fuel pump MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 282 of 1164

F OUTLINE

COMPONENT DESCRIPTIONS

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 283 of 1164

OUTLINE

Component Function Remark

Engine control unit (ECU) Controls operation of the following:

(Cont’d)

1. A/C (Cut-off) 1. A/C relay

2. Fail-safe function 2. Self-Diagnosis Checker and MIL

3. Fuel injection system 3. Injector

4. idle speed control 4. Idle speed control (ISC) valve

5. Ignition timing control system 5. Igniter

6. Monitor function 6. Monitor lamp (Self-Diagnosis Checker)

7. Pressure regulator control system 7. Solenoid valve

(Pressure regulator control) (BP)

8. Purge control system 8. Purge control solenoid valve

9. VICS 9. Solenoid valve (WCS) (DOHC) Fuel filter

Filters particles from fuel Fuel pump

Provides fuel to injectors l Operates while engine running l Installed in fuel tank Igniter

Receives spark signal from ECU and gener-

ates high voltage in ignition coil Ignition switch

Engine cranking signal sent to ECU (START position)

Inhibitor switch (ATX)

Detects in-gear condition; sends signal to Switch ON in N or P range

ECU Injector

Intake air thermosensor

Idle speed control (ISC)

valve

Main relay

(FUEL INJ relay)

MIL (Malfunction

indicator lamp)

Neutral switch (MTX)

Oxygen sensor

PCV valve

P/S pressure switch

Pressure regulator

Resonance chamber

Resonance duct

Separator

Stoplight switch

Solenoid valve

(Purge control)

Shutter valve actuator

(DOHC)

Throttle body

Throttle sensor

Injects fuel into intake port l Controlled by signals from ECU

l High-ohmic injector

Detects intake air temperature; sends signal Installed on dynamic chamber

to ECU

Controls bypass air amount Controlled by duty signal from ECU

Supplies electric current to injectors, ECU,

etc.

Lamp flashes to indicate malfunction code

number of input and output devices

Detects in-gear condition; sends signal to

ECU

Detects oxygen concentration; sends signal

to ECU

Controls blowby gas introduced into engine

Detects P/S operation; sends signal to ECU

Adjusts fuel pressure supplied to injectors

Reduces intake air noise

Reduces intake air noise

Prevents fuel from flowing into charcoal

canister

Detects braking operation (deceleration),

sends signal to ECU

Controls evaporative fumes from canister to

intake manifold

Closes/opens shutter valve to improve

torque characteristics

Controls intake air quantity

l Detects throttle valve fully closed/fully

opened condition (MTX) TEN terminal grounded

Switch ON in neutral

Zirconia ceramic and platinum coating

P/S: ON when steering wheel turned right or

left

Controlled by duty signal from ECU

For Variable inertia charging system (VICS*)

Integrated throttle sensor, dashpot, and ISC

valve

l Detects throttle valve opening angle

(A-W

l Sends signals to ECU

F-l 7

Page 295 of 1164

TROUBLESHOOTING GUIDE F

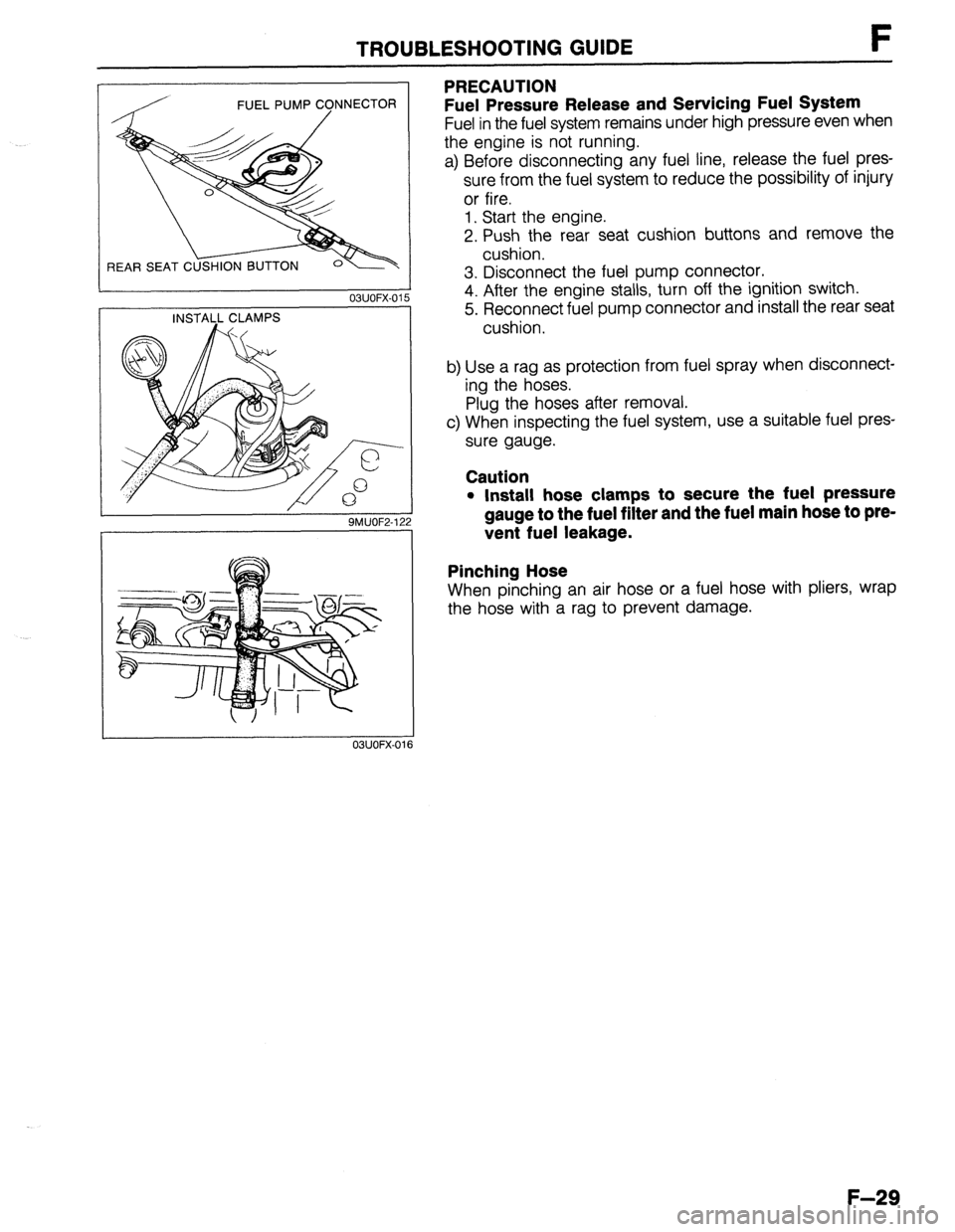

REAR SEAT C

03UOFX-01

9MUOF2-1;

PRECAUTION

Fuel Pressure Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure even when

the engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

or fire.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect fuel pump connector and install the rear seat

cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuel leakage.

Pinching Hose

When pinching an air hose or a fuel hose with pliers, wrap

the hose with a rag to prevent damage.

03UOFX-016

F-29

Page 296 of 1164

F TROUBLESHOOTING GUIDE

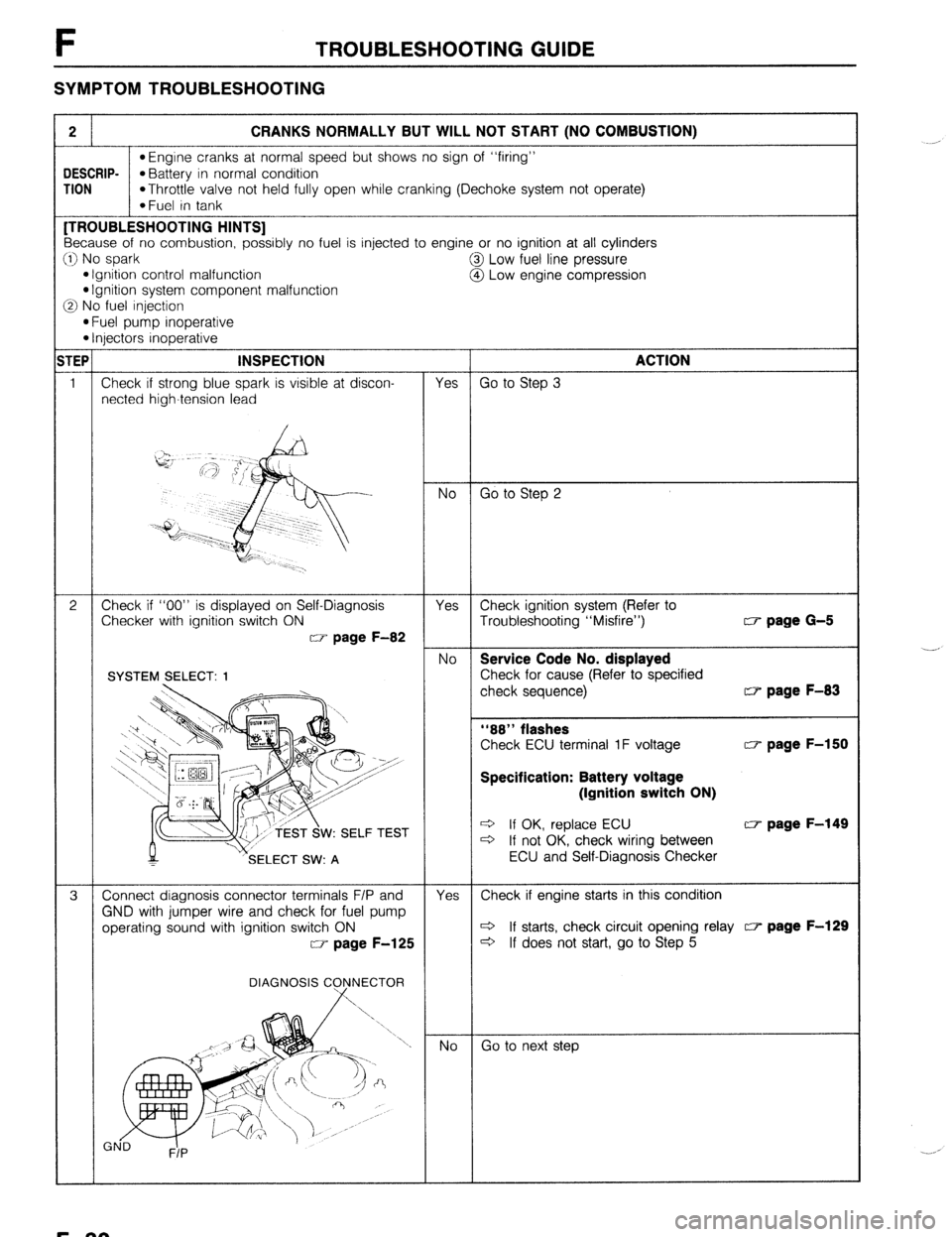

SYMPTOM TROUBLESHOOTING

2 CRANKS NORMALLY BUT WILL NOT START (NO COMBUSTION)

l Engine cranks at normal speed but shows no sign of “firing”

DESCRIP-

*Battery in normal condition

TION

*Throttle valve not held fully open while cranking (Dechoke system not operate)

*Fuel in tank [TROUBLESHOOTING HINTS]

Because of no combustion, possibly no fuel is injected to engine or no ignition at all cylinders

:I) No spark

@I Low fuel line pressure

l Ignition control malfunction

@ Low engine compression l Ignition system component malfunction

3 No fuel injection

l Fuel pump inoperative l Injectors inoperative

TEP INSPECTION

ACTION

1 Check if strong blue spark is visible at discon-

Yes Go to Step 3

netted high-tension lead

No Go to Step 2

2 Check if “00” is displayed on Self-Diagnosis

Yes Check ignition system (Refer to

Checker with ignition switch ON

Troubleshooting “Misfire”) w page G-5

w page F-82

No Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST e If OK, replace ECU w page F-149 c3 If not OK, check wiring between

SELECT SW: A ECU and Self-Diagnosis Checker

3 Connect diagnosis connector terminals F/P and

Yes Check if engine starts in this condition

GND with jumper wire and check for fuel pump

operating sound with ignition switch ON c3 If starts, check circuit opening relay c7 page F-129

w page F-125

c3 If does not start, go to Step 5

DIAGNOSIS C

Go to next step ._-,

._. ,

F-30

Page 298 of 1164

F TROUBLESHOOTING GUIDE

3 CRANKS NORMALLY BUT WILL NOT START (PARTIAL COMBUSTION) - WHEN ENGINE COLD

DESCRIP- *Engine cranks at normal speed but shows only partial combustion and will not continue to run

TION

l Battery in normal condition

*Fuel in tank

[TROUBLESHOOTING HINTS]

0 Air/Fuel mixture too rich

*Air cleaner element clogged

l Airflow meter stuck @ Low engine compression

@ Air/Fuel mixture too lean

l Fuel injection control malfunction

(Correction for coolant temperature)

*Low fuel line pressure

*Air leakage of intake air system

Checker with ignition switch ON

CT page F-83

w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST w page F-149

Fuel line pressure:

285-314 kPa (2.7-3.2 kg/cm’, 38-48 psi) If fuel line pressure quickly in-

creases, check pressure regulator CF- page F-129

d If fuel line pressure gradually in-

creases check for clogging be-

I pump and pressure

Check if fuel return hose is clogged or

F-32

Page 302 of 1164

F TROUBLESHOOTING GUIDE

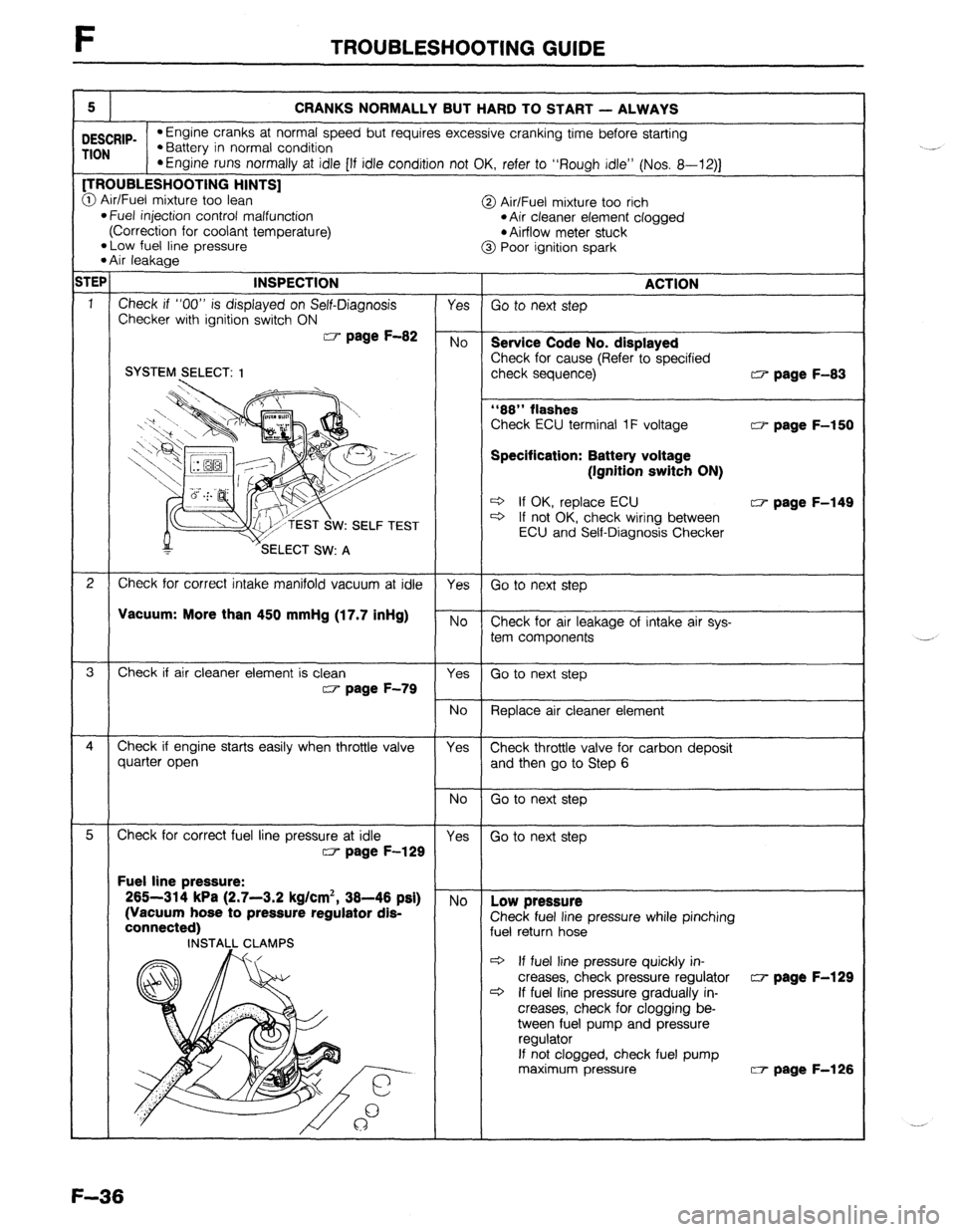

5

CRANKS NORMALLY BUT HARD TO START - ALWAYS

DESCRIP- l Engine cranks at normal speed but requires excessive cranking time before starting

TION l Battery in normal condition

*Engine runs normally at idle [If idle condition not OK, refer to “Rough idle” (Nos. 8-12)J [TROUBLESHOOTING HINTS]

@ Air/Fuel mixture too lean

@ Air/Fuel mixture too rich l Fuel injection control malfunction

(Correction for coolant temperature) *Air cleaner element clogged

l Airflow meter stuck

*Low fuel line pressure

l Air leakage @ Poor ignition spark

;TEP INSPECTION ACTION

1

Check if “00” is displayed on Self-Diagnosis Yes Go to next step

Checker with ignition switch ON W page F-82 No

Service Code No. displayed

Check for cause (Refer to specified SYSTEM SELECT: 1 check sequence) w page F-83

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignitlon switch ON)

* If OK, replace ECU w page F-149

W: SELF TEST c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

2 Check for correct intake manifold vacuum at idle

Yes Go to next step

VsCUUm: More than 450 mmHg (17.7 inHg) No Check for air leakage of intake air sys-

tem components

3 Check if air cleaner element is clean

Yes Go to next step w page F-79

No

Replace air cleaner element

4 Check if engine starts easily when throttle valve Yes Check throttle valve for carbon deposit

quarter open and then go to Step 6 Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm*, 38-46 psi)

(Vacuum hose to pressure regulator dis-

pressure while pinching

c3 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

If not clogged, check fuel pump

maximum pressure W- page F-126

F-36

Page 305 of 1164

TROUBLESHOOTING GUIDE F

1TEP INSPECTION

ACTION

7 Connect diagnosis connector terminals F/P and Yes

Go to next step

GND with jumper wire and check for correct fuel

line pressure with ignition switch ON w page F-122

No Low pressure

Check fuel line pressure while pinching Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm*, 38-46 psi) fuel return hose

c3 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

+ If fuel line pressure gradually in-

creases, check fuel line for clog-

ging between fuel pump and

pressure regulator

If not clogged, check fuel pump

maximum pressure High pressure w page F-126

Check if fuel return hose is clogged or

restricted

INSTALL CLAMPS c3 If OK, replace pressure regulator w page F-130 c3 If not OK, repair or replace hose

8

Try known good ECU and check if condition

Yes Replace ECU w page F-149

improves w page F-149 No

Change fuel to another brand

23UOFX-02

F-39

Page 306 of 1164

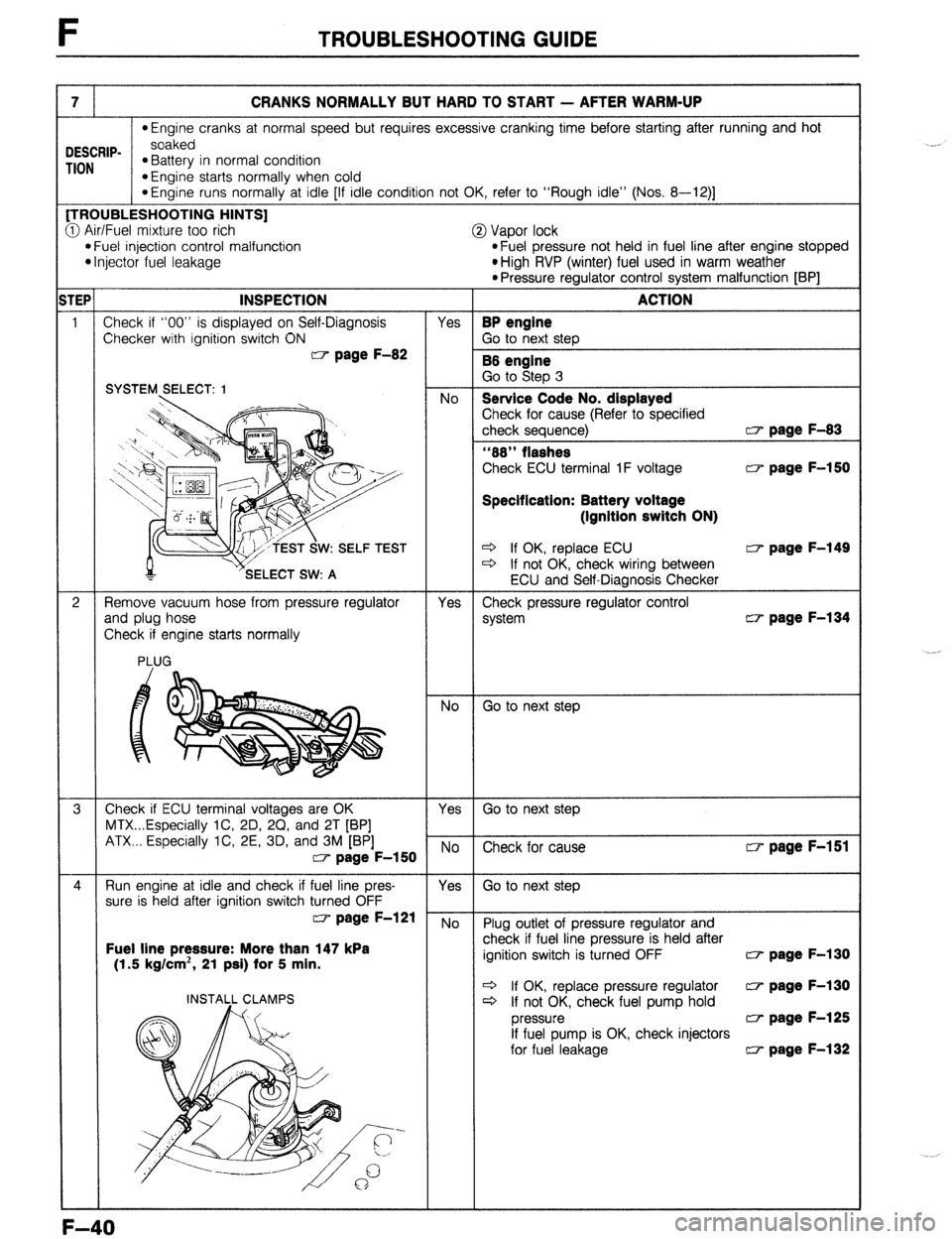

F TROUBLESHOOTING GUIDE

7 CRANKS NORMALLY BUT HARD TO START - AFTER WARM-UP

*Engine cranks at normal speed but requires excessive cranking time before starting after running and hot

DESCRIP- soaked

TION *Battery in normal condition

*Engine starts normally when cold

*Engine runs normally at idle [If idle condition not OK, refer to “Rough idle” (Nos. 8-12)] [TROUBLESHOOTING HINTS]

3 Air/Fuel mixture too rich

@ Vapor lock l Fuel injection control malfunction

*Fuel pressure not held in fuel line after engine stopped l Injector fuel leakage

*High RVP (winter) fuel used in warm weather

l Pressure regulator control system malfunction [BP] w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST c3 If OK, replace ECU w page F-149 * If not OK, check wiring between CT- page F-134

Fuel line pressure: More than 147 kPa

(1.5 kg/cm*, 21 psi) for 5 min. w page F-130

+ If OK, replace pressure regulator CT- page F-130

c3 If not OK, check fuel pump hold w page F-125

If fuel pump is OK, check injectors

for fuel leakage (3 page F-132

F-40

Page 309 of 1164

TROUBLESHOOTING GUIDE F

WEAR AND CA

DAMAGE AND

DETERIORATION

r;f> If OK, replace injector

=D If not OK, check for cause w page F-131

u page Bl-10

82-l 0

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm2, 38-48 psi) fuel line pressure while pinching

* If fuel line pressure quickly in-

creases, check pressure regulator L-Y page F-129

~3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

maximum pressure

CT page F-126

airflow meter moves smoot

_, .’

No Go to next step

I1

Check for correct engine compression

Yes Go to next step

CI page 81-10

82-l 0

Engine compression (Minimum):

l BP SOHC

834 kPa (8.5 kg/cm*, 121 psi)300 rpm

l BP DOHC

883 kPa (9.0 kg/cm*, 128 psi)-300 rpm

l B6 No Check for cause

CT page 81-10

82-l 0

932 kPa (9.5 kg/cm*, 135 psi)-300 rpm

I2 Connect System Selector to diagnosis connector

Yes Try known good ECU and check if con-

and set Test Switch to “SELF TEST” and check

dition improves

CT page F-149

for correct ignition timing at idle after warm-up

CT page F-79

Ignition timing (BTDC)

BP DOHC : Q”-ll”

BP SOHC : 4O-6O

B6

: 6”--8* No Adjust ignition timing

a- page F-79

23UOFX-Oi

F-43

Page 313 of 1164

TROUBLESHOOTING GUIDE F

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 36-46 psi)

(Vacuum hose to pressure regulator Ine pressure while pinching

d If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

* If fuel line pressure gradually in-

If not clogged, check fuel pump

maximum pressure w page F-126

Ignition timing (BTDC)

l BP DOHC : go-1 1 o l BP SOHC : 4”-6O

Resistance: 12-l 60

eck wiring between ECU

Engine compression (Minimum):

l BP SOHC :

634 kPa (6.5 kg/cm2, 121 psi)900 rpm

check distributor cap and

23UOFX-02

F-47