brake MAZDA MX-5 1994 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 460 of 1708

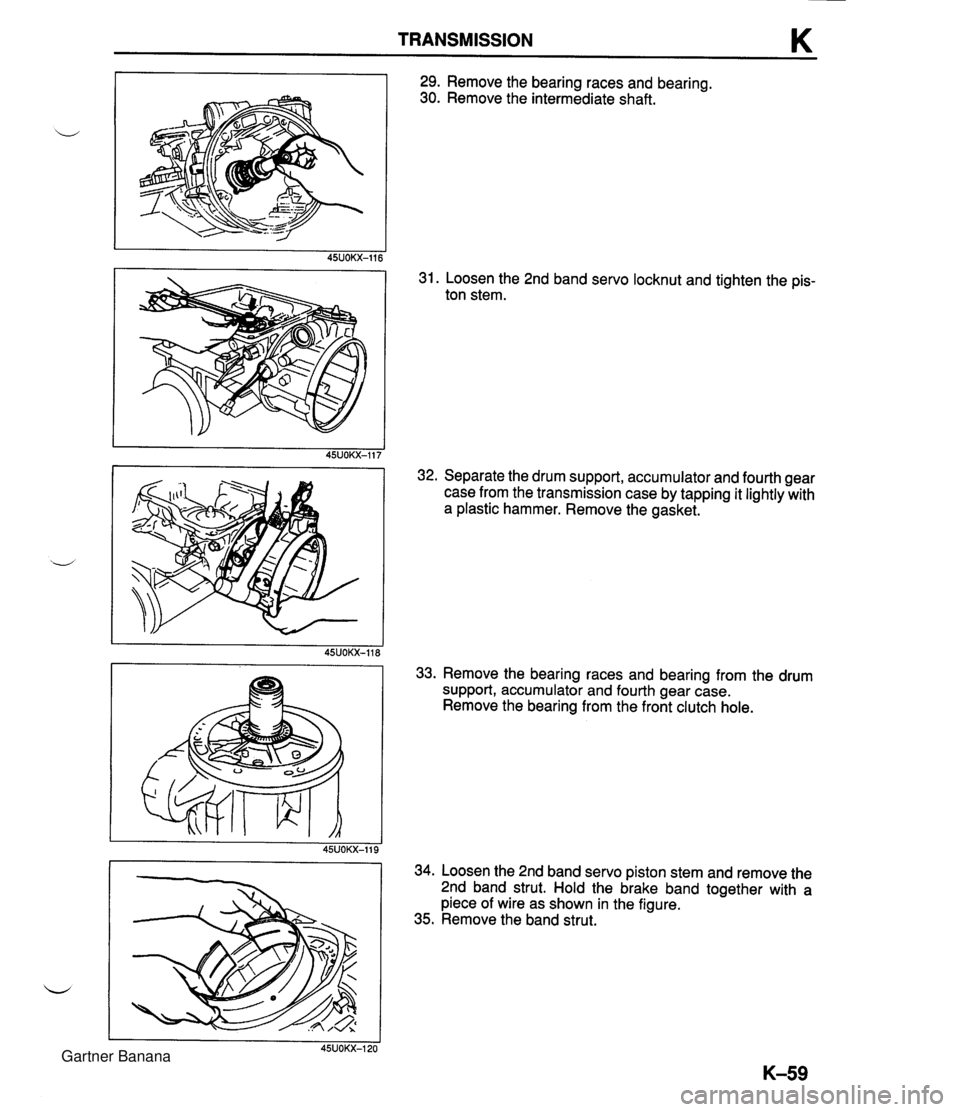

TRANSMISSION K 29. Remove the bearing races and bearing. 30. Remove the intermediate shaft. I 45UOKX-116 31. Loosen the 2nd band servo locknut and tighten the pis- ton stem. I 1 45UOKX-117 32. Separate the drum support, accumulator and fourth gear case from the transmission case by tapping it lightly with a plastic hammer. Remove the gasket. u 45UOKX-118 Remove the bearing races and bearing from the drum support, accumulator and fourth gear case. Remove the bearing from the front clutch hole. Loosen the 2nd band servo piston stem and remove the 2nd band strut. Hold the brake band together with a piece of wire as shown in the figure. Remove the band strut. Gartner Banana

Page 477 of 1708

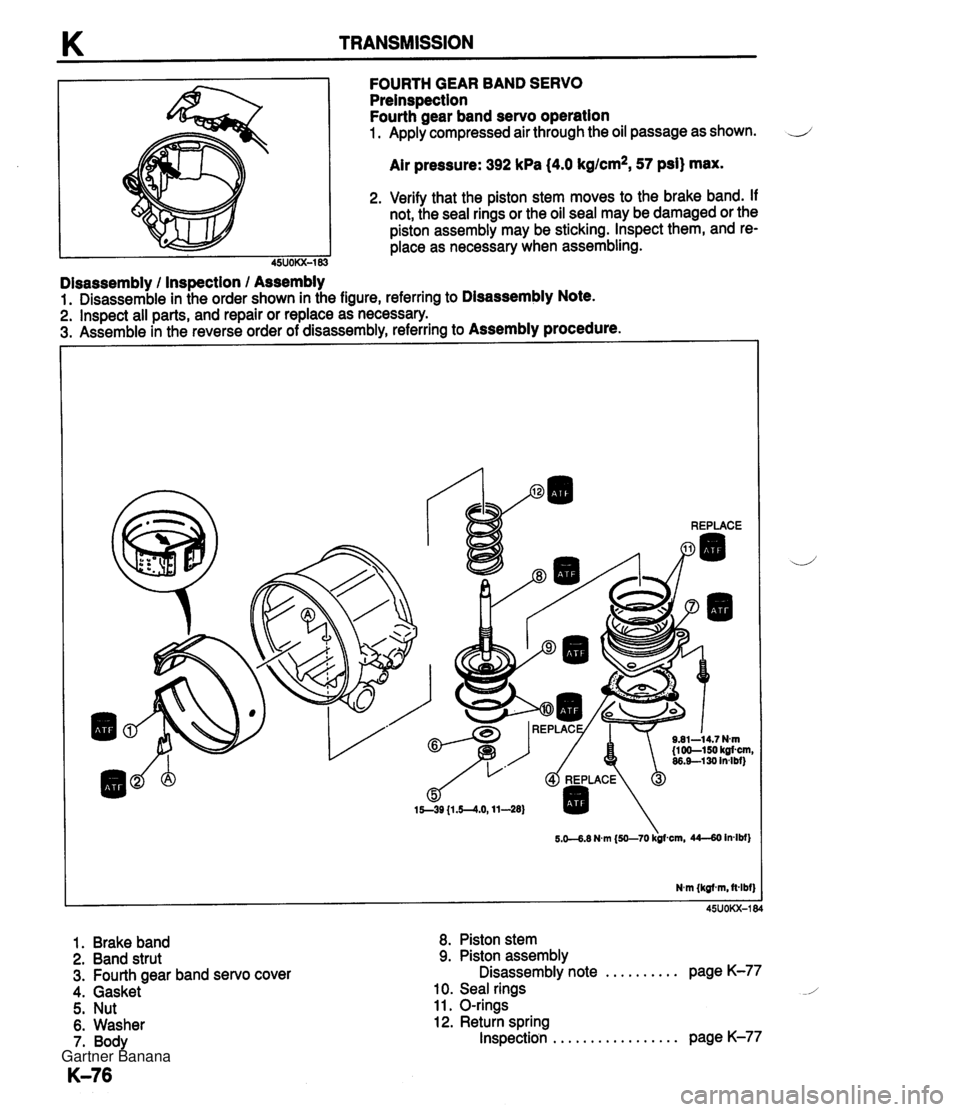

K TRANSMISSION FOURTH GEAR BAND SERVO Preinspection Fourth gear band servo operation 1. Apply compressed air through the oil passage as shown. .J Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. 2. Verify that the piston stem moves to the brake band. If not, the seal rings or the oil seal may be damaged or the piston assembly may be sticking. lnspect them, and re- place as necessary when assembling. 45UOKX-183 Disassembly I Inspection I Assembly 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. Inspect all parts, and repair or replace as necessary. 3. Assemble in the reverse order of disassembly, referring to Assembly procedure. 1. Brake band 2. Band strut 3. Fourth gear band servo cover 4. Gasket 5. Nut 6. Washer 7. Body 8. Piston stem 9. Piston assembly is assembly note . . . . . . . . . . page K-77 10. Seal rings 11. O-rings 12. Return spring Inspection . . . . . . . . . . . . . . . . . page K-77 Gartner Banana

Page 484 of 1708

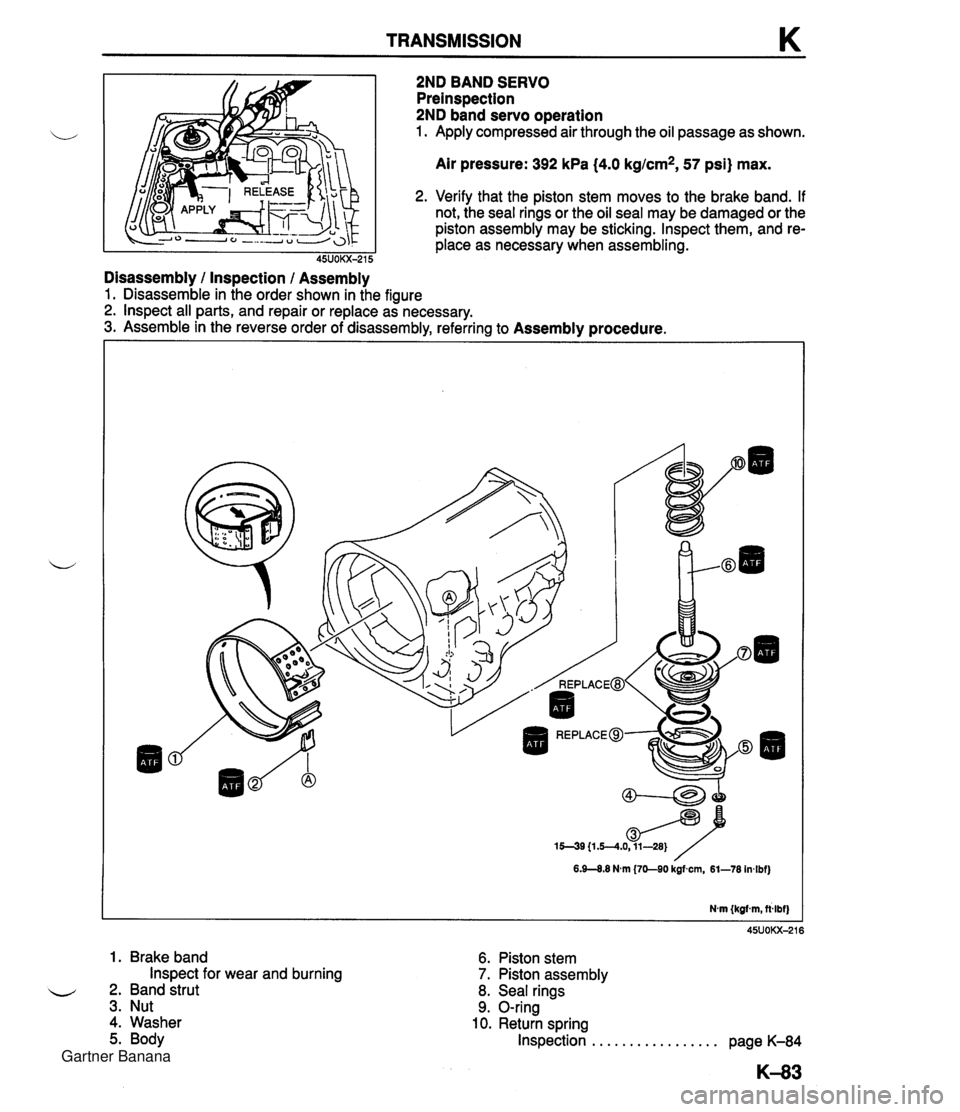

TRANSMISSION K 2ND BAND SERVO Preinspection 2ND band servo operation 1. Apply compressed air through the oil passage as shown. Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. 2. Verify that the piston stem moves to the brake band. If not, the seal rings or the oil seal may be damaged or the piston assembly may be sticking. lnspect them, and re- place as necessary when assembling. Disassembly 1 Inspection / Assembly 1. Disassemble in the order shown in the figure 2. lnspect all parts, and repair or replace as necessary. 3. Assemble in the reverse order of disassembly, referring to Assembly procedure. 1. Brake band lnspect for wear and burning - 2. Band strut 3. Nut 4. Washer 5. Body 6. Piston stem 7. Piston assemblv 8. Seal rings 9. O-ring 10. Return spring Inspection . . . . . . . . . . . . . . . . . page K-84 Gartner Banana

Page 503 of 1708

K TRANSMISSION LOW AND REVERSE BRAKE Preparation SST Preinspection Low and reverse brake operation 1. Apply compressed air through the oil passage as shown. 49 0378 346 Hex head wrench Air pressure: 392 kPa (4.0 kglcm2, 57 psi) max. For removal I installation of one-way clutch 2. Verify that the retaining plate moves toward the snap ring. If not, the seal ring or O-ring may be damaged or fluid may be leaking at the piston check ball. Inspect them, and replace as necessary when assembling. Clearance between retaining plate and snap ring 1. Measure the clearance between the retaining plate and the snap ring. Clearance: 0.8-1.05mm (0.032--0.041 in) i/ 2. Select and install the correct retaining plate when as- sembling. Gartner Banana

Page 504 of 1708

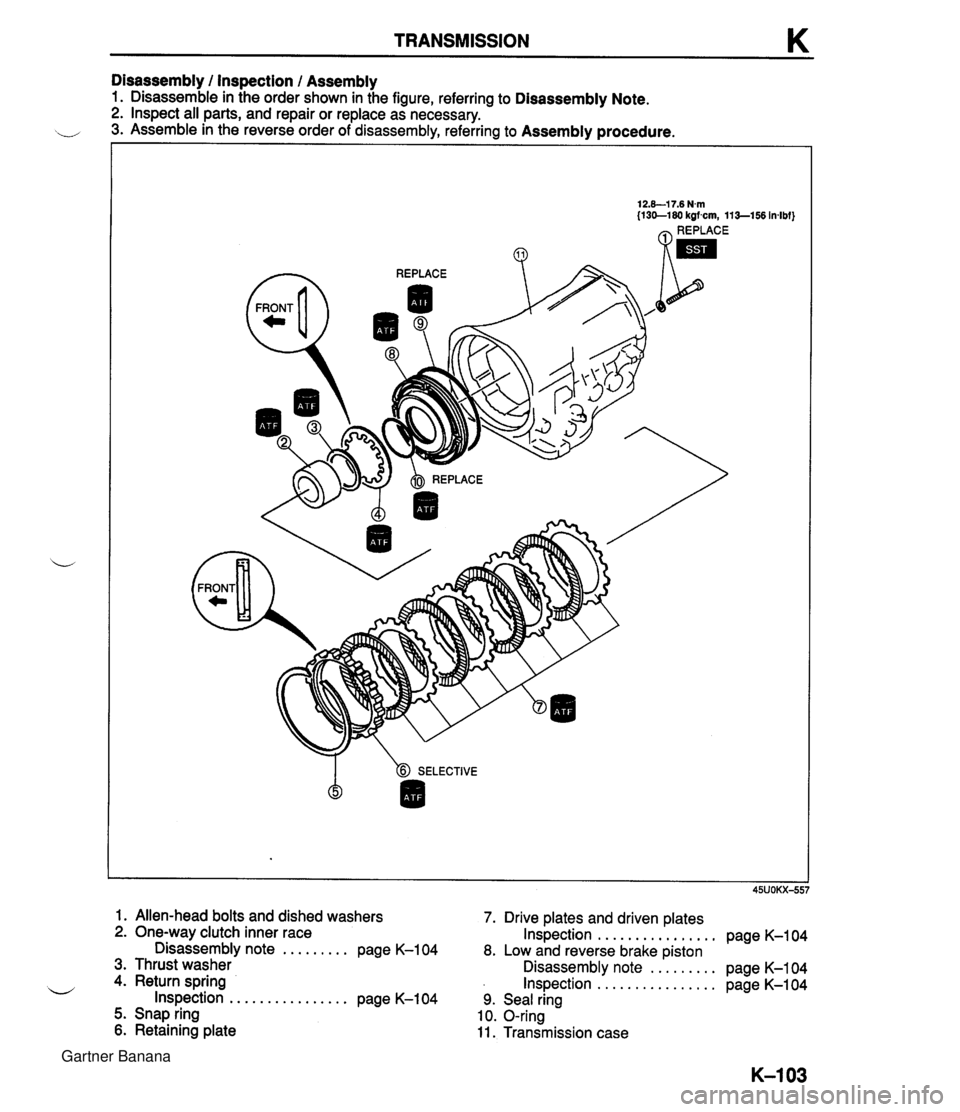

TRANSMISSION K Disassembly 1 Inspection 1 Assembly 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. Inspect all parts, and repair or replace as necessary. .,, 3. Assemble in the reverse order of disassembly, referring to Assemblv ~rocedure. FRONT @k 12.8-1 7.6 N.m (130-1 80 kgfcm, 113-156 In4bf) I b SELECTIVE 1. Allen-head bolts and dished washers 2. One-way clutch inner race Disassembly note ......... page K-104 3. Thrust washer w 4. Return spring Inspection ................ page K-104 5. Snap ring 6. Retaining plate 7. Drive plates and driven plates Inspection ................ page K-104 8. Low and reverse brake piston Disassembly note ......... page K-104 . Inspection ................ page K-104 9. Seal ring 10. O-ring 11. Transmission case Gartner Banana

Page 505 of 1708

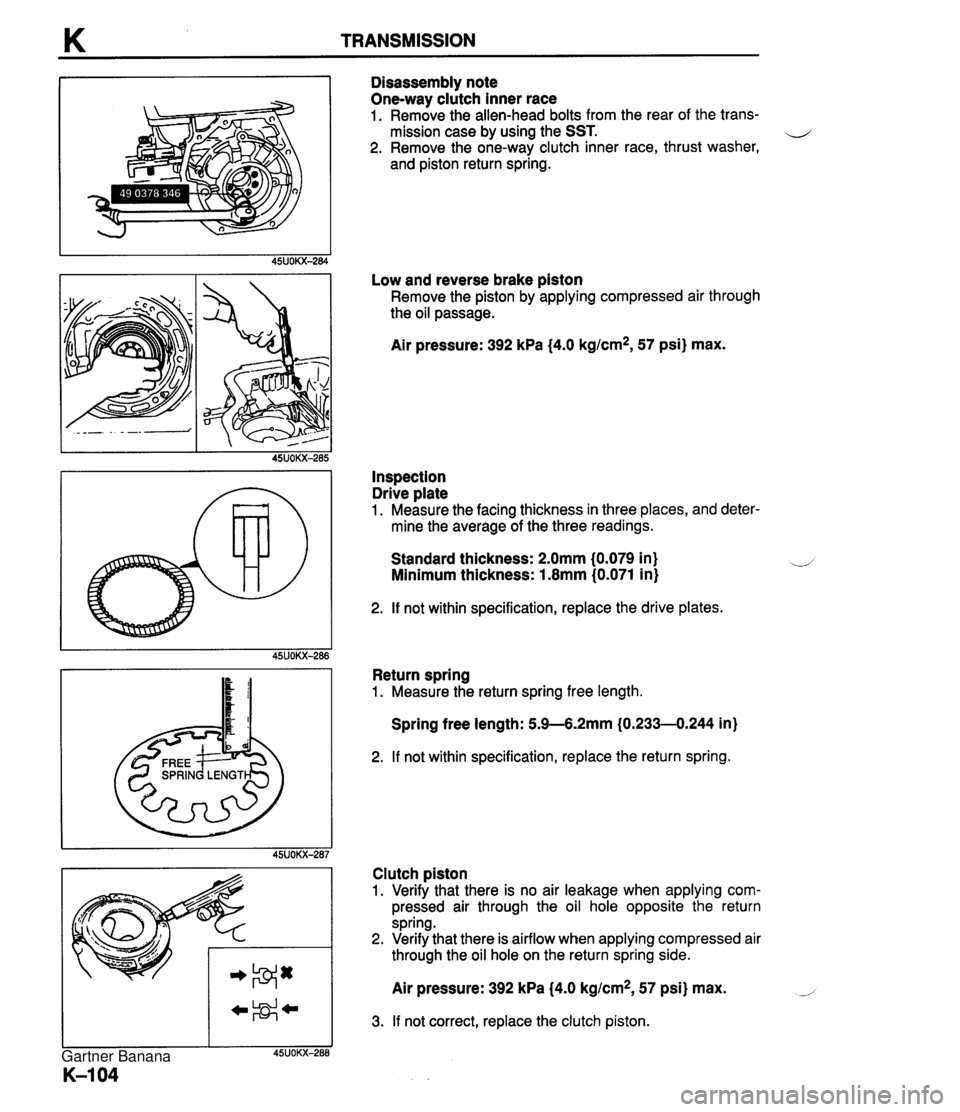

K TRANSMISSION Disassembly note One-way clutch inner race 1. Remove the allen-head bolts from the rear of the trans- mission case by using the SST. 4 2. Remove the one-wav clutch inner race, thrust washer, and piston return spring. Low and reverse brake &ton Remove the piston by gpplying compressed air through the oil passage. Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. Inspection Drive plate 1. Measure the facing thickness in three places, and deter- mine the average of the three readings. Standard thickness: 2.0mm (0.079 in) Minimum thickness: 1.8mm (0.071 in) 2. If not within specification, replace the drive plates. Return spring 1. Measure the return spring free length. Spring free length: 5.9-6.2mm (0.233-0.244 in) 2. If not within specification, replace the return spring. Clutch piston 1. Verify that there is no air leakage when applying com- pressed air through the oil hole opposite the return spring. 2. Verify that there is airflow when applying compressed air through the oil hole on the return spring side. Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. 3. If not correct, replace the clutch piston. Gartner Banana

Page 506 of 1708

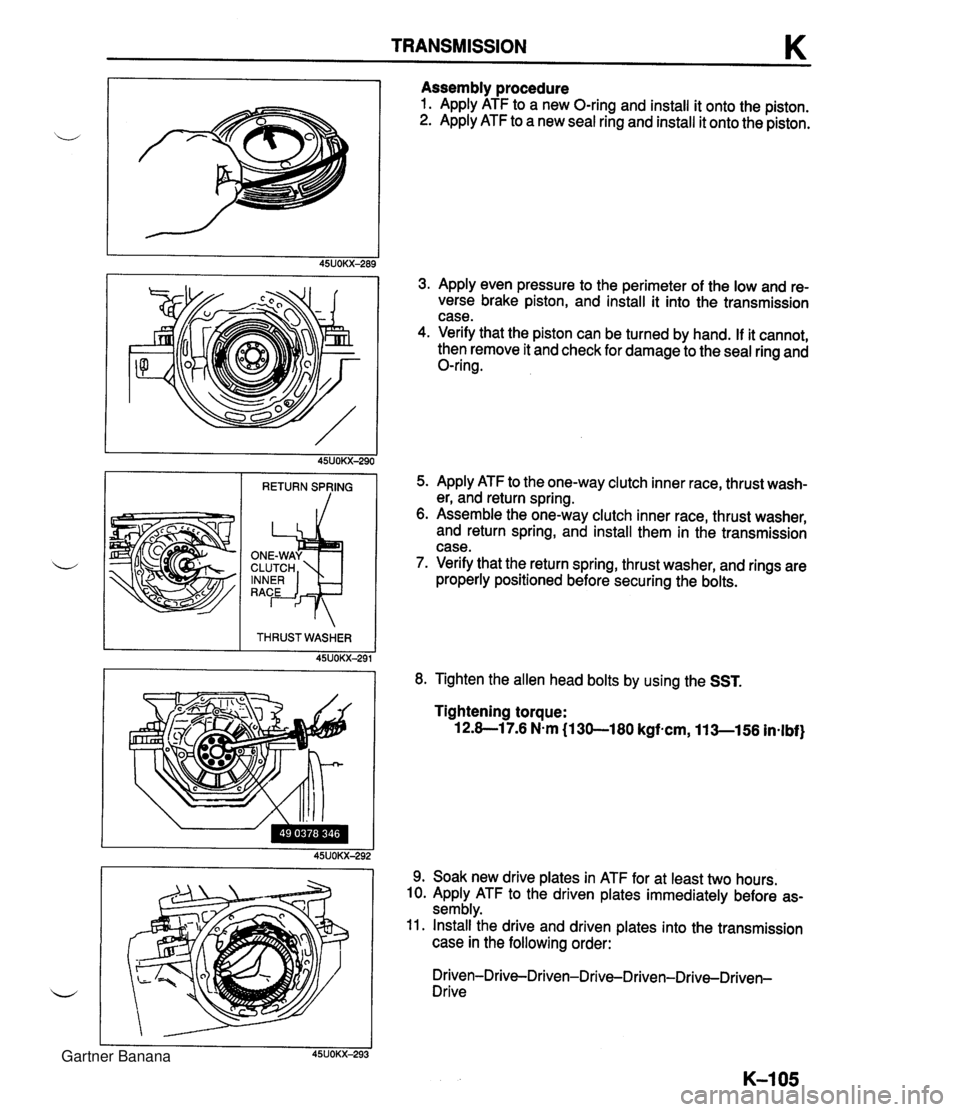

TRANSMISSION K Assembly procedure 1. Apply ATF to a new O-ring and install it onto the piston. 2. Apply ATF to a new seal ring and install it onto the piston. 3. Apply even pressure to the perimeter of the low and re- verse brake piston, and install it into the transmission case. 4. Verify that the piston can be turned by hand. If it cannot, then remove it and check for damage to the seal ring and O-ring. 5. Apply ATF to the one-way clutch inner race, thrust wash- er, and return spring. 6. Assemble the one-way clutch inner race, thrust washer, and return spring, and install them in the transmission case. 7. Verify that the return spring, thrust washer, and rings are properly positioned before securing the bolts. RETURN SPVING THRUSTWASHER 45UOKX-291 8. Tighten the allen head bolts by using the SST. Tightening torque: 12.8-1 7.6 N-m (1 30-180 kgfacm, 11 3-156 in-lbf) 9. Soak new drive plates in ATF for at least two hours. 10. Apply ATF to the driven plates immediately before as- sembly. 11. Install the drive and driven plates into the transmission case in the following order: Driven-Drive-Driven-Drive-Driven-Drive-Driven- Drive Gartner Banana

Page 507 of 1708

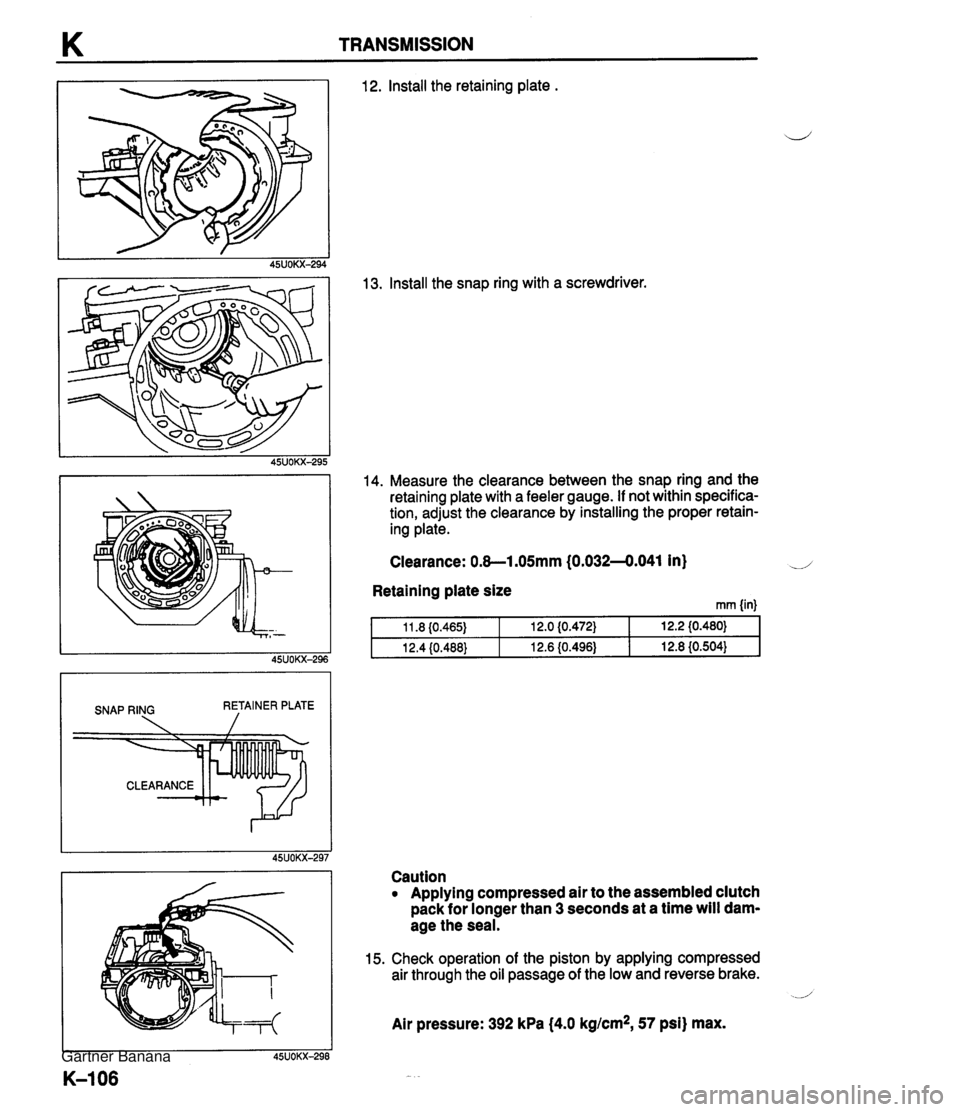

K TRANSMISSION SNAP RING RETAINER PLATE 12. lnstall the retaining plate . 13. Install the snap ring with a screwdriver. 14. Measure the clearance between the snap ring and the retaining plate with a feeler gauge. If not within specifica- tion, adjust the clearance by installing the proper retain- ing plate. Clearance: 0.8-1.05mm (0.032-4.041 in) d Retaining plate size rnrn {in) Caution Applying compressed air to the assembled clutch pack for longer than 3 seconds at a time will dam- age the seal. 15. Check operation of the piston by applying compressed air through the oil passage of the low and reverse brake. _i Air pressure: 392 kPa (4.0 kglcm*, 57 psi) max. Gartner Banana

Page 533 of 1708

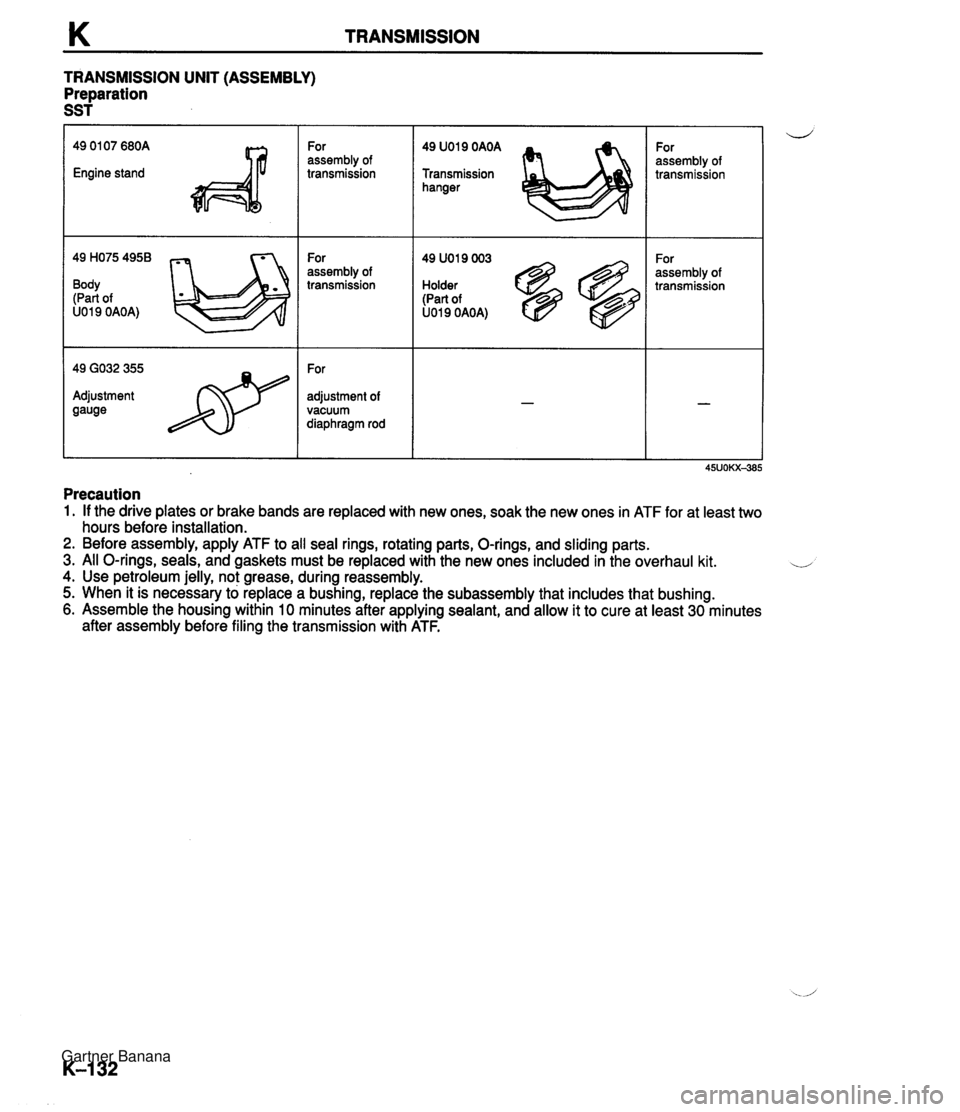

K TRANSMISSION TRANSMISSION UNIT (ASSEMBLY) Preparation SST 49 01 07 680A Engine stand 49 H075 4958 Body (Part of U019 OAOA) 49 GO32 355 Adjustment gauge For assembly of transmission For assembly of transmission For adjustment of vacuum diaphragm rod 49 UOI 9 OAOA Transmission hanger 49 U019 003 Holder (Part of U019 OAOA) For assembly of transmission For assembly of transmission Precaution 1. If the drive plates or brake bands are replaced with new ones, soak the new ones in ATF for at least two hours before installation. 2. Before assembly, apply ATF to all seal rings, rotating parts, O-rings, and sliding parts. 3. All O-rings, seals, and gaskets must be replaced with the new ones included in the overhaul kit. u 4. Use petroleum jelly, not grease, during reassembly. 5. When it is necessary to replace a bushing, replace the subassembly that includes that bushing. 6. Assemble the housing within 10 minutes after applying sealant, and allow it to cure at least 30 minutes after assembly before filing the transmission with ATF. Gartner Banana

Page 537 of 1708

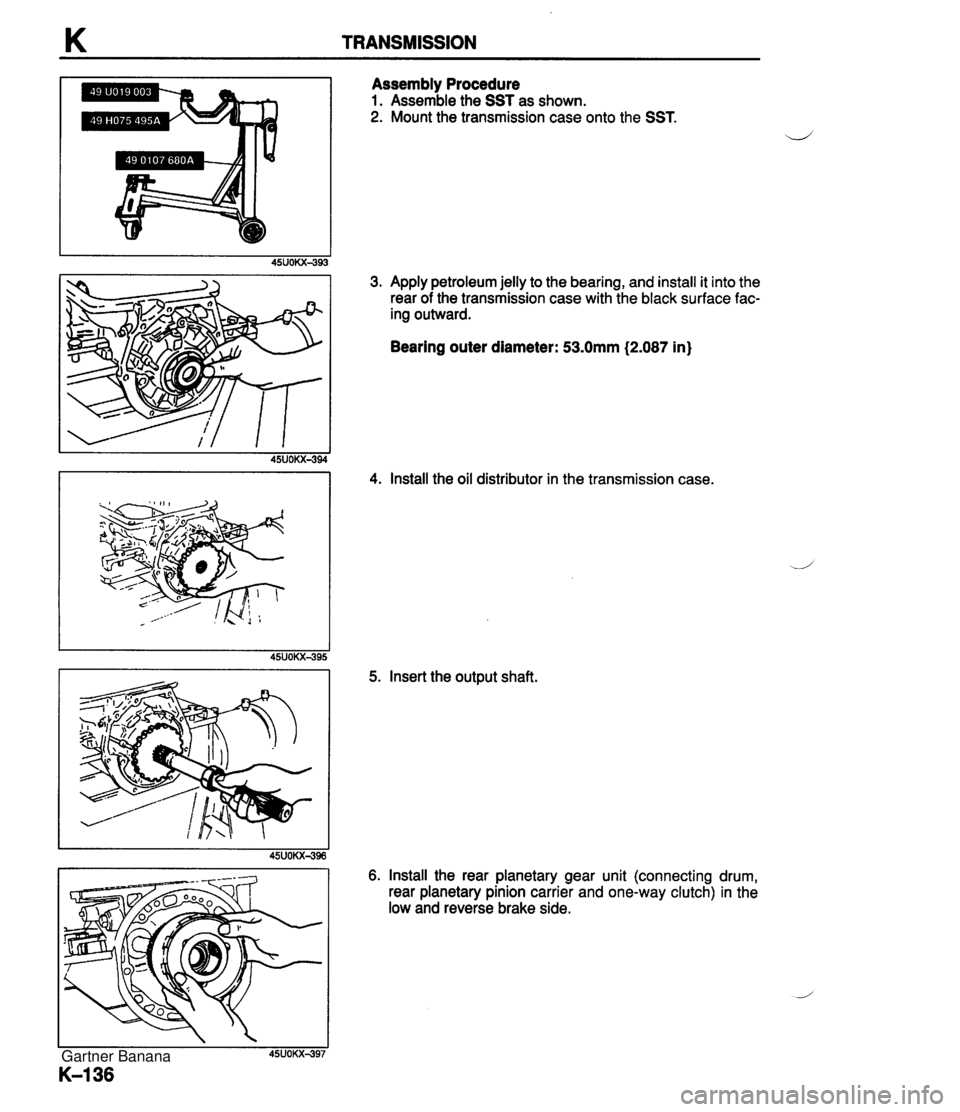

K TRANSMISSION Assembly Procedure 1. Assemble the SST as shown. 2. Mount the transmission case onto the SST. 3. Apply petroleum jelly to the bearing, and install it into the rear of the transmission case with the black surface fat- ing outward. Bearing outer diameter: 53.0mm (2.087 in) 4. Install the oil distributor in the transmission case. 5. Insert the output shaft. 6. Install the rear planetary gear unit (connecting drum, rear planetary pinion carrier and one-way clutch) in the low and reverse brake side. Gartner Banana