brake MAZDA MX-5 1994 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 540 of 1708

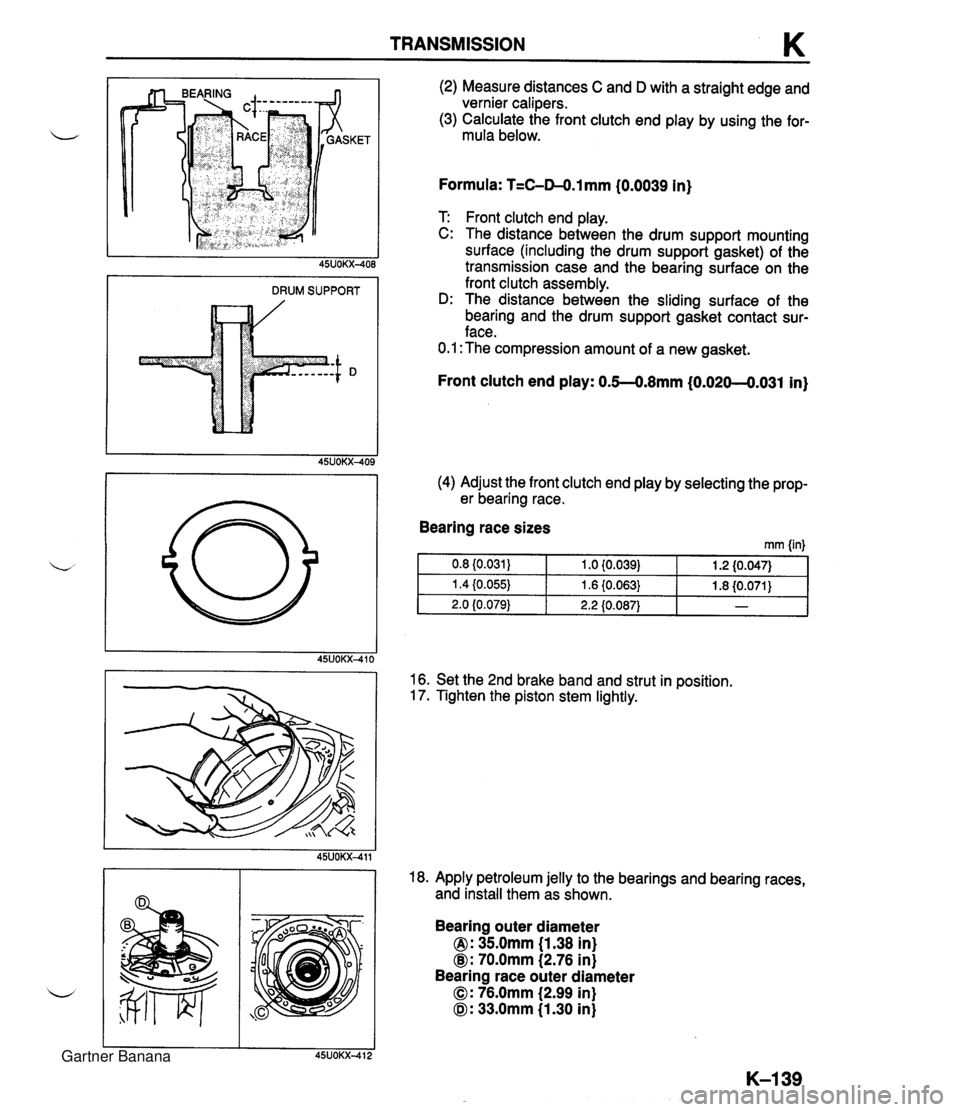

TRANSMISSION K DRUM SUPPORT (2) Measure distances C and D with a straight edge and vernier calipers. (3) Calculate the front clutch end play by using the for- mula below. Formula: T=C-04.1 mm {0.0039 In) T Front clutch end play. C: The distance between the drum support mounting surface (including the drum support gasket) of the transmission case and the bearing surface on the front clutch assembly. D: The distance between the sliding surface of the bearing and the drum support gasket contact sur- face. 0.1 :The compression amount of a new gasket. (4) Adjust the front clutch end play by selecting the prop- er bearing race. Front clutch end play: 0.5--0.8mm (0.020--0.031 in) Bearing race sizes rnm (in) 16. Set the 2nd brake band and strut in position. 17. Tighten the piston stem lightly. 18. Apply petroleum jelly to the bearings and bearing races, and install them as shown. Bearing outer diameter 0: 35.0mm (1.38 in) @: 70.0mm (2.76 in) Bearing race outer diameter 0: 76.0mm (2.99 in) 0: 33.0mm (1.30 in) Gartner Banana

Page 543 of 1708

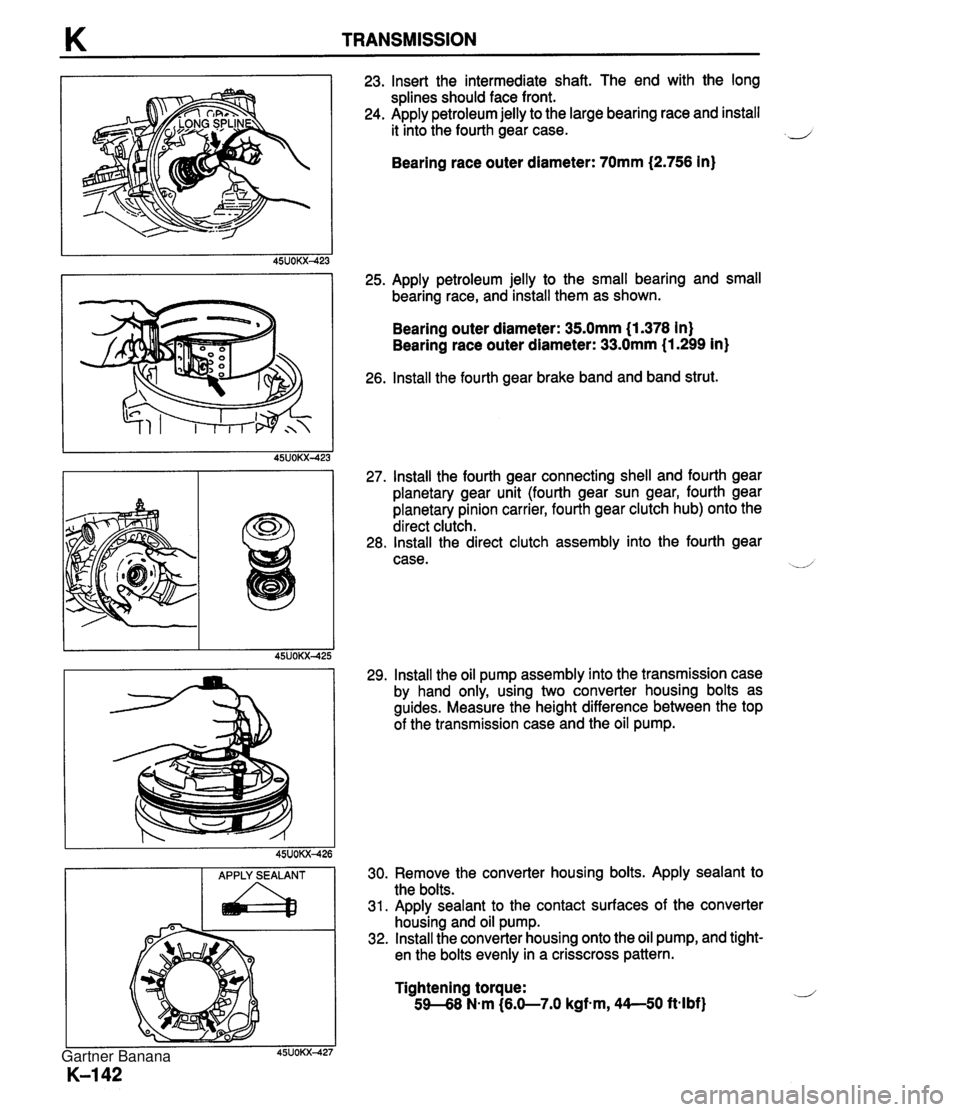

K TRANSMISSION APPLY SEALANT a 23. Insert the intermediate shaft. The end with the long splines should face front. 24. Apply petroleum jelly to the large bearing race and install it into the fourth gear case. 2 Bearing race outer diameter: 70mm (2.756 in) 25. Apply petroleum jelly to the small bearing and small bearing race, and install them as shown. Bearing outer diameter: 35.0mm (1.378 in) Bearing race outer diameter: 33.0mm (1.299 in) 26. lnstall the fourth gear brake band and band strut. 27. lnstall the fourth gear connecting shell and fourth gear planetary gear unit (fourth gear sun gear, fourth gear planetary pinion carrier, fourth gear clutch hub) onto the direct clutch. 28. lnstall the direct clutch assembly into the fourth gear case. --/ 29. lnstall the oil pump assembly into the transmission case by hand only, using two converter housing bolts as guides. Measure the height difference between the top of the transmission case and the oil pump. 30. Remove the converter housing bolts. Apply sealant to the bolts. 31. Apply sealant to the contact surfaces of the converter housing and oil pump. 32. lnstall the converter housing onto the oil pump, and tight- en the bolts evenly in a crisscross pattern. Tightening torque: 59-68 N-m (6.0-7.0 kgfm, 44--50 ft4bf) Gartner Banana

Page 544 of 1708

TRANSMISSION K 33. Apply ATF to the piston stem. 34. Adjust the 2nd brake band. (1) Loosen the locknut and tighten the piston stem. Tightening torque: 12.3--14.2 N-m (125--145 kgf-cm, lOg--l25 in-lbf) (2) Loosen the stem the number of turns shown below. Stem: 2 112 turns (3) Hold the stem and tighten the locknut. Tightening torque: 15-39 N.m (1.5-4.0 kgf-m, 11-28 ft-lbf) Caution Applying compressed air to the servo piston for longer than 3 seconds at a time will damage the seal. 35. Check the servo piston operation by applying com- pressed air through the oil passages of the 2nd band servo. @: Engage @: Release Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. 36. Apply ATF to the piston stem. Adjust the fourth gear brake band. (1) Loosen the locknut and tighten the piston stem. Tightening torque: 12-15 N-m (1.2-1.5 kgf-m, 8.7-11 ft-lbf) 11.8-14.7 N-m (1 20-150 kgf.cm, 105-1 30 in-lbf) (2) Loosen the stem the number of turns shown below. Stem: 2 turns Gartner Banana

Page 553 of 1708

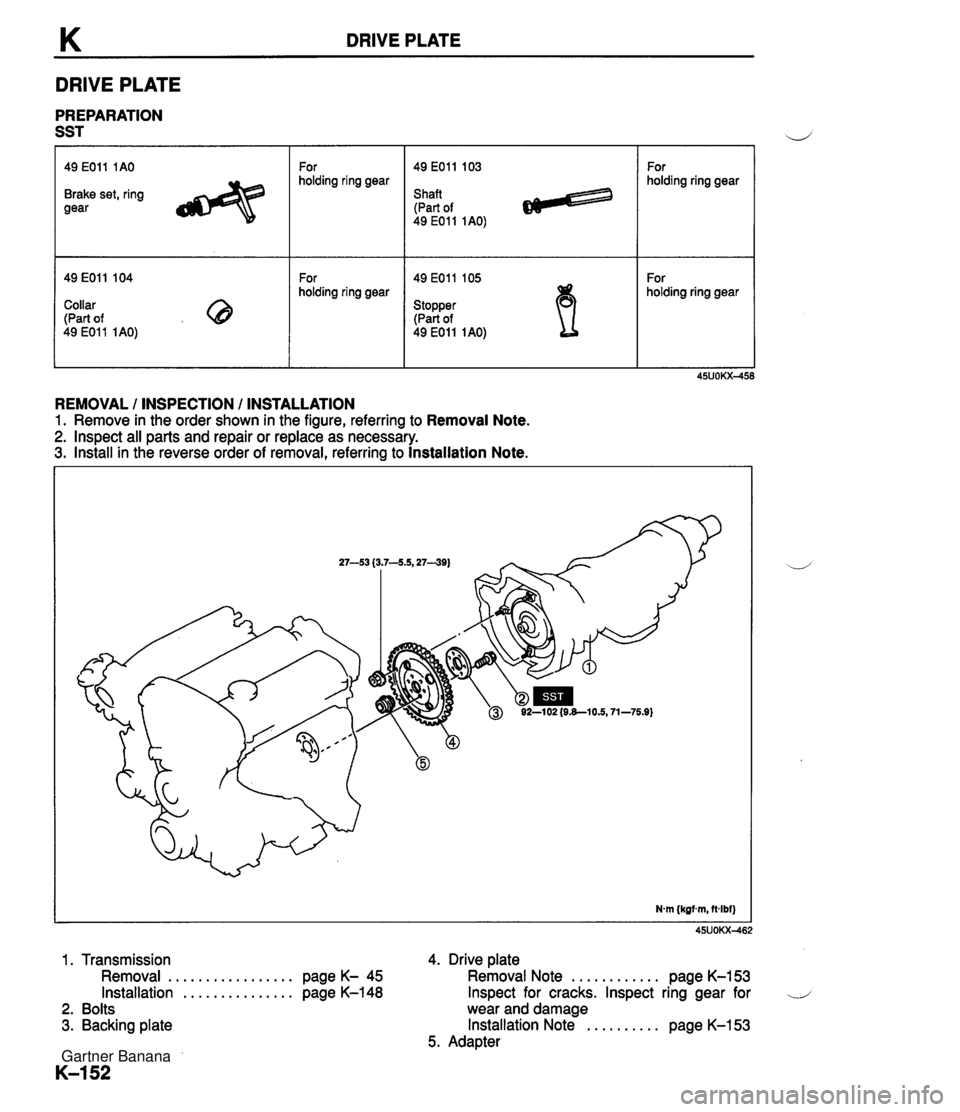

K DRIVE PLATE DRIVE PLATE PREPARATION SST Brake set, ring gear 49 EOll 104 Collar (Part of 49 E011 1AO) For holding ring gear For holding ring gear 49 EOll 103 Shaft (Part of - - 49 EOl 1 1 AO) Stopper (Part of 49 EOll 1AO) REMOVAL I INSPECTION I INSTALLATION 1. Remove in the order shown in the figure, referring to Removal Note. 2. lnspect all parts and repair or replace as necessary. 3. Install in the reverse order of removal, referring to Installation Note. For holding ring gear For holding ring gear 1. Transmission 4. Drive plate Removal ................. page K- 45 Removal Note ............ page K-153 Installation ............... page K-148 Inspect for cracks. Inspect ring gear for .J 2. Bolts wear and damage 3. Backing plate Installation Note .......... page K-153 5. Adapter Gartner Banana

Page 556 of 1708

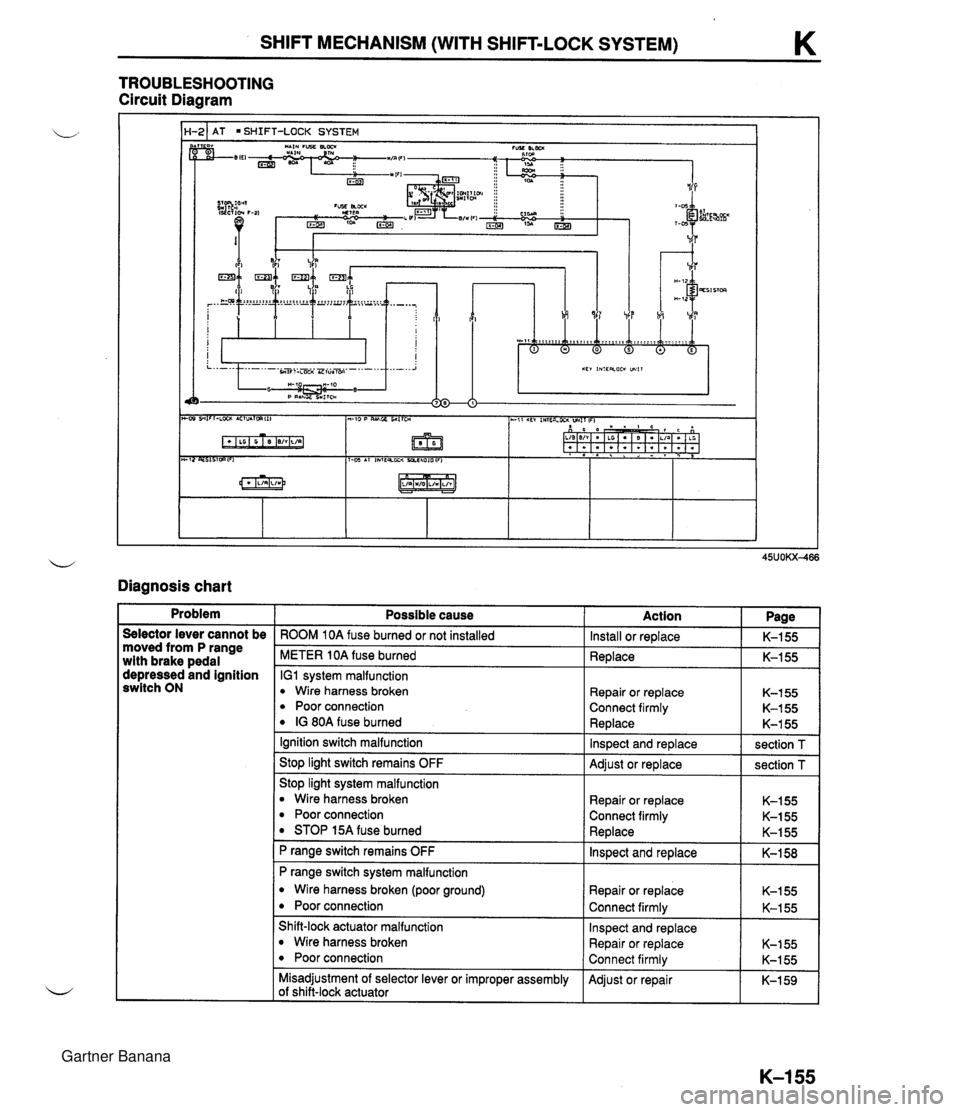

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K TROUBLESHOOTING Circuit Diagram - 1-21 AT SHIFT-LOCK SYSTEM Diagnosis chart Problem -- Selector lever cannot be moved from P range with brake pedal depressed and ignition switch ON Possible cause ROOM 1 OA fuse burned or not installed METER 10A fuse burned IG1 system malfunction Wire harness broken Poor connection IG 80A fuse burned Ignition switch malfunction Stop light switch remains OFF Stop light system malfunction Wire harness broken Poor connection STOP 15A fuse burned P range switch remains OFF P range switch system malfunction Wire harness broken (poor ground) Poor connection Shift-lock actuator malfunction Wire harness broken Poor connection Misadjustrnent of selector lever or improper assembly of shift-lock actuator Action I Page Repair or replace Connect firmly Replace Install or replace Replace K-155 K-155 Repair or replace K-155 Connect firmly K-155 Replace K-155 Inspect and replace Adjust or replace section T section T Repair or replace Connect firmly Inspect and replace Repair or replace Connect firmly Adjust or repair K-155 K-I55 K-155 K-155 K-159 Gartner Banana

Page 557 of 1708

K ' SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) Problem Possible cause Selector lever can be ROOM 1OA fuse burned or not installed moved lrom nnp. [stop light switch remains ON with ignition switch ON, but without brake pedal I Shift-lock actuator malfunction depressed Misadjustment of selector lever or improper assembly of shift-lock actuator Selector lever can be ROOM 10A fuse burned or not installed range Ignition switch malfunction with ignition switch OFF and brake pedal de- Shift-lock actuator malfunction pressed Misadjustrnent of selector lever or improper assembly of shift-iock actuator Shift-lock actuator op- P range switch remains ON eration heard when brake pedal depressed ' Misadjustment of selector lever or improper assembly with ignition switch ON of shift-lock actuator in other than P range Action -- Install or replace Adjust or replace lnspect and replace Adjust or replace Install or replace Inspect and replace inspect and replace Adjust or replace Inspect and replace Adjust or replace section T K-159 Selector lever remains locked when emergency override button oper- ated Emergency override button not pushed fully down Broken emergency override button lgnitlon key can be turned to lock position with selector lever in other than P range Push down fully and hold emergency override but- Misadjustment of indicator pedal ROOM 10A fuse burned or not installed Key interlock solenoid malfunction Wire harness broken Poor connection P range switch remains ON P range switch system malfunction Wire harness broken Poor connection lnspect and replace Repair or replace Connect firmly Adjust Install or replace K-161 - K-151 Inspect and replace Repair or replace Connect firmly I lanition kev cannot be I P ranae switch remains OFF I lns~ect and replace 1 K-158 I K-159 K-166 K-166 Key cylinder (push switch) malfunction Wire harness broken Poor connection Key interlock unit malfunction I ~~~~~$1~~~~ I Key iierlock solenoid malfunction I' I I Inspect and replace I K-158 I range Inspect and replace Repair or replace Connect firmly Inspect and replace Key cylinder (push switch) malfunction I Inspect and replace I section T section T K-155 K-155 section T I I Misadjustment of selector lever 1 Adjust I K-160 ] Gartner Banana

Page 558 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K POSSlBLt TO SHIFT c3 BRAKEPEDAL DEPRESSED 45UOKX42! EMERGENCY OVERRIDE BUTTON '

+ I SHIFT TO P RANGE 1 SHIFT-LOCK lnspection 1. Turn the ignition switch to ON engine OFF. 2. Verify that the selector lever is in P range. 3. Without the brake pedal depressed, verify that the selec- tor lever cannot be shifted from P range. 4. Depress the brake pedal and verify that the selector le- ver can be shifted from P range. 5. If not as specified, check the P range switch continuity andlor shift-lock actuator terminal voltage and continu- ity. (Refer to pages K-159.) EMERGENCY OVERRIDE BUTTON lnspection 1. Verify that the engine is off. 2. Verify that the selector is locked in P range. 3. Remove the indicator panel cover with the screwdriver as shown. 4. Insert the screwdriver into the emergency override hole, push down, and verify that the selector lever can be shifted from P range. 5. If not as specified, inspect and repair as necessary, re- ferring to the Troubleshooting diagnosis chart. (Refer to pages K-155.) KEY INTERLOCK lnspection 1. Turn the ignition switch to ON engine OFF. 2. Shift the selector lever to R range. 3. Verify that the ignition key cannot be turned to the LOCK position. 4. Shift the selector lever to P range. 5. Verify that the ignition key can be turned to the LOCK position. 6. If not as specified, inspect and repair as necessary, re- ferring to Troubleshooting. (Refer to pages K-155.) KEY INTERLOCK SOLENOID lnspection 1. Disconnect the negative battery cable. 2. Remove the column cover. 3. Disconnect the key interlock solenoid connector. 4. Insert the ignition key in the key cylinder. 5. Apply battery voltage between terminals 6 and C, and verify that the solenoid operates. 6. If not as specified, replace key interlock solenoid. 7. Connect the key interlock solenoid connector. 8. Install the column cover. 9. Connect the negative battery cable. Gartner Banana

Page 561 of 1708

K SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) CONNECTOR B CONNECTOR A 3. Lift up slightly on the selector lever, selector sleeve, and indicator panel, and disconnect the hold switch connec- tor. 4. Disconnect the HOLD switch connector. .--' 5. Shift the selector lever to P range. 6. Turn the ignition switch ON, and check terminal voltages and continuity, referring to the chart below. Disconnect the shift-lock actuator connector to check continuity be- tween terminal c (harness side) and ground. 7. If not as specified, repair the wiring harness and/or shift- lock actuator. I ~~UOKX-477 B+: Battery positive voltage I Connector I Terminal connectd to l terminal I Condition I Correct measurement vaive I I 1 I I A a B-C I P range, selector lever release button not depressed I OR I lBl e I B I P ranae, selector lever release button not depressed I OV I A B B B B 8. Grasp the HOLD switch wiring harness and pull it while pushing the selector knob down fully onto the selector le- ver. 9. Connect the HOLD switch connector. 10. Adjust the indicator panel. (Refer to page K-161.) Install the screws in the order shown in the figure. 11. Apply locking compound to the selector knob screw threads after the threads have been cleaned. Tighten the screws. Tightening torque: 2.0-2.9 N-m (20-30 kgf-cm, 18-26 in-lbf) b a b C (harness side) d 12. Install the rear console. 13. Connect the negative battery cable. 14. Verify correct operation of the shift-lock system. B-C B-C B-C Body B-C Constant Ignition switch OFF Ignition switch ON Constant Brake pedal released -t depressed OR B+ El+ on OV -+ B+ -1 Gartner Banana

Page 562 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K BUTTON NEED NOT BEDEPRESSED BUTTON MUST BE DEPRESSED 0.9--1.0mm 0.64.7mm i0.035--0.039 in} (0.024-0.028 in) I 0.5-0.6mm (0.02-0.024 in) 45UOKX-48 HEAVY-GAUGE WIRE , SLIDER '22EEL SELECTOR LEVER Inspection 1. Verify that the selector lever can only be shifted as shown in the figure. When shifting from P range, do so with the ignition switch ON and the brake pedal de- pressed. 2. Verify there is a click at each range when shifted from P -+ L range. 3. Verify that the positions of the selector lever and the indi- cator are aligned. 4. Verify that the button returns smoothly when pushed to shift. Adjustment Lever position 1. Disconnect the negative battery cable to deactivate the shift-lock. 2. Remove the rear console, selector knob, selector sleeve, and indicator panel. (Refer to "Shift-lock actuator inspection"; page K-159, steps 1-45.) 3. Loosen the locknut. 4. Shift the transmission to P range by pushing the adjust- ment lever forward. 5. Adjust the lever so that the clearance between the guide plate and the guide pin in P range with the push rod light- ly depressed is as shown. 6. Tighten the locknut. Tightening torque: 18-24 Nem (1.8-2.5 kgf-m, 14--18 ft-lbf) 7. Move the selector lever to N and D ranges and verify that there is the same clearance between the guide plate and the guide pin. 8. If not as specified, readjust the lever. 9. lnstall the indicator panel, selector sleeve, selector knob, and rear console in the reverse order of removal. 10. Check the selector lever operation. (Refer to "lnspec- tion"; page K-161.) Indicator panel 1. Remove the rear console. 2. Shift the selector lever to P range. 3. Loosen the indicator screws. 4. Align the alignment hole in the slider with the hole in the indictor panel. Install suitable heavy-gauge wire to hold the slider. 5. Tighten the indicator mounting screws in the order shown in the figure. 6. Remove the wire from the slider. 7. Verify that the selector lever properly aligns with the indi- cator in each range. 8. Verify correct operation of the emergency override but- ton. Gartner Banana

Page 563 of 1708

K SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) POSSIBLE TO SHIFT BRAKEPEDAL DEPRESSED P RANGE POSSIBLE TO TURN IN LOCK POSITION I Shift-lock System Operation Inspection Shift-lock system 1. Turn the ignition switch ON, engine OFF 2. Verify that the selector lever is in P range. u 3. Without the brake pedal depressed, verify that the selec- tor lever cannot be shifted from P range. 4. Depress the brake pedal. Verify that the selector lever can be shifted from P range. 5. Shift the selector lever to R range. 6. Verify that the ignition key cannot be turned to the LOCK position. 7. Shift the selector lever to P range. 8. Verify that the ignition key can be turned to the LOCK position. 9. If not as specified, inspect and repair as necessary, re- ferring to "Troubleshooting". Emergency override button 1. Verify that the engine is off. 2. Verify that the selector is locked in P range. 3. Remove the indicator panel cover with the screwdriver as shown. 4. Insert the screwdriver into the emergency override hole, ,, push down, and verify that the selector lever can be shifted from P range. 5. If not as specified, inspect and repair as necessary, re- ferring to "Troubleshooting". Gartner Banana