ECU MAZDA MX-5 1994 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 634 of 1708

MANUAL STEERING N Removal Note Locknut Before loosening the locknut from the tie-rod end, make a reference mark for proper reinstallation. Tie-rod endlsteering knuckle Caution The sharp edges of the SST can slice the tie-rod end dust boot. Install the SST so that the sharp edges are between the dust boot and the knuckle. 1. Remove the cotter pin. 2. Loosen the nut until it is flush with the end of the ball stud. 3. Disconnect the tie-rod end from the knuckle by using the SST. Tie-rod end boot 1. Secure the tie-rod end in a vise. 2. Place a chisel against the boot and hold it at the angle shown. 3. Remove the boot by tapping it with a hammer. Installation Note Tie rod end boot 1. Wipe the grease off the ball joint. 2. Put a small amount of lithium-based grease into a new dust boot. 3. Install the dust boot onto the tie-rod end by using the SST and a press. 4. Wipe away any excess grease. Steering gear boot Verify that the boot is not twisted or dented. Gartner Banana

Page 643 of 1708

N MANUAL STEERING LOWER BEARING 1 IT-71 GEAR HOUSING FACE NSK MARK DOWNWARD 15UONX-018 VENTILATION HOLE 95AONX-02; RACK CENTRAL POSITION 95AONX-025 N-16 Lower bearing 1. Apply grease to a new lower bearing. 2. Set the lower bearing onto the pinion shaft so that the NSK mark on the bearing faces downward. u 3. Insert the pinion shaft together with the lower bearing. 4. Press the pinion shaft to seat the lower bearing. 5. Apply grease to the inside of the gear housing as shown. Rack 1. Secure the mounting bracket in a vise. 2. Apply grease to the rack bushing. 3. Apply grease to the rack teeth and the sliding surface. Caution Do not plug the ventilation holes with the grease. Caution Installing the rack from the tube side can damage the rack bushing by dragging the rack teeth across it. When installing the rack, install it slowly and carefully. 4. Slide the rack in from the tube side. Pinion shaft 1. Apply grease to the inner race of the upper bearing and install it to the pinion shaft. 2. Apply grease to the teeth of the pinion shaft. 3. Turn the flat section of the rack toward the pinion, and insert the pinion. Gartner Banana

Page 644 of 1708

MANUAL STEERING N Rear cover 1. Apply grease to the outer race of the upper bearing and install it in the gear housing. 2. Install a new oil seal to the rear cover. 3. Apply sealant to the threads of the rear cover and install it into the gear housing. 4. Rotate the pinion to the left and right a few times to seat the bearing. 5. Tighten the rear cover so that the starting torque of the pinion is 200-350 g (7.1-12.3 oz} as checked by using the SST and a pull gauge. 6. Tighten the locknut. Do not allow the rear cover to turn. Tightening torque: 50--68 N-m (5.0-7.0 kgf.m, 37-50 ft.lbf} Adjusting cover 1. Carefully move the rack so that the pinion is set to the center (neutral position) of the rack gear as shown. 2. Install the roller assembly, needle roller, holder, dish springs, friction block, and the spring as shown. 3. Torque the adjusting cover to 9.8 N.m (1 kgf-m, 85 in.lbf), then loosen it 25O45". Use the SST to secure the adjusting cover and the locknut. Tightening torque: 40-58 N.m (4.CL6.0 kgf-m, 29--43 ft-lbf} 4. Measure the starting torque of the pinion by using the SST. Center position + 90" Pull gauge reading: 1,000-1,400 g (35-50 oz} Any other position Pull gauge reading: less than 1,700 g (60 or) 5. If not within specification, repeat steps 2 and 3. Gartner Banana

Page 655 of 1708

N ENGINE SPEED SENSING POWER STEERING Tie rod 1. Uncrimp the washer. 2. Carefully remove the tie rod. Pinion shaft assembly 1. Secure the mounting bracket in a vise. 2. Remove the retaining ring. 3. Tap the pinion shaft with a punch to remove it. Plug assembly 1. Remove the plug assembly from the pinion shaft. 2. Press out the upper bearhg and oil'seal by using the SST. 3. Remove the O-ring from the plug. Steering rack assembly 1. Remove the stop ring with a pin punch. 2. Temporarily tighten the tie rod to the tube side and pull it carefully to remove the rack. Backup ring and oil seal Tap the SST from the gear housing side to remove the backup ring and the oil seal. Gartner Banana

Page 659 of 1708

N ENGINE SPEED SENSING POWER STEERING 7. Attach the SST to the pinion and install the plug assem- bly. Adjusting cover 1. Tighten the mounting bracket in a vise. 2. Set the rack to the center position. 3. Tighten the adjusting cover to 4.9 N.m (50 kgf.cm, 43 in4bf) with the SST three times, then return it 25". 4. Apply sealant to the threads of the locknut. 5. Attach the locknut. 6. Measure the pinion torque by using the SST and a pull scale. Standard Center of rack + 90": 1 .O-1 .I N-m {I 0-1 2 kgf-cm, 8.7-1 0.4 in-lbf) ii Scale reading: 1 .&I .2 kg (2.2-2.64 Ib) 7. If not within specification, repeat steps 3 through 6. 8. Install the locknut. Tightening torque: 59-74 N.m (6.0-7.5 kgf.m, 44--54 ftdbf) Hermetic sealing inspection 1. Connect the SST to the power cylinder section of the gear housing. 2. Apply 53.3 kPa (400 mmHg, 15.7 inHg) vacuum with a vacuum pump and verify that it is held for at least 30 seconds. 3. If the vacuum is not held, replace the oil seal. Tie rod 1. Secure the rack gear in a vise, and tighten the tie rods with the wrench. Tightening torque: 79-98 N.m (8.0-10.0 kgf-m, 58-72 ft-lbf) 2. Align the washer with the rack groove, and crimp the washer. Gartner Banana

Page 663 of 1708

N ENGINE SPEED SENSING POWER STEERING Disassembly Note Oil pump Use the SSTwhen securing the oil pump in a vise, so that force is not applied to the pulley or shaft. Inspection Pump body front, rear lnspect the front and rear of the pump body for cracks and damage, and the friction surface of the rotor for wear. Replace the pump assembly if a problem is found. Cam ring, rotor, blade, side plate 1. lnspect the blade friction surface of the cam ring for wear. 2. lnspect the pump body of the rotor and side plate friction surface for wear. 3. lnspect the cam ring friction surface of the blade for -, wear. 4. lnspect clearance between the rotor and blade. Control valve, spring 1. lnspect the control valve for cracks, damage and block- age, and the friction surface for wear. 2. lnspect the spring for damage. Assembly Note Rotor Install the rotor with the indentification mark facing upward. Gartner Banana

Page 683 of 1708

BRAKE SYSTEM Disassembly / Assembly / lnspection 1. After removing the brake fluid, disassemble in the order shown in the figure. 2. lnspect all parts and repair or replace as necessary. 3. Assemble in the reverse order of removal, referring to Assembly Note. Caution The brake master cylinder Is made of aluminum, and can be easily damaged by tightening in a vise. When securing the master cylinder in a vise, tighten only the master cylinder flange. 1. Fluid level sensor connector 7. Snap ring Inspection ................... page P-17 8. Snap ring and spacer (ABS) 2. Screw 9. Primarv ist ton assemblv 3. Reservoir assembly inspect for abnormal wear, rust, and damage Inspect for damage and deformation 10. Secondary piston assembly 4. Bushings Inspect for abnormal wear, rust, and damage 5. Stop screw and O-ring 11. Master cylinder body e Assembly Note .............. page P-19 Inspect for abnormal wear, rust, and damage 6. Stop pin and O-ring (ABS) Replace unit as an assembly if damaged Assembly Note .............. page P-19 Gartner Banana

Page 716 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P ABS CONTROL UNIT 35-PIN CONNECTOR OHMMETER 15UOPX-OI Check rotor Check the rotor for missing or damaged teeth and replace as necessary. Check alternator Refer to section G. Check wheel-speed sensor Caution To prevent damage to the terminals, create a probe by wrapping a thin wire around the tester lead before inserting. 1. Using an ohmmeter, check for continuity at the control unit connector terminals. 0----0: Indicates continuity Right front Left rear Right rear 2. If the continuity is not as specified, check the wiring har- ness (Wheel-speed sensor - Control unit). 3. If the continuity is OK, check voltage between 1K and 1 G, 10 and 1 Q, 1 U and 1 F, and 1 L and 1 P while rotating the wheel one rotation per second by hand. 4. If voltage is not approximately 50 mV--60 mV, the wheel-speed sensor is faulty. 5. If voltage is approximately 50 mV-60 mV, the control unit is faulty. 1L Check hydraulics Verify that all brake fluid connections are tight and that no fluid is leaking. IP 1Q Left front 0--0 Check hydraulic unit wiring 1. Verify that the hydraulic unit connectors are properly secured. 2. Verify that the valve relay and motor relay are properly secured. IG 1K 0-4 1U 10 S-0 IF 0-4 Gartner Banana

Page 719 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) Disassembly 1 Assembly 1. Disassemble in the order shown in the figure. 2. Assemble in the reverse order of disassembly, referring to Assembly Note. 2.2-2.6 Nm [22-27 kgfcm, 2&29 [2--3,14--22) 6.9-9.8 Nm (70-1 00 kgfcm, 81-47 Inlbf) 1 15--25 11 S-2.5,11-18) 19-25 [1.92.6,14--19) t4.m [kgfm, Wlbf) 25uopx-o: 1. Nut, washer . 2. ABS bracket 3. Connector bolt 4. Gasket 5. Pipe joint 6. Bolt 7. Clip Installation Note 8. Cover 9. Motor relay ................... Inspection page P-56 10. Valve relay ................... Inspection page P-57 11. Casing 12. Mount 13. Stud ................. below 14. Nut, washer 15. Ground wire 16. Hydraulic unit Assembly note A SECTION A-A Clip Secure only the larger part of the wiring harness in the clips. The 2-pin connector part of the harness should re- main outside the clips. Gartner Banana

Page 745 of 1708

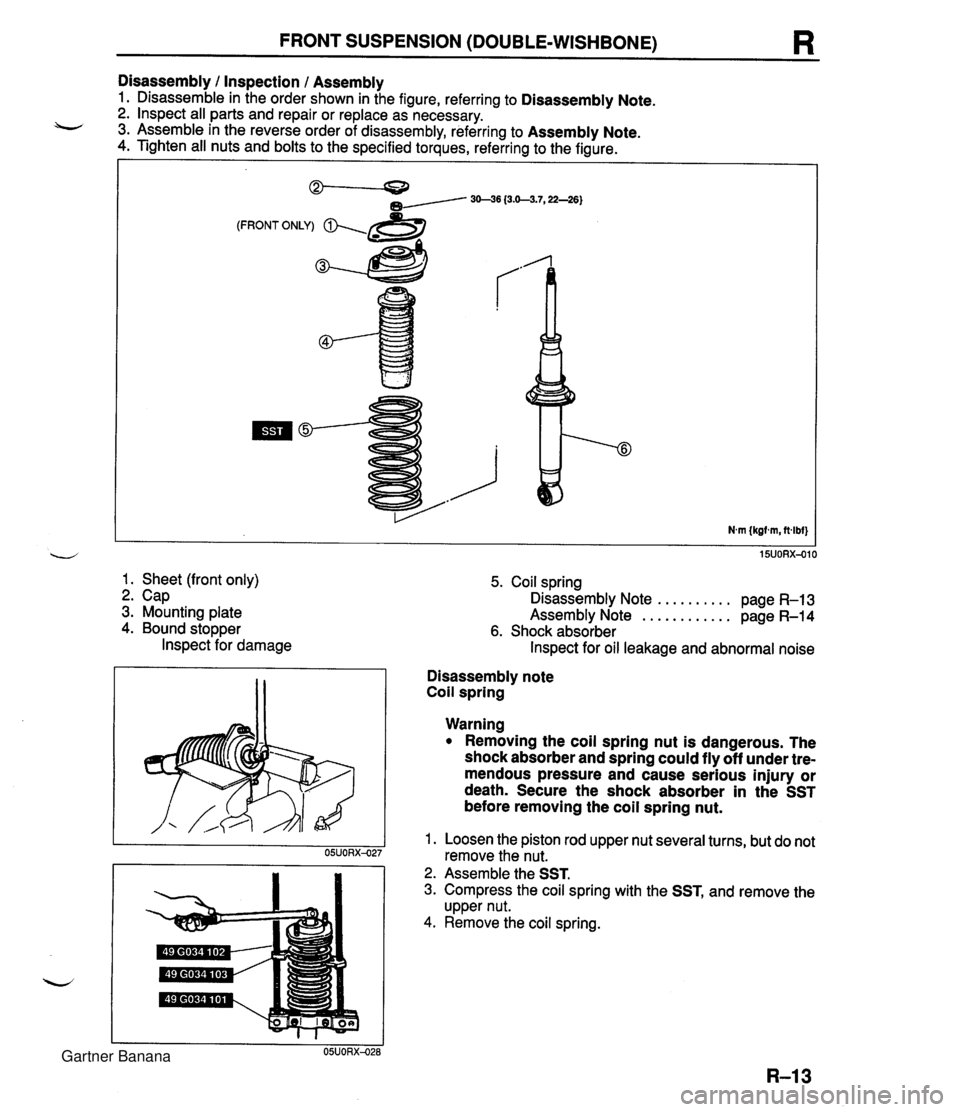

FRONT SUSPENSION (DOUBLE-WISHBONE) R Disassembly I Inspection I Assembly 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. lnspect all parts and repair or replace as necessary. 3. Assemble in the reverse order of disassembly, referring to Assembly Note. 4. Tighten all nuts and bolts to the specified torques, referring to the figure. (FRONT ONLY) & 3 1. Sheet (front only) 2. Cap 3. Mounting plate 4. Bound stopper lnspect for damage 5. Coil spring .......... Disassembly Note page R-13 ............ Assembly Note page R-14 6. Shock absorber lnspect for oil leakage and abnormal noise Disassembly note Coil spring Warning Removing the coil spring nut is dangerous. The shock absorber and spring could fly off under tre- mendous pressure and cause serious injury or death. Secure the shock absorber in the SST before removing the coil spring nut. 1. Loosen the piston rod upper nut several turns, but do not remove the nut. 2. Assemble the SST. 3. Compress the coil spring with the SST, and remove the upper nut. 4. Remove the coil spring. Gartner Banana