheft system alarm conditions . HEATER AND AIR CONDITIONER SYSTEMS ....................................... INDEX U- 2 ................................... HEATER U- 2 AIR CONDITIONER ......................... U- 3 TROUBLESHOOTING ......................... U- 4 CIRCUIT DIAGRAM ......................... U- 4 TROUBLESHOOTING GUIDE ................ U- 5 ..................................... HEATER U-15 ........................ STRUCTURAL VIEW U-15 HEATER UNIT .............................. U-16 BLOWER UNIT ............................. U-18 HEATER CONTROL UNIT .................... U-20 AIR CONDITIONER ........................... U-23 PREPARATION ............................. U-23 STRUCTURAL Vl EW ........................ U-23 SERVICE WARNINGS ....................... U-24 SERVICE CAUTIONS ........................ U-24 REFRIGERANT SYSTEM SERVICE PROCEDURE .............................. U-25 COOLING UNIT ............................. U-30 CONDENSER AND RECEIVER DRIER ........ U-33 REFRIGERANT LINES ....................... U-35 CONDENSER FAN .......................... U-36 AIC RELAY ................................. U-37 ................... CONDENSER FAN RELAY U-37 REFRIGERANT PRESSURE SWITCH ......... U-37 NC COMPRESSOR ......................... U-38 45U0Ux-001 Gartner Banana

Page 1065 of 1708

INDEX u AIR CONDITIONER 1. Cooling unit 5. Condenser fan relay ................... Removal 1 Installation ......... page U-30 Inspection page U-37 Disassembly I Assembly ...... page U-31 6. A/C compressor 2. Condenser Removal 1 Installation ......... page U-38 ...... Removal I Installation ......... page U-33 Disassembly I Assembly page U-41 3. Receiver drier 7. Magnetic clutch Removal I Installation ......... page U-33 Disassembly 1 Assembly ...... page U-39 4. AIC relay Inspection ................... page U-37 Gartner Banana

Page 1066 of 1708

Ix-ozl MAIN FUSE eLOCK MAIN AD FAN IX-071 L/Y (€1 \ G-01 G -01 FRONT (F) -A/C IAC) G-02 MAGNETIC CLUTCH (F) G-03 BLOHER WIT (F) 16-04 ?$WER&TVRE SNITCt .CONDENSOR FAN .HEATER AND AIR CONDITIONER I I '07 CONENSOR FAN (AC) G-08 REFRIGERANT PflESSURE SWITCH (AC) IG-09 A/C RELAY (ACI 16- 10 COMENSER FAN RELAY (AC) Gartner Banana

Page 1072 of 1708

TROUBLESHOOTING I ltem 1 Symptom Symptom: lnsuff icient cooling No cooling Intermittent cooling Ill Bubbles present in sight glass u Immediately after air conditioner turned off, refrigerant in sight glass stavs clear I. When air conditioner turned off, re- frigerant foams, and then sight glass becomes clear No bubbles present in sight glass Step 1 Checking refrigerant charge 1. Run the engine at a fast idle. 2. Operate the air conditioner at maximum cooling for a few minutes. 3. Observe the sight glass to determine the amount of re- frigerant and the related action as shown below. Amount of refrigerant Action Insufficient refrigerant Too much or proper amount of refrig- erant Too much refrigerant Step 2 Checking refrigerant pressure 1. Connect the manifold gauge set. 2. Operate the engine at 1,500 rpm and set the air condi- tioner to maximum cooling. 3. Measure the refrigerant pressure. 1 Proper amount of refrigerant Normal pressure Low-pressure side: 0.1 5-4.24 MPa (1.5--2.5 kgf/cm2, 22--35 psi) High-pressure side: 1.38-1.56 MPa (1 4.0-1 6.0 kgf/cm2, 200-227 psi) Check refrigerant pressure, go to Step 2 Turn air conditioner off, and watch bubbles (Refer to Items 3 and 4) Check refrigerant pressure, go to Step 2 Refrigerant amount normal 4. If the pressures not as specified, refer to the chart on the next page and check the system. ,d Gartner Banana

Page 1073 of 1708

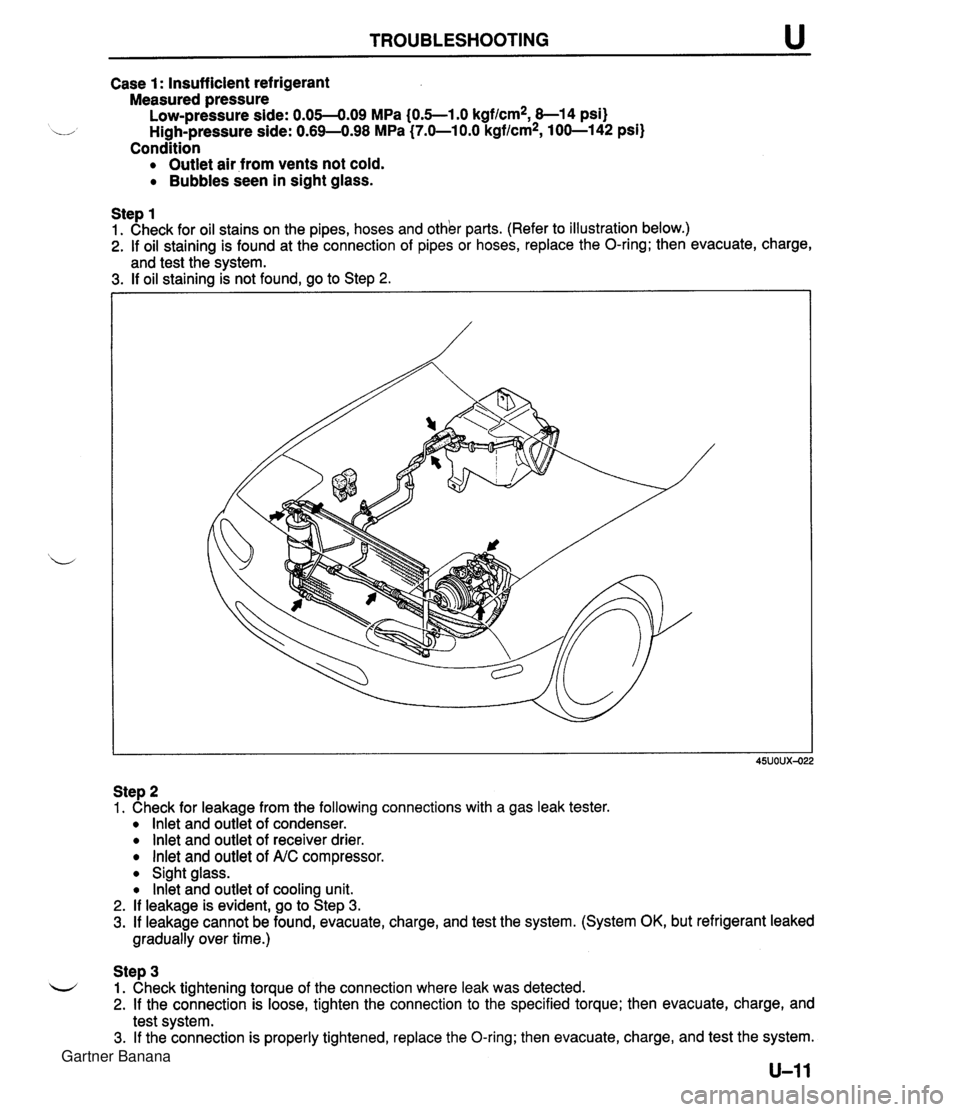

TROUBLESHOOTING Case 1: Insufficient refrigerant Measured pressure Low-pressure side: 0.05-4.09 MPa (0.5--1.0 kgf/cm2, 8-1 4 psi) u High-pressure side: 0.69-498 MPa (7.0-1 0.0 kgflcm2, 100-142 psi) Condition Outlet air from vents not cold. Bubbles seen in sight glass. Step 1 1. Check for oil stains on the pipes, hoses and other parts. (Refer to illustration below.) 2. If oil staining is found at the connection of pipes or hoses, replace the O-ring; then evacuate, charge, and test the svstem. 3. If oil staining k not found, go to Step 2. Step 2 1. Check for leakage from the following connections with a gas leak tester. lnlet and outlet of condenser. lnlet and outlet of receiver drier. lnlet and outlet of A.C compressor. Sight glass. lnkt and outlet of cooling unit. 2. If leakage is evident, go to Step 3. 3. If leakage cannot be found, evacuate, charge, and test the system. (System OK, but refrigerant leaked gradually over time.) Step 3 L-/ 1. Check tightening torque of the connection where leak was detected. 2. If the connection is loose, tighten the connection to the specified torque; then evacuate, charge, and test system. 3. If the connection is properly tightened, replace the O-ring; then evacuate, charge, and test the system. Gartner Banana

Page 1074 of 1708

TROUBLESHOOTING Case 2: Excessive refrigerant or insufficient condenser cooling Measured pressure Low-pressure side: 0.254.34 MPa (2.5--3.5 kgf/cm2, 3-9 psi) High-pressure side: 1.97-2.45 MPa (20.0-25.0 kgflcm*, 285--355 psi) Condition Outlet air from vents not cold. Note If the condenser fan does not operate when the air conditioner is operating, see "Condenser fan does not operate"; page U-9, before proceeding. Step 1 1. Make sure the condenser fan operates when the air con- ditioner is operating. If it does not operate, troubleshoot the condenser fan circuit (page U-9) before proceeding. 2. Check the condenser for bent fins or damage. Repair or replace if necessary. 3. If the condenser is OK, go to Step 2. Step 2 Verify that the refrigerant pressure is normal. Case 3: Air in system Measured pressure Low-pressure side: 0.254.29 MPa (2.5--3.0 kgflcmz, 36-42 psi) High-pressure side: 1.97-2.45 MPa (20.0-25.0 kgf/cm2, 285--355 psi) Condition Insufficient cooling. CAUSE ACTION 7 EVACUATE SYSTEM Step 1 Discharge the refrigerant system. Step 2 Evacuate the system to remove all air from it. (Refer to page U-25.) Step 3 Charge the system with refrigerant. (Refer to page U-25.) Step 4 After charging, measure the refrigerant pressure. (Refer to page U-29.) .- Step 5 If low- and high-pressure sides are still too high, replace the receiver drier. Gartner Banana