lock MAZDA MX-5 1994 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 82 of 1708

DISASSEMBLY Disassembly Note Connecting rod cap Before removing the connecting rod caps, measure the connecting rod side clearance. (Refer to page 8-64.) Connecting rod and piston assembly 1. Before removing the connecting rod and piston assem- bly, measure the connecting rod oil clearance. (Refer to page 8-64.) 2. Remove the Plastigage from the crankpin journals. 3. Use the handle of a hammer to remove the piston and connecting rod assembly through the top of the cylinder block. Piston ring Remove the piston rings with a piston ring expander (commercially available). Piston pin Remove the piston pin with the SST. Gartner Banana

Page 88 of 1708

INSPECTION / REPAIR OUT-OF-SQUARE I 9. Measure the valve stem protruding length (dimension L). Dimension L: 45.0mm (1.772 in) (1) If L is 45.0-E.5mm (l.772-l.79l in), no correc- tion is needed. (2) If L is 45.5-46.5mm (1.792-1.830 in), adjust with washer on spring seat area of cylinder head. (3) If L is 46.5mm (1.831 in) or more, replace cylinder head. Valve Spring 1. lnspect each valve spring for cracks or damage. 2. Measure the free length and out-of-square. Replace the valve spring if necessary. Free length Standard: 46.26mm (1.821 in) Minimum length: 39.5mm (1.56 in) with a set load of 224--253 N (22.G25.8 kgf, 50.2-56.7 Ibf) Out-of-square: 1.62mm (0.0638 in) max. CAMSHAFT 1. Set the front and rear journals on V-blocks. 2. Measure the camshaft runout. Replace the camshaft if necessary. Runout: 0.03mm (0.0012 in) max. 3. lnspect the camshaft for wear or damage. Replace the camshaft if necessary. 4. Measure the cam lobe heights at the two points as shown. Height Standard IN: 44.094mm (1,7360 in) EX: 44.600mm (1.7560 in) Minimum IN: 43.894mm (1,7281 in) EX: 44.400mm (1.7480 in) Gartner Banana

Page 90 of 1708

INSPECTION / REPAIR B (9) Measure the oil clearances. Oil clearance:0.035-0.081 mm (0.0014--0.0031 in) Maximum: 0.15mm (0.006 in) (1 0) If the oil clearance exceeds specification, replace the cylinder head. 7. Measure the camshaft end play. If the end play exceeds specification, replace the camshaft andlor the cylinder head. End play: 0.074.1 9mm (0.0028-0.0074 in) Maximum: 0.20mm (0.008 in) HLA 1. lnspect the friction surfaces of each HLA for wear or damage. Replace the HLA if necessary - do not at- tempt to repair it. 2. Hold the bucket body and press the plunger by hand. If the plunger moves, it is defective. Replace the HLA - do not attempt to repair it. CYLINDER BLOCK 1. lnspect the cylinder block for the following. Repair or re- place the cylinder block as necessary. (1 ) Leakage damage (2) Cracks (3) Scoring of wall 2. Measure the distortion of the top surface of the cylinder block in the six directions shown in the figure. Distortion: 0.15mm (0.006 in) max. 3. If the distortion exceeds specification, repair by grinding or replace the cylinder block. Height: 221.5mm (8,720 in) Grinding: 0.20mm (0.008 in) max. Gartner Banana

Page 94 of 1708

INSPECTION / REPAIR B MAIN JOURNAL I I DIMENSION R: 1.5mm (0.06 in} I CRANKSHAFT 1. Check the journals and pins for damage, scoring, and oil hole clogging. 2. Set the crankshaft on V-blocks. 3. Measure the crankshaft runout at the center journal. Replace the crankshaft if necessary. Runout: 0.04mm (0.0016 in) max. 4. Measure each journal diameter in X and Y directions at two points. Main journal Diameter: 49.938-49.956mm (1.9661-1.9667 in) Out-of-round: 0.05mm (0.0020 in) max. Crankpin journal Diameter: 44.94044.956mm 11.7693--1.7699 in) Out-of-round: 0.05mm (0.0020 in) max. 5. If the diameter is less than the minimum, grind the jour- nals to match an undersize bearing. Undersize bearing: 0.25mm (0.010 in), 0.50mm (0.020 in}, 0.75mm (0.030 in) Main journal diameter undersize mm {in) I bear in^ size I Diameter I 10.25 {0.010) undersize 1 49.70449.708 (1.9569--1.9570) 1 Main journal diameter undersize mm {in} 0.50 {0.010) undersize 0.75 {0.030) undersize I Bearing size I Diameter I 49.454--49.458 {I .9479-11.9471) 49.20449.208 11.9372-1.9373) ( 0.25 {0.010} undersize 1 44.690-44.706 {I .7595--1.7600) 1 BEARING Main Bearing and Connecting Rod Bearing Check the main bearings and the connecting rod bear- ings for peeling, scoring, and other damage. 0.50 {0.010) undersize - 0.75 (0.030) undersize 44.440-44.456 (1.7497-1.7502) 44.19044.206 (1.7398-1.7403) Gartner Banana

Page 97 of 1708

ASSEMBLY 1. Do not reuse gaskets or oil seals. 2. Clean all parts before reinstallation. 3. Apply new engine oil to all sliding and rotating parts. 4. Replace plain bearings if they are peeled, burned, or otherwise damaged. 5. Tighten all bolts and nuts to the specified torques. CYLINDER BLOCK (INTERNAL PARTS) Torque Specifications CYLINDER WALLS I#- WASHER, NEW JOURNALS AND BEARINGS NEW Connecting Rod and Piston Assembly 1. Install one piston pin clip into the clip groove in the pis- ton. 2. Assemble the piston and the connecting rod. 3. Apply clean engine oil to the piston pin. 4. Install the piston pin from the side opposite the clip. 5. Tap the piston pin in with the SST until the pin contacts the clip. . , If the pin cannot be installed easily, replace the connect- ing rod. 6. Install the second clip into the clip groove in the piston. Gartner Banana

Page 99 of 1708

B ASSEMBLY I PLASTIGAGE I Oil Jet lnstall the oil jets. Tightening torque: 12-1 7 N.m (1.2-1.8 kgf.m, 9-1 3 ft4bf) Crankshaft 1. Before installing the crankshaft, inspect the main bear- ing oil clearances as follows. Oil clearance inspection (1) Remove all foreign material and oil from the journals and bearings. (2) lnstall the grooved upper main bearings in the cylin- der block. (3) lnstall the thrust bearings with the oil groove facing the crankshaft. (4) Set the crankshaft in the cylinder block. (5) Position plastigage atop the journals in the axial direction. (6) Do not rotate the crankshaft when measuring the oil clearances. Install the lower main bearings and the main bearing caps according to the cap number and + mark. Tighten the main bearing cap bolts in two or three steps in the order shown in the figure. Tightening torque: 54--58 N-m I5.5--6.0 kgf.m, 40-43 ft4bf) (9) Remove the main bearing caps, and measure the plastigage at each journal at the widest point for the smallest clearance, and at the narrowest point for the largest clearance. (10) If the oil clearance exceeds specification, grind the crankshaft and use undersize main bearings. (Refer to page B-57.) , d' Oil clearance: 0.018-0.036mm (0.0008--0.0014 in) Maximum: 0.lOmm (0.004 in) Gartner Banana

Page 101 of 1708

ASSEMBLY , MATCHINGMARKS A SIDE CLEARANCE 1 2. Apply a liberal amount of clean engine oil to the cylinder walls, pistons, and piston rings. 3. Check the piston rings for correct end gap alignment. 4. Insert each piston assembly into the cylinder block with ..-, the F mark facing the front of the engine. Use a piston ring compressor (commercially available). Connecting Rod Cap 1. Align the matching marks on the cap and the connecting rod and install the connecting rod cap. 2. Measure the connecting rod bearing oil clearances us- ing the same procedure as for the main bearing oil clear- ance. Tightening torque: 48-50 N.m (4.8-5.1 kgf.m, 35--36 ftlbf} Oil clearance: 0.020-0.044mm (0.0008-0.0017 in) Maximum: 0.lOmm (0.004 in) 3. If the oil clearance exceeds the maximum, grind the crankshaft and use undersize bearings. (Refer to page 8-57.) U' 4. Measure the connecting rod side clearances. Side clearance: 0.11 O4.262rnm (O.OO44-O.OIO3 in) Maximum: 0.30mm (0.01 2 in) 5. If the clearance exceeds the maximum, replace the con- necting rod and cap. Apply a liberal amount of clean engine oil to the crank pin journals and connecting rod bearings. Install the connecting rod caps with the matching marks aligned. 8. Tighten the connecting rod cap nuts in two or three steps. Tightening torque: 48-50 N-m (4.8-5.1 kgf-m, 35--36 ftdbf) Gartner Banana

Page 102 of 1708

ASSEMBLY B CYLINDER BLOCK (EXTERNAL PARTS) Torque Specifications 7.9-10.7 Nm (80-110 kgfwn, 70--95.4 in4bf) OIL SEAL. NEW 7.9-10.7 Nm (80-110 kgfcm, 7045.4 Indbf) Nm (kgf m, ftlbf) 05UOBX-198 Rear Cover 1. Apply a small amount of clean engine oil to the lip of a new oil seal. 2. Push the oil seal slightly in by hand. 3. Using a pipe, press the oil seal in evenly until it is flush with the edge of the rear cover. L Note Oil seal outer diameter: 100mm (3.94 in} Oil seal inner diameter: 83mm (3.27 in} Gartner Banana

Page 105 of 1708

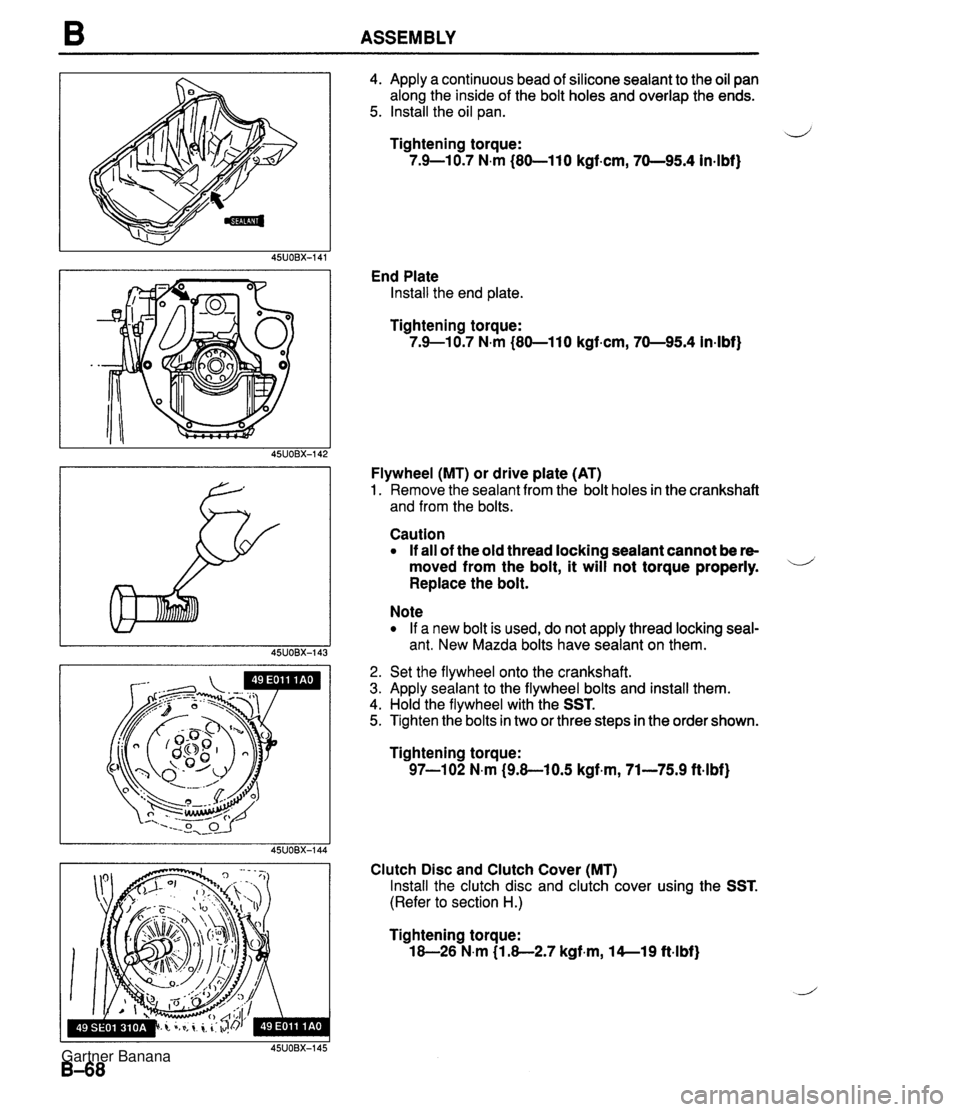

B ASSEMBLY 4. Apply a continuous bead of silicone sealant to the oil pan along the inside of the bolt holes and overlap the ends. 5. Install the oil pan. ij Tightening torque: 7.9-10.7 N.m (80-110 kgf-cm, 70-95.4 in4bf) End Plate Install the end plate. Tightening torque: 7.9--10.7 N.m (80-110 kgf.cm, 70-95.4 in-lbf) Flywheel (MT) or drive plate (AT) 1. Remove the sealant from the bolt holes in the crankshaft and from the bolts. Caution If all of the old thread locking sealant cannot be re- moved from the bolt, it will not torque properly. - Replace the bolt. Note If a new bolt is used, do not apply thread locking seal- ant. New Mazda bolts have sealant on them. 2. Set the flywheel onto the crankshaft. 3. Apply sealant to the flywheel bolts and install them. 4. Hold the flywheel with the SST. 5. Tighten the bolts in two or three steps in the order shown. Tightening torque: 97-102 N.m (9.8-10.5 kgf+m, 71-75.9 ft.lbf) Clutch Disc and Clutch Cover (MT) Install the clutch disc and clutch cover using the SST. (Refer to section H.) Tightening torque: 18-26 N.m (1.8-2.7 kgf.m, 14--19 ftlbf) Gartner Banana

Page 108 of 1708

ASSEMBLY Cylinder Head Gasket 1. Remove all foreign material from the top of the cylinder block. 2. Place the new cylinder head gasket in position. Cylinder Head 1. Install the cylinder head. 2. Apply clean engine oil to the bolt threads and seat faces. 3. Tighten the cylinder head bolts in two or three steps in the order shown. Tightening torque: 76-81 N-m (7.7--8.3 kgf.m, 56-60 ft4bf) Thermostat Housing 1. Remove all foreign material from the thermostat housing mounting surface. 2. Install a new O-ring and the thermostat housing. Tightening torque: 19-25 N.m (1.9-2.6 kgf.m, 14--18 ft-lbf) Seal Plate Install the seal plate on the cylinder head. Tightening torque: 7.9-10.7 N-m (80-110 kgfem, 70-95.4 in4bf) HLA 1. Apply clean engine oil to the friction surfaces. 2. If the HLA are being reused, install them in the position from which they were removed. 3. Verify that the HLA move smoothly in their bores. Gartner Banana