brake light MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 679 of 1164

CONVENTIONALBRAKESYSTEM P

1 SUOPX-001

03UOPX-03

0

o3uoPx-os

0

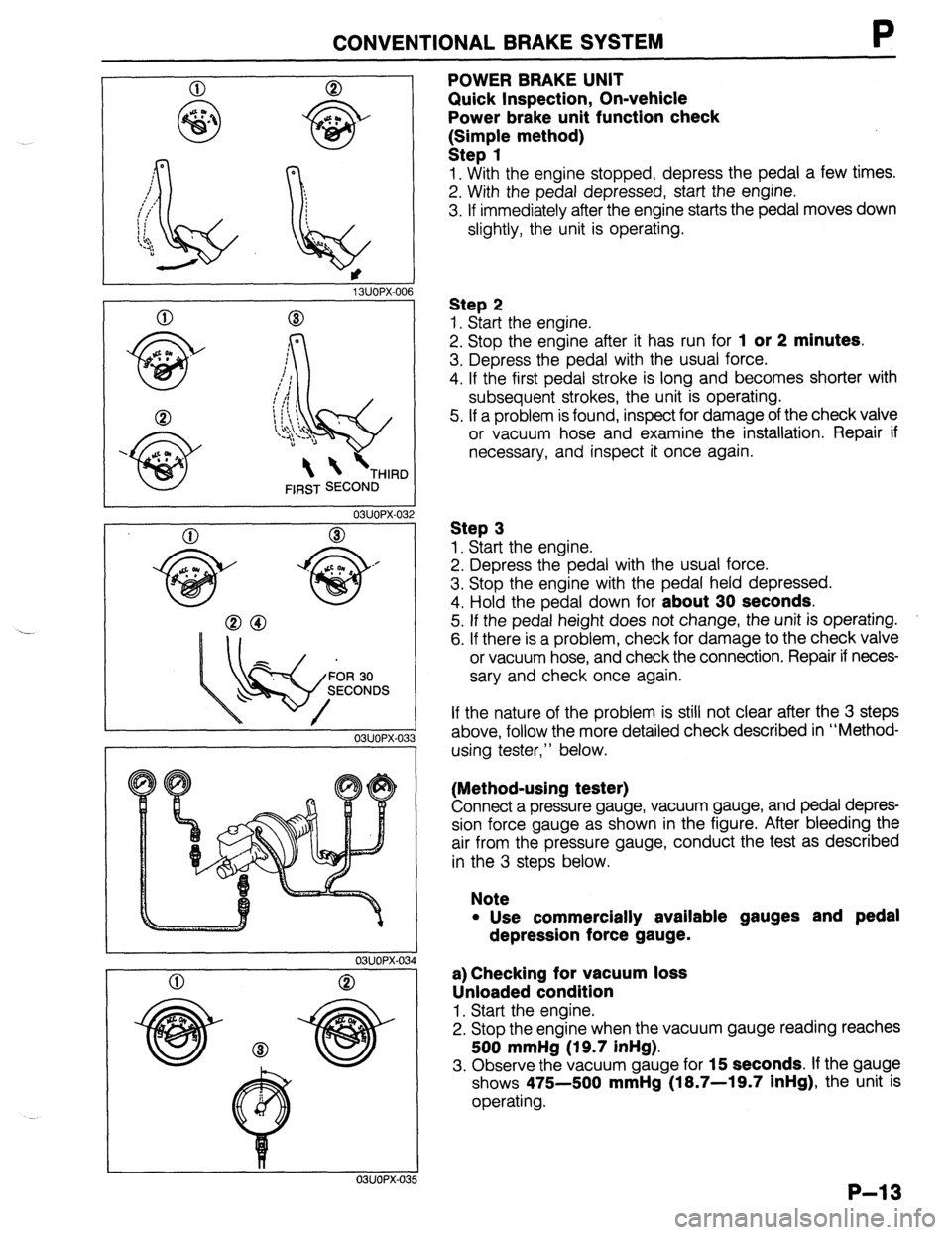

POWER BRAKE UNIT

Quick Inspection, On-vehicle

Power brake unit function check

k:;;p{e method)

1. With the engine stopped, depress the pedal a few times.

2. With the pedal depressed, start the engine.

3. If immediately after the engine starts the pedal moves down

slightly, the unit is operating.

Step 2

1. Start the engine.

2. Stop the engine after it has run for

1 or 2 minutes.

3. Depress the pedal with the usual force.

4. If the first pedal stroke is long and becomes shorter with

subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the check valve

or vacuum hose and examine the installation. Repair if

necessary, and inspect it once again.

Step 3

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal held depressed.

4. Hold the pedal down for

about 30 seconds.

5. If the pedal height does not change, the unit is operating.

6. If there is a problem, check for damage to the check valve

or vacuum hose, and check the connection. Repair if neces-

sary and check once again.

If the nature of the problem is still not clear after the 3 steps

above, follow the more detailed check described in “Method-

using tester,” below.

(Method-using tester)

Connect a pressure gauge, vacuum gauge, and pedal depres-

sion force gauge as shown in the figure. After bleeding the

air from the pressure gauge, conduct the test as described

in the 3 steps below.

Note

l Use commercially available gauges and pedal

depression force gauge.

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading reaches

500 mmHg (19.7 inHg).

3. Observe the vacuum gauge for 15 seconds. If the gauge

shows 475-500

mmHg (18.7-19.7 inHg), the unit is

operating.

P-13

Page 867 of 1164

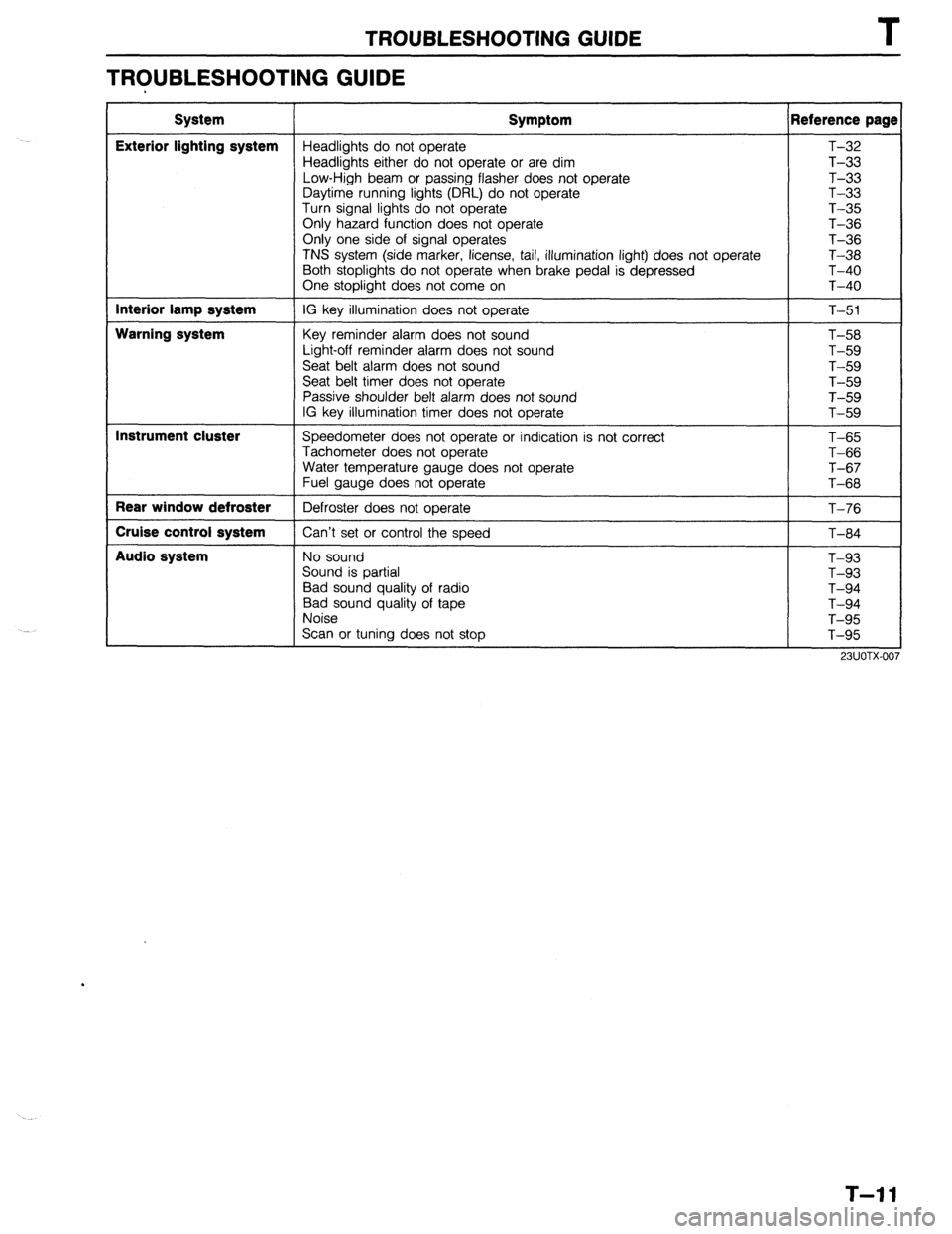

TROUBLESHOOTING GUIDE T

TROUBLESHOOTING GUIDE

System

Exterior lighting system

Interior lamp system

Warning system

Instrument cluster

Rear window defroster

Cruise control system

Audio system Symptom Reference page

Headlights do not operate T-32

Headlights either do not operate or are dim T-33

Low-High beam or passing flasher does not operate T-33

Daytime running lights (DRL) do not operate T-33

Turn signal lights do not operate T-35

Only hazard function does not operate T-36

Only one side of signal operates

T-36

TNS system (side marker, license, tail, illumination light) does not operate T-38

Both stoplights do not operate when brake pedal is depressed T-40

One stoplight does not come on T-40

IG key illumination does not operate

T-51

Key reminder alarm does not sound

Light-off reminder alarm does not sound

Seat belt alarm does not sound

Seat belt timer does not operate

Passive shoulder belt alarm does not sound

IG key illumination timer does not operate T-58

T-59

T-59

T-59

T-59

T-59

Speedometer does not operate or indication is not correct

Tachometer does not operate

Water temperature gauge does not operate

Fuel gauge does not operate

Defroster does not operate

Can’t set or control the speed T-65

T-66

T-67

T-68

T-76

T-84

No sound

Sound is partial

Bad sound quality of radio

Bad sound quality of tape

Noise

Scan or tuning does not stop T-93

T-93

T-94

T-94

T-95

T-95

T-l 1

Page 889 of 1164

EXTERIOR LIGHTING SYSTEM T

Headlights either do not operate or are dim Low-High beam or passing flasher does not

J operate

Burnt out bulb or poor grounding J

03UOTX-049 Defective combination switch

03UOTX-050

(Canada) Daytime running lights (DRL) do not operate

Confirm that headlights operate with the light switch ON

(second position) OK

Turn OFF the light switch and turn ON the ignition

switch when parking level pulling

I

Check head 30A main fuse OK

Check DRL resistor OK Repair DRL resistor 10A fuse

Confirm battery voltage on R and L/G wire of the DRL NG

relay Repair harness (Fuse - DRL relay)

I

I

Check the DRL relay

Repair DRL relay

1 OK

Confirm battery voltage on (BRNV) wire of the DRL con-

trol unit NG

Repair harness (DRL relay - DRL control unit) OK

Confirm battery voltage on (L/G) wire of the DRL control NG

unit Repair harness (Rear wiper fuse - DRL control unit) OK

Confirm continuity of (G/R) wire of the DRL control unit x Repair harness (DRL control unit - Parking brake

to ground switch) or check the parking brake switch 1 OK

Confirm continuity on (B) wire of the DRL control unit to

NG

ground Repair harness (DRL control unit ground) OK

-1 NG

Confirm approx. 8V on the DRL resistor Repair harness (DRL control unit - DRL headlight)

I

Confirm battery voltage on (

Confirm approx. 8V on (R/W) wire of the DRL resistor Repair harness (DRL resistor - DRL relay)

Repair harness (DRL control unit - DRL resistor)

23UOTX-019

T-33

Page 896 of 1164

I

EXTERIOR LIGHTING SYSTEM

Both stoplights do not operate when brake pedal is

depressed

i

Check stop 20A fuse

I Short circuit

Confirm battery voltage on G/W wire of the stoplight

switch

I Repair harness (Fuse - Stoplight switch) OK

Check the voltage with the brake pedal depressed

I

BD

c

Confirm battery voltage on G Replace the stoplight switch

8) OK

Confirm battery voltage on G Repair harness (Stoplight switch - Stoplight)

(B

Confirm continuity on B wir Repair harness (Stoplight - Body ground)

I I I

I

Replace the bulb

I

23UOTX-023 One stoplight does not come on

Burnt out bulb or faulty grounding

03UOTX-058

T-40

Page 903 of 1164

EXTERIOR LIGHTING SYSTEM T

03UOTX-07

STOPLIGHT SWITCH

Inspection

1. Remove the stoplight switch connector.

2. Connect an ohmmeter between terminals of the stoplight

switch.

3. Confirm continuity between the terminals when the brake

pedal is depressed.

SACK-UP LIGHT SWITCH (For MTX)

Inspection

1. Remove the back-up light switch connector.

2. Shift to the reverse position.

3. Confirm continuity between the R/G and the B/Y wire of the

connector.

LICENSE PLATE LIGHT

Removal / Inspection / Installation

1. Remove in the order shown in the figure.

2. inspect all parts and repair or replace as necessary

3. Install in the reverse order of removal.

PROTEGi

1. Nut

2. Gasket

3. Bulb 4. License plate light (Rear finisher)

Visual inspection

T-47

Page 920 of 1164

2L BUZZER 2A 28 2C 2D 1A 3K l--r nnmn

I I‘ I

1C 3L 2E 2G IL iG 1F 1D tB

3F 38 3G 1E 3D

l-l rt

II l-l

l-l It II l-l 1J 11 1H

1G IF 1E 1D 1C 1B 1A 2L 2K 2J 21 2H 2G 2F 2E 2D 2C 28 2A

r-l It ,I 3L 3K 3J 31 3H 3G 3F 3E 3D 3C 3B 3A

Ter- I I minal Connected to 1 1A Combination switch

1B Ground

IC Fuel tank unit

1 ID 1 EGI control unit

I

II L 1J 1

L Ter-

minal Connected to

2A Speed sensor output

28 Light switch (high beam)

2C Turn switch (L)

20 Turn switch (R)

2E Ground

2F Ground

2L 1 IGI battery Ter-

minal Connected to

3A

38 Alternator

3c

30 Oil pressure switch

3E

3F Parking brake switch, Brake fluid switch

3G Passive shoulder belt control unit

3H h

I 31

3J

3K

IG2 battery

3L Water temperature gauge unit

Page 938 of 1164

CRUISE CONTROL SYSTEM

I

23UOTX-056

1 23UOTX-057

Inspection Procedure

Quick inspection of cruise control system

1. Locate the cruise control connector.

2. Connect a 1.4W test light between terminals f and d, with

connector attached to control unit. -1

Note

l There is no wire in terminal d of the connector. Push

the test light through the connector and touch the

corresponding pin on the control unit.

3. Turn the ignition switch to ON.

4. Verify that the MAIN switch is OFF. (The MAIN indicator lamp

is OFF.)

5. Press the RESUMElACCEL switch and the MAIN switch

simultaneously to activate the system inspection. (The MAIN

indicator lamp will come ON.)

6. Operate each switch as described below and verify the oper-

ation codes.

7. Press the MAIN switch to deactivate the system inspection.

(The MAIN indicator lamp will go OFF.)

Note

l The cruise control system will not operate when in

the self-diagnosis mode.

Operation Code Numbers

Inspection of cruise control system

The test light will flash if the system is operating correctly. If the light fails to flash, inspect the system.

Note

l Shift the selector lever to D or R range before operating the inspection. (For ATX)

l Shift to the gear except the neutral position. (For MTX)

Procedure

Press SET/COAST switch Pattern of output signal Code

(Test light) No. Actlon to inspect ON

n II 21 Inspect cruise control switch

(Refer to page T-21)

OFF

Press RESUMElACCEL switch

ON

n 22 inspect cruise control switch

(Refer to page T-21)

OFF

Depress brake pedal

ON

n ml 31 Inspect stoplight switches

(Refer to pages T-47 and

OFF T-88)

Turn ignition switch to ON and shift the ON 35 Inspect inhibitor switch

selector lever to P or N range (For ATX) (Refer to Section K) or clutch

Depress clutch pedal (For MTX) switch (Refer to Section F)

OFF

Drive vehicle above 40 km/h (25 mph) ON 37 Inspect speed sensor or wire

harness

OFF

I

1

. . . _

T-82

Page 942 of 1164

I

CRUISE CONTROL SYSTEM

s q 0 m

9 e c a

t rpn i j

h

f d b

*

Inspection

Cruise control unit

1. Connect a voltmeter between cruise control unit and ground.

2. Turn the ignition switch ON and check the terminal voltages

as described below.

03UOTX-146

VB: Batterv voltage

c (Output) Actuator

I ov

Approx. 9V

e (Input)

I Cruise control main

I

VB switch (NC)

f (Input)

9 Wv-4 Cruise control main

switch (N.0)

EC-AT control unit

VB

V0

h (Output) (only ATX)

Stoplight switch 2 (N.C) Approx. 9V

i (hW Note I

Inhibitor switch (ATX)

I ov

Approx. 5V Disconnect t

EGI control

Clutch switch (MTX)

ov unit connector Approx. 5V

Cruise control switch

(Set/coast switch) V0

Approx. 5V unit connector

a

S I Battery

I VI3 t

1 Ground I ov Procedure

Ignition switch ON

Main switch ON

Ignition switch ON

Main switch ON

ignition switch ON

Main switch ON

Ignition switch ON

Main switch ON

Ignition switch ON

Main switch ON

“N” or “P” range and main switch ON

Other range and main switch ON

Clutch pedal depressed and main switch ON

Main switch ON

Horn switch OFF

Ignition switch ON

Brake pedal depressed

Main switch ON

While pushing the resumelaccel switch after main switch

ON

Main switch ON

While pushing the set/coast switch after main switch ON

Main switch ON

Brake pedal depressed

While rotating the rear tire

Constant

Constant

23UOTX-OE $0

‘,.__,

_ _-_,’

T-86

Page 943 of 1164

CRUISE CONTROL SYSTEM T

OSUOTX-14

PEDAL HEIGHT

03UOTX-I 4’

OSUOTX-18

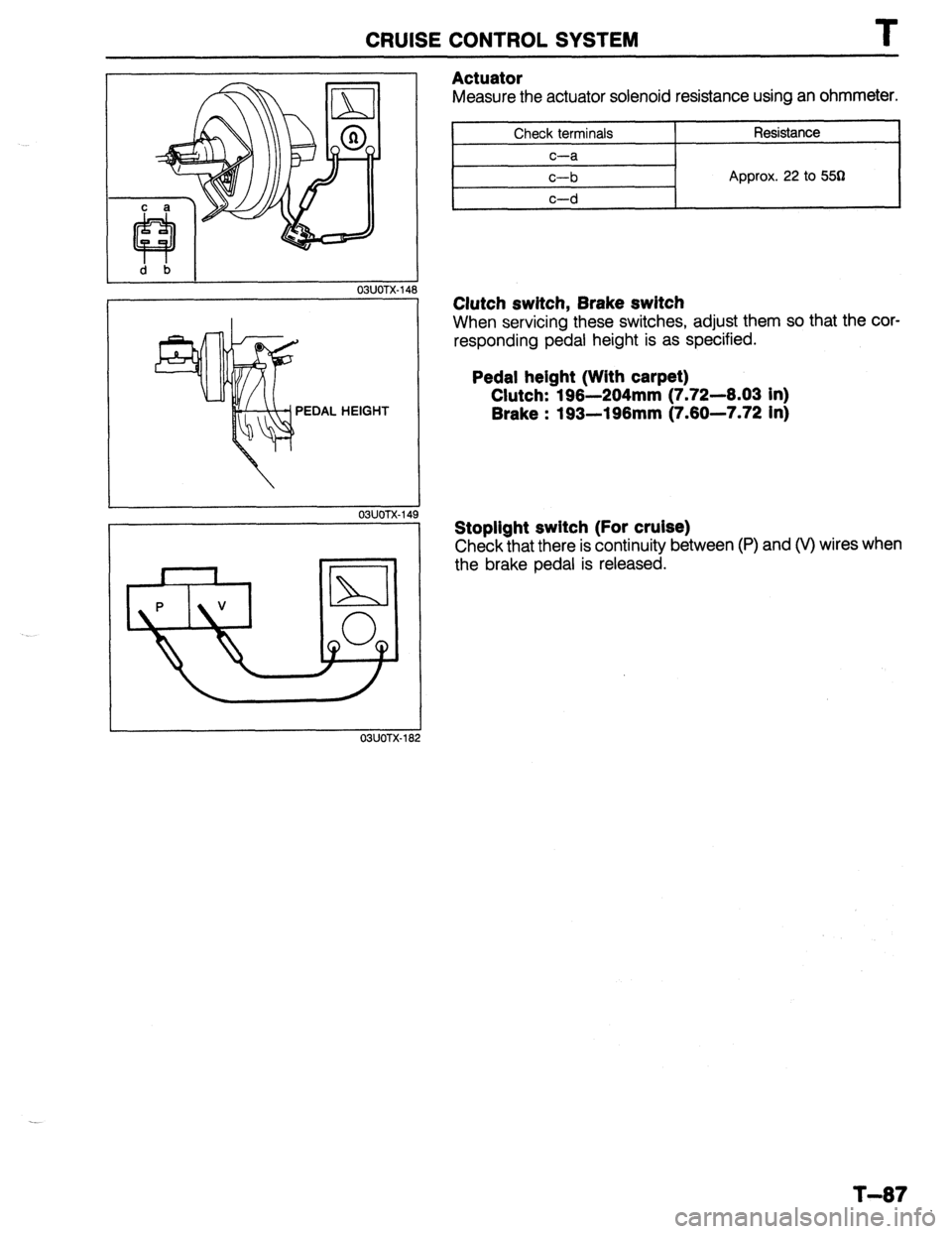

Actuator

Measure the actuator solenoid resistance using an ohmmeter.

Check terminals

c-a

c-b Resistance

Approx. 22 to 553

Clutch switch, Brake switch

When servicing these switches, adjust them so that the cor-

responding pedal height is as specified.

Pedal height (With carpet)

Clutch: 196-204mm (7.72--6.03 in)

Brake : 193-196mm (7.60-7.72 in)

Stoplight switch (For cruise)

Check that there is continuity between (P) and (V) wires when

the brake pedal is released.

T-87

Page 1034 of 1164

TD TECHNICAL DATA

Coil Spring Specifications (See page R-5 for coil spring applications)

*’ Main identification mark color: Indicated on second coil from bottom. l * Auxiliary identification mark color: Indicated on third coil from bottom.

T. BODY ELECTRICAL SYSTEM

Item

Headlight

Frnnt tl wn sinnnl/Pnrkinn linht

Specification (W) (Bulb Trade number)

65145 (9004)

2718 II I 571

I

“‘VW, I u”“y’ 1. I” \’ ‘V’,

uinh mount stoplight 18.4 (1141)

turn single light 27 (1156)

Y-,-~p light 27 (1156)

Rear side marker light (Sedan) 3.8 (194)

License plate light 7.5 (89) [PROTEGE], 5 (168) [3HBl

Interior 10

Interior and spot lamp

spot 6

Interior lamp 10

‘i--” Spot lamp (in overhead console)

8 (67)

Cargo room lamp 5 (168)

Trunk room lamp 5 (168)

I I

ntminr Iamnc

I

Curtesy lamp

High beam

Turn light

Brake

Hold

) Charge 5 (168)

3.4

3.4

3

3 (158)

i

Oil pressure

Washer

Seat belt

Malfunction

Fuel

illumination 3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3.4 Indicator and

warning lamps

Check 3 (158)

Dif. lock

I 3 (158) .-

,

-.-’

I

I

TD-20