wheel MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 4 of 1708

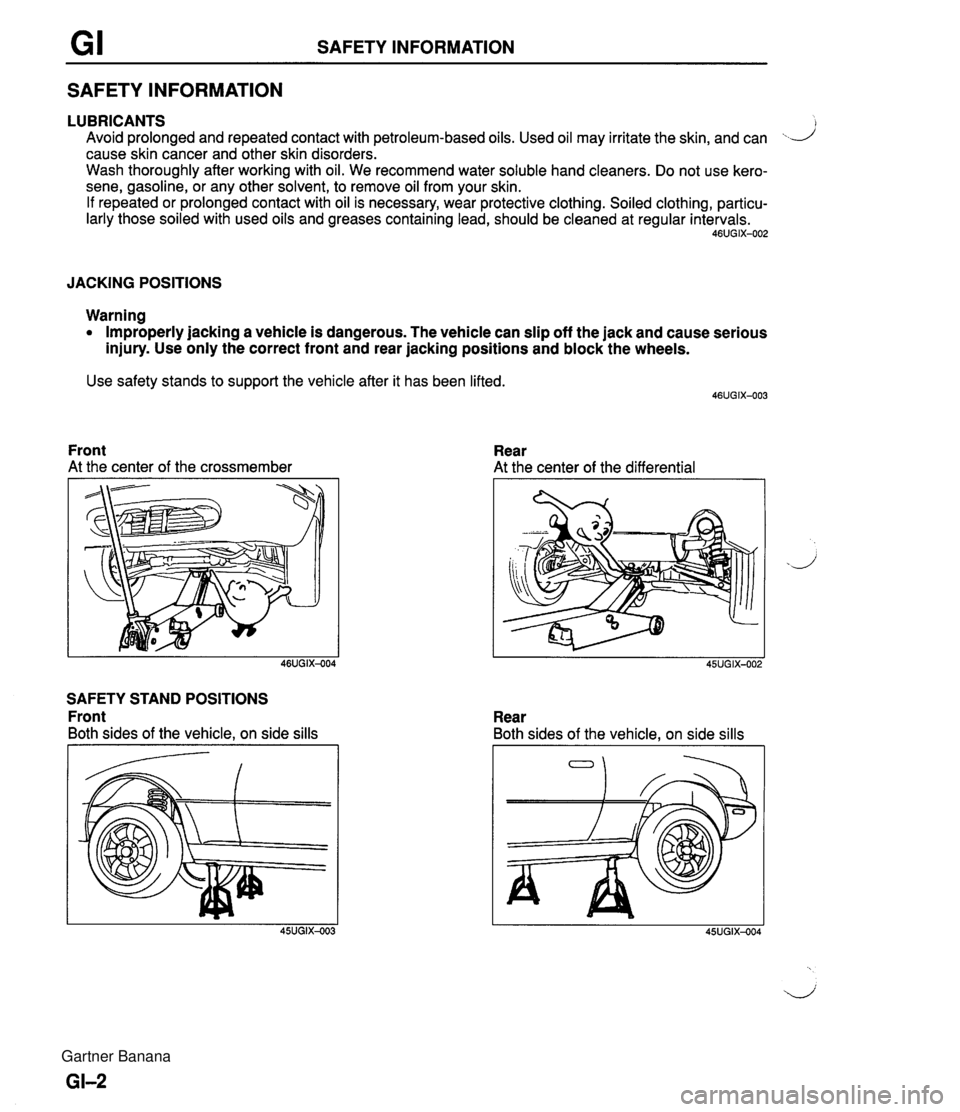

SAFETY INFORMATION SAFETY INFORMATION LUBRICANTS ) Avoid prolonged and repeated contact with petroleum-based oils. Used oil may irritate the skin, and can ...--/ cause skin cancer and other skin disorders. Wash thoroughly after working with oil. We recommend water soluble hand cleaners. Do not use kero- sene, gasoline, or any other solvent, to remove oil from your skin. If repeated or prolonged contact with oil is necessary, wear protective clothing. Soiled clothing, particu- larly those soiled with used oils and greases containing lead, should be cleaned at regular intervals. 46UGIX-002 JACKING POSITIONS Warning Improperly jacking a vehicle is dangerous. The vehicle can slip off the jack and cause serious injury. Use only the correct front and rear jacking positions and block the wheels. Use safety stands to support the vehicle after it has been lifted. Front At the center of the crossmember SAFETY STAND POSITIONS Front Both sides of the vehicle, on side sills Rear At the center of the differential Rear Both sides of the vehicle, on side sills Gartner Banana

Page 9 of 1708

ABBREVIATIONS 4BDC .... 4BS ...... 4CC ...... 4T ........ 4TDC ..... 4TF ...... 4TS ...... 3AC ...... 3BDC .... 3TDC ..... :ID ....... 2U ....... IOHC .... IRL ...... ITM ...... IC-AT .... iGRA .... EGRV .... ELR ...... EPC ...... ESPS ..... ETS ...... EX ....... FMEM .... HFC ...... HLA ...... H U ....... IC ........ IG ........ IN ........ INT ....... LFC ...... LH ....... LSD ...... M ........ MAF RTN . MT ....... PCTS ..... PCV ...... PIP ....... PRC ...... PIS ....... PMI ...... PWR GND RH ....... RPM ...... RTS ...... SIG RTN . . SLS ...... ... SPOUT S R ....... SST ...... ST ....... SW ....... TDC ...... TNS ...... TRS ...... VPWR .... WSS ..... WTS...... After bottom dead center Antilock brake system Accessory Automatic transmission After top dead center Automatic transmission fluid Ambient temperature sensor Bypass air control Before bottom dead center Before top dead center Cylinder identification display Control unit Double overhead camshaft Daytime running light Diagnostic test mode Electronically controlled automatic transmission EGR air solenoid valve EGR vacuum solenoid valve Emergency locking retractor Electronic pressure control Engine speed sensing power steering Evaporator temperature sensor Exhaust Failure mode effects management High fan control Hydraulic lash adjuster Hydraulic unit Integrated circuit Ignition Intake Intermittent Low fan control Left hand Limited slip differential Motor Mass airflow return Manual transmission Passenger compartment temperature sensor Positive crankcase ventilation Profile ignition pickup Pressure regulator control Power steering Power window Power ground Right hand Revolutions per minute Reduce torque signal Signal return Slip lockup signal Spark output Sensor rotor Special service tool Start Switch Top dead center Tail number side (taillights, license plate lights and side marker lights) Torque reduced signal Vehicle power Wheel speed sensor Water temperature sensor Gartner Banana

Page 21 of 1708

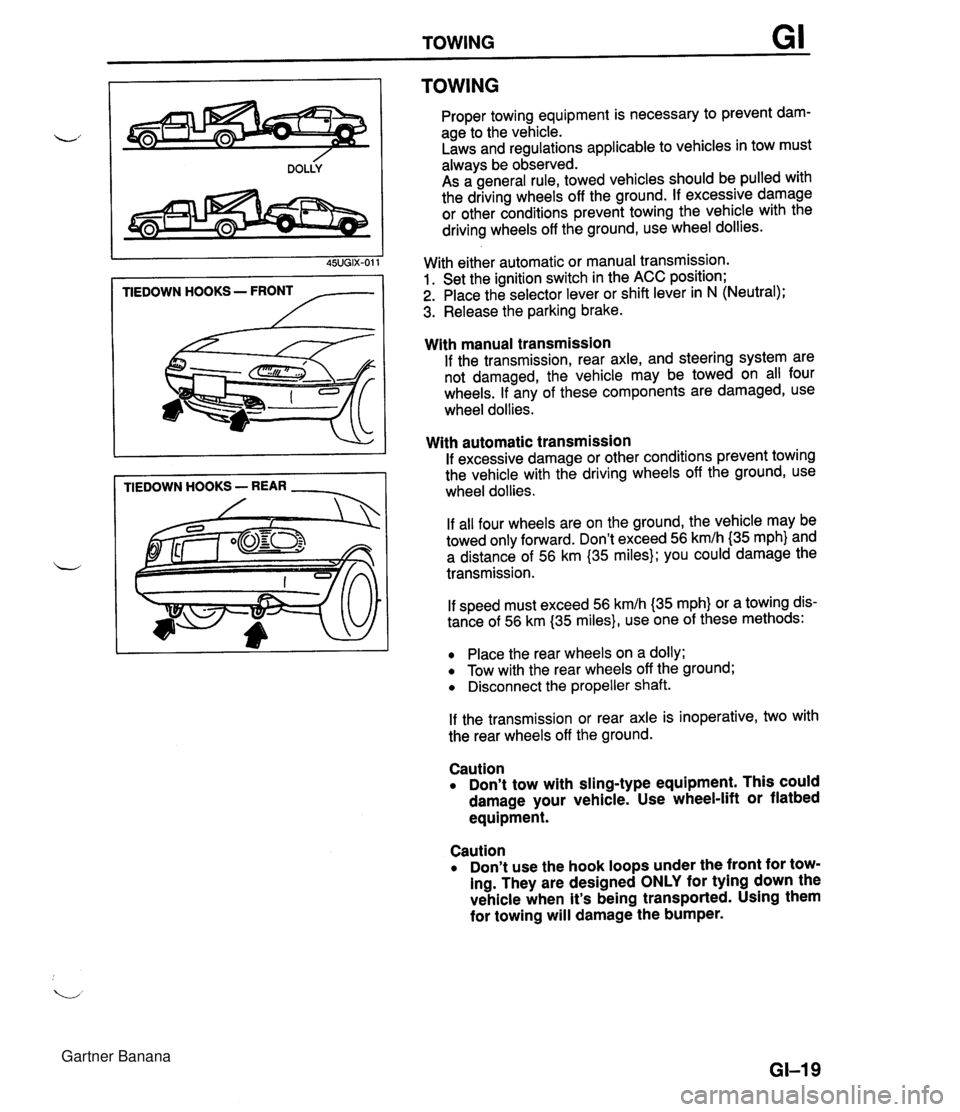

TOWING TIEDOWN HOOKS - FRONT /-- TIEDOWN HOOKS - REAR - TOWING Proper towing equipment is necessary to prevent dam- age to the vehicle. Laws and regulations applicable to vehicles in tow must always be observed. As a general rule, towed vehicles should be pulled with the driving wheels off the ground. If excessive damage or other conditions prevent towing the vehicle with the driving wheels off the ground, use wheel dollies. With either automatic or manual transmission. 1. Set the ignition switch in the ACC position; 2. Place the selector lever or shift lever in N (Neutral); 3. Release the parking brake. With manual transmission If the transmission, rear axle, and steering system are not damaged, the vehicle may be towed on all four wheels. If any of these components are damaged, use wheel dollies. With automatic transmission If excessive damage or other conditions prevent towing the vehicle with the driving wheels off the ground, use wheel dollies. If all four wheels are on the ground, the vehicle may be towed only forward. Don't exceed 56 kmlh {35 mph} and a distance of 56 km (35 miles); you could damage the transmission. If speed must exceed 56 kmlh (35 mph} or a towing dis- tance of 56 km (35 miles}, use one of these methods: Place the rear wheels on a dolly; Tow with the rear wheels off the ground; Disconnect the propeller shaft. If the transmission or rear axle is inoperative, two with the rear wheels off the ground. Caution Don't tow with sling-type equipment. This could damage your vehicle. Use wheel-lift or flatbed equipment. Caution Don't use the hook loops under the front for tow- ing. They are designed ONLY for tying down the vehicle when it's being transported. Using them for towing will damage the bumper. GI-I 9 Gartner Banana

Page 23 of 1708

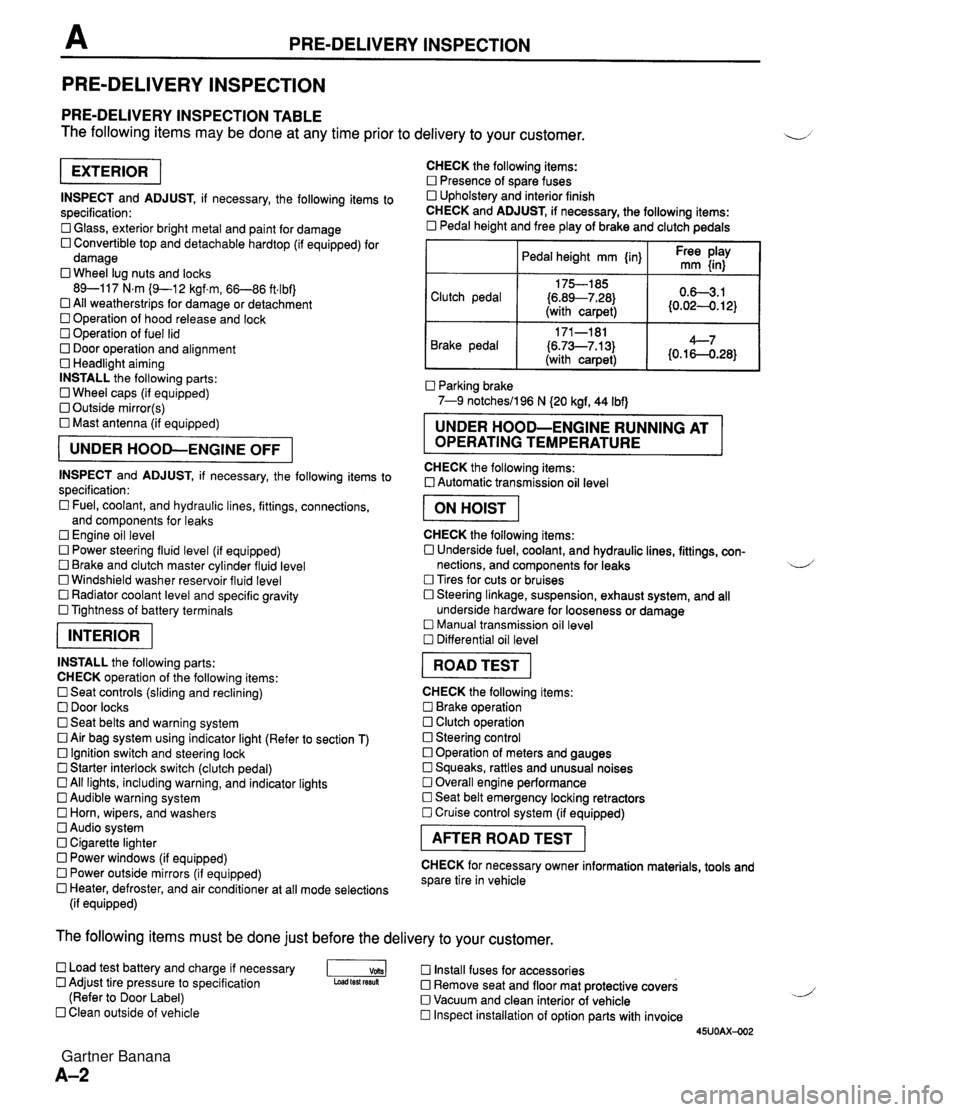

PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION TABLE The following items may be done at any time prior to delivery to your customer. INSPECT and ADJUST, if necessary, the following items to specification: 0 Glass, exterior bright metal and paint for damage 0 Convertible top and detachable hardtop (if equipped) for damage 0 Wheel lug nuts and locks 89-117 N.m (9-1 2 kgf.m, 66-86 ft4bf) 0 All weatherstrips for damage or detachment Operation of hood release and lock Operation of fuel lid 0 Door operation and alignment Headlight aiming INSTALL the following parts: Wheel caps (if equipped) 0 Outside mirror(s) 0 Mast antenna (if equipped) UNDER HOOD-ENGINE OFF INSPECT and ADJUST, if necessary, the following items to specification : Fuel, coolant, and hydraulic lines, fittings, connections, and components for leaks Engine oil level 0 Power steering fluid level (if equipped) Brake and clutch master cylinder fluid level 0 Windshield washer reservoir fluid level 0 Radiator coolant level and specific gravity 0 Tightness of battery terminals pKiq INSTALL the following parts: CHECK operation of the following items: 0 Seat controls (sliding and reclining) 0 Door locks 0 Seat belts and warning system 0 Air bag system using indicator light (Refer to section T) Ignition switch and steering lock 0 Starter interlock switch (clutch pedal) All lights, including warning, and indicator lights 0 Audible warning system 0 Horn, wipers, and washers Audio system 0 Cigarette lighter Power windows (if equipped) 0 Power outside mirrors (if equipped) 0 Heater, defroster, and air conditioner at all mode selections (if equipped) CHECK the following items: Presence of spare fuses 0 Upholstery and interior finish CHECK and ADJUST, if necessary, the following items: 0 Pedal height and free play of brake and clutch pedals I Pedal height mm {in} I Ft: $iy I Clutch pedal {6.89--7.28) (with carpet) Parking brake 7-9 notchesil96 N (20 kgf, 44 Ibf) 0.63.1 (0.024. 12) Brake pedal RUNNING AT OPERATING TEMPERATURE CHECK the following items: 0 Automatic transmission oil level 171-181 (6.73--7.13) (with carpet) I ON HOIST I 4--7 {0.16-0.28} CHECK the following items: 0 Underside fuel, coolant, and hydraulic lines, fittings, con- nections, and components for leaks 4 Tires for cuts or bruises 0 Steering linkage, suspension, exhaust system, and all underside hardware for looseness or damage Manual transmission oil level Differential oil level I ROAD TEST I CHECK the following items: Brake operation Clutch operation 0 Steering control 0 Operation of meters and gauges Squeaks, rattles and unusual noises 0 Overall engine performance Seat belt emergency locking retractors 0 Cruise control system (if equipped) I AFTER ROAD TEST I CHECK for necessary owner information materials, tools and spare tire in vehicle The following items must be done just before the delivery to your customer. 0 Load test battery and charge if necessary -1 Install fuses for accessories Adjust tire pressure to specification Load test fesuk 0 Remove seat and floor mat protective covers (Refer to Door Label) 0 Vacuum and clean interior of vehicle Clean outside of vehicle Inspect installation of option parts with invoice 45UOAX-002 Gartner Banana

Page 63 of 1708

B ON-VEHICLE MAINTENANCE REAR OIL SEAL Replacement 1. Disconnect the negative battery cable. 2. Remove the transmission. (MT Refer to section J. AT: Refer to section K.) 3. Remove in the order shown in the figure, referring to Removal Note. 4. Install in the reverse order of removal, referring to lnstallation Note. Nm (kgfm, ft-lbf) I 1. Clutch cover, clutch disc (MT) 4. Oil seal Removal / Installation ......... section H Removal Note .................. below 2. Flywheel (MT) Installation Note ........... page 6-27 ......... Removal / Installation section J 3. Drive plate (AT) ......... Removal / Installation section K Removal Note Oil seal 1. Cut the oil seal lip with a razor knife. 2. Remove the oil seal with a screwdriver protected with a rag. 05UOBX-063 Gartner Banana

Page 75 of 1708

DISASSEMBLY ROTATION ARROW - Disassembly Note Pulley lock bolt 1. Hold the flywheel (MT) or drive plate (AT 2. Loosen the pulley lock bolt. 3. Remove the pulley lock bolt. ') with the SST. Timing belt 1. ~rGect the tensioner with a rag. 2. Loosen the tensioner lock bolt. Ply the tensioner out- ward with a bar. 3. Tighten the lock bolt with the tensioner spring fully ex- tended. 4. Mark the timing belt rotation for proper reinstallation. 5. Remove the timing belt. Gartner Banana

Page 79 of 1708

B DISASSEMBLY CYLINDER BLOCK (EXTERNAL PARTS) Disassemble in the order shown in the figure, referring to Disassembly Note. GASKET, REPLACE - L 1. Clutch cover, clutch disc (MT) Removal 1 Installation ......... section H 2. Flywheel (MT), drive plate (AT) Disassembly Note .......... page 8-43 3. End plate 4. Oil pan Disassembly Note .......... page B43 5. Oil strainer 6. Oil pan baffle Disassembly Note .......... page B-44 7. Water pump 8. Oil pump ...... Disassembly 1 Assembly section D 9. Front oil seal Disassembly Note .......... page B-43 10. Rear cover 11. Rear oil seal Disassembly Note .......... page 6-43 Gartner Banana

Page 80 of 1708

DISASSEMBLY B PROTECT PUMP BODY WlTH RAG 05UOBX-10; I PROTECT REAR COYER WITH RAG I Disassembly Note Flywheel (MT) or drive plate (AT) 1. Hold the flywheel with the SST. 2. Remove the flywheel lock bolts. 3. Remove the flywheel. Oil pan 1. Remove the oil pan mounting bolts. Caution Pry tools can easily scratch the cylinder block and oil pan contact surfaces. 2. Insert a screwdriver only at the points shown in the fig- ure. 3. Remove the oil pan. Oil pan baffle 1. Insert a screwdriver between the cylinder block and the baffle to separate them. 2. Remove the baffle. Front oil seal Remove the oil seal with a screwdriver protected with a rag. Rear oil seal Remove the oil seal with a screwdriver protected with a rag. Gartner Banana

Page 105 of 1708

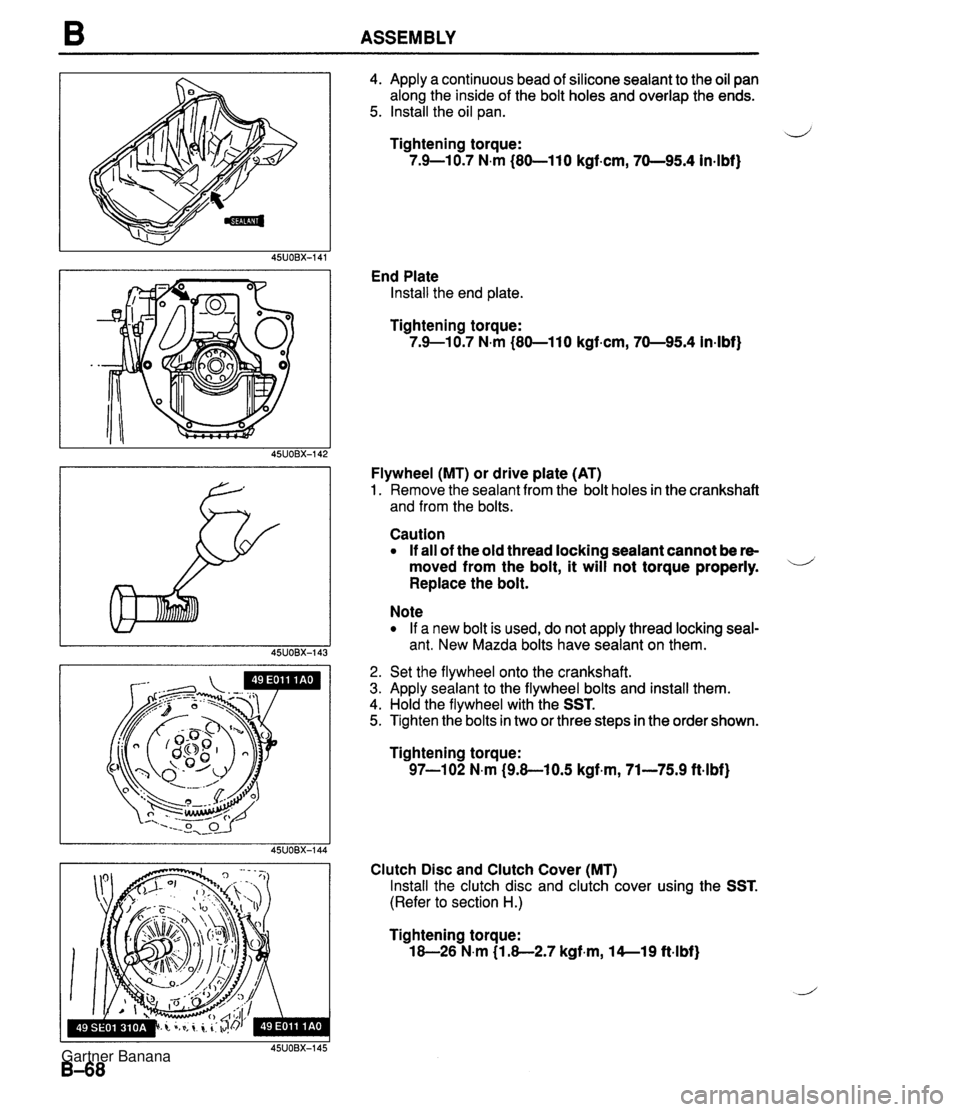

B ASSEMBLY 4. Apply a continuous bead of silicone sealant to the oil pan along the inside of the bolt holes and overlap the ends. 5. Install the oil pan. ij Tightening torque: 7.9-10.7 N.m (80-110 kgf-cm, 70-95.4 in4bf) End Plate Install the end plate. Tightening torque: 7.9--10.7 N.m (80-110 kgf.cm, 70-95.4 in-lbf) Flywheel (MT) or drive plate (AT) 1. Remove the sealant from the bolt holes in the crankshaft and from the bolts. Caution If all of the old thread locking sealant cannot be re- moved from the bolt, it will not torque properly. - Replace the bolt. Note If a new bolt is used, do not apply thread locking seal- ant. New Mazda bolts have sealant on them. 2. Set the flywheel onto the crankshaft. 3. Apply sealant to the flywheel bolts and install them. 4. Hold the flywheel with the SST. 5. Tighten the bolts in two or three steps in the order shown. Tightening torque: 97-102 N.m (9.8-10.5 kgf+m, 71-75.9 ft.lbf) Clutch Disc and Clutch Cover (MT) Install the clutch disc and clutch cover using the SST. (Refer to section H.) Tightening torque: 18-26 N.m (1.8-2.7 kgf.m, 14--19 ftlbf) Gartner Banana

Page 112 of 1708

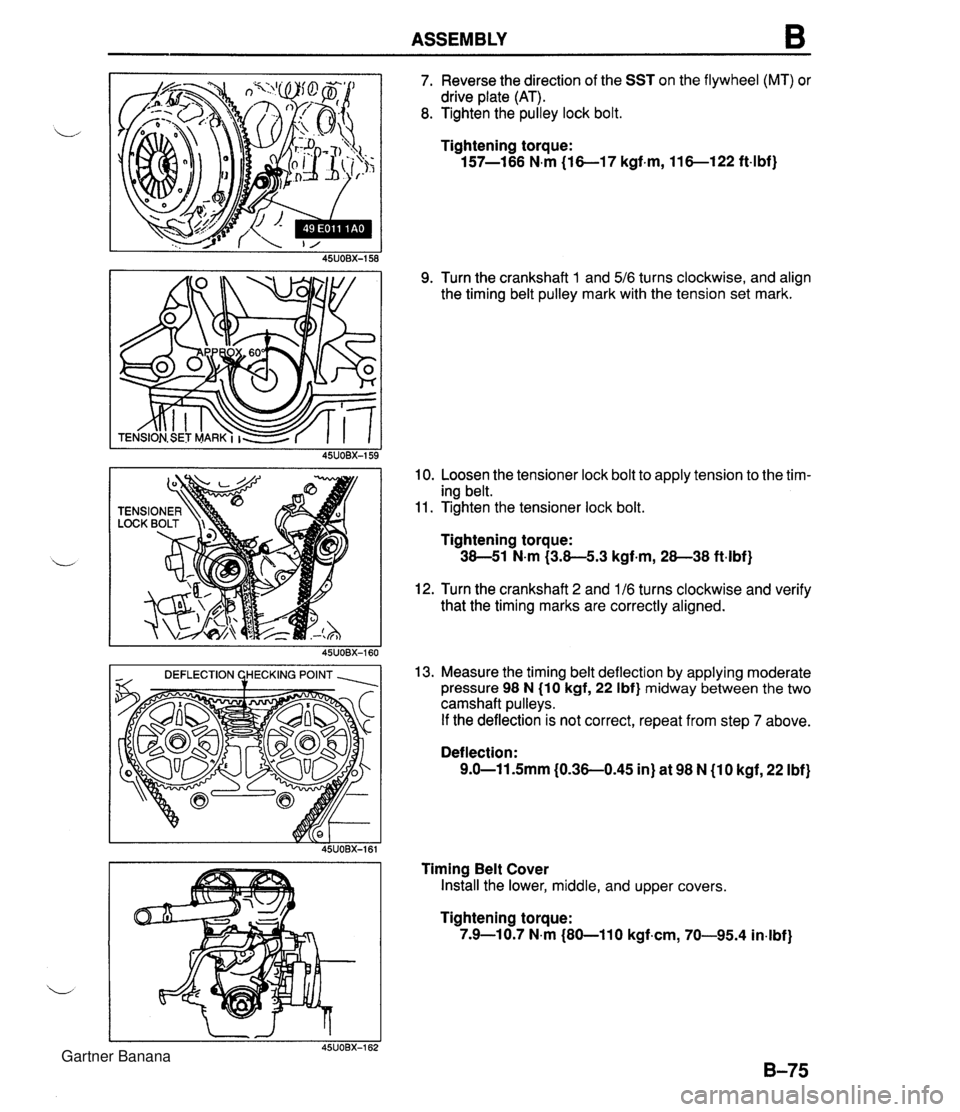

ASSEMBLY B r/ DEFLECTION %HECKING POINT , 7. Reverse the direction of the SST on the flywheel (MT) or drive plate (AT). 8. Tighten the pulley lock bolt. Tightening torque: 157-166 N-m (16-17 kgf.m, 116-122 ft-lbf) 9. Turn the crankshaft 1 and 516 turns clockwise, and align the timing belt pulley mark with the tension set mark. 10. Loosen the tensioner lock bolt to apply tension to the tim- ing belt. 11. Tighten the tensioner lock bolt. Tightening torque: 38-51 N-m (3.8-5.3 kgf-m, 28-38 ft4bf) 12. Turn the crankshaft 2 and 116 turns clockwise and verify that the timing marks are correctly aligned. 13. Measure the timing belt deflection by applying moderate pressure 98 N (10 kgf, 22 Ibf) midway between the two camshaft pulleys. If the deflection is not correct, repeat from step 7 above. Deflection: 9.0-11.5mm (0.36-0.45 in) at 98 N (1 0 kgf, 22 Ibf) Timing Belt Cover Install the lower, middle, and upper covers. Tightening torque: 7.9-10.7 N.m (80-110 kgf.cm, 70-95.4 in4bf) Gartner Banana