wheel alignment MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 20 of 1164

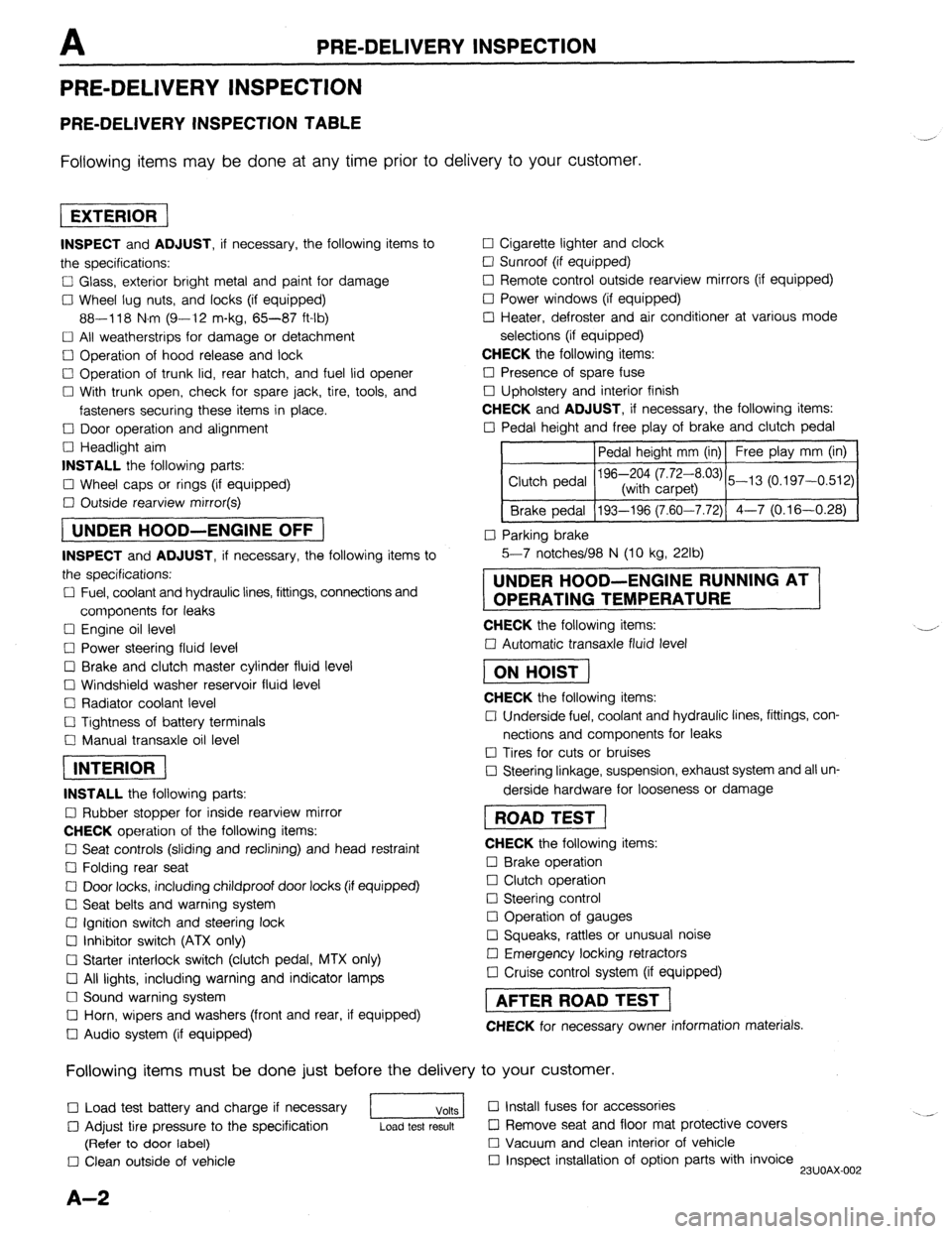

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 601 of 1164

FRONT AXLE M

WHEEL HUB, STEERING KNUCKLE

Preinspection

Wheel bearing play

1. Remove the wheel and tire.

2. Remove the brake caliper assembly and disc plate.

3. Position a dial indicator against the wheel hub. Push and

pull the wheel hub by hand in the axial direction and meas-

ure the wheel bearing play.

4. If the bearing play exceeds specification, check and adjust

the locknut torque or replace the wheel bearing if necessary.

Removal / Installation

d Maximum wheel bearing play: 0.05mm (0.002 in)

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to

Installation Note.

4. After installation, check the front wheel alignment. (Refer to Section R.)

SERVIC\E, SECTION R

7 93--12? W.-L%” COTiER PIN, REPLACE

(9.5-12.9, 69-S

39-54

(4.0-5.6, 29-40) 39-64 ’ 236-319 (24.0-32.5, 174-235)

(4.4-6.0, 32-43)

66-67)

N.m (m-kg, it-lb)

23UOMX-006

1. Wheel and tire

2. Locknut

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . page M- 6

3. Brake caliper assembly

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section P

4. Disc plate

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section P

5. Tie rod end

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . page M- 6

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . page M- 6 6. Lower ball joint

7. Knuckle, wheel hub, and dust cover

Inspect wheel hub for cracks and damage

Inspect knuckle spindle for cracks and

damage

Inspect dust cover for damage and dis-

tortion

Disassembly / Inspection I

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page M- 7

M-5

Page 607 of 1164

REAR AXLE M

L.3”“I”lh-” I

Removal / Inspection / Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to

Installation Note.

4. After installation, bleed the brake system, adjust the parking brake lever stroke (Refer to Section P.) and

DRUM BRAKE TYPE

Preinspection

Wheel bearing play

1. Remove the wheel and tire.

2. Position a dial indicator against the brake drum. Push and

pull the rear brake assembly by hand in the axial direction

and measure the wheel bearing play.

3. If the bearing play exceeds specification, check and adjust

the locknut torque or replace the wheel bearing if necessary.

Maximum wheel bearing play: 0.05mm (0.002 in)

66-l 17 (6.7-l 1.9, 63-66)

45-59

(4.6:6.0, 33-43)

check the rear wheel alignment (Refer to Section R.)

SEiWICE, SECTION R /

I

GA

19-26 (1.9-2.6, 14-19)

177-235

(16.0-24.0, 130-174) d

REPLACE REPLACE

(9.0-12.0,

65-67)

N.m (m-kg, ft-lb)

7RI ImAX-ni

J 3

1. Wheel and tire

2. Hub cap

3. Locknut

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . page M-l 2

4. Brake drum

5. Hub bearing assembly

Inspect for cracks and damage

Disassembly I Assembly . . . . . . . . . . . . page M-l 3 6. Parking brake cable

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section P

7. Brake pipe

Removal Note .,.......................... page M-12

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . page M-l 2

8. Rear brake assembly

Service ,,........................................ Section P

9. Rear spindle

Inspect for cracks and damage

M-l 1

Page 671 of 1164

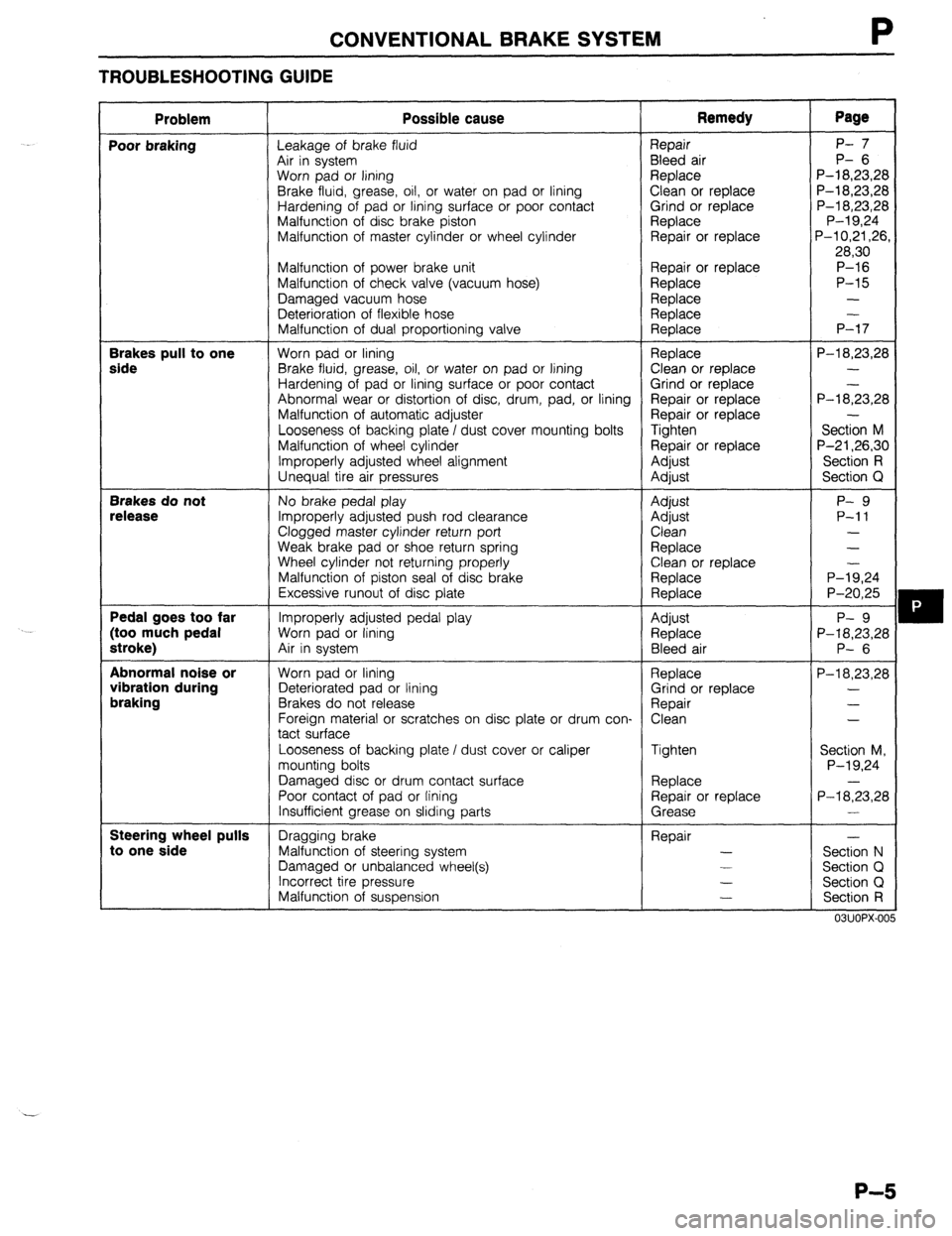

CONVENTIONAL BRAKE SYSTEM

TROUBLESHOOTING GUIDE

Problem Possible cause Remedy Page

Poor braking

Leakage of brake fluid Repair P- 7

Air in system Bleed air P- 6

Worn pad or lining Replace P-l 8,23,28

Brake fluid, grease, oil, or water on pad or lining Clean or replace P-18,23,28

Hardening of pad or lining surface or poor contact Grind or replace P-l 8,23,28

Malfunction of disc brake piston Replace P-l 9,24

Malfunction of master cylinder or wheel cylinder Repair or replace P-l 0,21,26,

28,30

Malfunction of power brake unit Repair or replace P-16

Malfunction of check valve (vacuum hose) Replace P-15

Damaged vacuum hose Replace -

Deterioration of flexible hose Replace -

Malfunction of dual proportioning valve Replace P-17 Brakes pull to one

Worn pad or lining Replace P-l 8,23,28 side Brake fluid, grease, oil, or water on pad or lining Clean or replace -

Hardening of pad or lining surface or poor contact Grind or replace

Abnormal wear or distortion of disc, drum, pad, or lining Repair or replace P-l 8;3,28

Malfunction of automatic adjuster Repair or replace -

Looseness of backing plate I dust cover mounting bolts Tighten Section M

Malfunction of wheel cylinder Repair or replace P-21,26,30

Improperly adjusted wheel alignment Adjust Section R

Unequal tire air pressures

Adjust Section Q Brakes do not

No brake pedal play Adjust P- 9 release Improperly adjusted push rod clearance Adjust P-11

Clogged master cylinder return port Clean -

Weak brake pad or shoe return spring Replace -

Wheel cylinder not returning properly

Clean or replace

Malfunction of piston seal of disc brake Replace P-l;,24

Excessive runout of disc plate

Replace P-20,25 Pedal goes too far

Improperly adjusted pedal play Adjust P- 9 (too much pedal Worn pad or lining

Replace P-18,23,28 stroke) Air in system

Bleed air P- 6 Abnormal noise or

Worn pad or lining

Replace P-18,23,28 vibration during Deteriorated pad or lining Grind or replace - braking Brakes do not release Repair -

Foreign material or scratches on disc plate or drum con- Clean -

tact surface

Looseness of backing plate / dust cover or caliper Tighten

Section M,

mounting bolts P-l 9,24

Damaged disc or drum contact surface Replace -

Poor contact of pad or fining Repair or replace

P-18,23,28

Insufficient grease on sliding parts Grease - Steering wheel pulls

Dragging brake Repair - to one side Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Cl

Incorrect tire pressure -

Section Q

Malfunction of suspension -

Section R

mm> IAn\, ,.e

P-5

Page 707 of 1164

R

SUSPENSION

INDEX ...................................................... R- 2

FRONT SUSPENSION ..............................

R- 2

REAR SUSPENSION ................................ R- 3

OUTLINE .................................................. R- 4

SPECIFICATIONS ....................................

TROUBLESHOOTING GUIDE.. .................... ;I ;

WHEEL ALIGNMENT ................................. R- 7

PRE-INSPECTION ....................................

FRONT WHEEL ALIGNMENT.. .................. ;I ;

REAR WHEEL ALIGNMENT.. .................... R- 9

FRONT SUSPENSION (STRUT). .................. R-l 0

PREPARATION ....................................... R-l 0

FRONT SHOCK ABSORBER AND SPRING . . R-11

FRONT LOWER ARM

............................... R-l 6

FRONT STABILIZER ................................

R-l 6

REAR SUSPENSION (STRUT). .................... R-20

PREPARATION ....................................... R-20

REAR SHOCK ABSORBER AND SPRING .... R-21

LATERAL LINK AND TRAILING LINK.. ....... R-26

REAR STABILIZER .................................. R-27

REAR CROSSMEMBER ............................ R-29

23UORX-001

Page 708 of 1164

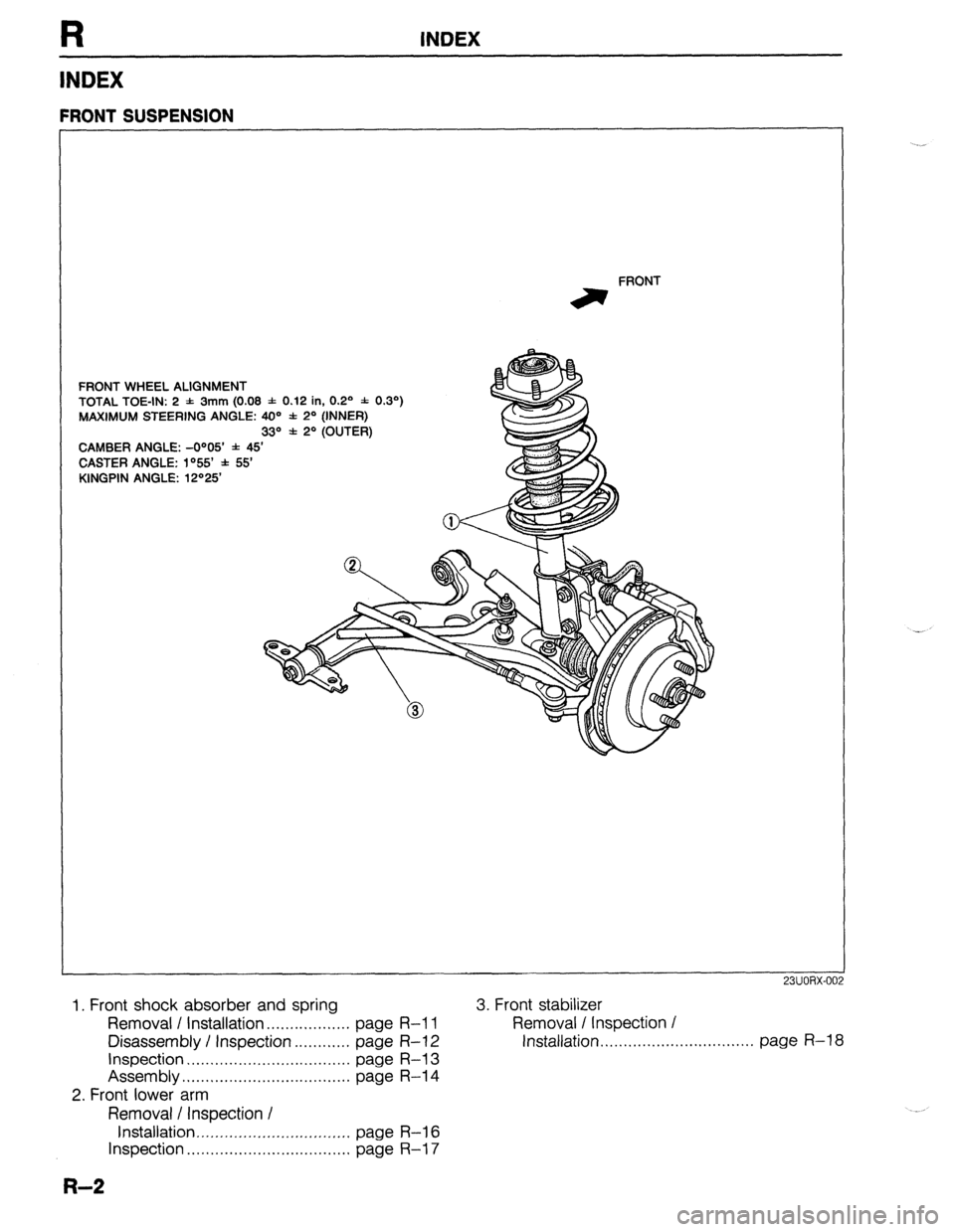

R INDEX

INDEX

FRONT WHEEL ALIGNMENT

TOTAL TOE-IN: 2 -1: 3mm (0.08 f 0.12 in, 0.2’ * 0.3’)

MAXIMUM STEERING ANGLE: 40=’ * 2’ (INNER)

33“ f 2O (OUTER)

CAMBER ANGLE: -O”05’ * 45’

CASTER ANGLE: lo55 f 55

KINGPIN ANGLE: 12“25 FRONT

irr

FRONT SUSPENSION

1. Front shock absorber and spring

Removal I Installation . . . . . . . . . . . . . . . . . . page R-l 1

Disassembly / Inspection . . . . . . . . . . . . page R-l 2

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 3

Assembly . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 4

2. Front lower arm

Removal / Inspection I

Installation ,,...,.......,...........,.._..,. page R-l 6

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-l 7

R-2

3. Front stabilizer

Removal / Inspection /

Installation, . . . . . . ,. . . . . . . . . . . . . . . . . . . . . . . . . page R-l 8

Page 709 of 1164

INDEX

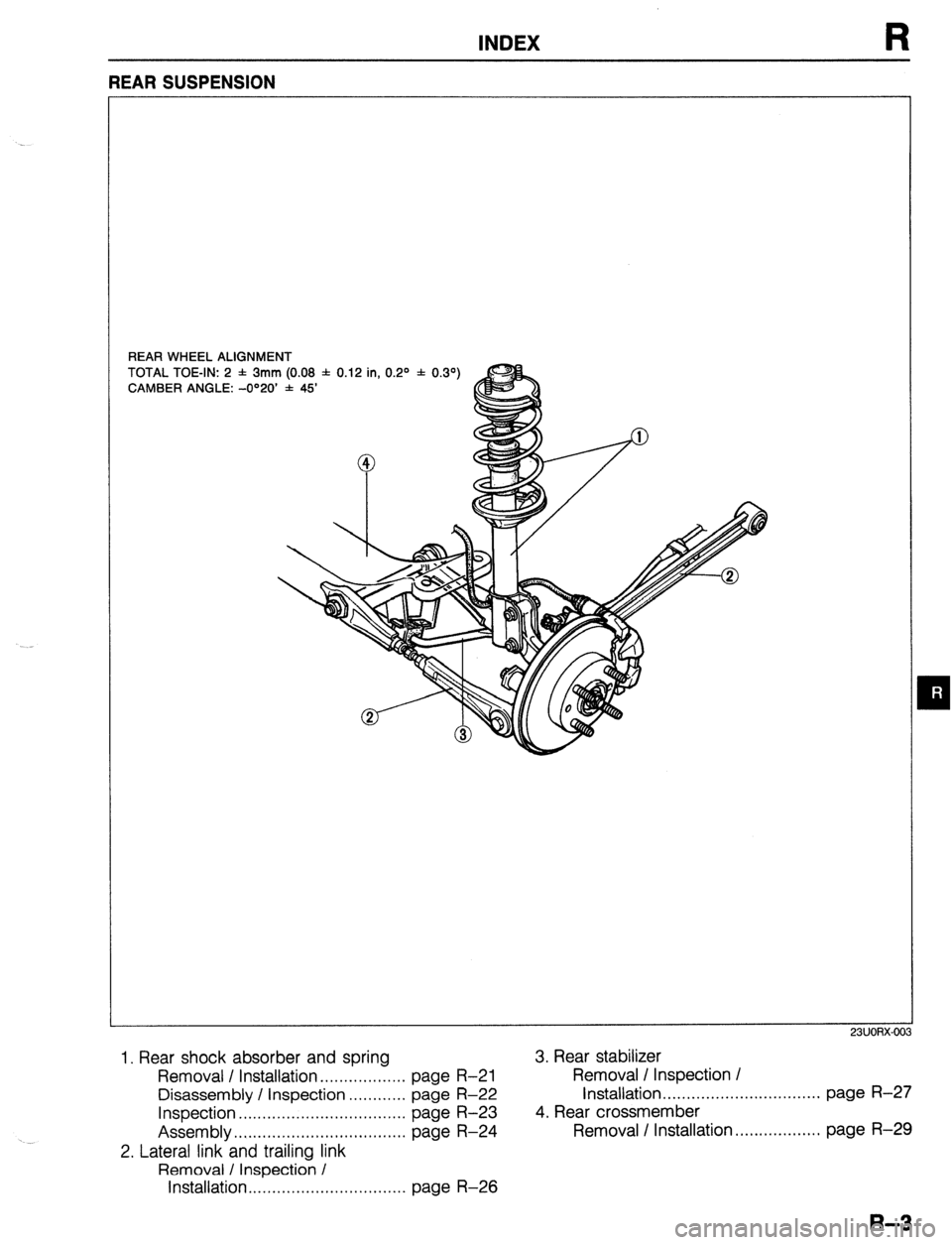

REAR WHEEL ALIGNMENT

TOTAL TOE-IN: 2 f 3mm (0.08 f 0.12 in, 0.2O * 0.39

CAMBER ANGLE: -O”20’ * 45’

m

1. Rear shock absorber and spring 3. Rear stabilizer

Removal / Installation . . . . . . . . . . . . . . . . . . page R-21 Removal / Inspection /

Disassembly / Inspection . . . . . . . . . . . . page

R-22 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . ...*... page R-27

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-23 4. Rear crossmember

Assembly.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page R-24 Removal I Installation. . . . . . . . . . . . . . . . . . page R-29

2. Lateral link and trailing link

Removal / Inspection /

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page R-26

Page 710 of 1164

R OUTLINE

OUTLINE

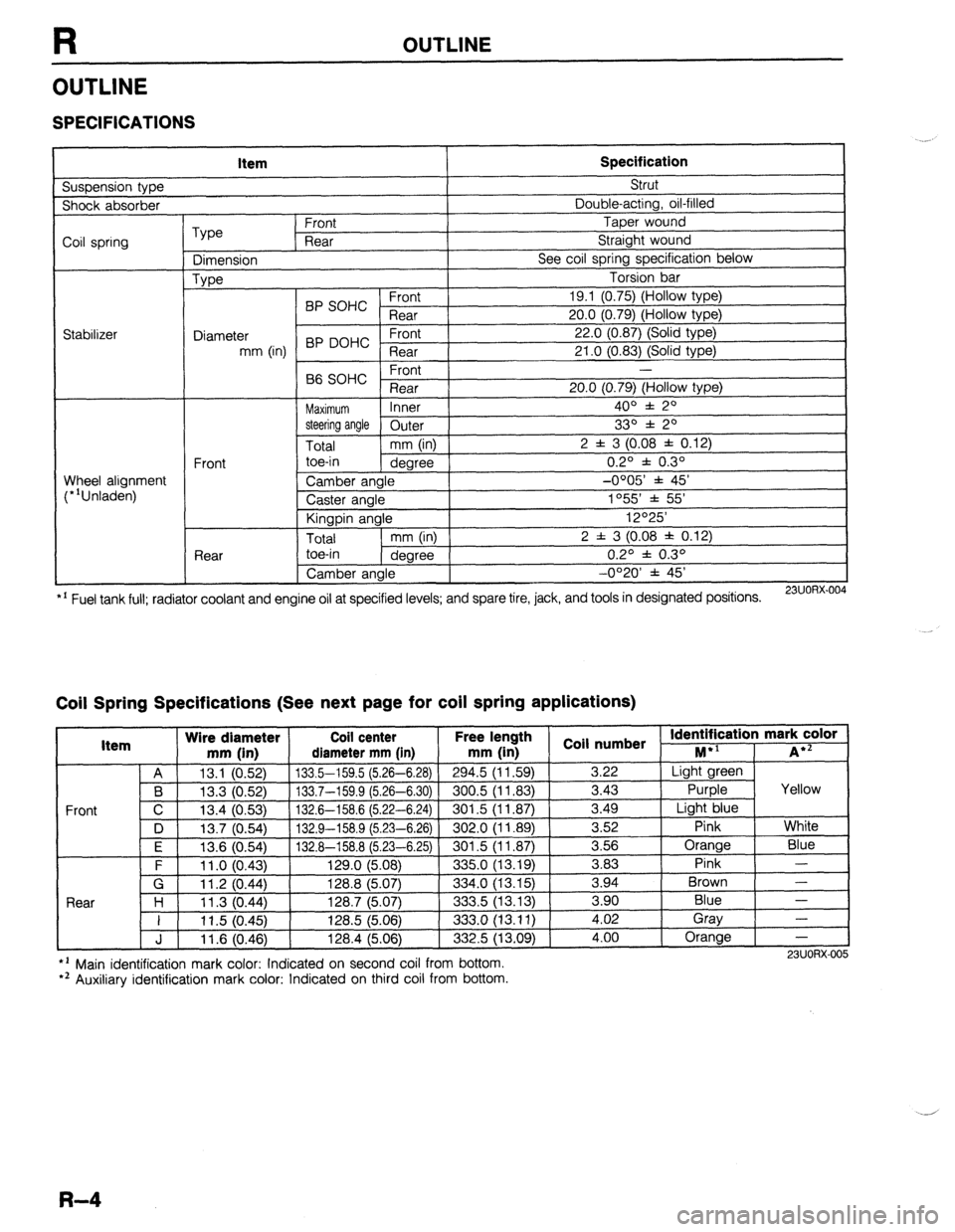

SPECIFICATIONS

Suspension type Item Specification Strut

Shock absorber Double-acting, oil-filled

Coil spring

Stabilizer Type Front Taper wound

Rear Straight wound

Dimension See coil spring specification below

Type Torsion bar

BP SOHC Front 19.1 (0.75) (Hollow type)

Rear 20.0 (0.79) (Hollow type)

Diameter 22.0 (0.87) (Solid type)

mm (in) BP DOHC ;eTrt

21 .O (0.83) (Solid type)

P ,

-

66 SOHC rronr

Rear 20.0 (0.79) (Hollow type)

Maximum Inner 400 f 20

steering angle

Outer 330 f 20

Total mm (in) 2 f 3 (0.08 f 0.12)

Front toe-in

degree 0.2O f 0.3O

Wheel alignment

(*‘Unladen) Camber angle -0005’ f 45’

Caster angle 1055 * 55’

Kingpin angle 12O25’

Total mm (in) 2 f 3 (0.08 * 0.12)

Rear toe-in

degree 0.2O f 0.3O

Camber angle -0°20’ f 45’

*’ Fuel tank full; radiator coolant and engine oil at specified levels; and spare tire, jack, and tools in designated positions.

23UORX.004

Coil Spring Specifications (See next page for coil spring applications)

I Item Wire diameter Coil center Free lel.=-. .

mm iin1 rliamotor mm [in mm (in 1 coil numbs

Front

nath

1 _ . . *St Identification mark color +l

., . . . . I...,

-*.....-.“, * . . . . . ,..-, -....- I--‘, M iA*=

A 13.1 (0.52) 133.5-159.5 (5.26-6.28)

294.5 (11.59) 3.22 Light green

B 13.3 (0.52) 133.7-159.9 (5.26-6.30) 300.5 (11.83)

3.43 Purple Yellow

C 13.4 (0.53)

132.6-158.6 (5.22-6.24) 301.5 (11.87) 3.49

Light blue

D 13.7 (0.54)

132.9-158.9 (5.23-6.26) 302.0 (11.89) 3.52

Pink White

I F I 12f3 Kl5Al I 1.17 A-l!% 8 f!i PR-Fi 751

I RrIl .5 II 1 6x71 I 3.56 Orange

Blue

3 83 Pink -

Brown - .“._ \“.- .,

. “W.., ~ - -. - \-. -- -. - -, -- .-

\’ .‘-‘I t

F 11 .o (0.43) 129.0 (5.08)

335.0 (13.19) -.--

G 11.2 (0.44) 128.8 (5.07)

334.0 (13.15) 3.94

Rnnr l-4

1 I ? 07 AA 1387 /5n7

.?m !i 113 1% 3 an Blue - I I I I .” \v.-7, I&V., \V.“., ---.., \.-. .-, I 11.5 (0.45) 128.5 (5.06)

333.0 (13.11) i:oi Gray

-

J 11.6 (0.46) 128.4 (5.06)

332.5 (13.09) 4.00 Orange

-

l ’ Main identification mark color: Indicated on second coil from bottom.

*’ Auxiliary identification mark color: Indicated on third coil from bottom. 23UORX-005

R-4

Page 712 of 1164

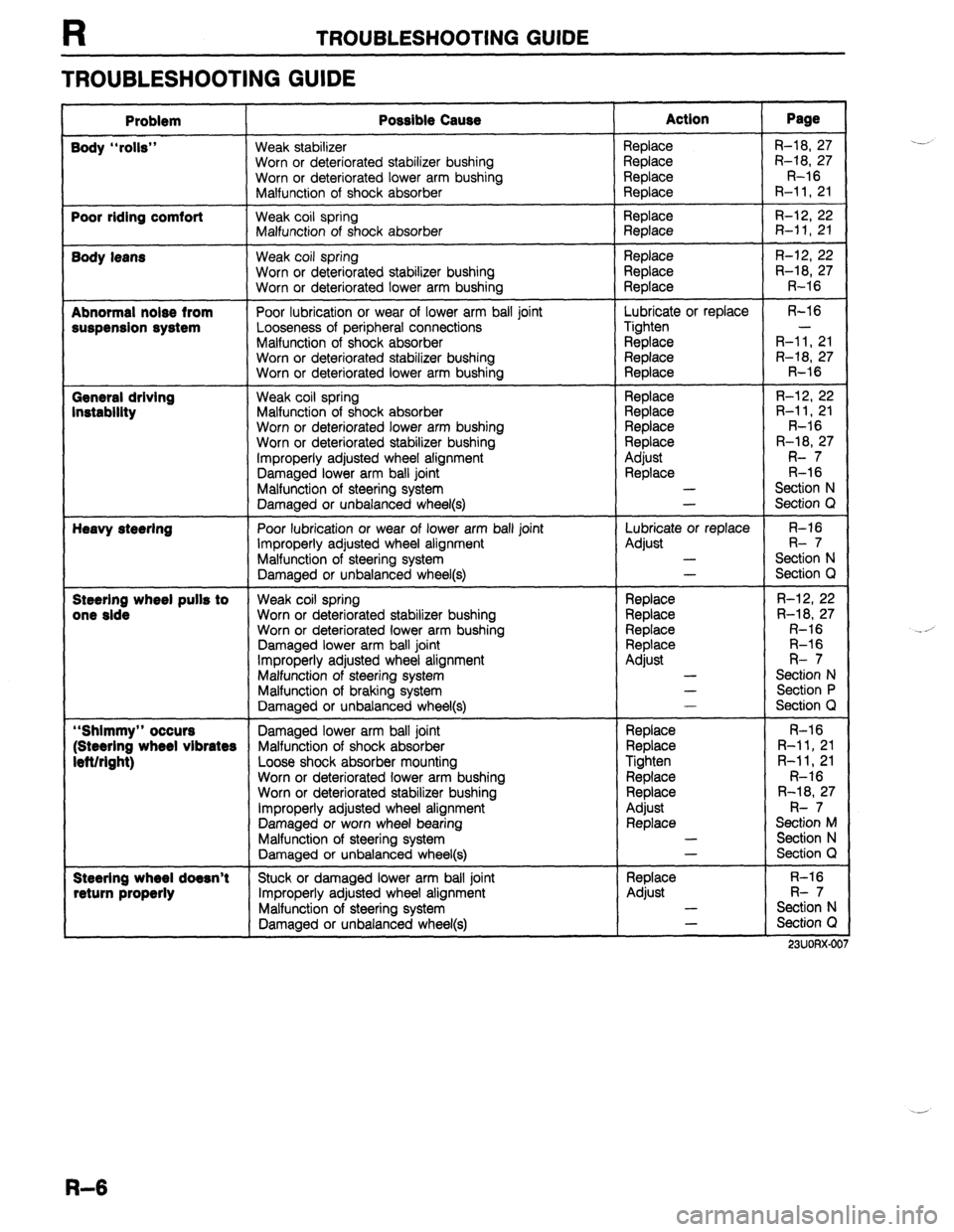

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Problem Possible Cause Action Page

Body “rolls” Weak stabilizer Replace R-18, 27

Worn or deteriorated stabilizer bushing Replace R-18, 27

Worn or deteriorated lower arm bushing

Replace R-16

Malfunction of shock absorber

Replace R-11,21

Poor riding comfort Weak coil spring Replace R-12, 22

Malfunction of shock absorber Replace R-11,21

Body leans Weak coil spring Replace R-12, 22

Worn or deteriorated stabilizer bushing

Replace R-18, 27

Worn or deteriorated lower arm bushing Replace R-16

Abnormal noise from Poor lubrication or wear of lower arm ball joint Lubricate or replace R-16

suspension system Looseness of peripheral connections Tighten -

Malfunction of shock absorber Replace R-11, 21

Worn or deteriorated stabilizer bushing Replace R-18, 27

Worn or deteriorated lower arm bushing

Replace R-16

General driving Weak coil spring Replace R-12, 22

Instability Malfunction of shock absorber Replace R-11, 21

Worn or deteriorated lower arm bushing Replace R-16

Worn or deteriorated stabilizer bushing Replace R-18, 27

Improperly adjusted wheel alignment Adjust R- 7

Damaged lower arm ball joint

Replace R-l 6

Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Q

Heavy steering

Poor lubrication or wear of lower arm ball joint Lubricate or replace R-16

Improperly adjusted wheel alignment

Adjust R- 7

Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Q

Steerlng wheel pulls to Weak coil spring

Replace R-12, 22

one side

Worn or deteriorated stabilizer bushing Replace R-18, 27

Worn or deteriorated lower arm bushing Replace R-16

Damaged lower arm ball joint Replace R-16

Improperly adjusted wheel alignment Adjust R- 7

Malfunction of steering system -

Section N

Malfunction of braking system -

Section P

Damaged or unbalanced wheel(s) -

Section Q

“Shimmy” occurs Damaged lower arm ball joint Replace R-16

(Steering wheel vibrates Malfunction of shock absorber

Replace R-11, 21

left/right) Loose shock absorber mounting

Tighten R-11, 21

Worn or deteriorated lower arm bushing

Replace R-16

Worn or deteriorated stabilizer bushing Replace R-18, 27

Improperly adjusted wheel alignment

Adjust R- 7

Damaged or worn wheel bearing Replace Section M

Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Q

Steering wheel doesn’t Stuck or damaged lower arm ball joint

Replace R-16

return properly Improperly adjusted wheel alignment Adjust R- 7

Malfunction of steering system -

Section N

Damaged or unbalanced wheel(s) -

Section Q

_-..--..__

23UUHXJJC

.-_,

.-

R-6

Page 713 of 1164

WHEEL ALIGNMENT

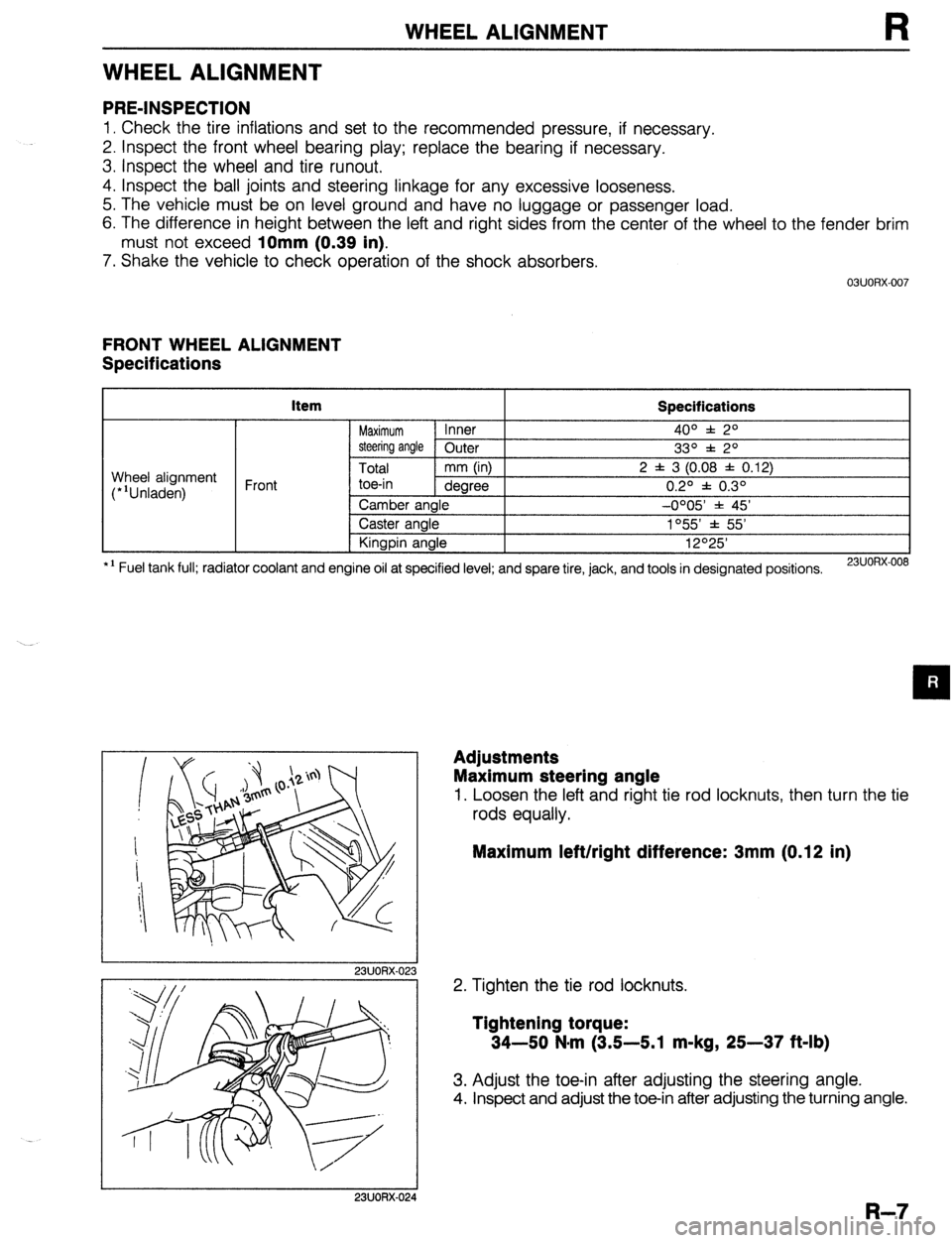

WHEEL ALIGNMENT

PRE-INSPECTION

1. Check the tire inflations and set to the recommended pressure, if necessary.

2. Inspect the front wheel bearing play; replace the bearing if necessary.

3. inspect the wheel and tire runout.

4. Inspect the ball joints and steering linkage for any excessive looseness.

5. The vehicle must be on level ground and have no luggage or passenger load.

6. The difference in height between the left and right sides from the center of the wheel to the fender brim

must not exceed

10mm (0.39 in).

7. Shake the vehicle to check operation of the shock absorbers.

03UORX.007

FRONT WHEEL ALIGNMENT

Specifications

item

Specifications

Maximum Inner 4o” f: 2O

steering angle Outer

33O f 2O

Total mm (in) 2 f 3 (0.08 f 0.12)

toe-in dearee 0.20 f 0.30 Wheel alignment

(*‘Unladen) Front

*I Fuel tank full; radiator coolant and Camber angle -0005 * 45’

Caster angle 1°55’ f 55’

Kingpin angle 12O25’

engine oil at specified level; and spare tire, jack, and tools in designated positions.

23UORX-008

I

I 23UORX-023

Adjustments

Maximum steering angle

1. Loosen the left and right tie rod locknuts, then turn the tie

rods equally.

Maximum left/right difference: 3mm (0.12 in)

2. Tighten the tie rod locknuts.

Tightening torque:

34-50 N-m (3.5-5.1 m-kg, 25-37 ft-lb)

3. Adjust the toe-in after adjusting the steering angle.

4. Inspect and adjust the toe-in after adjusting the turning angle.

I 23UORX-024

R-7