fuel pump MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 324 of 1164

TROUBLESHOOTING GUIDE

TEP INSPECTION

ACTION

7 Check for correct fuel line pressure at idle Yes Check if fuel line pressure decreases w page F-129 when accelerating quickly Fuel line pressure:

c3 If decreases, check fuel line and fil- 265-314 kPa (2.7-3.2 kg/cm’, 38-46 psi) ter for clogging (Vacuum hose to pressure regulator dis- *

If no decrease, go to next step connected)

INSTALL CLAMPS No Low pressure

Check fuel line pressure while pinching

fuel return hose

+ If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

+ If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

If not clogged, check fuel pump .*

maximum pressure w page F-126

8 Connect System Selector to diagnosis connector Yes Check if ignition timing advances when

and set Test Switch to “SELF TEST” and check accelerating

for correct ignition timing at idle after warm-up w page F-79

c3 If advances, go to next step

c3 If not advance, replace ECU w page F-149

Ignition timing (BTDC)

l BP DOHC : go-1 1 o l BP SOHC : 4’-8’

l B6 : 6O--8O No Adjust w page F-79

9

Check if air duct and air hoses are correctly Yes Go to next step

installed w page F-109

No

Repair

10 Check if exhaust system is restricted Yes Repair or replace w page F-136

No SOHC

Go to Step 12 DOHC

Go to next step

11 Check if variable inertia control system (VICS) is

Yes Go to next step

OK w page F-118

No

Repair or replace

12 Try known good ECU and check if condition

improves w page F-149

-’

F-58

Page 326 of 1164

F TROUBLESHOOTING GUIDE

TEP INSPECTION ACTION

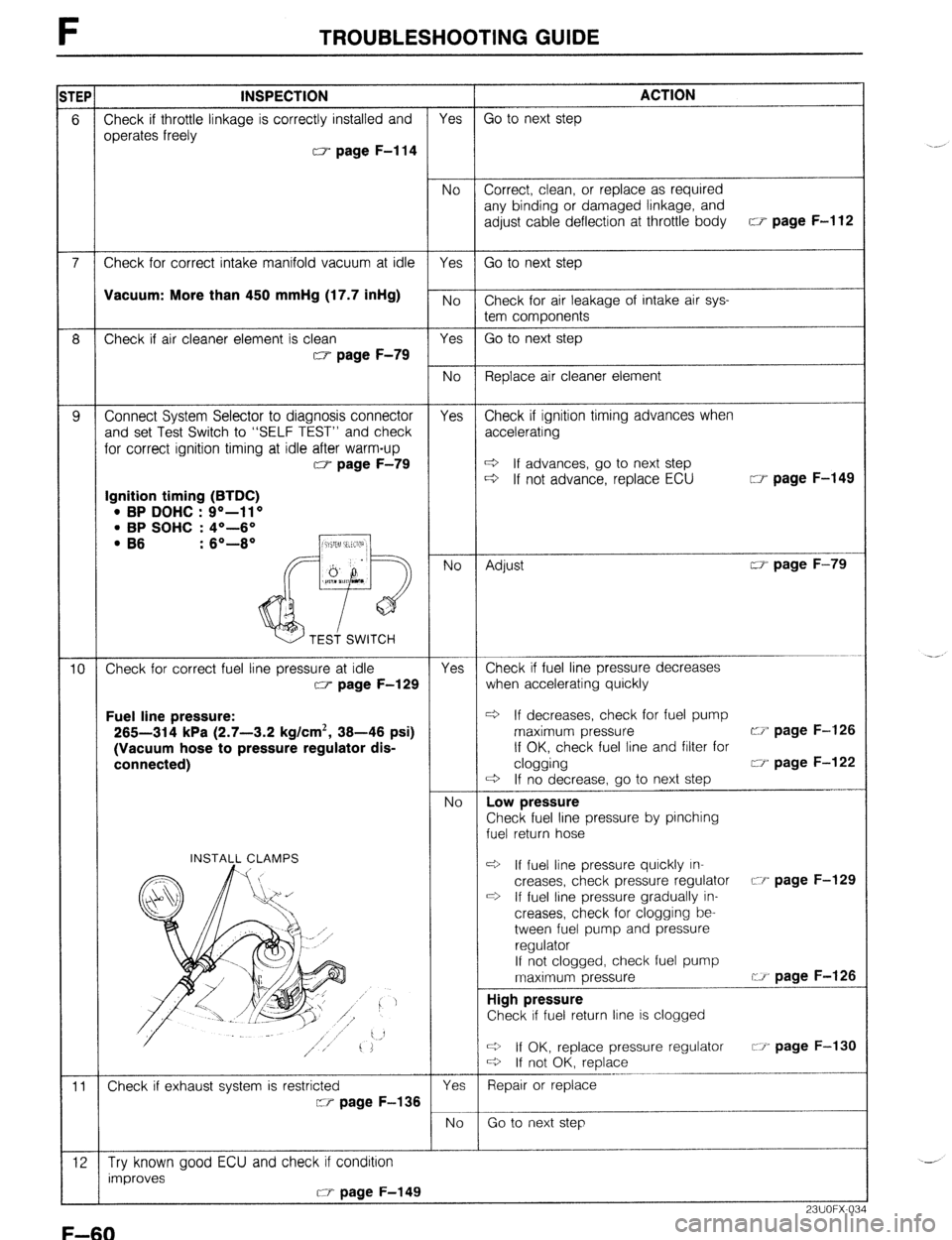

6 Check if throttle linkage is correctly installed and Yes Go to next step

operates freely

w page F-l 14

No Correct, clean, or replace as required

any binding or damaged linkage, and

adjust cable deflection at throttle body CT page F-l 12

7 Check for correct intake manifold vacuum at idle Yes Go to next step

Vacuum: More than 450 mmHg (17.7 intig) -

No

Check for air leakage of intake air sys-

tem components

8 Check if air cleaner element is clean Yes Go to next step

w page F-79

No Replace air cleaner element

9 Connect System Selector to diagnosis connector Yes Check if ignition timing advances when

and set Test Switch to “SELF TEST” and check accelerating

for correct ignition timing at idle after warm-up

w page F-79 c3 If advances, go to next step

c3 If not advance, replace ECU [II page F-149

Ignition timing (BTDC)

l BP DOHC : Q”-1 1 o l BP SOHC : 4O-6’

’ B6 : 6O-8O

No Adjust CT+ page F-79

10 Check for correct fuel line pressure at idle Yes Check if fuel line pressure decreases

w page F-129 when accelerating quickly

Fuel line pressure: c3 If decreases, check for fuel pump

265-314 kPa (2.7-3.2 kg/cm*, 38-46 psi) maximum pressure w page F-126

(Vacuum hose to pressure regulator dis- If OK, check fuel line and filter for

connected) clogging CI,’ page F-122

+ If no decrease, go to next step

-

No Low pressure

Check fuel line pressure by pinching

fuel return hose

cti If fuel line pressure quickly In-

creases, check pressure regulator CT page F-129

ti If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

If not clogged, check fuel pump

maximum pressure cr page F-126

-

High pressure

Check if fuel return line is clogged

Q If OK, replace pressure regulator C-Y- page F-130

+ If not OK, replace

--_I. 1”1-~~-~~

11 Check if exhaust system is restricted Yes Repair or replace

C-T- page F-136

No Go to next step

12 Try known good ECU and check if condition

improves

CT page F-149

23UOFX-034

F-60

Page 328 of 1164

F TROUBLESHOOTING GUIDE

ITEP

INSPECTION ACTION

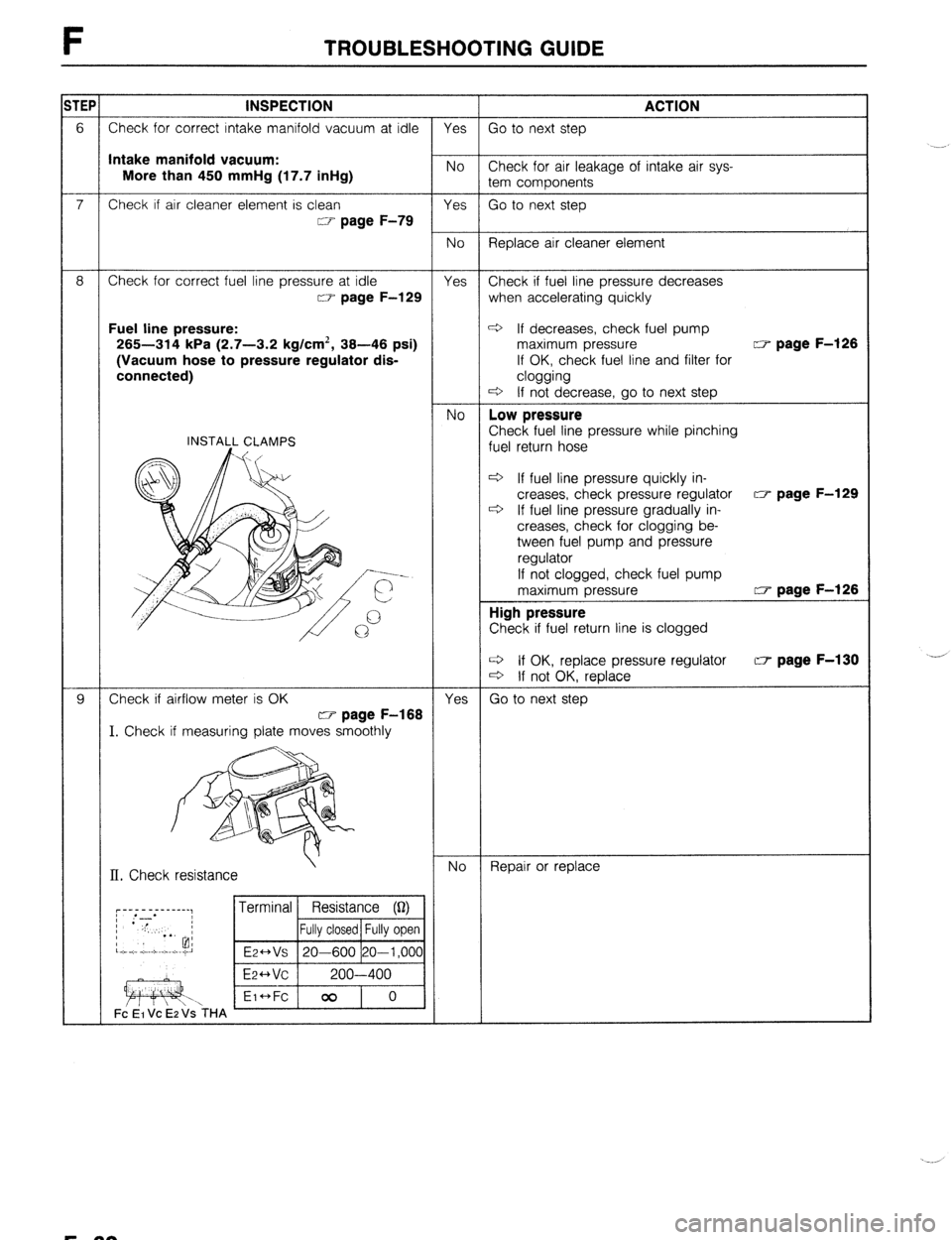

6 Check for correct intake manifold vacuum at idle Yes Go to next step

Intake manifold vacuum:

More than 450 mmHg (17.7 inHg) No Check for air leakage of intake air sys-

tem components

7 Check if air cleaner element is clean Yes Go to next step

w page F-79

No Replace air cleaner element

8 Check for correct fuel line pressure at idle Yes Check if fuel line pressure decreases

CT= page F-129 when accelerating quickly

Fuel line pressure: c3 If decreases, check fuel pump

265-314 kPa (2.7-3.2 kg/cm’, 38-46 psi) maximum pressure w page F-126

(Vacuum hose to pressure regulator dis- If OK, check fuel line and filter for

connected) clogging

ti If not decrease, go to next step

No Low pressure

INSTALL CLAMPS Check fuel line pressure while pinching

fuel return hose

9 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

If not clogged, check fuel pump

maximum pressure w page F-126

High pressure

Check if fuel return line is clogged

c3 If OK, replace pressure regulator CT page F-130

d If not OK, replace

9 Check if airflow meter is OK

Yes Go to next step

w page F-188

I. Check if measurin late moves smoothly

II. Check resistance No Repair or replace

F-62

Page 332 of 1164

iTEP INSPECTION ACTION

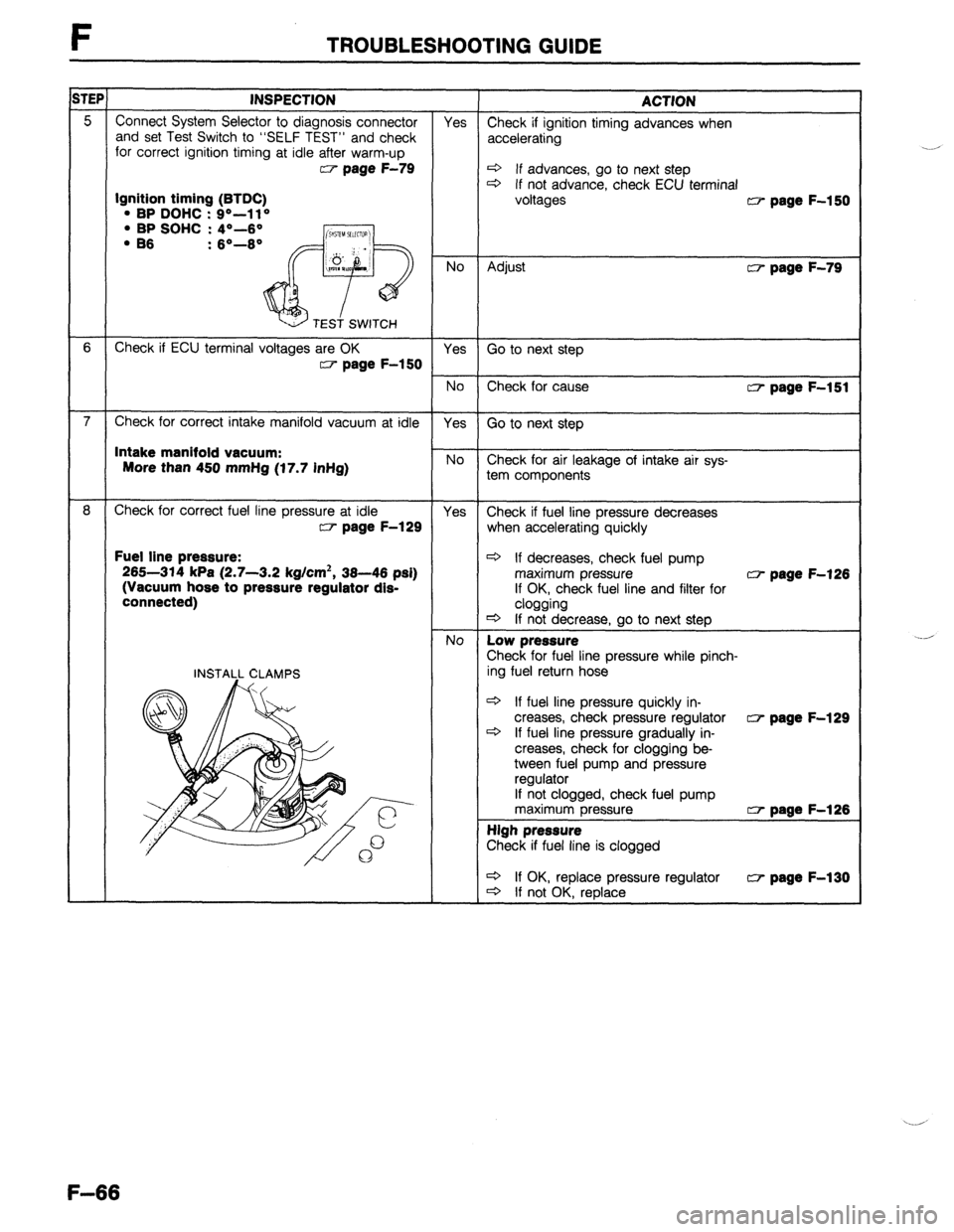

5 Connect System Selector to diagnosis connector Yes

and set Test Switch to “SELF TEST” and check Check if ignition timing advances when

for correct ignition timing at idle after warm-up accelerating w page F-79

* If advances, go to next step

r3 If not advance, check ECU terminal Ignition timing (BTDC)

voltages l BP DOHC : go--ll” w page F-150 l BP SOHC : 4O-6O

. B6 : 6O-6O

No

Adjust w page F-79

6

Check if ECU terminal voltages are OK

Yes Go to next step w page F-150

No

Check for cause ~7 page F-151

7

Check for correct intake manifold vacuum at idle

Yes Go to next step Intake manifold vacuum:

More than 450 mmHg (17.7 inHg) No

Check for air leakage of intake air sys-

tem components

8 Check for correct fuel line pressure at idle

Yes Check if fuel line pressure decreases w page F-129

when accelerating quickly Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 39-46 psi)

(Vacuum hose to pressure regulator dls-

connected)

d If decreases, check fuel pump

maximum pressure (3‘ page F-126

If OK, check fuel line and filter for

clogging

* If not decrease, go to next step

No Low pressure

Check for fuel line pressure while pinch-

ing fuel return hose

c3 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

+ If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

If not clogged, check fuel pump

maximum pressure w page F-126

High pressure

Check if fuel line is clogged

* If OK, replace pressure regulator w page F-130

c3 If not OK, replace

F-66

Page 338 of 1164

F TROUBLESHOOTING GUIDE

STEP INSPECTION ACTION

5 Check for correct fuel line pressure at idle Yes Check if fuel line pressure decreases

w page F-129 when accelerating quickly

Fuel line pressure: + If it decreases, check for clogging

265-314 kPa (2.7-3.2 kg/cm’, 36-46 psi) between fuel pump and pressure

(Vacuum hose to pressure regulator dis- regulator

connected) * If not decrease, go to next step

INSTALL CLAMPS No Low pressure

Check fuel line pressure while pinching

fuel return hose

c3 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

If not clogged, check fuel pump

maximum pressure w page F-126

6 Check if cooling system is OK Yes Go to next step

w page E-13

No Repair or replace

l Thermostat w page E-9

l Electric cooling fan w page E-16 l Radiator w page E-6

7 Try known good ECU and check if condition Yes Replace ECU CT page F-149

improves

CT= page F-149 No

Change fuel to another brand or use

higher octane fuel

23lJOFX.0: .-._ ,

F-72

Page 367 of 1164

SELF-DIAGNOSIS FUNCTION F

TEP

6

7

8

9

IO

11 INSPECTION

Check for correct fuel line pressure at idle

IV page F-122

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 38-46 psi)

(Vacuum hose to pressure regulator

disconnected)

Check intake air system components for air

leakage

Check for misfire of dead cylinder from Step 5

inspection

Check for injector operating sound at idle of

dead cylinder from Step 5 inspection -

Replace injector at dead cylinder from Step 5 in-

spection

CI page F-131

Check if same Code No. is present following

performing after-repair procedure

CT page F-104

Try known good ECU and check if condition

Improves

CT page F-149 Yes

No

Yes If not clogged, check fuel pump

maximum pressure

Go to Step 11

No Replace

--

Yes Repair or replace ignition system

No

Yes

No

Yes

No

T L ACTION

Go to next step

Low pressure

Check fuel line pressure while pinching

fuel return hose

~3 If fuel line pressure quickly in-

creases, check pressure regulator

v page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

CT page F-126

Go to next step

Go to next step

Check for battery voltage at injector

connector terminal-wire (W/R)

L3 If Yes, replace injector c7 page F-131

+ If No, check wire harness for short

or open

Go to next step

Removed injector at fault

Circuit Diagram

ATX

OXYGENSENSOR

R/L

ECU

-------------- ---

BILG

23UOFX-07

F-10'

Page 386 of 1164

F FUEL SYSTEM

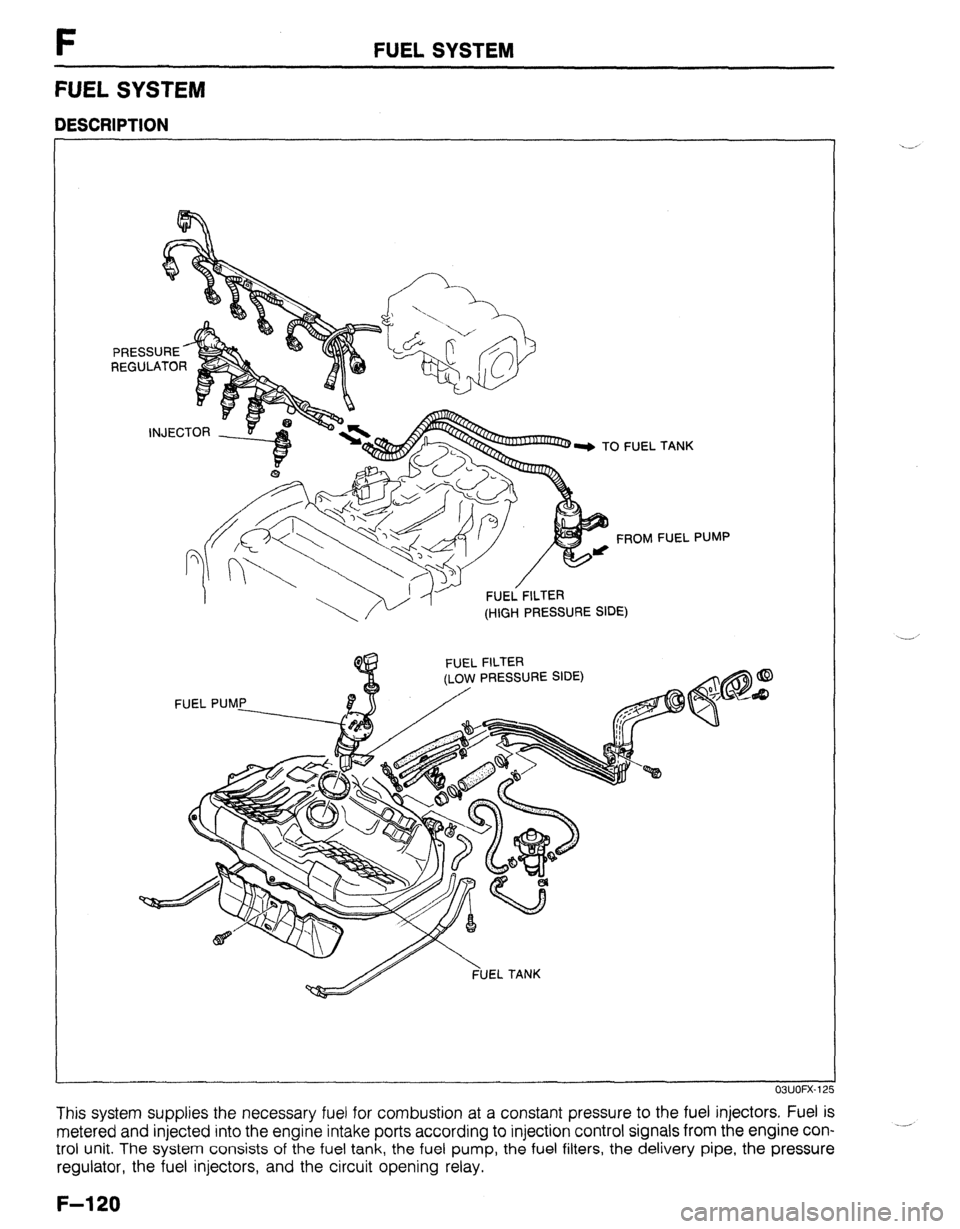

FUEL SYSTEM

DESCRIPTION

FUEL FILTER

(HIGH PRESSURE SIDE) . TANK

FUEL PUMP

PRESSURE SIDE)

OWOFX-12

This system supplies the necessary fuel for combustion at a constant pressure to the fuel injectors. Fuel is

metered and injected into the engine intake ports according to injection control signals from the engine con-

trol unit. The system consists of the fuel tank, the fuel pump, the fuel filters, the delivery pipe, the pressure

regulator, the fuel injectors, and the circuit opening relay. ._*

F-l 20

Page 387 of 1164

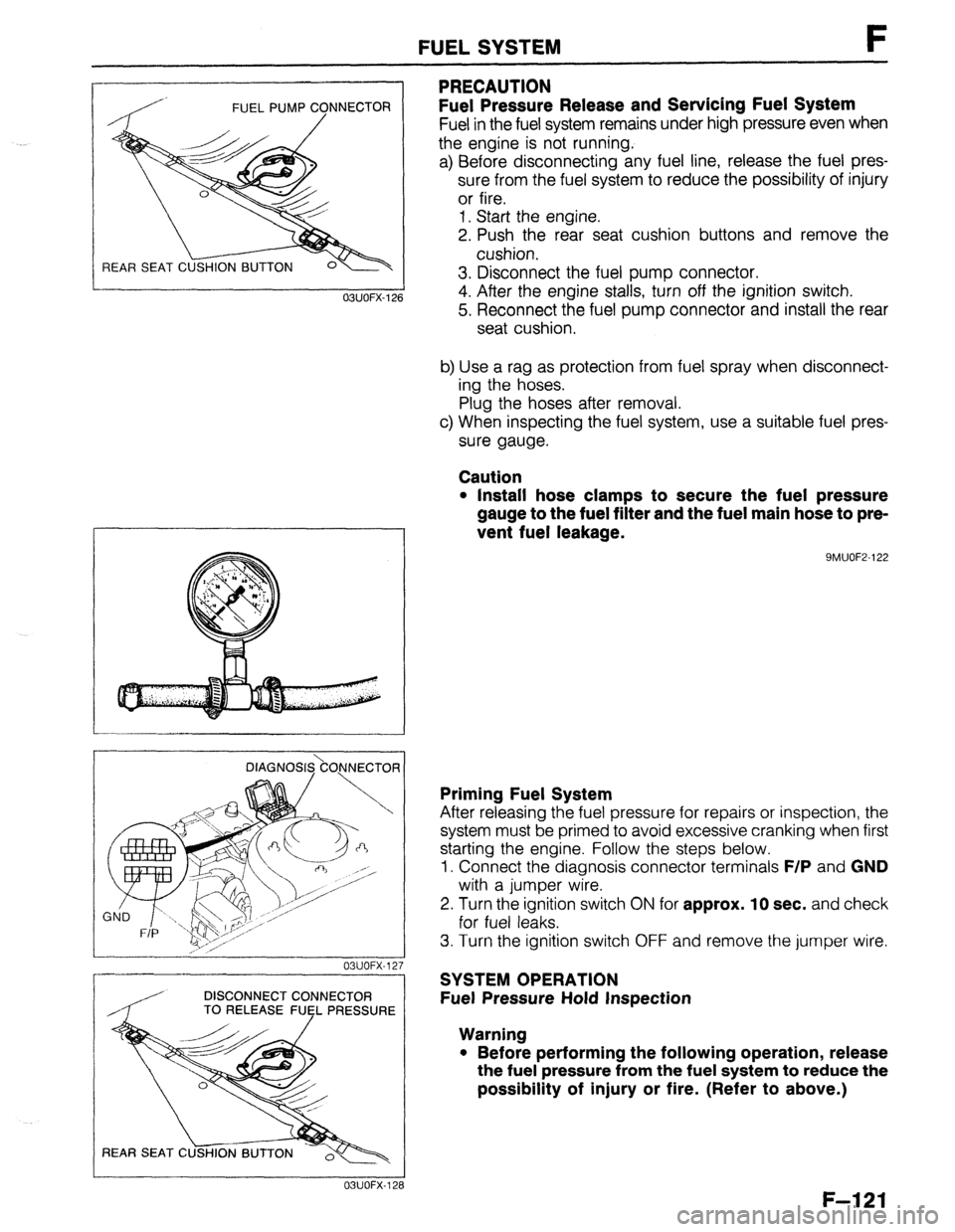

FUEL PUMP CONNECTOR

/

REAR SEAT C

FUEL SYSTEM F

PRECAUTION

Fuel Pressure Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure even when

the engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

or fire.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuel leakage.

9MUOF2-122 OBUOFX-126

DlAGNOS&O,NNECTOR

03UOFX-12.

-

DISCONNECT CONNECTOR

/ TO RELEASE FUEL PRESSURE

03UOFX-12;

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps below.

1. Connect the diagnosis connector terminals

F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 sec. and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

SYSTEM OPERATION

Fuel Pressure Hold Inspection

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to above.)

F-121

Page 388 of 1164

F FUEL SYSTEM

OSUOFX-129

DIAGNOSIS.\CO.NNECTOR j

/, I 23UOFX-104

DISCONNECT CONNECTOR

TO RELEASE FlJsL PRESSURE

L 23UOFX-105

INSTALL CLAMPS

DIAGNOSI$kO)lNECTOfl

I

23UOFX-ll

F-l 22

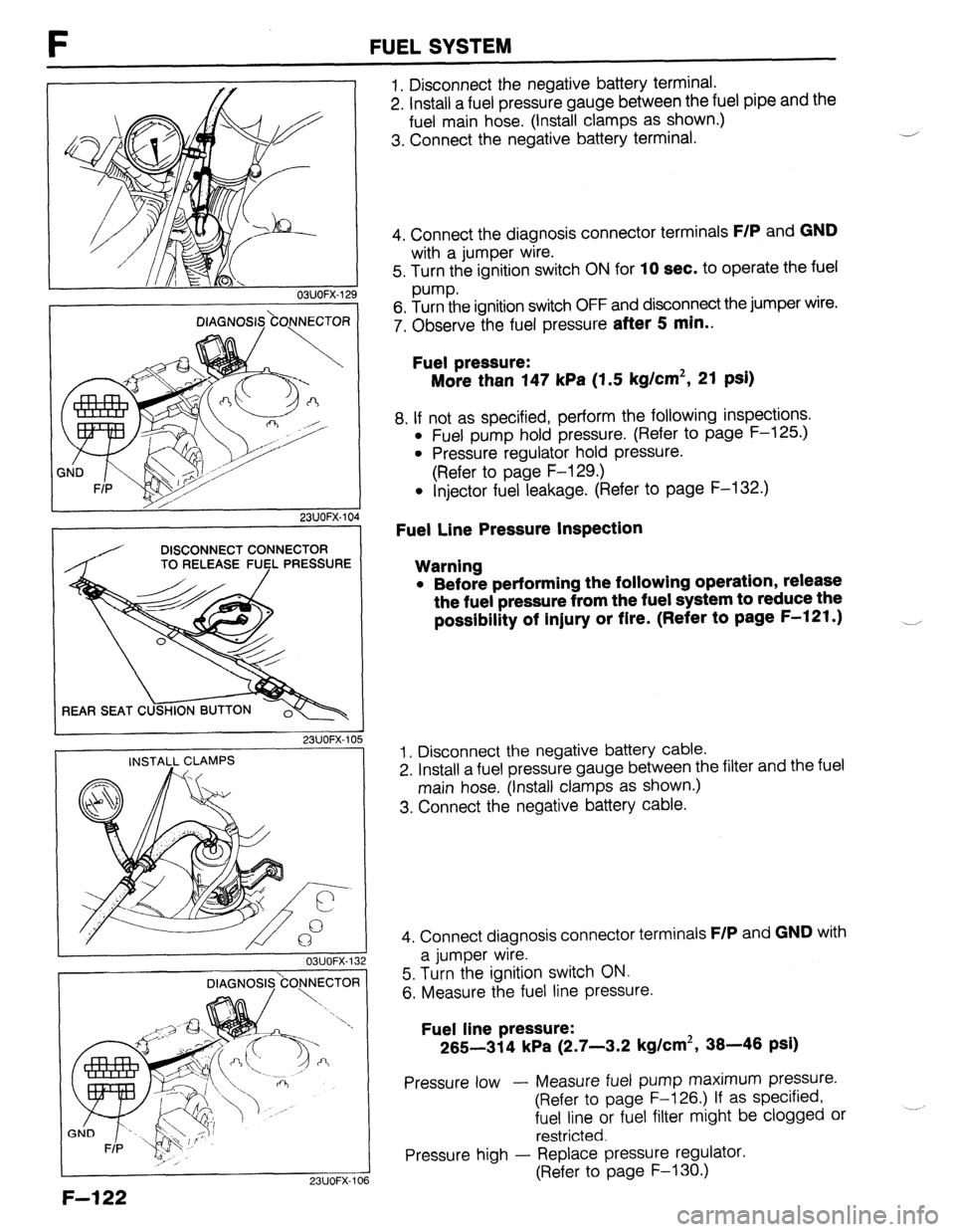

1. Disconnect the negative battery terminal.

2. Install a fuel pressure gauge between the fuel pipe and the

fuel main hose. (Install clamps as shown.)

3. Connect the negative battery terminal. J

4. Connect the diagnosis connector terminals

F/P and GND

with a jumper wire.

5. Turn the ignition switch ON for

10 sec. to operate the fuel

pump.

6. Turn the ignition switch OFF and disconnect the jumper wire.

7. Observe the fuel pressure

after 5 min..

Fuel pressure:

More than 147 kPa (1.5 kg/cm2, 21 psi)

8. If not as specified, perform the following inspections.

l Fuel pump hold pressure. (Refer to page F-125.)

l Pressure regulator hold pressure.

(Refer to page F-129.)

l Injector fuel leakage. (Refer to page F-132.)

Fuel Line Pressure Inspection

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121.) __,

1. Disconnect the negative battery cable.

2. Install a fuel pressure gauge between the filter and the fuel

main hose. (Install clamps as shown.)

3. Connect the negative battery cable.

4. Connect diagnosis connector terminals

F/P and GND with

a jumper wire.

5. Turn the ignition switch ON.

6. Measure the fuel line pressure.

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm2, 38-46 psi)

Pressure low - Measure fuel pump maximum pressure.

(Refer to page F-126.) If as specified,

fuel line or fuel filter might be clogged or

restricted.

Pressure high - Replace pressure regulator.

(Refer to page F-130.)

Page 389 of 1164

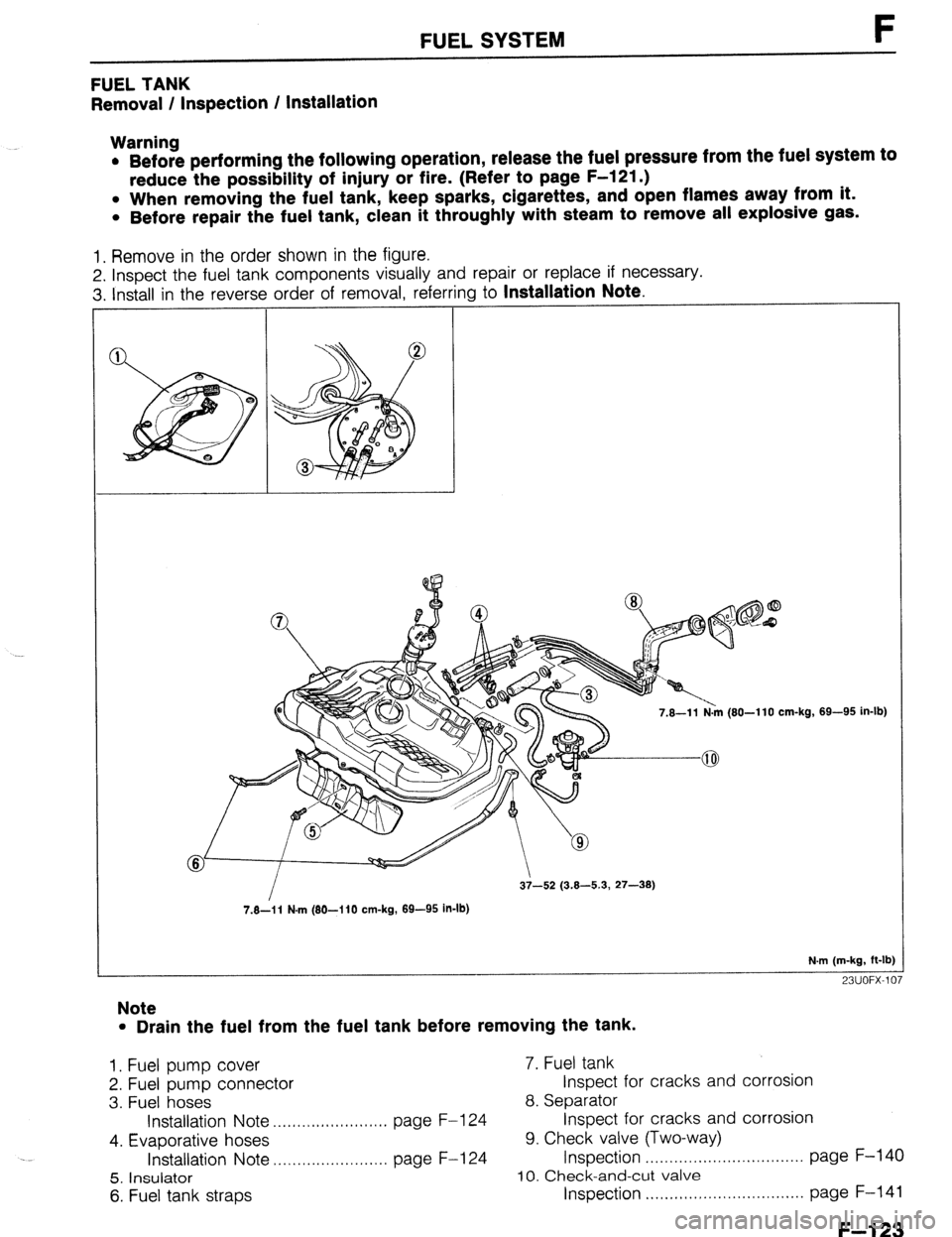

FUEL SYSTEM F

FUEL TANK

Removal / Inspection / Installation

Warning

l Before performing the following operation, release the fuel pressure from the fuel system to

reduce the possibility of injury or fire. (Refer to page F-121 .)

l When removing the fuel tank, keep sparks, cigarettes, and open flames away from it.

l Before repair the fuel tank, clean it throughly with steam to remove all explosive gas.

1. Remove in the order shown in the figure.

2. Inspect the fuel tank components visually and repair or replace if necessary.

3. Install in the reverse order of removal, referring to

Installation Note.

7.8-l 1 N.m (80-l 10 cm-kg,

7.8-i 1 N-m (80-I 10 cm-kg, 89-95 in-lb) 69-95 in-lb)

N.m (m-kg, ft-lb]

23UOFX-107

Note

l Drain the fuel from the fuel tank before removing the tank.

1. Fuel pump cover 7. Fuel tank

2. Fuel pump connector Inspect for cracks and corrosion

3. Fuel hoses 8. Separator

Installation Note . ..., I .I,,,,I,I,.,.I.,,. page F-l 24 Inspect for cracks and corrosion

4. Evaporative hoses 9. Check valve (Two-way)

Installation Note ,..,..,................. page F-l 24 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-140

5. Insulator 10. Check-and-cut valve

6. Fuel tank straps Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-141

F--l 23