air condition MAZDA MX-5 1994 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 686 of 1708

BRAKE SYSTEM P (20 kgf, 44 Ibf) (20 kgf, 44 Ibf) Loaded condition 1. Start the engine. 2. Depress the brake pedal with a force of 196 N (20 kgf, 44 Ibf). 3. With the brake pedal depressed, stop the engine when the vacuum gauge indicates 66.7 kPa I500 mmHg, 19.7 inHg). 4. Observe the vacuum gauge for 15 seconds. If the gauge indicates 63.4-66.6 kPa (475--500 mmHg, 18.7-19.7 inHg), the unit is operating. b) Checking for hydraulic pressure 1. If with the engine stopped (vacuum 0 kPa (0 mmHg, 0 inHg}) the fluid pressure is within specification, the unit is operating. 1 Pedal force Fluid pressure 2. Start the engine. Depress the brake pedal when the vac- uum reaches 66.7 kPa (500 mmHg, 19.7 inHg). If the fluid pressure is within specification, the unit is operat- ing. 1 96 N {20 kgf, 44 Ibf) I Pedal force I Fluid pressure I 1,079-1,177 kPa {I 1-1 2 kgf/cm2, 156-1 71 psi) lnspection of Check Valve 196 N {20 kgf, 44 Ibf) Note There is an arrow on the hose to indicate direction of hose installation. 5,199--5,494 kPa {53-56 kgf/cm2, 754--796 psi} lnspection 1. Disconnect both ends of the vacuum hose. 2. Apply suction and pressure to the hose from the engine side. Verify that air flows only toward the engine. If air passes in both directions or not at all, replace the vac- uum hose (along with the check valve). Gartner Banana

Page 731 of 1708

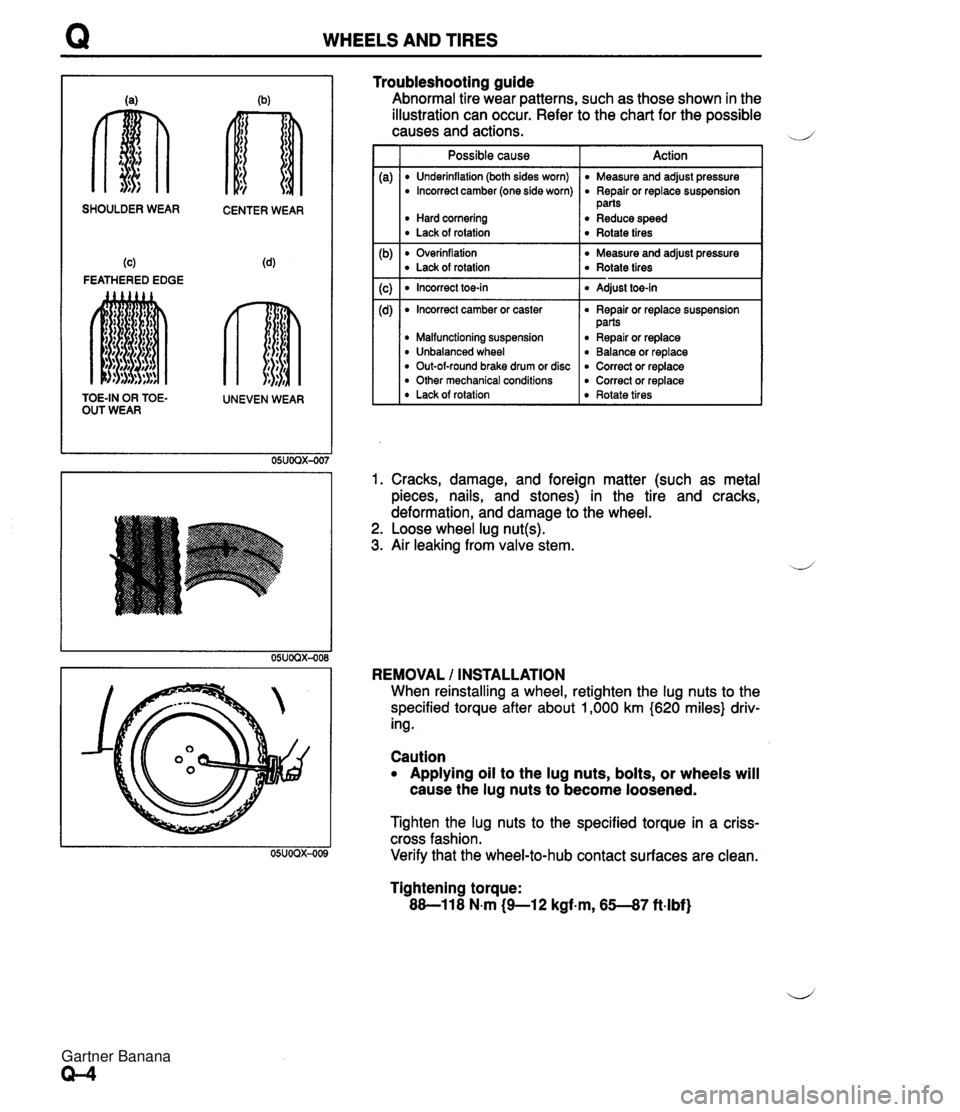

WHEELS AND TIRES SHOULDER WEAR CENTER WEAR (c) (4 FEATHERED EDGE TOE-IN OR TOE- UNEVEN WEAR OUT WEAR Troubleshooting guide Abnormal tire wear patterns, such as those shown in the illustration can occur. Refer to the chart for the possible causes and actions. d' Possible cause I Action I I Underinflation (both sides worn) I Measure and adjust pressure Overinflation Measure and adjust pressure Lack of rotation Rotate tires I Incorrect camber (one side worn) Hard cornering Lack of rotation Incorrect toe-in I Adjust toe-in I Repair or replace suspension parts Reduce speed Rotate tires 1. Cracks, damage, and foreign matter (such as metal pieces, nails, and stones) in the tire and cracks, deformation, and damage to the wheel. 2. Loose wheel lug nut(s). 3. Air leaking from valve stem. Incorrect camber or caster Malfunctioning suspension Unbalanced wheel Out-of-round brake drum or disc Other mechanical conditions Lack of rotation REMOVAL / INSTALLATION When reinstalling a wheel, retighten the lug nuts to the specified torque after about 1,000 km (620 miles} driv- ing. Repair or replace suspension parts Repair or replace Balance or replace Correct or replace Correct or replace Rotate tires Caution Applying oil to the lug nuts, bolts, or wheels will cause the lug nuts to become loosened. Tighten the lug nuts to the specified torque in a criss- cross fashion. Verify that the wheel-to-hub contact surfaces are clean. Tightening torque: 88-11 8 N.m (9-1 2 kgf.m, 65--87 ft-lbf) Gartner Banana

Page 733 of 1708

Before beginning any service procedure. refer to section T of this manual for I air bag system service warnings and audio antitheft system alarm conditions . INDEX ....................................... R- 2 OUTLINE ..................................... R- 4 SPECIFICATIONS ........................... R- 4 TROUBLESHOOTING GUIDE .................. R- 5 WHEEL ALIGNMENT .......................... R- 6 PRE-INSPECTION .......................... R- 6 FRONT WHEEL ALIGNMENT ................. R- 6 .................. REAR WHEEL ALIGNMENT R- 9 FRONT SUSPENSION (DOUBLE-WISHBONE) ... R-11 PREPARATION ............................. R-11 SHOCK ABSORBER AND SPRING ............ R-11 LOWER ARM ............................... R-15 UPPER ARM ............................... R-17 STABILIZER ................................ R-19 CROSSMEMBER ........................... R-20 REAR SUSPENSION (DOUBLE-WISHBONE) .... R-21 PREPARATION ............................. R-21 SHOCK ABSORBER AND SPRING ............ R-22 LOWER ARM ............................... R-23 UPPER ARM ............................... R-24 STABILIZER ................................ R-25 CROSSMEMBER ........................... R-26 25UORX-001 Gartner Banana

Page 759 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . BODY INDEX ............................. S- 2 HOOD ............................. S- 5 COMPONENTS ................... S- 5 DOOR ............................. S- 7 COMPONENTS ................... S- 7 WINDOW REGULATOR. GLASS. AND GUIDE ....................... S- 9 COMPONENTS ................... S- 9 ......... DOOR LOCK AND OPENER S-15 ................... COMPONENTS S-15 TRUNK LID ........................ S-16 COMPONENTS ................... S-16 .... TRUNK LID LOCK AND OPENER S-18 COMPONENTS ................... S-18 ......... POWER WINDOW SYSTEM S-19 .............. STRUCTURAL VIEW S-19 TROUBLESHOOTING ............. S-20 ........ b POWER WINDOW SWITCH S-22 ... POWER WINDOW REGULATOR S-22 ......... FUEL-FILLER LID OPENER S-23 COMPONENTS ................... S-23 FRONT BUMPER ................... S-24 COMPONENTS ................... S-24 REAR BUMPER .................... S-25 COMPONENTS ................... S-25 ........... MOLDING AND GARNISH S-27 COMPONENTS ................... S-27 OUTSIDE MIRROR ................. S-30 STRUCTURAL VIEW .............. S-30 ............. TROUBLESHOOTING S-31 POWER OUTSIDE MIRROR ....... S-33 POWER OUTSIDE MIRROR SWITCH ........................ S-33 COMPONENTS ................... S-34 WINDSHIELD WIPER AND WASHER . S-35 TROUBLESHOOTING ............. S-35 WIPER MOTOR .................. S-38 ................ WASHER MOTOR S-38 FRONT WIPER AND WASHER ........................ SWITCH S-38 ................... COMPONENTS S39 WINDSHIELD ...................... S-44 PREPARATION ................... S-44 ................... COMPONENTS S-44 REAR WINDOW GLASS ......... (DETACHABLE HARDTOP) S-48 PREPARATION ................... S48 ................... COMPONENTS S48 REAR WINDOW .............. (CONVERTIBLE TOP) S-52 ................... COMPONENTS S-52 ....... DASHBOARD AND CONSOLE S-56 ................... COMPONENTS S56 TRIM .............................. S-59 COMPONENTS ................... S-59 ................. FLOOR COVERING S-62 ................... COMPONENTS -21 SEAT BELT ........................ S-63 COMPONENTS ................... S-63 ...................... SEAT BELT S-64 ................ BUCKLE SWITCH S-64 SEAT .............................. S-65 ................... COMPONENTS S-65 ................ CONVERTIBLE TOP S-67 PREPARATION ................... S-67 ................... COMPONENTS S-67 ........... DETACHABLE HARDTOP S-81 COMPONENTS ................... S-81 BRACE BAR ....................... S-84 ................... COMPONENTS S-84 ......... UNDERBODY DIMENSIONS S-85 PROJECTED DIMENSIONS ........ S-85 ..... STRAIGHT-LINE DIMENSIONS S-87 45uoSx-001 Gartner Banana

Page 899 of 1708

T LIGHTING SYSTEM Troubleshooting Symptom: Stoplights do not illuminate (All). 45UOTX-105 '' HIGH-MOUNT STOPLIGHT 05UOTX-12: Step 1 1. Check STOP 15A fuse in the fuse box. 2. If the fuse is burned, replace it. Check and repair the wire harness, if necessary. 3. If the fuse is OK, go to Step 2. ~easure the voltage at the following terminal wires of the stoplight switch connector. B+: Battery positive voltage Inspection 1 ~erm w I voltage 1 condition Action I B+ I Check B terminal I Repair wiring harness Other I (STOP 15A fuse - Storrliaht switch) I Brake pedal B+ I Go to Step 3 depressed Other 1 Check stoplight switch w -- 1. 6heck the stoplight bulbs. 2. If a bulb is burned, replace it. 3. If the bulbs are OK, go to Step 4. Step 4 Measure the voltage at the following terminal wires of the right and left rear combination light connectors. B+: Batterv ~ositive voltacle -. - '"spection I Terminal I Voltage 1 condition Action Brake pedal depressed B+ Other B+ Other Check F terminal Repair wiring harness (Stoplight switch - Rear combina- tion light) Repair wiring harness (Rear combination light - GND) Check for poor connection of con- nectors Gartner Banana

Page 900 of 1708

LIGHTING SYSTEM T u I Symptom: Stoplights does not illuminate (One only). 45UOTX-108 STOPLIGHT 'I HIGH-MOUNT STOPLIGHT Removal / Installation - -- 1. stoplight, High-mount stoplight 2. Remove and install as shown in the figure. Step 1 1. Check the stoplight bulb of the faulty side. 2. If a bulb is burned, replace it. 3. If the bulb is OK, go to Step 2. Step 2 Measure the voltage at the following terminal wires of the faulty rear combination ligjht connector. B+: Battery ~ositive voltaae -. - I Inspection I TernM I Voltage I condition Action - STOPLIGHT (LH AND RH) HIGH-MOUNT STOPLIGHT Brake pedal depressed F B+ Other B+ Other Check F terminal Repair wiring harness (Stoplight switch - Rear mrnbina- tion light) Repair wiring harness (Rear combination light - GND) Check for poor connection of con- nectors Gartner Banana

Page 918 of 1708

LIGHTING SYSTEM T Symptom: Daytime running lights (DRL) do not illuminate. (Turn signals function normally.) DRL operate with engine running and following switches are off: Headlight switch Turn signal switch (Selected turn signal light flashes, other light remains illumi- nated) Hazard warning switch Parking brake switch (Parking brake released) Step 1 1. Position the vehicle on a flat surface and block the wheels to prevent vehicle movement. 2. Turn the ignition switch to ON. 3. Measure the voltage at the following terminal wires of the DRL control unit. 4. If correct, replace the DRL control unit. B+: Battery positive voltage Step 2 1. Disconnect the parking brake switch connector. 2. Check for continuity between the terminal of the switch and a body ground. Terminal J (L) u Connected to WIPER 20A fuse I(B) B (R) C (WIR) Parking brake lever Pulled one notch Continuity Yes Released Test condition Constant GND Parking brake switch Headlight switch No I 3. If not as specified, adjust or replace the parking brake switch. 4. If correct, repair wiring harness. (DRL control unit - Parking brake switch) Specification B+ Constant Parking brake released Headlight switch off Action Repair wiring harness (WIPER 20A - DRL control unit) Other B+ Other Repair wiring harness (DRL control unit - GND) Go to Step 2 Go to Step 3 Gartner Banana

Page 942 of 1708

CRUISE CONTROL SYSTEM B+: Battery Dositive voltage erminall Win color . . .. Action Connected to Cruise actuator Cruise actuator Test condition Main switch OFF Main switch ON Cruise A\actuator Specification Main switch OFF Main switch ON PCMT OV 9V Main switch OFF . Main switch ON Brake switch Go to Step 8 OV . 9V Ignition switch OFF lanition switch ON ParklNeutral switch Cruise control Main switch ON switch (Set switch and coast switch) Check main switch OV 9V - Brake pedal depressed Brake ~edal released Clutch switch Check main switch OV B+ Shift to "N" or "P" range Shift to other ranae Go to section K OV 9V Clutch pedal depressed Clutch pedal released Stoplight switch Go to Step 4 OV 5V Cruise control switch (Resume switch and accel switch) speed I While rotating rear tires I beMeenM,, sor Run I GO to Step 9 Go to section K OV B+ Brake pedal depressed Brake pedal released Cruise actuator I I I Battery 1 Constant I B+ I Repair wiring harness Go to Step 5 Main switch ON While turning resume switch after main switch ON B+ OV Main switch OFF Step 4 - Inspection of brake switch 1. Disconnect the brake switch connector. 2. Check for continuity between terminals of the switch. Go to Step 7 B+ OV OV GND 1 Constant Pedal position Go to Step 6 OV I Repair wiring harness Terminal A B 1 I Main switch ON 9V 45UOTX-19 Go to Step 8 3. If not as specified, replace the brake switch. 4. If the switch is OK, repair the wiring harness (fuse - brake switch - control unit). Pedal released Pedal depressed M: Continuity 0 0 Gartner Banana

Page 949 of 1708

CRUISE CONTROL SYSTEM B+: Battery positive voltage L rmlnall Wire color M Specification (RIL). . N Action Connected to (G) 0 CELERATOR DAL 9MUOTX-263 Test condition Cruise control switch (Set switch and coast switch) (w) P S T ACTUATOR CABLE Removal 1. Disconnect the actuator cable from the accelerator ped- al. 2. Remove the clamp at the inside of the firewall. (P) 3. Disconnect the actuator cable from the actuator. 4. Remove the clamps and the actuator cable. Main switch ON While turning set switch after main switch ON Check stoplight switch (Refer to page T-105) Stoplight switch Cruise control switch (Resume switch and accel switch) (WIG) (B) Installation Install in the reverse order of removal. Adjustment Remove the clamp and adjust the nut so that actuator cable free play is as shown when the cable is pressed lightly. B+ OV Brake pedal depressed I B+ Main switch ON While turning resume switch after main switch ON Actuator Cable play: 1 .O-3.0mm (0.04--0.12 in) Brake pedal released OV 9V Main switch OFF Main switch ON Vehicle speed sensor Battery GND Check cruise control switch (Refer to page T-106) OV B+ OV Check actuator (Refer to page T-107) Run out betweeno-5V B+ OV rotating rear tires Constant Constant d Check cruise control switch (Refer to page T-106) Check vehicle speed sensor (Refer to page T-106) Repair wire Re~air wire Gartner Banana

Page 1003 of 1708

SRS AIR BAG SYSTEM SYSTEM DIAGRAM PASSENGER-SIDE S-SENSOR AIR BAG MODULE I IG1 B+ HORN RELAY CLOCK SPRING BACK-UP BATTERY I AIR BAG SYSTEM WARNING LIGHT SENSOR -7 System Operation During collision When either of the D-sensors and the S-sensor are activated (closed) simultaneously by shock of a colli- sion, the circuit to the inflator is completed. The inflator creates nitrogen gas and the air bag is deployed. The air bag vents the nitrogen gas from the vent hole on the back side of the bag to reduce shock to the driver and to allow easier exit from the vehicle. During normal condition and malfunction The diagnostic module constantly monitors the components and wiring of the air bag system for malfunc- tion, open circuits, and short circuits. .J If a malfunction is detected, the diagnostic module illuminates or flashes the warning light. In the case of a short circuit in the sensors or sensor harnesses, the diagnostic module activates the warning light and shuts down the system to prevent accidental deployment of the air bag. Gartner Banana