coolant level MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 252 of 1164

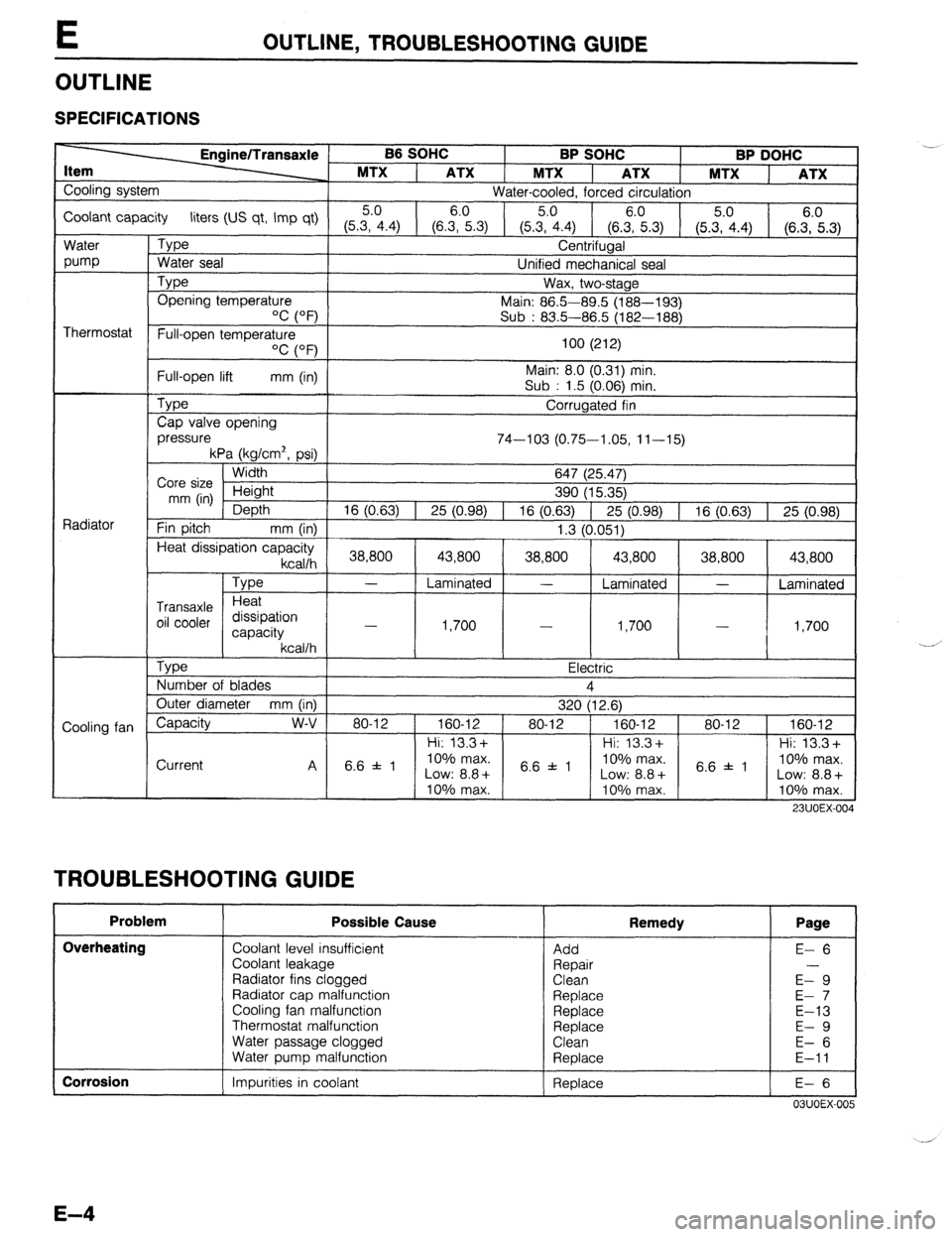

E OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

B6 SOHC

BP SOHC BP DOHC

MTX

1 ATX 1 MTX ATX 1 MTX

ATX

Cooling system

Water-cooled, forced circulation

Coolant capacity liters (US qt, Imp qt) 5.0 6.0

5.0

(5.3, 4.4) (6.3, 5.3)

(5.35.04.4) (6.zi.3) (5.3, 4.4) (6.::.3)

Water

pump

Thermostat

Radiator

Cooling fan

L Type

Water seal Centrifugal

Unified mechanical seal

Type Opening temperature

‘C (OF’) Wax, two-stage

Main: 86.5-89.5 (188-193)

Sub : 83.5-86.5 (182-188)

Full-open temperature

OC (OF)

Full-open lift mm (in)

Type

Cap valve opening

pressure 100 (212)

Main: 8.0 (0.31) min.

Sub : 1.5 (0.06) min.

Corrugated fin

74-103 (0.75-1.05, 11-15)

kPa (kg/cm2, psi)

Width

Core size Height

mm (in)

Depth

Fin pitch

mm (in) 647 (25.47)

390 (15.35)

16 (0.63) 1 25 (0.98) 1 16 (0.63) 1 25 (0.98) 1 16 (0.63) 1 25 (0.98)

1.3 (0.051)

Heat dissipation capacity

kcallh 1 38,800 [ 43,800 ( 38,800 1 43,800 1 38,800 1 43,800 1

Type

Transaxle Heat

oil cooler dissipation

capacity

kcallh

Tvoe

- Laminated - Laminated -

Laminated

1,700

I .I -?nn

- -

I,,“”

I

I - I 4 Ye,-. I,IVV 1

, a-

- Electric

Number of blades 4

Outer diameter mm (in)

320 (12.6)

Capacity w-v 80-12 1 160-12 ) 80-12 ) 160-12 1 80-12 1 160-12

1 Hi: 13.3+ 1 1 Hi: 13.3+ 1 1 Hi: 13.3+

Current

TROUBLESHOOTING GUIDE I I I I

Problem Possible Cause

Overheating

Coolant level insufficient

Coolant leakage

Radiator fins clogged

Radiator cap malfunction

Cooling fan malfunction

Thermostat malfunction

Water passage clogged

Water puma malfunction .- Remedy Page

Add

Repair

Clean

Replace

Replace

Replace

Clean

Reolace E- 6

E-9

E- 7

E-13

E- 9

E- 6

E-11

I Corrosion

1 Impurities in coolant 1 Replace

I E-6 I

03UOEX-005

Page 253 of 1164

ENGINE COOLANT E

ENGINE COOLANT

PREPARATION

SST

49 9200 145

For 49 9200 146

For

inspection of inspection of

cooling system Adapter A cooling system

pressure (Part of pressure

49 9200 145)

05UOEX-00

INSPECTION

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap when removing it.

l When removing the radiator cap, loosen it slowly

to the first stop until the pressure in the radiator is

released, and then remove it.

03UOEX~006

Coolant Level (Engine cold)

1. Verify that the coolant level is near the radiator filler neck.

2. Remove the coolant level gauge and check the coolant level.

Coolant Quality

1. Verify that there is no buildup of rust or scale around the

radiator cap or radiator filler neck.

2. Verify that coolant is free of oil. Replace the coolant if

necessary.

Coolant Leakage

1. Connect a radiator tester (commercially available) and the

SST to the radiator filler neck.

2. Apply

103 kPa (1.05 kg/cm2, 15 psi) pressure to the

system.

3. Verify that the pressure is held.

If not, check for coolant leakage.

E-5

Page 344 of 1164

F ENGINE TUNE-UP

ENGINE TUNE-UP

PREPARATlON

SST

I

I I

49 BO19 9AO

System Selector For

inspection of igni-

tion timing and

idle speed

hA ‘I

03UOFX-04

03UOFX-04

03UOFX-04

NG POINT

03UOFX-04 03UOFX-045

BASIC INSPECTION

Engine Oil

1. Remove the engine oil level gauge and check the engine

oil level and oil condition.

2. Add or change the oil as necessary.

Coolant

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap before carefully

removing it.

1. Remove the coolant level gauge from the coolant reservoir.

2. Check that the coolant level is between the L and F marks

of the gauge.

3. Add coolant if necessary.

Battery

1. Check for corrosion on the terminals and for loose cable

connections. If necessary, clean the clamps and tighten

them firmly.

2. Check that the electrolyte level is between the UPPER LEV-

EL and LOWER LEVEL marks.

3. Add distilled water if necessary.

4. Check the specific gravity with a hydrometer.

Gravity: 1.27-l .29 (at 20% [68OF] )

Page 710 of 1164

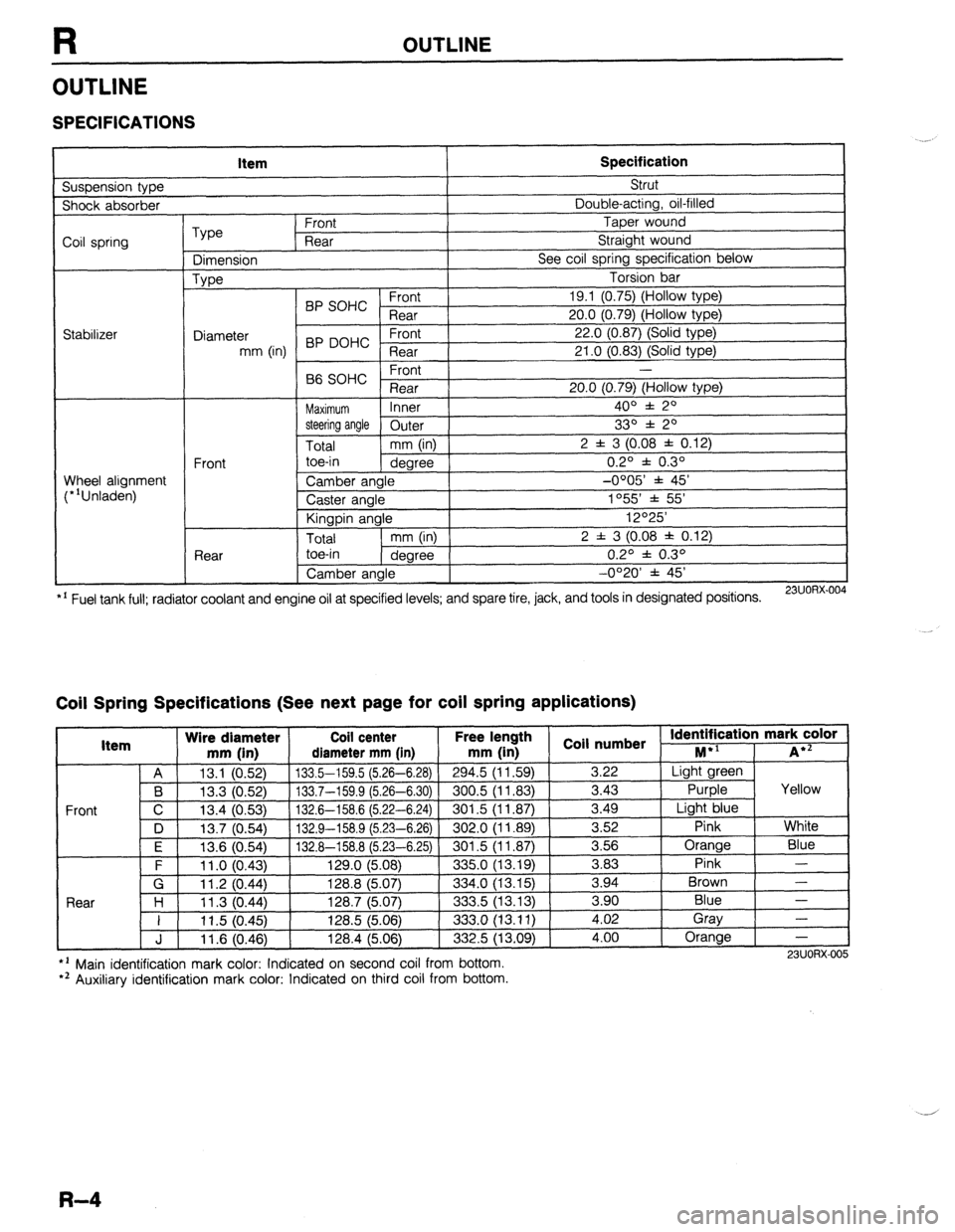

R OUTLINE

OUTLINE

SPECIFICATIONS

Suspension type Item Specification Strut

Shock absorber Double-acting, oil-filled

Coil spring

Stabilizer Type Front Taper wound

Rear Straight wound

Dimension See coil spring specification below

Type Torsion bar

BP SOHC Front 19.1 (0.75) (Hollow type)

Rear 20.0 (0.79) (Hollow type)

Diameter 22.0 (0.87) (Solid type)

mm (in) BP DOHC ;eTrt

21 .O (0.83) (Solid type)

P ,

-

66 SOHC rronr

Rear 20.0 (0.79) (Hollow type)

Maximum Inner 400 f 20

steering angle

Outer 330 f 20

Total mm (in) 2 f 3 (0.08 f 0.12)

Front toe-in

degree 0.2O f 0.3O

Wheel alignment

(*‘Unladen) Camber angle -0005’ f 45’

Caster angle 1055 * 55’

Kingpin angle 12O25’

Total mm (in) 2 f 3 (0.08 * 0.12)

Rear toe-in

degree 0.2O f 0.3O

Camber angle -0°20’ f 45’

*’ Fuel tank full; radiator coolant and engine oil at specified levels; and spare tire, jack, and tools in designated positions.

23UORX.004

Coil Spring Specifications (See next page for coil spring applications)

I Item Wire diameter Coil center Free lel.=-. .

mm iin1 rliamotor mm [in mm (in 1 coil numbs

Front

nath

1 _ . . *St Identification mark color +l

., . . . . I...,

-*.....-.“, * . . . . . ,..-, -....- I--‘, M iA*=

A 13.1 (0.52) 133.5-159.5 (5.26-6.28)

294.5 (11.59) 3.22 Light green

B 13.3 (0.52) 133.7-159.9 (5.26-6.30) 300.5 (11.83)

3.43 Purple Yellow

C 13.4 (0.53)

132.6-158.6 (5.22-6.24) 301.5 (11.87) 3.49

Light blue

D 13.7 (0.54)

132.9-158.9 (5.23-6.26) 302.0 (11.89) 3.52

Pink White

I F I 12f3 Kl5Al I 1.17 A-l!% 8 f!i PR-Fi 751

I RrIl .5 II 1 6x71 I 3.56 Orange

Blue

3 83 Pink -

Brown - .“._ \“.- .,

. “W.., ~ - -. - \-. -- -. - -, -- .-

\’ .‘-‘I t

F 11 .o (0.43) 129.0 (5.08)

335.0 (13.19) -.--

G 11.2 (0.44) 128.8 (5.07)

334.0 (13.15) 3.94

Rnnr l-4

1 I ? 07 AA 1387 /5n7

.?m !i 113 1% 3 an Blue - I I I I .” \v.-7, I&V., \V.“., ---.., \.-. .-, I 11.5 (0.45) 128.5 (5.06)

333.0 (13.11) i:oi Gray

-

J 11.6 (0.46) 128.4 (5.06)

332.5 (13.09) 4.00 Orange

-

l ’ Main identification mark color: Indicated on second coil from bottom.

*’ Auxiliary identification mark color: Indicated on third coil from bottom. 23UORX-005

R-4

Page 713 of 1164

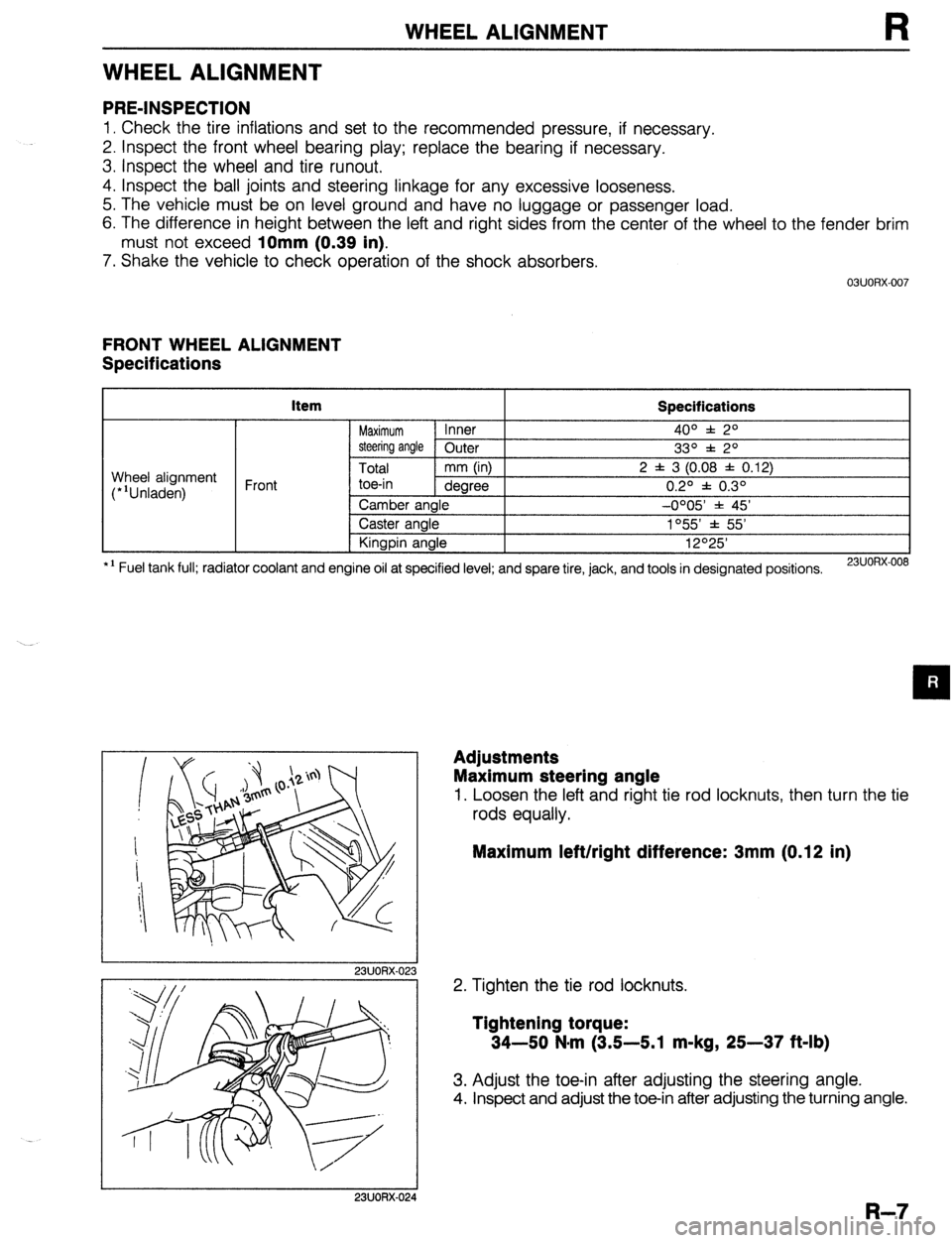

WHEEL ALIGNMENT

WHEEL ALIGNMENT

PRE-INSPECTION

1. Check the tire inflations and set to the recommended pressure, if necessary.

2. Inspect the front wheel bearing play; replace the bearing if necessary.

3. inspect the wheel and tire runout.

4. Inspect the ball joints and steering linkage for any excessive looseness.

5. The vehicle must be on level ground and have no luggage or passenger load.

6. The difference in height between the left and right sides from the center of the wheel to the fender brim

must not exceed

10mm (0.39 in).

7. Shake the vehicle to check operation of the shock absorbers.

03UORX.007

FRONT WHEEL ALIGNMENT

Specifications

item

Specifications

Maximum Inner 4o” f: 2O

steering angle Outer

33O f 2O

Total mm (in) 2 f 3 (0.08 f 0.12)

toe-in dearee 0.20 f 0.30 Wheel alignment

(*‘Unladen) Front

*I Fuel tank full; radiator coolant and Camber angle -0005 * 45’

Caster angle 1°55’ f 55’

Kingpin angle 12O25’

engine oil at specified level; and spare tire, jack, and tools in designated positions.

23UORX-008

I

I 23UORX-023

Adjustments

Maximum steering angle

1. Loosen the left and right tie rod locknuts, then turn the tie

rods equally.

Maximum left/right difference: 3mm (0.12 in)

2. Tighten the tie rod locknuts.

Tightening torque:

34-50 N-m (3.5-5.1 m-kg, 25-37 ft-lb)

3. Adjust the toe-in after adjusting the steering angle.

4. Inspect and adjust the toe-in after adjusting the turning angle.

I 23UORX-024

R-7

Page 715 of 1164

WHEEL ALIGNMENT

REAR WHEEL ALIGNMENT

Specifications

kern Specifications

Total mm (in) 2 f 3 (0.08 f 0.12)

Wheel alignment

(*‘Unladen) Rear toe-in

degree 0.2O f 0.3O

Camber angle -0020’ f 45’

*I Fuel tank full; radiator coolant and engine oil at specified level; and spare tire, jack, and tools in designated positions.

13UORX-012

Adjustment

Total toe-in

1. Loosen the lateral link locknuts.

2. Turn the lateral link adjustment link to adjust.

Note

l One turn of the link changes 11.3mm (0.44 in).

3. Tighten the lateral link locknuts to the specified torque.

Tightening torque:

55-64 N,m (5.6-6.5 m-kg, 41-47 ft-lb)

R-9

Page 1033 of 1164

TECHNICAL DATA

Q. WHEELS AND TIRES

Item Specifications

Wheel

Size

Off set Standard: 13x5-J, 14x5 l/2-JJ

Temporary

mm (in) 1 _ spare: 14x4-T

45 (1.77)

I Diameter of oitch circle

mm (in) I 100 (3.94)

r I Pl

-

Inflation pressure kPa (kg/cm*, psi) Front 1 8

I 9

Runout limit

Unbalance limit mm (in) ;lii.raltLa’

a (02) ’

13 inch wheel: 11 (0.

R. SUSPENSION Item Specifications

Suspension type Strut

)e Double-acting, oil-filled

I Shock absorber tyf

Coil spring

Type

Dimension

Type Front Taper wound

Rear Straight wound

See next page

Torsion bar

I

I C.rrn,

19.1 (0.75)

20.0 (0.79)

22.0 (0.87)

21 .O f0.83)

Wheel alignment

(“‘Unladened) BP SOHC ;;a;

Diameter

mm (in) BP DOHC - ;la;t

Front -

B6 SOHC

Rear 20.0 (0.79)

Maximum Inner 4o” f 2O

steering angle Outer

Total mm (in) 2 f 3 (0.08 j

Front toe-in

dearee

.-.._

Rear

.--. I --- ~~

Camber angle

Caster angle

Kingpin angle

I Total

I mm OnI I I toe-in

1 dearee I , --U’-- 1

Camber angle

I 33O * 2O

: 0.12)

0.2O f 0.3O

-0OO5’ * 45’

1055’ * 55’

12O25’

2 f 3 (0.08 f 0.12)

0.2O f 0.3O

-0°20’ f 45’

l ’ Fuel tank full; radiator coolant and engine ail at specified level; and spare tire, jack, and tools in designated posmons.

TD-19