height MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 23 of 1708

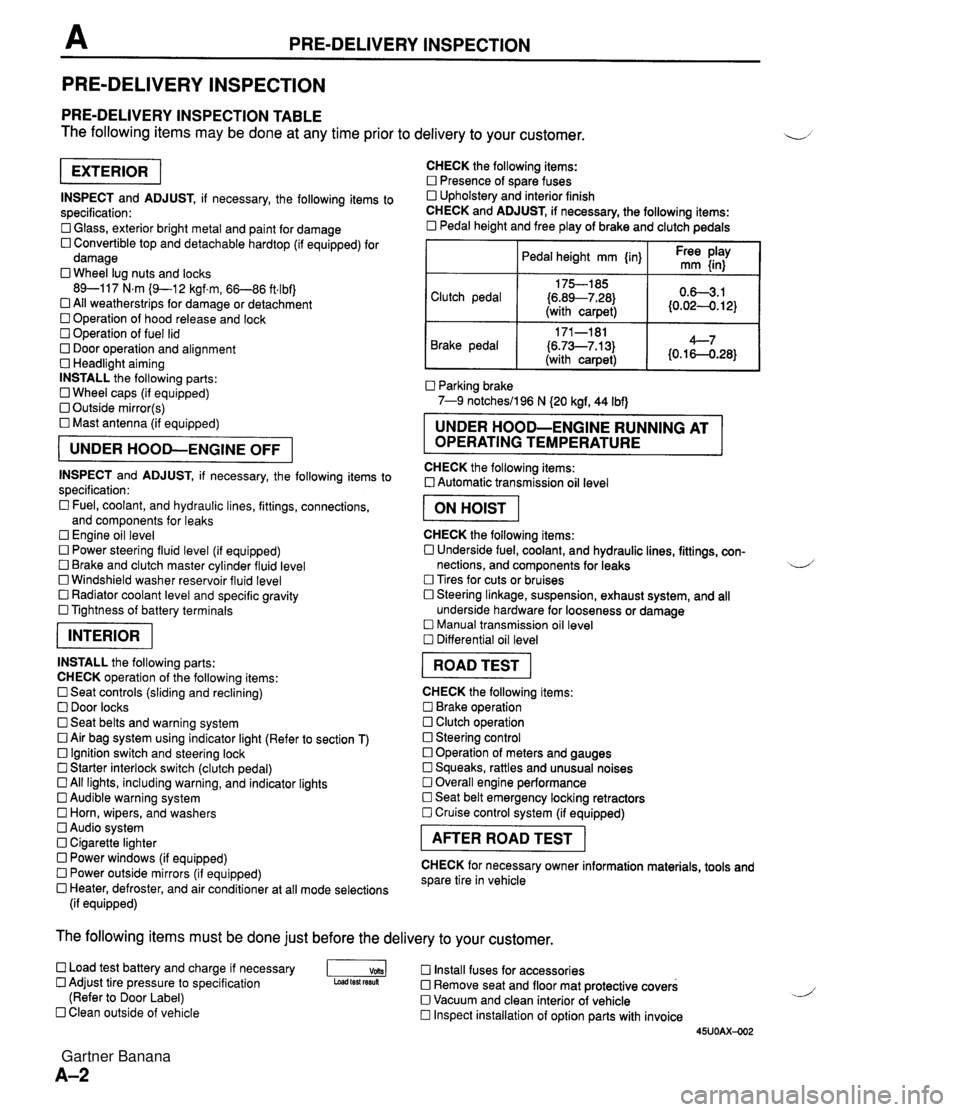

PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION TABLE The following items may be done at any time prior to delivery to your customer. INSPECT and ADJUST, if necessary, the following items to specification: 0 Glass, exterior bright metal and paint for damage 0 Convertible top and detachable hardtop (if equipped) for damage 0 Wheel lug nuts and locks 89-117 N.m (9-1 2 kgf.m, 66-86 ft4bf) 0 All weatherstrips for damage or detachment Operation of hood release and lock Operation of fuel lid 0 Door operation and alignment Headlight aiming INSTALL the following parts: Wheel caps (if equipped) 0 Outside mirror(s) 0 Mast antenna (if equipped) UNDER HOOD-ENGINE OFF INSPECT and ADJUST, if necessary, the following items to specification : Fuel, coolant, and hydraulic lines, fittings, connections, and components for leaks Engine oil level 0 Power steering fluid level (if equipped) Brake and clutch master cylinder fluid level 0 Windshield washer reservoir fluid level 0 Radiator coolant level and specific gravity 0 Tightness of battery terminals pKiq INSTALL the following parts: CHECK operation of the following items: 0 Seat controls (sliding and reclining) 0 Door locks 0 Seat belts and warning system 0 Air bag system using indicator light (Refer to section T) Ignition switch and steering lock 0 Starter interlock switch (clutch pedal) All lights, including warning, and indicator lights 0 Audible warning system 0 Horn, wipers, and washers Audio system 0 Cigarette lighter Power windows (if equipped) 0 Power outside mirrors (if equipped) 0 Heater, defroster, and air conditioner at all mode selections (if equipped) CHECK the following items: Presence of spare fuses 0 Upholstery and interior finish CHECK and ADJUST, if necessary, the following items: 0 Pedal height and free play of brake and clutch pedals I Pedal height mm {in} I Ft: $iy I Clutch pedal {6.89--7.28) (with carpet) Parking brake 7-9 notchesil96 N (20 kgf, 44 Ibf) 0.63.1 (0.024. 12) Brake pedal RUNNING AT OPERATING TEMPERATURE CHECK the following items: 0 Automatic transmission oil level 171-181 (6.73--7.13) (with carpet) I ON HOIST I 4--7 {0.16-0.28} CHECK the following items: 0 Underside fuel, coolant, and hydraulic lines, fittings, con- nections, and components for leaks 4 Tires for cuts or bruises 0 Steering linkage, suspension, exhaust system, and all underside hardware for looseness or damage Manual transmission oil level Differential oil level I ROAD TEST I CHECK the following items: Brake operation Clutch operation 0 Steering control 0 Operation of meters and gauges Squeaks, rattles and unusual noises 0 Overall engine performance Seat belt emergency locking retractors 0 Cruise control system (if equipped) I AFTER ROAD TEST I CHECK for necessary owner information materials, tools and spare tire in vehicle The following items must be done just before the delivery to your customer. 0 Load test battery and charge if necessary -1 Install fuses for accessories Adjust tire pressure to specification Load test fesuk 0 Remove seat and floor mat protective covers (Refer to Door Label) 0 Vacuum and clean interior of vehicle Clean outside of vehicle Inspect installation of option parts with invoice 45UOAX-002 Gartner Banana

Page 84 of 1708

INSPECTION I REPAIR INSPECTION 1 REPAIR PREPARATION SST 49 801 2 005 Remover & installer, valve guide Nut (Part of 49 LO1 2 OAO) For removal of valve guide 49 LO1 2 002 Body (Part of 49 LO 1 2 OAO) For installation of valve guide For installation of valve guide 49 LO1 2 OAO Installer set, 4 8 valve seal & valve guide t~@ Installer (Part of 49 LO1 2 OAO) For installation of valve guide For installation of valve guide 1. Clean all parts, being sure to remove all gasket fragments, dirt, oil or grease, carbon, moisture residue, and other foreign materials. 2. Inspection and repairs must be performed in the order specified. L 45UOBX485 CYLINDER HEAD 1. lnspect the cylinder head for damage, cracks, and leak- age of water and oil. Replace the cylinder head if neces- sary. 2. Measure the cylinder head distortion in the six directions shown in the figure. Distortion: 0.lOmm (0.004 in} max. 3. lnspect the following and repair or replace the cylinder head as necessary. (1) Sunken valve seats (2) Damaged intake and exhaust manifold contact sur- faces (3) Excessive camshaft oil clearances and end play 4. If the cylinder head distortion exceeds specification, grind the cylinder head surface. 5. If the cylinder head height is not within specification, re- place it. Height: 133.8-1 34.0mm (5.268-5.275 in) Grinding: O.lOmm (0.004 in} max. Gartner Banana

Page 86 of 1708

INSPECTION I REPAIR B WITH CARBON EX CUTTER 7. If the clearance exceeds specification, replace the valve and/or valve guide. 8. Measure height A of each valve guide. Replace the valve guide if necessary. Height: 18.3-18.9mm (0.7214.744 in) Replacement of valve guide Although the intake and exhaust valve guides are differ- ent, use the exhaust valve guide to replace the intake valve guide. Removal Remove the valve guide from the side opposite the com- bustion chamber with the SST. Installation 1. Assemble the SST so that depth L is as specified. Depth L: 18.3-18.9mm (0.7214.744 in) 2. Tighten the nut. 3. Tap the valve guide in from the side opposite the com- bustion chamber until the SST contacts the cylinder head. 4. Verify that the valve guide height is within specification. Height: 18.3-18.9mm (0.721-4.744 in) 5. If not, repeat steps 14. Gartner Banana

Page 88 of 1708

INSPECTION / REPAIR OUT-OF-SQUARE I 9. Measure the valve stem protruding length (dimension L). Dimension L: 45.0mm (1.772 in) (1) If L is 45.0-E.5mm (l.772-l.79l in), no correc- tion is needed. (2) If L is 45.5-46.5mm (1.792-1.830 in), adjust with washer on spring seat area of cylinder head. (3) If L is 46.5mm (1.831 in) or more, replace cylinder head. Valve Spring 1. lnspect each valve spring for cracks or damage. 2. Measure the free length and out-of-square. Replace the valve spring if necessary. Free length Standard: 46.26mm (1.821 in) Minimum length: 39.5mm (1.56 in) with a set load of 224--253 N (22.G25.8 kgf, 50.2-56.7 Ibf) Out-of-square: 1.62mm (0.0638 in) max. CAMSHAFT 1. Set the front and rear journals on V-blocks. 2. Measure the camshaft runout. Replace the camshaft if necessary. Runout: 0.03mm (0.0012 in) max. 3. lnspect the camshaft for wear or damage. Replace the camshaft if necessary. 4. Measure the cam lobe heights at the two points as shown. Height Standard IN: 44.094mm (1,7360 in) EX: 44.600mm (1.7560 in) Minimum IN: 43.894mm (1,7281 in) EX: 44.400mm (1.7480 in) Gartner Banana

Page 90 of 1708

INSPECTION / REPAIR B (9) Measure the oil clearances. Oil clearance:0.035-0.081 mm (0.0014--0.0031 in) Maximum: 0.15mm (0.006 in) (1 0) If the oil clearance exceeds specification, replace the cylinder head. 7. Measure the camshaft end play. If the end play exceeds specification, replace the camshaft andlor the cylinder head. End play: 0.074.1 9mm (0.0028-0.0074 in) Maximum: 0.20mm (0.008 in) HLA 1. lnspect the friction surfaces of each HLA for wear or damage. Replace the HLA if necessary - do not at- tempt to repair it. 2. Hold the bucket body and press the plunger by hand. If the plunger moves, it is defective. Replace the HLA - do not attempt to repair it. CYLINDER BLOCK 1. lnspect the cylinder block for the following. Repair or re- place the cylinder block as necessary. (1 ) Leakage damage (2) Cracks (3) Scoring of wall 2. Measure the distortion of the top surface of the cylinder block in the six directions shown in the figure. Distortion: 0.15mm (0.006 in) max. 3. If the distortion exceeds specification, repair by grinding or replace the cylinder block. Height: 221.5mm (8,720 in) Grinding: 0.20mm (0.008 in) max. Gartner Banana

Page 306 of 1708

CONTROL SYSTEM LOCK 4. If not as specified, replace the main relay. MAIN RELAY lnspection 1. Verify that the main relay clicks when turning the ignition switch OFF -+ ON. 2. Apply battery positive voltage to terminal A and ground terminal B of the main relay. 3. Use an ohmmeter to check continuity of the terminals as shown. CLUTCH SWITCH Inspection 1. Disconnect the clutch switch connector. 2. Connect an ohmmeter to the switch. 3. Check continuity of the switch. Battery positive voltage applied - Continuity - Terminals CD L 4. If not as specified, replace the clutch switch. Battery positive voltage not applied No continuity Pedal Depressed Released Replacement 1. Disconnect the clutch switch connector. 2. Loosen the locknut. 3. Remove the clutch switch. 4. Install in the reverse order of removal. 5. Adjust the pedal height. (Refer to Section H.) Continuity Yes No 4. If not as specified, replace the neutral switch. NEUTRAL SWITCH lnspection 1. Disconnect the neutral switch connector. 2. Connect an ohmmeter to the switch. 3. Check continuity of the switch. Transmission Neutral Other ranges Continuity , Yes No Gartner Banana

Page 338 of 1708

OUTLINE, TROUBLESHOOTING GUIDE H OUTLINE SPECIFICATIONS I Clutch control L' Clutch cover Clutch disc Clutch pedal - Enginerrransmission BP DOHC item - M15M-D 1 Master cvlinder inne I Hydraulic Inner diameter mm {in) I 150 (5.91) I Pressure plate side I n n rn cr Tvpe . . Set load N {kgf, Ibf) Outer diameter mm {in) Pedal ratio 6.13 Full stroke mm {in) I 120 (4.72) Diaphraam spring .-.- 4,310 (440,968) 21 5 18.46) . - Height mm {in) * diameter mm {in) TROUBLESHOOTING GUIDE . - I 75--185 i6.89--7.283 15.87 (0.625) . - Release cylinder inner diameter mm {in) Clutch fluid I Problem I Possible Cause 19.05 i0.750) FMVSS116 DOT-3 Clutch disc facing surface hardened or oil on surface Pressure plate damaged u Diaphragm spring damaged or weak lnsufficient clutch pedal play I Slipping I Clutch disc facing worn excessively I Flywheel damaged Faulty disengagement I Clutch disc damaged or excessive runout Clutch disc spines rusted or worn Oil on clutch disc facing Diaphragm spring weak Excessive clutch pedal play Insufficient clutch fluid Leakage of clutch fluid I 1 Clutch disc facing hardened or damaged Clutch vibrates when accelerating I I Clutch disc facing rivets loose Oil on clutch disc facing Torsion dampers weak Clutch pedal stlcks Abnormal noise Pressure plate damaged or excessive runout Flywheel surface hardened or damaged Loose or worn engine mount Pedal shaft not pro~erlv lubricated Clutch release collar damaged Poor lubrication of release collar sleeve Torsion dampers weak Excessive crankshaft end play I I Pilot bearing worn or damaged I I Worn ~ivot points of release fork Action Replace Repair or replace Repair or replace Replace Adjust ~ebair or replace Replace Remove rust or replace Repair or replace Replace Adjust Add fluid Locate and repair or replace Repair or replace Replace Repair or replace Replace Replace Repair or replace Tighten or replace Lubricate or replace Replace Lubricate or replace Replace Repair Replace Repair or replace Page H-14 H-14 H-14 H-14 H-14 H-14 section B H- 6 H-14 H-14 H-14 section B H-14 H-14 45UOHX-OC Gartner Banana

Page 340 of 1708

CLUTCHPEDAL H Minimum disengagement height: 68mm (2.68 in) (With carpet) CLUTCHPEDAL ADJUSTMENT Height lnspection 1. Measure the distance from the upper surface of the ped- al pad to the carpet. Pedal height: 175--185mm (6.89-7.28 in) (With carpet) 2. If necessary, adjust the height. Adjustment 1. Disconnect the clutch switch connector. 2. Loosen locknut @ and turn clutch switch @I until the height is correct. I 3. Tighten locknut @. Tightening torque: l3.Cl7.6 N-m (1 4Gl8O kgf-cm, 122-1 56 in-IM) 4. After adjustment, inspect the free play. Free Play lnspection 1. Depress the clutch pedal by hand until clutch resistance is felt. Free play: 0.6-3.lmm (0.02-0.12 in) Total free play: S13mm (0.20-0.51 in) 2. If necessary, adjust the free play. Adjustment 1. Loosen locknut 0 and turn push rod 03 until free play is correct. 2. Verify that the disengagement height as measured from the upper surface of the pedal pad to the carpet is correct when the pedal is fully depressed. 3. Tighten locknut 0. Tightening torque: 11 .&l6.6 N.m (120-1 70 kgtcm, 105--147 in.lbf} 4. After adjustment, inspect the height. Gartner Banana

Page 342 of 1708

CLUTCH PEDAL, CLUTCH MASTER CYLINDER H CLUTCH MASTER CYLINDER PREPARATION SST b 49 0259 7708 For disconnecting Wrench, flare and connecting nut clutch pipe Removal Note Spring 1. Place the clutch pedal assembly in the vise. 2. Pry the spring off the clutch pedal as shown in the figure. Installation Note Spring 1. Place the clutch pedal assembly in the vise. 2. Install the spring onto the clutch pedal as shown in the ~ - figure. 3. Adjust the clutch pedal height and free play after installa- tion. (Refer to page H-5.) Gartner Banana

Page 344 of 1708

CLUTCH MASTER CYLINDER H After-installation Procedure 1. Bleed the clutch system. (Below) I 2. Add fluid to the reservoir MAX mark. ' 3. Inspect and adjust the clutch pedal height and free play. (Refer to page H-5.) AIR BLEEDING The clutch hydraulic system must be bled to remove air introduced whenever a hydraulic line is disconnected. Caution Clutch fluid will damage painted surfaces. If clutch fluid does get on a painted surface, wipe it off immediately. 1. Remove the bleeder cap from the clutch release cylinder and attach a vinyl hose to the bleeder plug. 2. Insert the other end of the vinyl hose into a fluid-filled clear container. 3. Working with another person, have the person depress the clutch pedal several times, then hold it down. 4. With the clutch pedal depressed, loosen the bleeder screw by using the SST to let fluid and air escape. Close the bleeder screw. 5. Repeat steps 3 and 4 until no air bubbles are seen in the fluid. Make sure the reservoir is always 314 full or more during this procedure. 6. Modify the bleeder screw tightening torque to allow for use of a torque wrench-SST combination. (Refer to sec- tion GI "Torque Formulas".) 7. Tighten the bleeder screw by using the SST. Tightening torque: 5.9-8.8 N.m (60-90 kgf.cm, 53-78 in4bf) 8. Fill the reservoir to MAX with new fluid of the specified type. 9. Check for correct clutch operation. 10. Verify that there is no fluid leakage. Gartner Banana