tow MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 3 of 1164

GENERAL INFORMATION

IMPORTANT INFORMATION ..................... GI- 2

BASIC ASSUMPTIONS ............................ GI- 2

SAFETY RISK ........................................ GI- 2

POSSIBLE LOSS OF WARRANTY ............. GI- 2

WARNING ON LUBRICANTS

AND GREASES .................................... GI- 2

HOW TO USE THIS MANUAL.. .................. GI- 3

PREPARATION ...................................... GI- 3

REPAIR PROCEDURE ............................. GI- 3

SYMBOLS ............................................. GI- 4

NOTES, CAUTIONS, AND WARNINGS.. ..... GI- 4

FUNDAMENTAL PROCEDURES.. ............... GI- 4

PROTECTION OF THE VEHICLE .............. GI- 4

A WORD

ABOUT SAFETY ....................... GI- 5

PREPARATION OF TOOLS

AND MEASURING EQUIPMENT.. ........... GI- 5

SPECIAL TOOLS .................................... GI- 5

REMOVAL OF PARTS ............................. GI- 5

DISASSEMBLY ...................................... GI- 5

REASSEMBLY ....................................... GI- 6

ADJUSTMENTS ..................................... GI- 7

RUBBER

PARTS AND TUBING ................

GI- 7

JACK AND SAFETY STAND POSITIONS.. .. GI- 6

VEHICLE LIFT (P-SUPPORT TYPE)

POSITIONS ............................................ GI- 6

TOWING .................................................. GI- 9

IDENTIFICATION NUMBER LOCATIONS ..... 61-10

UNITS ..................................................... GI-10

ABBREVIATIONS ..................................... GI-10

CAUTION ................................................ GI-1 1

INSTALLATION OF MOBILE

TWO-WAY RADIO SYSTEM .................... GI-11

REMOVAL OF IGNITION KEY ON

AUTOMATIC TRANSAXLE MODEL.. ........

GI-1 1

ELECTRICAL TROUBLESHOOTING TOOLS GI-12

CAUTION WITH ELECTRICAL PARTS ........

GI-13

03UGIX-001

Page 11 of 1164

TOWING

.-

WHEEL dOLLlES

03UGIX-00

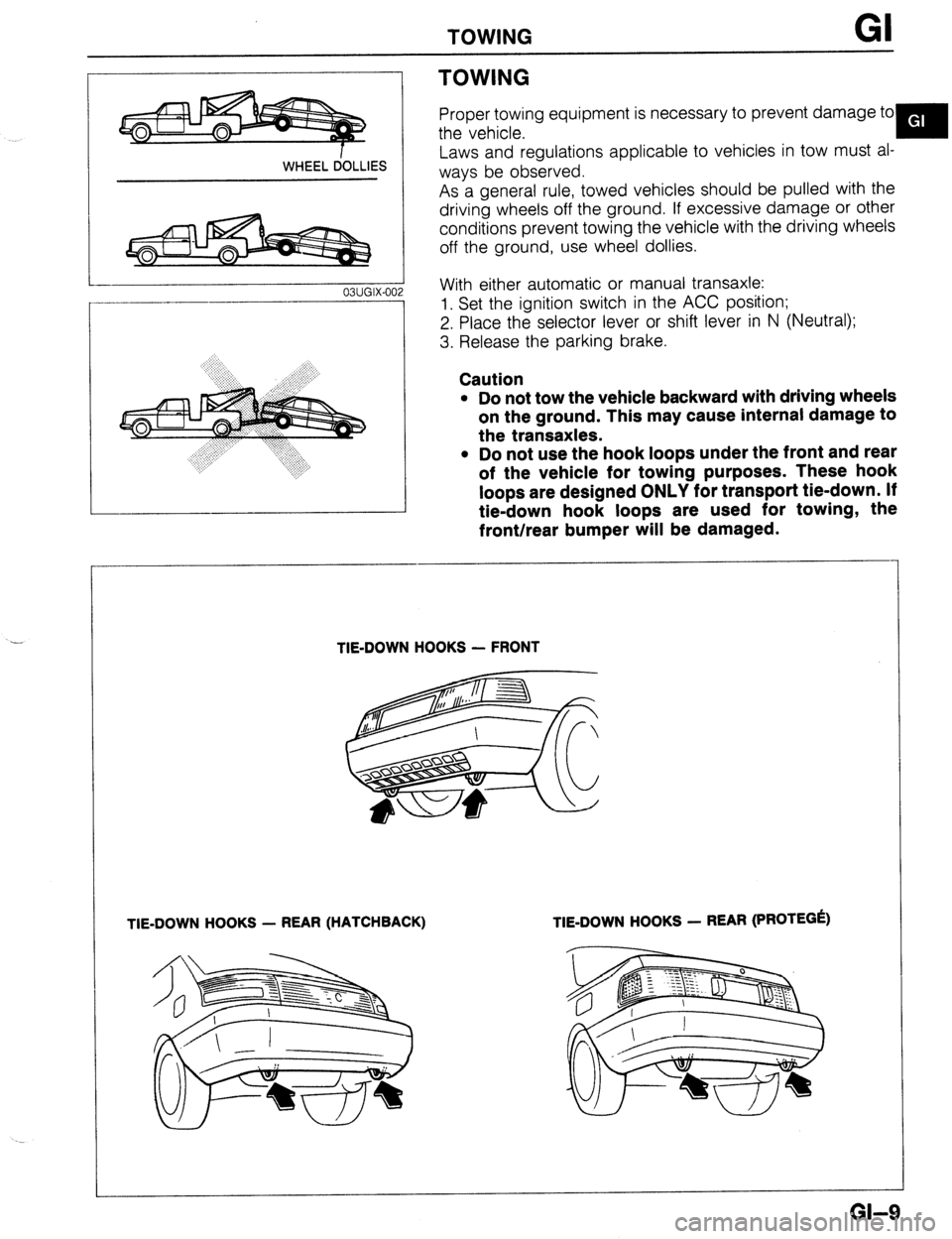

TOWING

Proper towing equipment is necessary to prevent damage to

the vehicle.

Y

Laws and regulations applicable to vehicles in tow must al-

ways be observed.

As a general rule, towed vehicles should be pulled with the

driving wheels off the ground. If excessive damage or other

conditions prevent towing the vehicle with the driving wheels

off the ground, use wheel dollies.

With either automatic or manual transaxle:

1. Set the ignition switch in the ACC position;

2. Place the selector lever or shift lever in N (Neutral);

3. Release the parking brake.

Caution

l Do not tow the vehicle backward with driving wheels

on the ground. This may cause internal damage to

the transaxles.

l Do not use the hook loops under the front and rear

of the vehicle for towing purposes. These hook

loops are designed ONLY for transport tie-down. If

tie-down hook loops are used for towing, the

front/rear bumper will be damaged.

TIE-DOWN HOOKS - FRONT

TIE-DOWN HOOKS - REAR (HATCHBACK) TIE-DOWN HOOKS - REAR (PROTEGk)

GI-9

Page 54 of 1164

Bl ON-VEHICLE MAINTENANCE

01 EOBX-056

23UOBi -0:

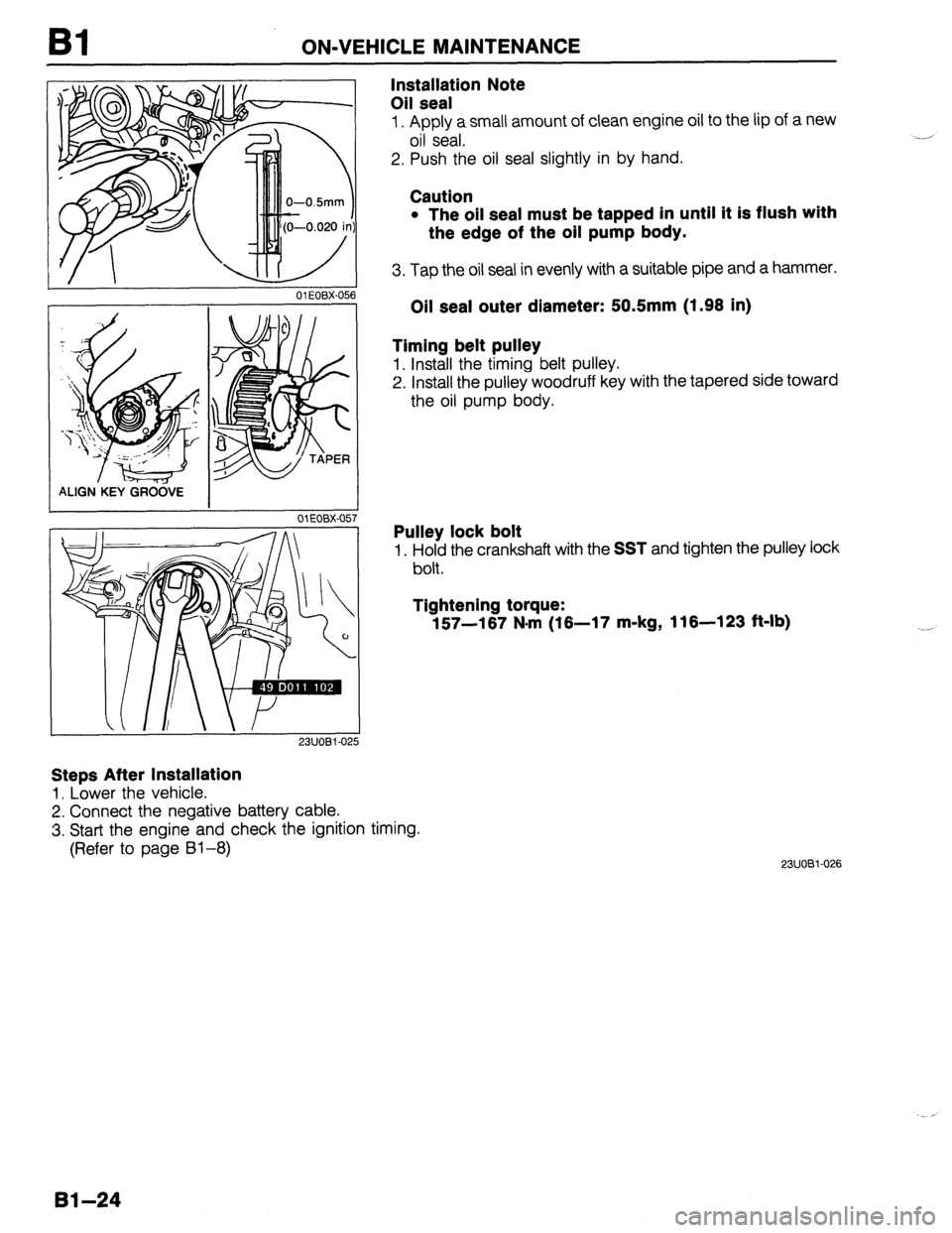

Steps After Installation

1. Lower the vehicle.

2. Connect the negative battery cable.

3. Start the engine and check the ignition timing.

(Refer to page 61-8)

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the oil pump body.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-167 N*rn (16-17 m-kg, 116-123 ft-lb)

23UOBi-026

Bl-24

Page 105 of 1164

ASSEMBLY Bl

OWOBX-20

23UOBl-049

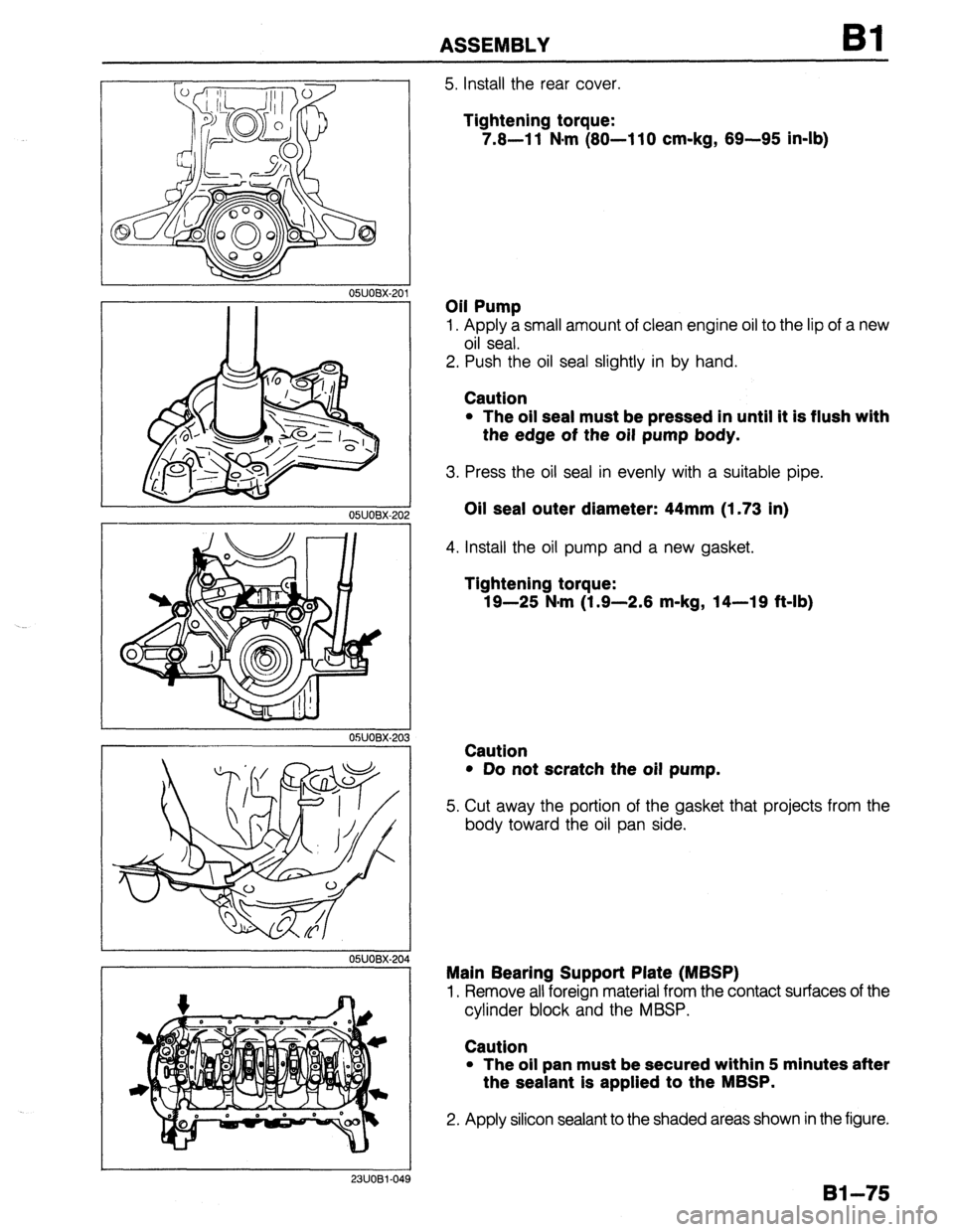

5. Install the rear cover.

Tightening torque:

7.8-l 1 N*m (80-l 10 cm-kg, 89-95 in-lb)

Oil Pump

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be pressed in until it is flush with

the edge of the oil pump body.

3. Press the oil seal in evenly with a suitable pipe.

Oil seal outer diameter: 44mm (1.73 in)

4. Install the oil pump and a new gasket.

Tightening torque:

19-25 N-m (1.9-2.8 m-kg, 14-19 ft-lb)

Caution

l Do not scratch the oil pump.

5. Cut away the portion of the gasket that projects from the

body toward the oil pan side.

Main Bearing Support Plate (MBSP)

1, Remove all foreign material from the contact surfaces of the

cylinder block and the MBSP.

Caution

l The oil pan must be secured within 5 minutes after

the sealant is applied to the MBSP.

2. Apply silicon sealant to the shaded areas shown in the figure.

81-75

Page 111 of 1164

ASSEMBLY

03UOBi -144

03UOBl-214

GREATER THAN (i

CYLINDER HEAD SIDE

05UOBX-21

f36 SOHC

B6 SOHC

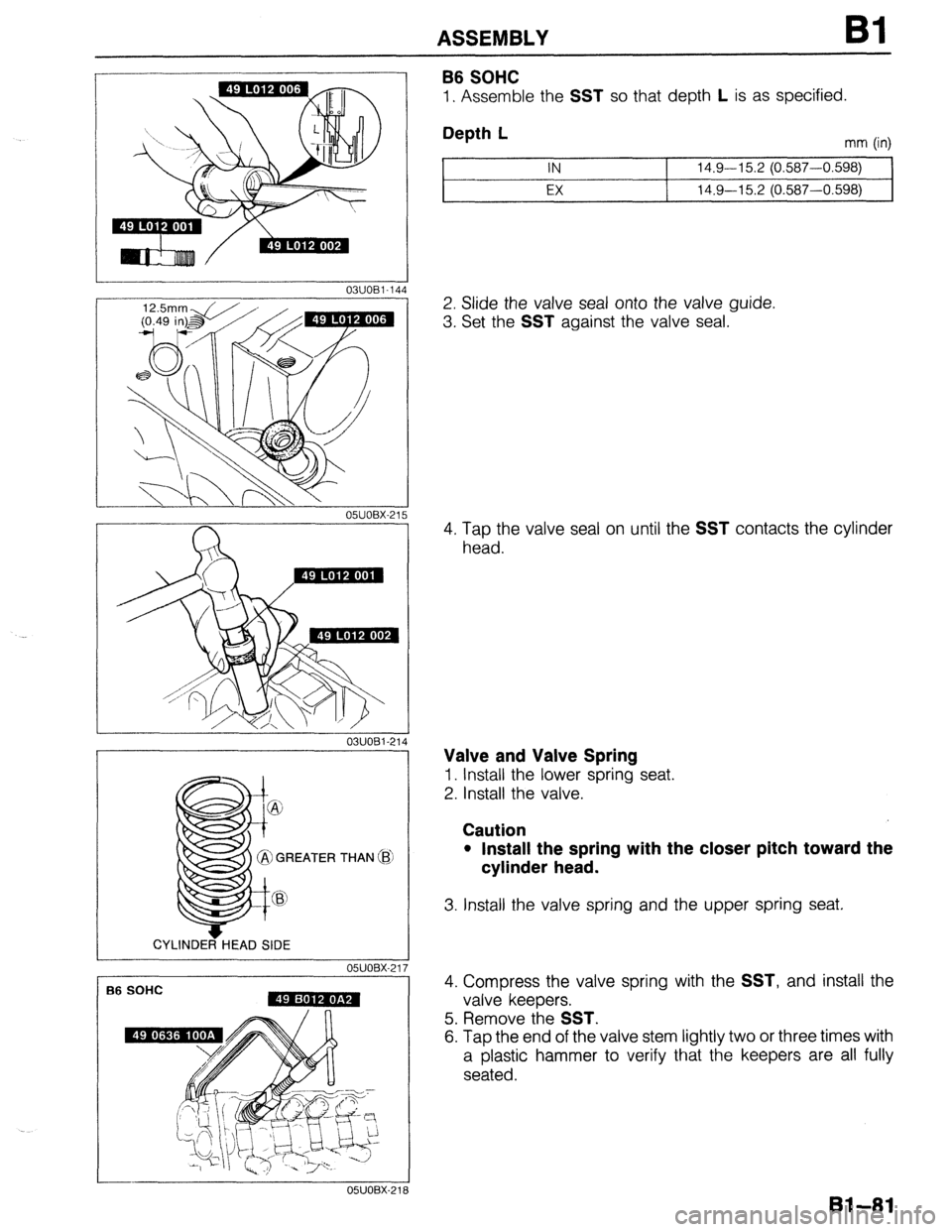

1. Assemble the SST so that depth L is as specified.

Depth L mm (in) 1 IN 14.9-15.2 (0.587-0.598)

EX 14.9-15.2 (0.587-0.598)

2. Slide the valve seal onto the valve guide.

3. Set the

SST against the valve seal.

4. Tap the valve seal on until the

SST contacts the cylinder

head.

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

Caution

l Install the spring with the closer pitch toward the

cylinder head.

3. Install the valve spring and the upper spring seat.

4. Compress the valve spring with the

SST, and install the

valve keepers.

5. Remove the

SST.

6. Tap the end of the valve stem lightly two or three times with

a plastic hammer to verify that the keepers are all fully

seated.

131-81

Page 159 of 1164

ON-VEHICLE MAINTENANCE

I 05UOBX-063

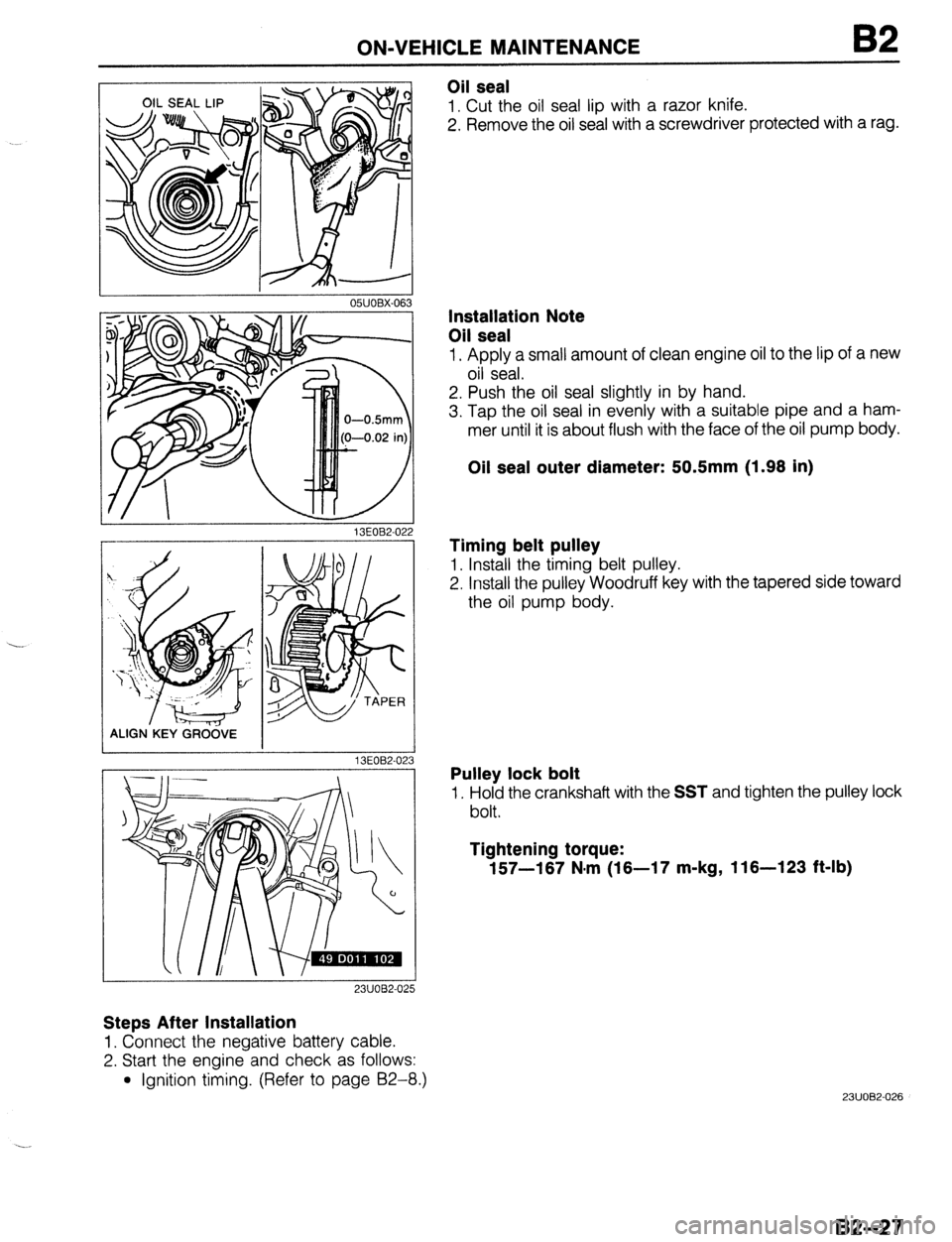

Oil seal

1. Cut the oil seal lip with a razor knife.

2. Remove the oil seal with a screwdriver protected with a rag.

13EOB2-02

ALIGN.KEY GRCi&E

13EOB2-02

23UOB2-025

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page 92-8.)

3

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

3. Tap the oil seal in evenly with a suitable pipe and a ham-

mer until it is about flush with the face of the oil pump body.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley Woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-187 N.m (18-17 m-kg, 116-123 ft-lb)

23UOB2-026

82-27

Page 207 of 1164

ASSEMBLY 82

03UOB2-09

03UOB2-094

-

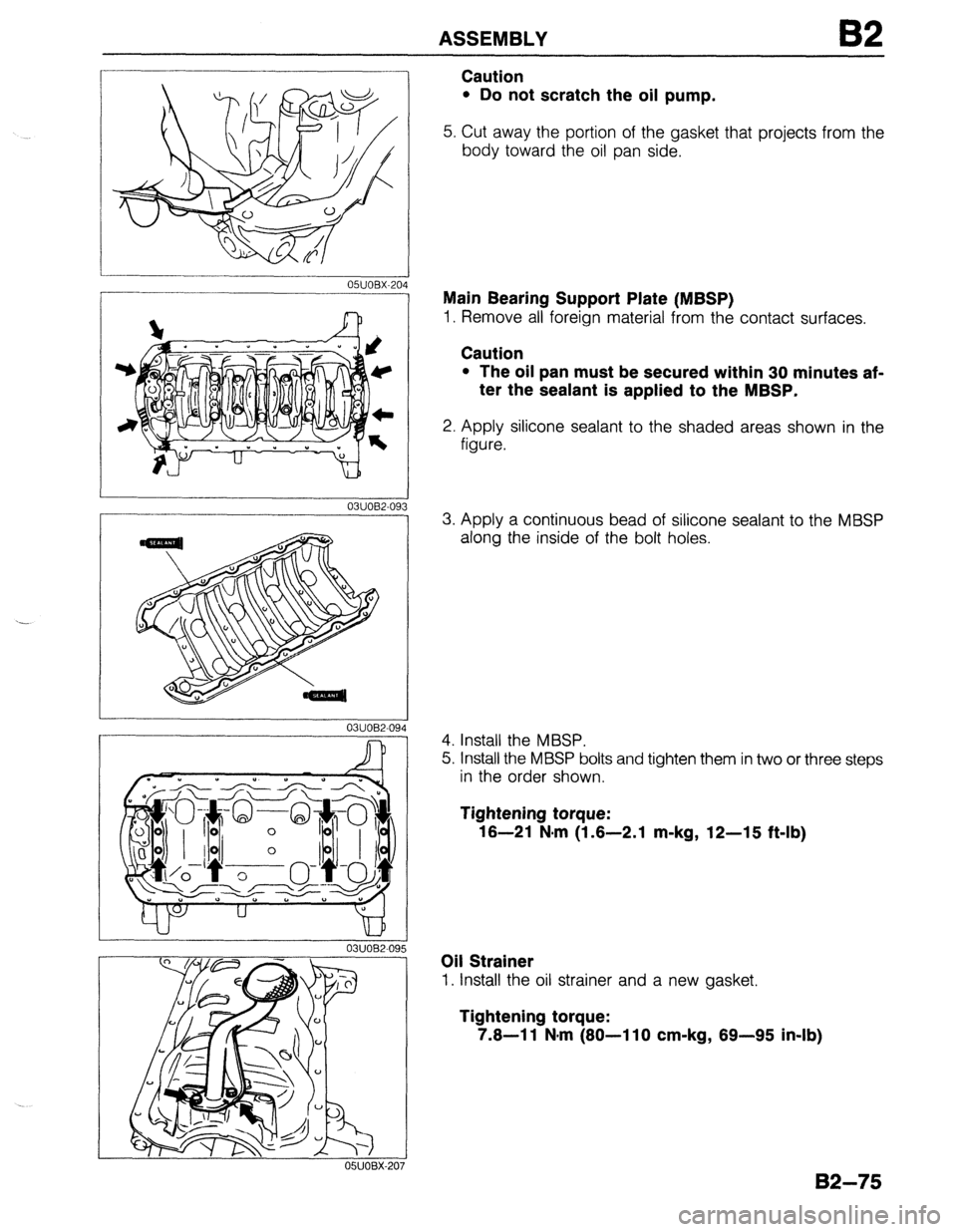

Caution

l Do not scratch the oil pump.

5. Cut away the portion of the gasket that projects from the

body toward the oil pan side.

Main Bearing Support Plate (MBSP)

1. Remove all foreign material from the contact surfaces.

Caution

l The oil pan must be secured within 30 minutes af-

ter the sealant is applied to the MBSP.

2. Apply silicone sealant to the shaded areas shown in the

figure.

3. Apply a continuous bead of silicone sealant to the MBSP

along the inside of the bolt holes.

4. Install the MBSP.

5. Install the MBSP bolts and tighten them in two or three steps

in the order shown.

Tightening torque:

16-21 N,m (1.6-2.1 m-kg, 12-15 ft-lb)

Oil Strainer

1. Install the oil strainer and a new gasket.

Tightening torque:

7.6-l 1 N-m (80-l 10 cm-kg, 89-95 in-lb)

B2-75

Page 210 of 1164

I32 ASSEMBLY

Qill’ ’ 23UOB2-050

03UOB2-10

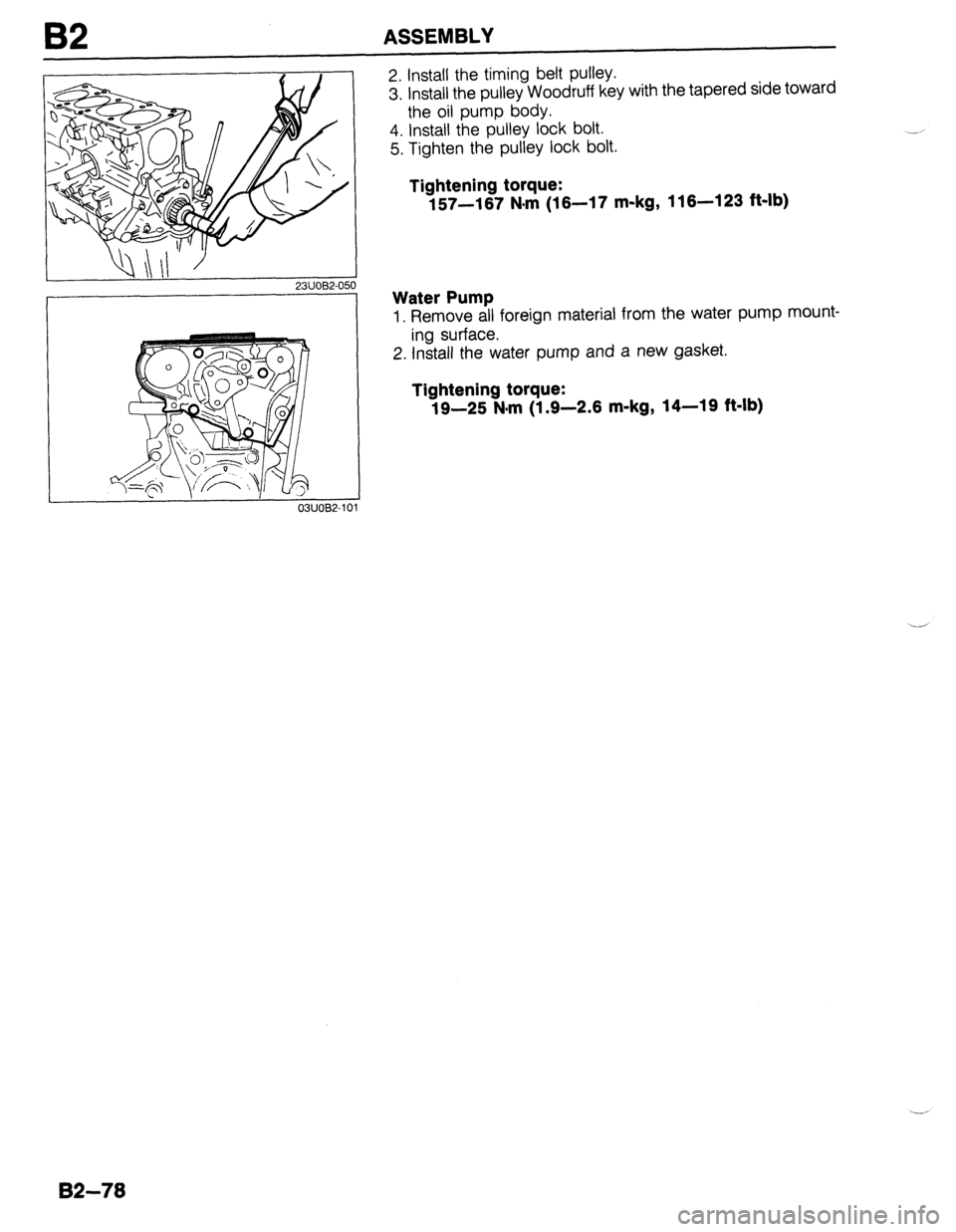

2. Install the timing belt pulley.

3. install the pulley Woodruff key with the tapered side toward

the oil pump body.

4. Install the pulley lock bolt.

5. Tighten the pulley lock bolt.

Tightening torque:

157-167 N#rn (16-17 m-kg, 116-123 ft-lb)

Water Pump

1. Remove all foreign material from the water pump mount-

ing surface.

2. Install the water pump and a new gasket.

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

82-78

Page 212 of 1164

62 ASSEMBLY

I OWOBX-21!

I CYLINDER HEAD SIDE

05UOBX-2

I

05UOBX-21 6

i

17

05UOBX-2

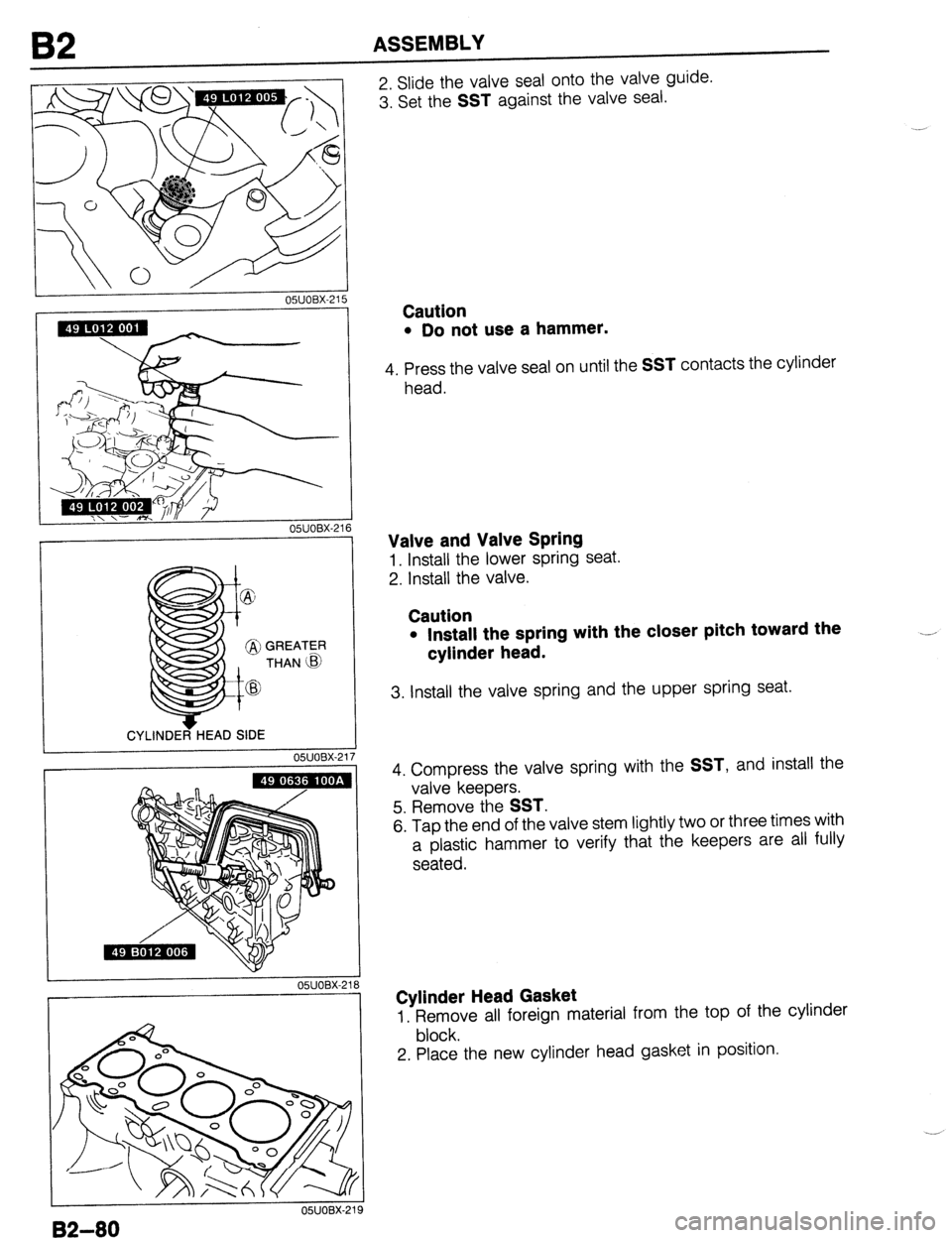

2. Slide the valve seal onto the valve guide.

3. Set the

SST against the valve seal.

Caution

l Do not use a hammer.

4. Press the valve seal on until the SST contacts the cylinder

head.

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

Caution

l Install the spring with the closer pitch toward the

cylinder head. .---

3. Install the valve spring and the upper spring seat.

4. Compress the valve spring with the

SST, and install the

valve keepers.

5. Remove the

SST.

6. Tap the end of the valve stem lightly two or three times with

a plastic hammer to verify that the keepers are all fully

seated.

Cylinder Head Gasket

1. Remove all foreign material from the top of the cylinder

block.

2. Place the new cylinder head gasket in position.

82-80

Page 247 of 1164

OIL PUMP D

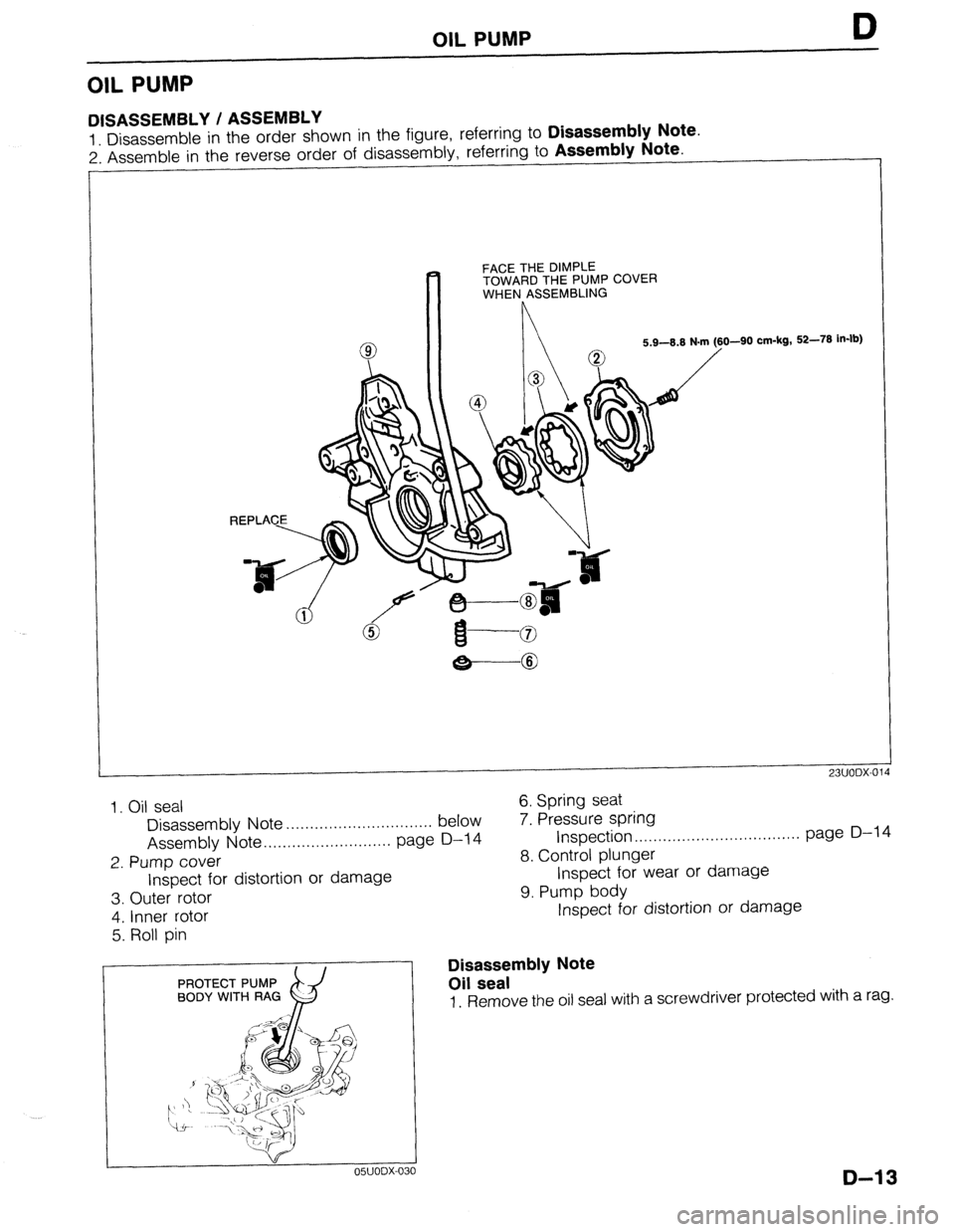

OIL PUMP

DISASSEMBLY / ASSEMBLY

1 Disassemble in the order shown in the figure, referring to Disassembly Note.

2: Assemble in the reverse order of disassembly, referring to Assembly Note.

FACE THE DIMPLE

TOWARD THE PUMP COVER

WHEN ASSEMBLING

O-90 cm-kg, 52-78 in-lb)

-8

23UODX-014

1. Oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

Assembly Note .,,..,.....,..,............ page D-14

2. Pump cover

Inspect for distortion or damage 6. Spring seat

7. Pressure spring

Inspection ..,..,.....,..,..,..,.............. page D-l 4

8. Control plunger

Inspect for wear or damage

9. Pump body

3. Outer rotor

4. Inner rotor

5. Roll pin

PROTECT PUMP

BODY WITH RAG

x9 05UODX-OC IO

Inspect for distortion or damage

Disassembly Note

Oil seal

1. Remove the oil seal with a screwdriver protected with a rag.

D-13