cruise control MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 13 of 1164

CAUTION GI

CAUTION

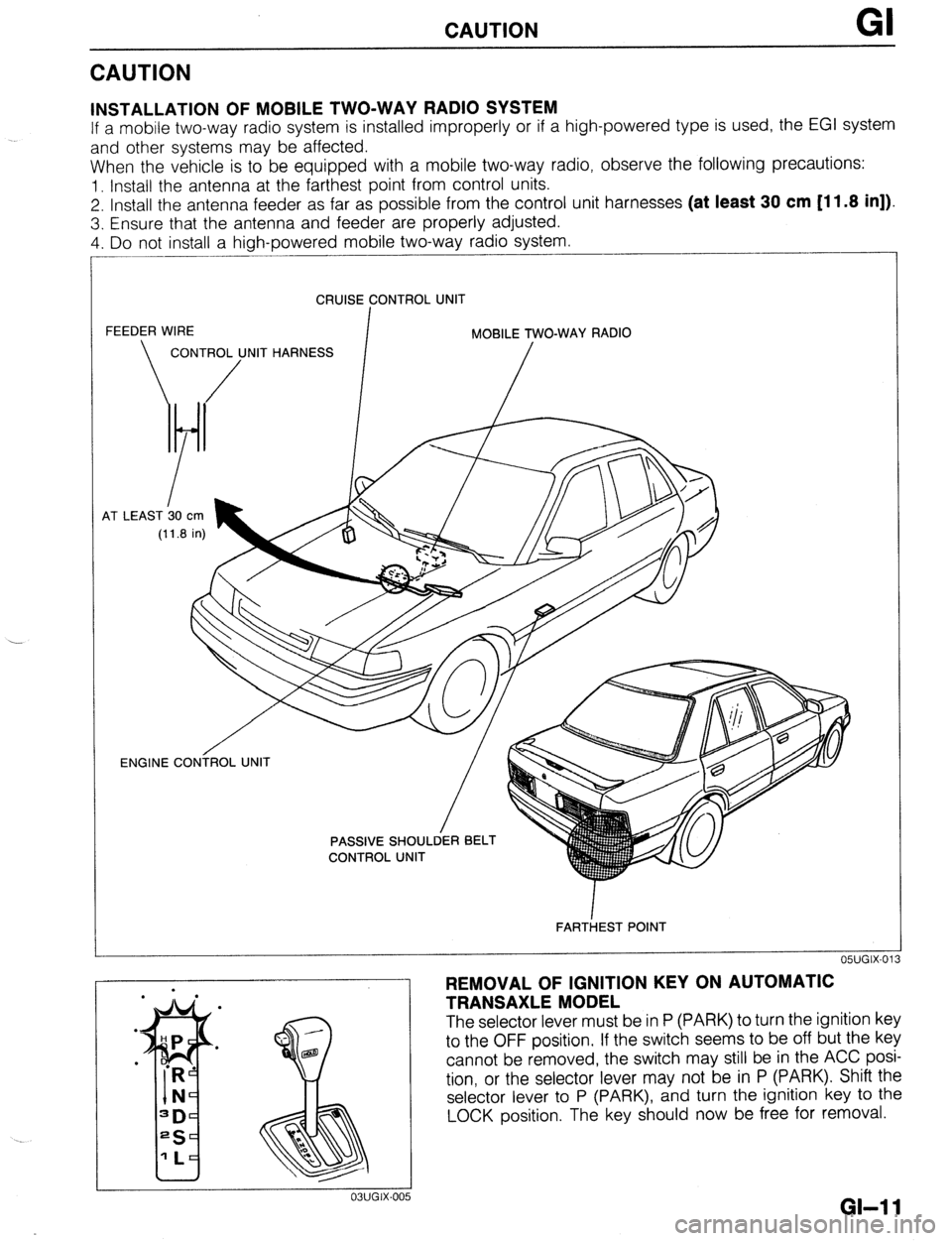

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a mobile two-way radio system is installed improperly or if a high-powered type is used, the EGI system

and other systems may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

1. Install the antenna at the farthest point from control units.

2. Install the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [11.8 in]).

3. Ensure that the antenna and feeder are properly adjusted.

4. Do not install a high-powered mobile two-way radio system.

CRUISE CONTROL UNIT

FEEDER WIRE

I MOBILE TWO-WAY RADIO

CONTROL UNIT HARNESS

/ /

4T LEAST b0

cm

(11.8 in)

OWGIX-013 ENGINE CONiROL UNIT

/

FARTiEST POINT

REMOVAL OF IGNITION KEY ON AUTOMATIC

TRANSAXLE MODEL

The selector lever must be in P (PARK) to turn the ignition key

to the OFF position. If the switch seems to be off but the key

cannot be removed, the switch may still be in the ACC posi-

tion, or the selector lever may not be in P (PARK). Shift the

selector lever to P (PARK), and turn the ignition key to the

LOCK position. The key should now be free for removal.

GI-1 1

Page 20 of 1164

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

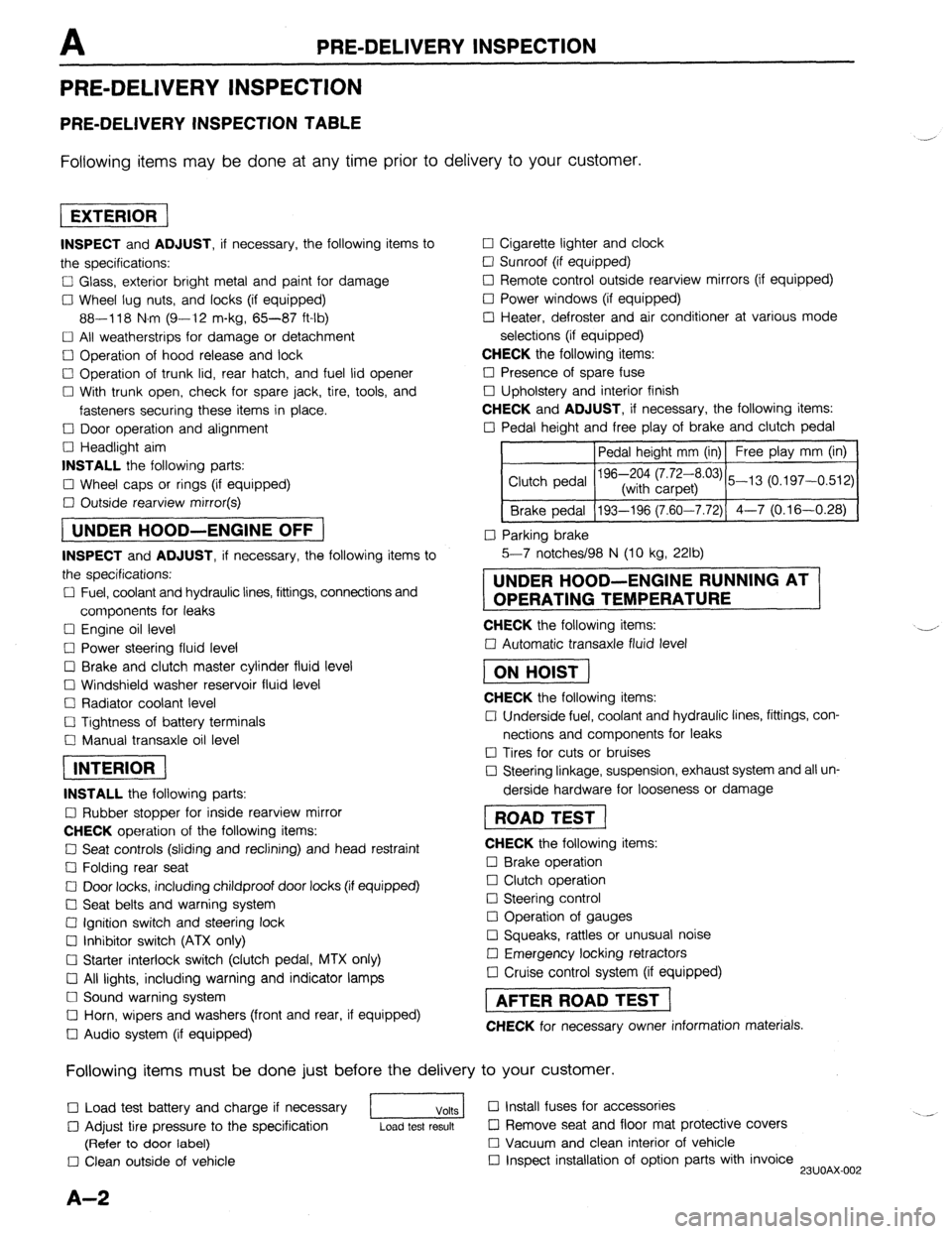

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 47 of 1164

ON-VEHICLE MAINTENANCE Bl

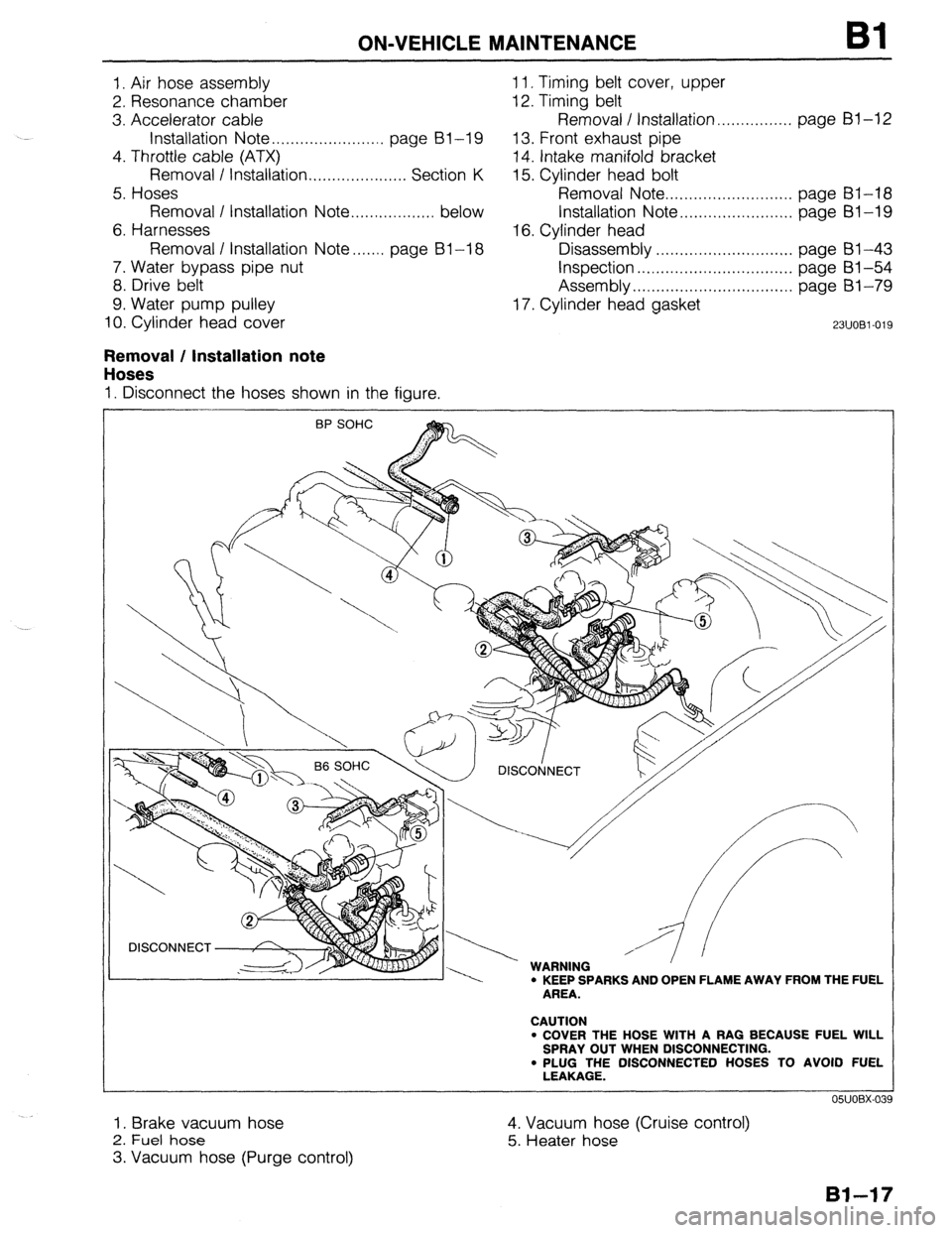

I. Air hose assembly 1 I. Timing belt cover, upper

2. Resonance chamber 12. Timing belt

3. Accelerator cable Removal / Installation.. . . . . . . . . . . . . . . page Bl-12

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page BI-I9 13. Front exhaust pipe

4. Throttle cable (ATX)

14. Intake manifold bracket

Removal / Installation . . . . . . . . . . . . . . . . . . . . . Section K 15. Cylinder head bolt

5. Hoses Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page BI-18

Removal I Installation Note ..,............... below Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Bl-I9

6. Harnesses 16. Cylinder head

Removal I Installation Note....... page BI-I8 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 61-43

7. Water bypass pipe nut

Inspection . . , . . . . . . . . . . . . . . . . . . . . . . . . . ., . . page BI -54

8. Drive belt Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page BI-79

9. Water pump pulley 17. Cylinder head gasket

10. Cylinder head cover

23UOBl-019

Removal / Installation note

Hoses

I. Disconnect the hoses shown in the figure.

\ / DlSCOtjNECT

, w I.,,, -----. WARNING ’ ’ ’ l KEEP SPARKS AND OPEN FLAME AWAY FROM THE FUEL

AREA.

CAUTION

l COVER THE HOSE WITH A RAG BECAUSE FUEL WILL

SPRAY OUT WHEN DISCONNECTING.

. PLUG THE DISCONNECTED HOSES TO AVOID FUEL

LEAKAGE.

I. Brake vacuum hose

2. Fuel hose

3. Vacuum hose (Purge control) 4. Vacuum hose (Cruise control)

5. Heater hose

Page 60 of 1164

Bl REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

BP SOHC

1. Brake vacuum hose

2. Fuel hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bl-30

05UOBX-078

03UOBi -050

below 3. Vacuum hose (Purge control)

4. Vacuum hose (Cruise control)

5. Heater hose

Removal Note ..,,,................................ below

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

Page 165 of 1164

REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

J”“DC-” I I

1. Fuel hose

3. Brake vacuum hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

4. Vacuum hose (Purge control)

2. Heater hose

Removal Note . . . . . . . . . . . . . , . . . . . . . . . . . .

05UOBX-078

0311082-052

. . . . .

below 5. Vacuum hose (Cruise control)

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

82-33

Page 231 of 1164

INSTALLATION

Step 4

I. Connect the hoses shown in the figure.

Caution Speedometer cable

1. Install the speedometer cable.

Exhaust pipe

1. Install the exhaust pipe and a gasket; then loosely tighten

the lock nuts.

2. Loosely tighten the bracket bolts.

3. Tighten the lock nuts.

Tightening torque:

31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb)

4. Tighten the bracket bolts.

Tightening torque:

37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

VACUUM HOSE

(CRUISE CONTROL) BRAKE, VACUUM HOSE 1 VACUUM HOSE

(PURGE CONTROL)

HEATER HOSE

FUE’L HOSE

03UOB2-14

B2-9:

Page 280 of 1164

F OUTLINE

A comparison of the new and previous models is as follows.

Engine Control Unit Terminal Relation Ship Chart

Connected to

Headlight switch Terminal

Connected to Terminal

New Previous New Previou

1H IU

Water thermosensor 2E 2Q

Diagnosis connector

(TEN terminal) / II 1 IK 1 1 Throttle sensor

Rear window defroster switch

I I 21 2K

Ground (California)

Main relay (Canada)

A/C relay

Vehicle speed sensor

P/S pressure switch

A/C switch

Blower control switch 1K 2H

IL 1J

1M --

1N 1P

10 IQ

1P 1s Distributor

(G-signal) [DOHC]

Intake air thermosensor

Solenoid valve

(Purge control)

Ground (Injector)

Ground (Output)

Ground (CPU) 2J 2G

2K 2P

20 2x

___

Stoplight switch 1Q 10

Ground (Input)

1 I I 1 ! 3D ! 2D

Cruise control main switch

1 lS / - II8cRalnardega,y

Throttle sensor

(Idle switch)

Distributor

(Ne-signal) 1T 1N

2A 2E

2B 20

2C 2N Solenoid valve

(VICS)

--.-- I_-

Solenoid valve

(Pressure regulator) [BP] 31 2s

-- -_

3M 2T

Airflow meter

Oxygen sensor

-

Fan switch 1 2D 1 IR 1 1 lniector (Nos. 2, 4) I 3v I 2v

23UOFX-01 I

F-l 4

Page 286 of 1164

F TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

ENGINE CONTROL OPERATION CHART

Note

Input Device and Engine Conditions

l The data in this chart is for reference only.

INPUT DEVICES APPROX,- SENSORS

MATE TIME G& THROTTLE SENSOR

(BASED ON TRIBUTOR

WATER INTAKE

10-16°C, (G. OXYGEN AIRFLOW AIR

VT

POW

.50-6OOF

SIGNAL)” ;;;;;f- SENSOR METER

AMBIENT) (Ne-SIGNAL) THERMO- TERMINAL TERMINAL yE\MINAL

CONDITIONS SENSOR (ATX)

WX)

A

c

CRANKING

-COLD ENGINE Signal has Signal has Signal has Signal has Slgnal has Slgnal has

l COLD AIR zero no affect no effect no effect no effect no effect

no effect

. COLD COOLANT on ECU on ECU on ECU on ECU on ECU

on ECU

Cool to A A

COLD START

warm: Low volume Closed Closed

Closed

-FAST IDLE

One

Medium airflow: throttle: throttle:

l COLD AIR

minute

voltage High volt-

Low volt- Low volt- throttle.

Low volt-

* COLD COOLANT

(3.5” and :zo:o, ,,Pbove 1’,“,“$; a(ogi-O,8”) ;149&“) we W)

dropping) to high

(68OF)]:

COLD DRIVEAWAY voltage A

Above

-PART THROTTLE Two (O-0.9”) 2.3”

l COLD AIR minutes

l COLD COOLANT

v v ,,

Warm: Medi- Sensor Moderate II

WARM DRIVEAWAY

volume air-

-PART THROTTLE Three N&IGNAL um voitage hot:

flow: Low

l WARM AIR minutes Sends all Vvwrox switching l WARM COOLANT cylinders 0.7V and

from high to medium

Part Part

TDC signal dropping) voltage voltage

throttle: throttle.

)

A (0.9V) (1 .o-3.5”)

to ECU

.“~ Medium Medium

HOT CRUISE

s voltage voltage

Open

l WARM AIR G-

SIGNAL”’ to low (0.8-3.0”) (4.5-5.5”) throttle:

l WARM COOLANT High

Sends No. voltage

1 cylinder (0.1”) voltage

1 (battery

TDC (com-

1 I voltage)

HOT ACCELERATION pression)

-60% THROTTLE signal to

Moderate

ECU

to strong

High Cool lo warm

voltage ;$,“,” Of j-20-4OT

f t

HOT ACCELERATION

More’ than Hot: Low (0.9”) Low (-4-‘04”F)l: W,ds open

voltage 1.5-4.3v

throttle: Wide open

-WIDE OPEN

four voltage

High volt- throttle

THROTTLE (0.5-1.5V)

minutes (Below High

0.5”) age (Above

voltage (OV)

t 1 3.OV)

I,

A 1. /I

DECELERATION

-CLOSED THROTTLE

HOT CURB IDLE

-EXTENDED

HOT ENGINE

SHUTDOWN Low

voltage

(0”) Low Closed Closed

Closed

volume throttle: throttle.

throttle.

of airflow:

~~~~!$$ (Above Low Low

Low

voltage voltage

voltage

to low 3.OV) (0.2-0.N) (4.5-5 5V) (OV)

voltage

(0.75%

t t 1 0.25”)

r v 1 I I

Sensor

hot: Low

OFF OFF voltage

-

(0.1”) until OFF OFF OFF OFF

OFF

sensw

COOIS

._-

Page 288 of 1164

F TROUBLESHOOTING GUIDE

Output Devices and Engine Conditions

Note

. The data in this chart is for reference only.

INJECTOR

CONDITIONS

CRANKING

-COLD ENGINE

l COLD AIR l COLD COOLANT

COLD START

-FAST IDLE

l COLD AIR l COLD COOLANT

COLD DRIVEAWAY

-PART THROTTLE

l COLD AIR l COLD COOLANT

WARM DRIVEAWAY

-PART THROTTLE

. WARM AIR

l WARM COOLANT

HOT CRUISE

l WARM AIR l WARM COOLANT Zero

One

mrnute

Two

minutes

Three

minutes

I AIR

INJECTION “AL”E

INJECTION TlMlNG

A

All A

cylinders

each

ignition

pulse

1

Rich Open:

coolant

tem-

perature:

Below

40%

(104OF)

,

I/

Rich and

2-group” 1’

lean l-group” /I

,

i

HOT ACCELERATION

-60% THROTTLE

-lOT ACCELERATION

-WIDE OPEN

THROTTLE

Closed ISC

VALVE

1, THREE-WAY

SOLENOID SOLENOID

VALVE VALVE

(PURGE

(PRESSURE

CONTROL) REGULATOR

CONTROL)‘3

c

OFF

(Purge

cut)

Large

1

, AK

RELAY

amount or

bypass air

OFF

(Vacuum

to

pressure

regulator)

After start-

rng: ON dur-

ing hot start

only (Vacu-

um cut)

OFF

l 2 SOHC, *’ BP

F-22

Page 426 of 1164

CONTROL SYSTEM

VB: Battery voltage

erminal Input Output

Connection to Test condition Correct voltage

Remark

1L

0 A/C relay Ignition switch ON VB

A/C switch ON at idle Below 2.5V

A/C switch OFF at idle V0

-

1M 0

1N 0 Vehicle speed

sensor

P/S pressure

switch While driving 4--5v

Vehicle stopped 0 or 8V

Ignition switch ON

VB

P/S ON at idle

ov

P/S OFF at idle Vi3 -

-

10 0 A/C switch A/C switch ON

A/C switch OFF Below 2.5V ignition switch

VB ON and blower

motor ON

IP 0 Blower control

switch Blower control switch OFF or 1st position Ve ignition switch

Blower control switch 2nd or higher po- Below 1 .OV ON

sition

1Q 0

1R 0

1s 0

IT 0 Stoplight switch Brake pedal released Below 1 .OV

-

Brake pedal depressed VI3

Inhibitor switch N or P range ov Ignition switch

(P, N ranges) ON

Other range VI3

Cruise control main Normal condition

VB Ignition switch

switch ON

Set or Resume switch ON or vehicle speed Below 1 .OV

8 km/h (5 mph) lower than preset speed

(Driving vehicle cruise control operation)

Throttle sensor Accelerator pedal released Below 1 .OV Ignition switch

(Idle switch)

Accelerator pedal depressed V0 ON

1u - - -

- - -

1v - - - -

- -

2A 0 Distributor Ignition switch ON Approx. OV

(Ne-signal) or 5V -

Idle Approx. 2V

LY”“l I. A3 311 blFY.1.

J

- .*

F-160