bulb MAZDA MX-5 1994 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 900 of 1708

LIGHTING SYSTEM T u I Symptom: Stoplights does not illuminate (One only). 45UOTX-108 STOPLIGHT 'I HIGH-MOUNT STOPLIGHT Removal / Installation - -- 1. stoplight, High-mount stoplight 2. Remove and install as shown in the figure. Step 1 1. Check the stoplight bulb of the faulty side. 2. If a bulb is burned, replace it. 3. If the bulb is OK, go to Step 2. Step 2 Measure the voltage at the following terminal wires of the faulty rear combination ligjht connector. B+: Battery ~ositive voltaae -. - I Inspection I TernM I Voltage I condition Action - STOPLIGHT (LH AND RH) HIGH-MOUNT STOPLIGHT Brake pedal depressed F B+ Other B+ Other Check F terminal Repair wiring harness (Stoplight switch - Rear mrnbina- tion light) Repair wiring harness (Rear combination light - GND) Check for poor connection of con- nectors Gartner Banana

Page 905 of 1708

T LIGHTING SYSTEM FRONT TURN REAR TURN Step 9 1. Reconnect connector and turn the ignition switch to ON. 2. Set the turn signal switch to the right position and mea- sure voltage at terminal G(G/W) of the flasher unit con- -i nector. B+: Batterv ~ositive voltaae I Other I Replace flasher unit I Voltage 3. Set the turn signal switch to the left position and measure voltage at terminal D(G/B) of the flasher unit connector. Action B+: Battery positive voltage Alternates OV and B+ I Go to Step 10 I Voltage I Action I 1 Alternates OV and B+ 1 Go to Ste~ 10 1 I Other I Replace flasher unit I Step 10 1. Disconnect the turn signal light connectors. 2. Set the turn signal switch to the left or right position. 3. Measure the voltage at the terminals of the combination light connector. Light 1 Terminal I Voltage I I Alternates Front Alternates Front C (GIO) OV and B+ LH Alternates qyr I A (WB, I OV and B+ Ln I 1 Other - B+: Battery positive voltage Action I Go to Step 11 Go to Step 11 Go to Step 11 I Repair wiring harness (Flasher unit - Front combination liaht) Go to Step 11 I Repair wiring harness (Flasher unit - Rear combination light) 1. Turn the ignition switch to OFF. 2. Remove and check the bulbs. I Position I BUM I Action I Hazard warning 7 Hazard warning Bulb OK Burn OK Replace bulb Repair wiring harness (Front combination light - GND) Replace bulb Repair wiring harness (Rear combination light - GND) 4 Gartner Banana

Page 912 of 1708

LIGHTING SYSTEM T Troubleshooting Symptom: Back-up light(s) does not illuminate. 45UOTX-I 36 Step 1 1. Check METER 15A fuse. 2. If the fuse is burned, replace it. Check and repair the wire harness, if necessary. 3. If the fuse is OK, go to Step 2. Step 2 1. Check the back-up light bulbs. 2. If a bulb is burned, replace it. 3. If the bulbs are OK, go to Step 3. Step 3 1. Turn the ignition switch ON, and shift the transmission to reverse. 2. Measure the voltacle at the terminal wires of the rear combination light cknectors. B+: Battery positive voltage . light Action C Left B+ Other Right Check F terminal Go to Step 4 F C T-67 F '+ Other B+ Other Repair wiring harness (Rear combination light - GND) Check for poor connection of back- up light connector Check F terminal Go to Step 4 B+ Other Repair wiring harness (Refer combination light - GND) Check for poor connection of back- up light connector Gartner Banana

Page 915 of 1708

LIGHTING SYSTEM - -- -- Troubleshooting I Symptom: Taillights, side marker lights, and license plate lights do not illuminate. 45UOTX-141 Step 1 1. Check TAIL 15A fuse. 2. If the fuse is burned, replace it. Check and, if necessary, repair the wiring harness. 3. If the fuse is OK, go to Step 2. Step 2 1. Turn the headlight switch ON. 2. Measure the voltage at the following terminal wires of the - TNS relay connedor. B+: Battery positive voltage - Terminal 1 Voltage 1 Action I B+ I Go to Step 3 C (WIL) Other I Check D terminal B+ Other Go to Step 4 Check A terminal A (WIR) Step 3 1. Check the bulbs of each light. 2. If the bulb is burned, replace the bulb. 3. If the bulbs are OK, repair wiring harness between the TNS relay and the body ground of each light. B (WIR) B+ Other Check B terminal Repair wiring harness (TAIL 15A fuse - TNS relay) B+ Other Replace TNS relay Repair wiring harness (TAIL 15A fuse - TNS relay) Gartner Banana

Page 924 of 1708

LIGHTING SYSTEM T - --- -- Troubleshooting I Symptom: Interior llght(s) do not illuminate. 45UOTX-161 CONTRYL SWITCH Step 1 Verify the trouble symptom by operating the control switch and opening the doors. Go to the specified Step. Symptom Interior light(s) do not illuminate when control switches are in any position Step 2 1. Check the ROOM 10A fuse. 2. If the fuse is burned, replace it. Check and repair the wire harness if necessary. 3. If the fuse is OK, go to Step 3. Next step Step 2 Interior light(s) illuminate when control switches are in ON position, but do not illumi- nate with door open when switches are in DOOR position lnterior light(s) illuminate when control switches are in DOOR position, but do not illuminate when switches are in ON position Step 3 1. Check the bulb of each light. 2. If a bulb is burned, replace it. 3. If the bulbs are OK, go to Step 4. Step 5 Step 7 45UOTX-162 Gartner Banana

Page 1033 of 1708

Possible cause u 0 Burnt air bag warning light bulb Defective diagnostic module Defective wiring harness Step 1 Carry out "Before Servicing" procedure under GEN- ERAL PROCEDURES, page T-1 60. Air bag system warning light does not illuminate for 6 seconds Flowchart No.1 Step 2 1. Disconnect the diagnostic module connector. 2. Turn the ignition switch to ON. 3. Check the air bag warning light. I Llght condition I Action 1 Symptom 1 Illuminate I Replace diagnostic module (Refer to ~aae T-208) 1 -- I Not illuminate I GO to step 3 J Step 3 1. Remove the instrument cluster. 2. Check the air bag system warning light bulb. I Repair wiring harness (Diagnostic module--Instrument cluster) I Bulb Burnt Action Replace bulb .- Gartner Banana

Page 1090 of 1708

u AIR CONDITIONER Performance Test After finishing repairs, conduct a performance test of the air conditioning system as follows. 1. Connect the manifold gauge set. (Refer to page U-25.) 2. Start the engine and keep the engine speed at 1,500 rpm. 3. Operate the air conditioner at maximum cooling. 4. Open all windows and doors. 5. Place a dry-bulb thermometer in the center ventilator outlet. 6. Place a dry and wet thermometer close to the blower in- let. 7. Wait until the air conditioner outlet temperature stabi- lizes. If the high-pressure side becomes too high, pour cool water on the condenser. If it is too low, cover the front of the condenser. Stabilized condition Blower inlet temperature: 30-35°C (86-95°F) High-pressure side: 1.38-1.56 MPa (1 4.0-1 6.0 kgflcm*, 200-227 psi) 8. After the air conditioner stabilizes, read the dry and wet thermometer at the air inlet. 9. Calculate the relative humidity from the chart below by comparing the wet- and dry-bulb readings. Gartner Banana

Page 1091 of 1708

AIR CONDITIONER u "C "F 26 24 22 20 18 16 14 12 10 40 59 60 70 RELATIVE HUMIDITY I ltem I Symptom 10. Read the dry thermometer at the air outlet, and calculate the difference between the inlet dry bulb and outlet dry bulb temperatures. 11. Verify that the intersection of the relative humidity and temperature difference is in the shaded zone. Checking Refrigerant Charge 1. Run the engine at a fast idle. 2. Operate the air conditioner at maximum cooling for a few minutes. 3. Determine the amount of refrigerant as shown below by observing the sight glass. 1 Bubbles present in sight glass 2 No bubbles present in sight glass Immediately after air conditioner turned OFF, refrigerant in sight glass stavs clear 141 When air conditioner turned OFF, re- frigerant foams, and then sight glass becomes clear -- Amount of refrigerant Insufficient refrigerant Action Check refrigerant pressure -- Too much or proper amount of refrig- erant Too much refrigerant Checking Refrigerant Pressure 1. Connect the manifold gauge set. (Refer to page U-25.) 2. Operate the engine at 1,500 rpm and set the air condi- tioner to maximum cooling. 3. Measure the low- and high-pressure sides. Turn air conditioner OFF, and watch bubbles (Refer to Items 3 and 4) Check refrigerant pressure Proper amount of refrigerant Stabilized condition Low-pressure side: 0.15-4.24 MPa {I .5--2.5 kgf/cm2, 22-35 psi) High-pressure side: 1.38-1.56 MPa (1 4.61 6.0 kgflcm*, 200-227 psi) Refrigerant amount normal Gartner Banana

Page 1094 of 1708

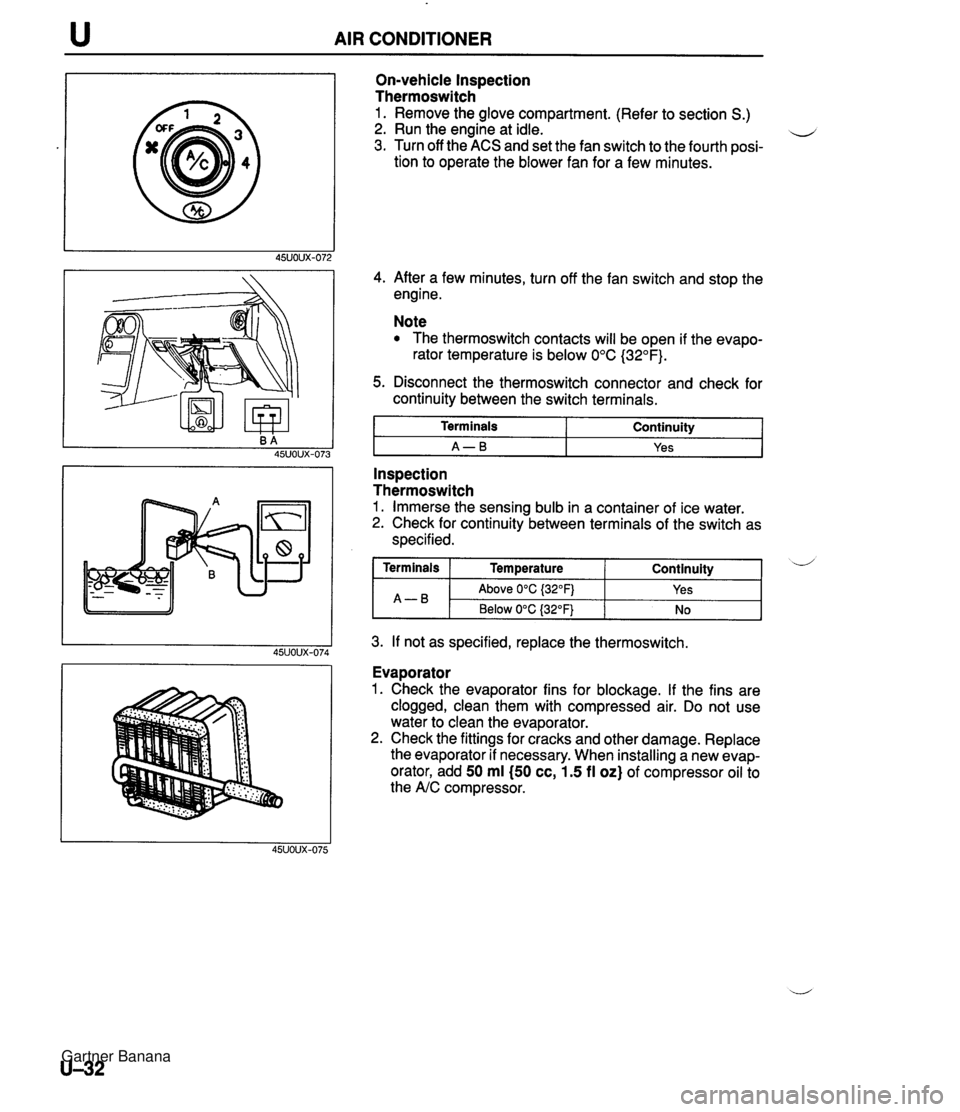

AIR CONDITIONER On-vehicle Inspection Thermoswitch 1. Remove the glove compartment. (Refer to section S.) 2. Run the engine at idle. u 3. Turn off the ACS and set the fan switch to the fourth posi- tion to operate the blower fan for a few minutes. 4. After a few minutes, turn off the fan switch and stop the engine. Note The thermoswitch contacts will be open if the evapo- rator temperature is below 0°C (32°F). 5. Disconnect the thermoswitch connector and check for continuity between the switch terminals. I Terminals I Continuity I I A-B I Yes I - -- Inspection Thermoswitch 1. Immerse the sensing bulb in a container of ice water. 2. Check for continuity between terminals of the switch as specified. 3. If not as specified, replace the thermoswitch. Continuity ( Terminals I Temperature A-B Evaporator 1. Check the evaporator fins for blockage. If the fins are clogged, clean them with compressed air. Do not use water to clean the evaporator. 2. Check the fittings for cracks and other damage. Replace the evaporator if necessary. When installing a new evap- orator, add 50 ml (50 cc, 1.5 fl oz) of compressor oil to the A/C compressor. d Above 0°C {32OFj Below 0°C (32°F) Yes No Gartner Banana

Page 1123 of 1708

TECHNICAL DATA 1 Charge I 1.4 Belt 1.4 r. BODY ELECTRICAL SYSTEM 1 Air bag I 2 1 Retractor 1.4 Item Wattage (Bulb trade number) Hold Anti lock Wamlng and indicator lights 1.4 1.4 Washer Rear window defroster Beam Turn (LH and RH) Illumination Malfanction indicator Brake 1.4 1.4 I Exterior lights 3.4 3.4 3.4 x 4 1.4 1.4 Headlights Front turn signawparking lights Front side marker lights License plate lights Rear turn signal lights Rear side marker lights Stop/taillights Back-UP linhts High-mount stoplight I 18.4 (921) ACS 1 1.4 Hazard switch 1.4 60140 2718 (1 157 NA) 3.8 (1 94) 7.5 27 (1 1 56) 3.8 (1 94) 2718 {I 157) 27 (1 1561 Interior llahts - I lllumination lights I Cruise control main switch I 1.4 I 5 Ash tray U. HEATER AND AIR CONDITIONING SYSTEM I Item I Specit lcations I 3.4 Heater control switch ane el I 1.4 STANDARD BOLT AND NUT TIGHTENING TORQUE Refrigerant amount S (04 Compressor oil amount rnl {cc, fl oz) Refrigerant normal pressure MPa (kgflcm2, psi) 600 {2 1.21 130-1 70 {I 30-1 70,3.9-5.1) Low pressure: 0.154.25 (1 .5-2.5,21-361 Hiah Pressure: 1 37-1.57 (1 4--16, 199--228) Gartner Banana