warning MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 137 of 1164

ENGINE TUNE-UP PROCEDURE 82

ENGINE TUNE-UP PROCEDURE

PREPARATION

SST

49 BO19 9AO

drive belt tension

23UOB2-048

OBUOBX-158

I’ ,

OSJOBX-001

V BELT

V RIBBED BELT

_

x 0 x

3

L

03UOB2-005

ENGINE OIL

Inspection

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temperature and

stop it.

3. Wait for 5 minutes.

4. Remove the oil level gauge and check the oil level and con-

dition.

5. Add or replace oil if necessary.

Note

l The distance between the L and F marks on the level

gauge represents 0.8 liter (0.85 US qt, 0.70 Imp qt).

ENGINE COOLANT

Inspection

Coolant level (engine cold)

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap when removing it.

1. Verify that the coolant level is near the radiator filler neck.

2. Remove the coolant level gauge and check the coolant level.

3. Add coolant if necessary.

Coolant quality

1. Verify that there is no buildup of rust or scale around the

radiator cap or radiator filler neck.

2. Verify that the coolant is free of oil.

3. Replace the coolant if necessary.

DRIVE BELT

Inspection

1. Check the drive belts for wear, cracks, and fraying. Replace

if necessary.

2. Verify that the drive belts are correctly mounted on the

pulleys.

B2-5

Page 148 of 1164

82 ON-VEHICLE MAINTENANCE

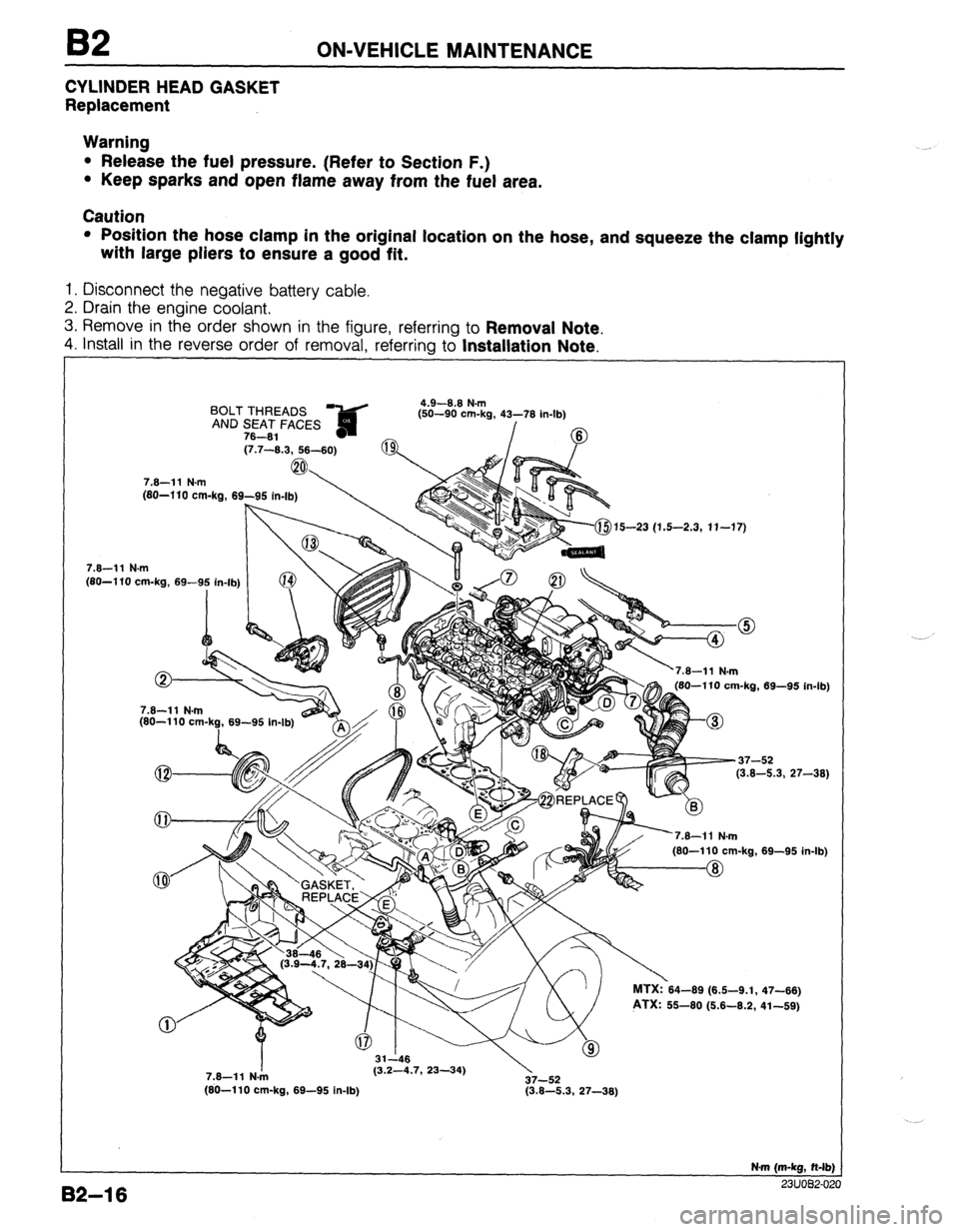

CYLINDER HEAD GASKET

Replacement

Warning

l Release the fuel pressure. (Refer to Section F.)

l Keep sparks and open flame away from the fuel area.

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. install in the reverse order of removal, referrina to Installation Note.

BOLT THREADS ?&d 4.9-8.8 N.m

fsn-an om.h 41-‘71( ir

AND SEAT FACES ,-- -- -... ..=, _” . _ ..I-lb)

78-81 - /

(7.7-8.3, 58-60)

7.8-11 N.m

(80-l 10 cm-ka, 69-95

, . . . . . . (80-l 10 cm-kg, 69-9: in-lb) (j-$15-23 (1.5-2.3, 11-17)

82-l 6

7.8-11 N.m

(80-110 cm-k?, 69-95 In-lb) 180-110 cm-ka. 69-95 in-lb

-37-52

(3.8-5.3, 27-38)

’

nl MTX:?64-69 (6.6-9.1,

PTX: 55-60 (6.6-8.2, 69-95 in. .Ib)

47-86)

41-69)

7.8-11 N./n (3.2-4.7, 23-34)

37-52

(80-110 cm-kg, 69-95 in-lb) (3.8-5.3, 27-38)

N-m (m-kg, N-lb)

^^. .^_^ __

Page 163 of 1164

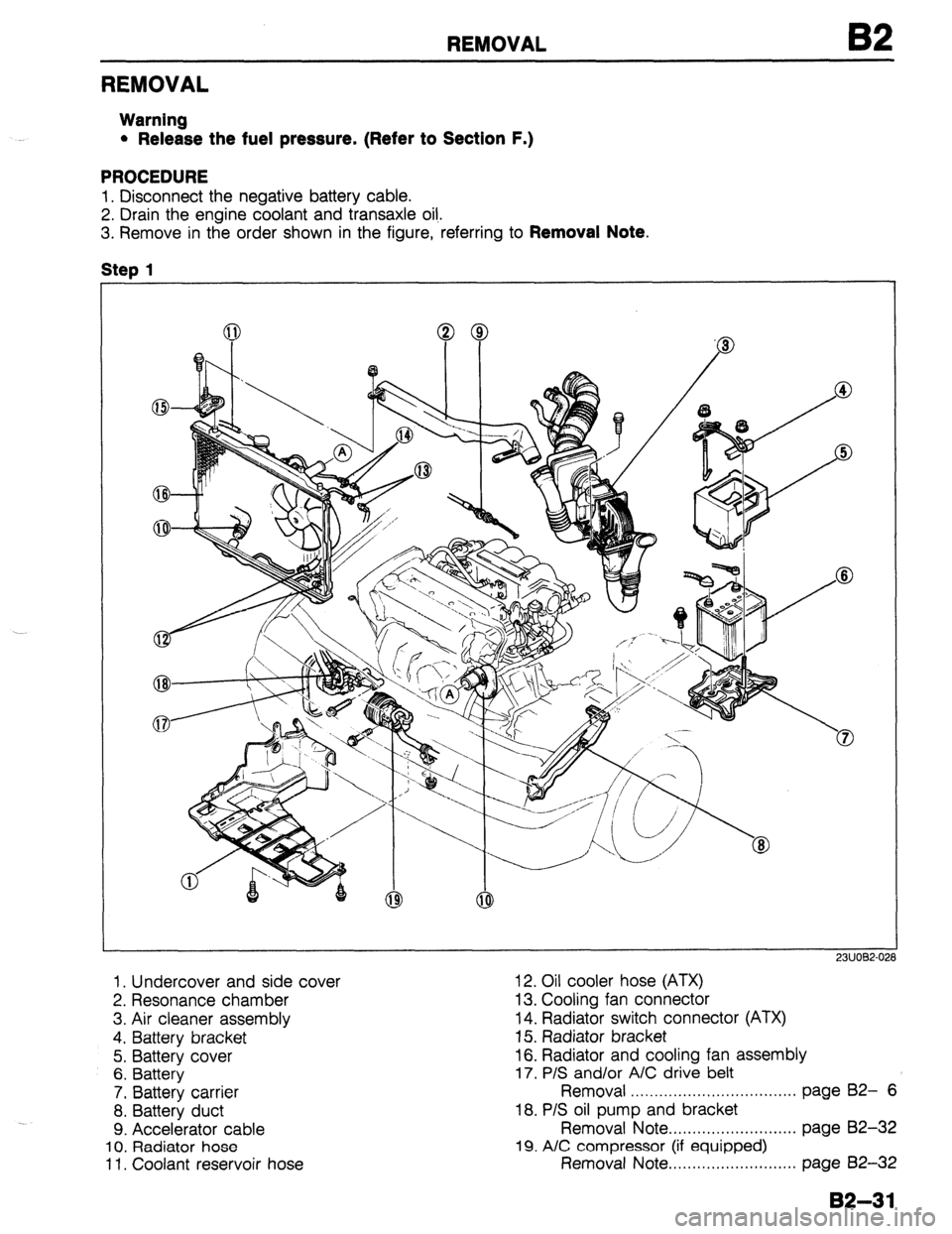

REMOVAL

REMOVAL

Warning

l Release the fuel pressure. (Refer to Section F.)

PROCEDURE

1. Disconnect the negative battery cable.

2. Drain the engine coolant and transaxle oil,.

3. Remove in the order shown in the figure, referring to

Removal Note.

Step

1

1. Undercover and side cover 12. Oil cooler hose (ATX)

2. Resonance chamber 13. Cooling fan connector

3. Air cleaner assembly 14. Radiator switch connector (ATX)

4. Battery bracket 15. Radiator bracket

5. Battery cover 16. Radiator and cooling fan assembly

6. Battery

17. P/S and/or A/C drive belt

7. Battery carrier Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2- 6

8. Battery duct 18. P/S oil pump and bracket

9. Accelerator cable Removal Note . . . . . . . . . . . . . . . . . . . . + . . . . . . page 82-32

10. Radiator hose 19. A/C compressor (if equipped)

11. Coolant reservoir hose Removal Note.. . . . . . . . . . . . . . . . . . . . . . . . . . page 82-32

B2-31

Page 165 of 1164

REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

J”“DC-” I I

1. Fuel hose

3. Brake vacuum hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

4. Vacuum hose (Purge control)

2. Heater hose

Removal Note . . . . . . . . . . . . . , . . . . . . . . . . . .

05UOBX-078

0311082-052

. . . . .

below 5. Vacuum hose (Cruise control)

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

82-33

Page 227 of 1164

INSTALLATION B2

Step 2

Warning

l Be sure the vehicle is securely supported on Safety stands.

Torque Specifications

‘4-l 03

‘.5-10.5, 54-76)

37-52 (3.8-5.3, 27-38)

/

37-52 (3.8-5.3, 27-38)

64-89 (6.5-9.1, 47-66) 64-89 (6.5-9.1, 47-66)

N.m (m-kg, ft-II

OWOBX-21

Engine mount member (ATX)

1. Install the engine mount member.

Tightening torque:

64-89 N*m (6.5-9.1 m-kg, 47-66 ft-lb)

I I 03UOB2-130 1132-95

Page 241 of 1164

ENGINE OIL, OIL FILTER D

b

I

03UODX-00

ONODX-01

r

03UODX-011

ENGINE OIL

INSPECTION

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temperature and

stop it.

3. Wait for five minutes.

4. Remove the oil level gauge and check the oil level and con-

dition.

5. Add or replace oil as necessary.

Note

l The distance between the L and F marks on the level

gauge represents 0.8 liter (0.85 US qt, 0.70 Imp qt).

REPLACEMENT

Warning

l Be careful when draining; the oil is hot.

1. Warm up the engine to normal operating temperature and

stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

4. Install a new gasket and the drain plug.

Tightening torque:

29-41 N,m (3.0-4.2 m-kg, 22-30 ft-lb)

5. Refill the engine with the specified type and amount of en-

gine oil.

6. Refit the oil filler cap.

7. Run the engine and check for leaks.

8. Check the oil level and add oil if necessary.

Oil pan capacity

B6 SOHC

BP SOHC and DOHC

liters (US qt, Imp qt)

3.0 (3.2, 2.6)

3.6G.843.2)

w

03UODX-011

D-7

Page 253 of 1164

ENGINE COOLANT E

ENGINE COOLANT

PREPARATION

SST

49 9200 145

For 49 9200 146

For

inspection of inspection of

cooling system Adapter A cooling system

pressure (Part of pressure

49 9200 145)

05UOEX-00

INSPECTION

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap when removing it.

l When removing the radiator cap, loosen it slowly

to the first stop until the pressure in the radiator is

released, and then remove it.

03UOEX~006

Coolant Level (Engine cold)

1. Verify that the coolant level is near the radiator filler neck.

2. Remove the coolant level gauge and check the coolant level.

Coolant Quality

1. Verify that there is no buildup of rust or scale around the

radiator cap or radiator filler neck.

2. Verify that coolant is free of oil. Replace the coolant if

necessary.

Coolant Leakage

1. Connect a radiator tester (commercially available) and the

SST to the radiator filler neck.

2. Apply

103 kPa (1.05 kg/cm2, 15 psi) pressure to the

system.

3. Verify that the pressure is held.

If not, check for coolant leakage.

E-5

Page 254 of 1164

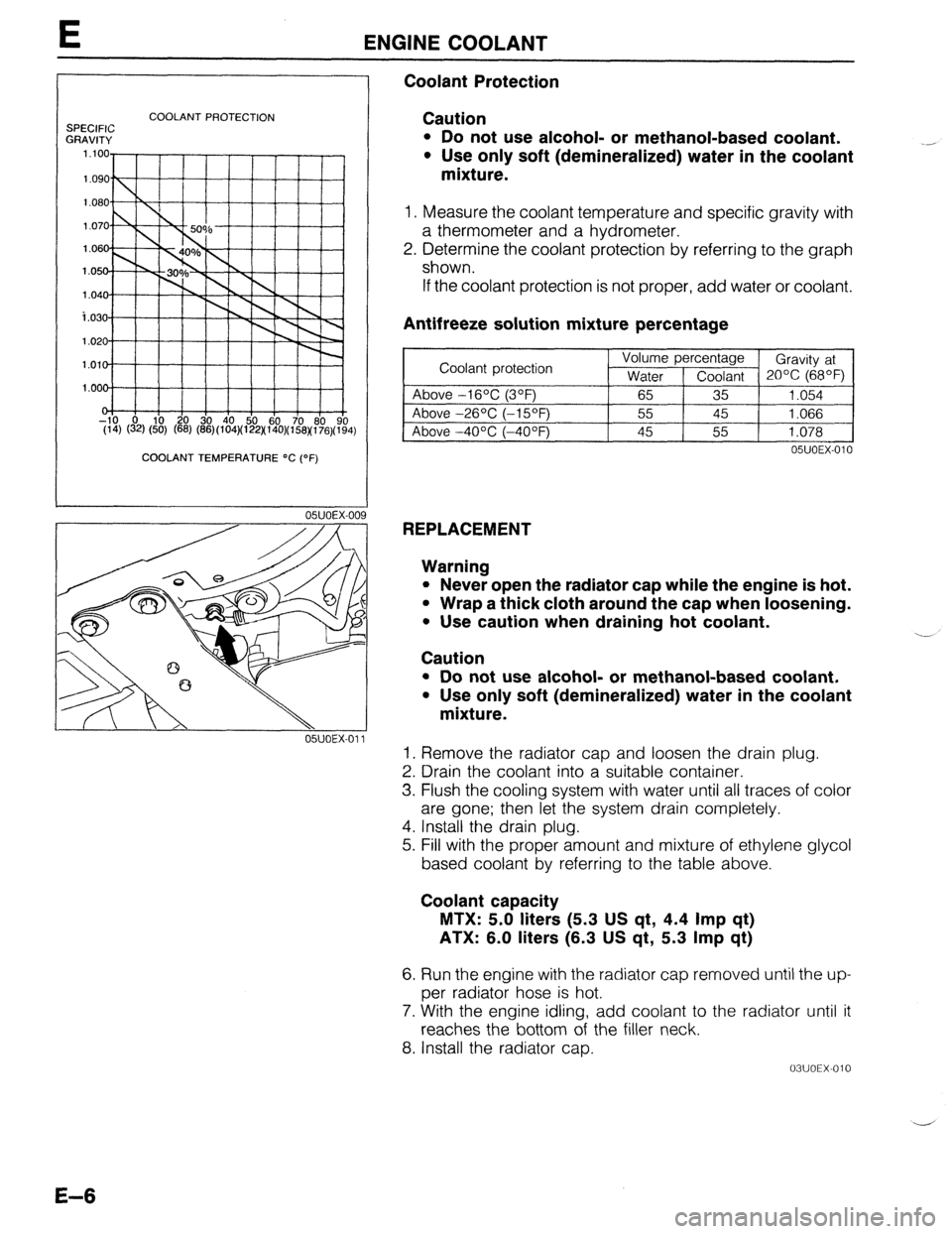

E ENGINE COOLANT

SPECIFIC

GRAVITY COOLANT PROTECTION

l.OOd ’ ’ I I I I I

0, I I

-10 0 i 10 20 30 40 50 60

70 60 90

(14) (32) (50) (66) (66)(104)(122)(140)(158~176)(194)

COOLANT TEMPERATURE OC (OF)

Coolant Protection

Caution

l Do not use alcohol- or methanol-based coolant.

l Use only soft (demineralized) water in the coolant

mixture.

1. Measure the coolant temperature and specific gravity with

a thermometer and a hydrometer.

2. Determine the coolant protection by referring to the graph

shown.

If the coolant protection is not proper, add water or coolant.

Antifreeze solution mixture percentage

~1

05UOEX-010

REPLACEMENT

Warning

l Never open the radiator cap while the engine is hot.

l Wrap a thick cloth around the cap when loosening.

. Use caution when draining hot coolant.

Caution ..-

l Do not use alcohol- or methanol-based coolant.

l Use only soft (demineralized) water in the coolant

mixture.

1. Remove the radiator cap and loosen the drain plug.

2. Drain the coolant into a suitable container.

3. Flush the cooling system with water until all traces of color

are gone; then let the system drain completely.

4. Install the drain plug.

5. Fill with the proper amount and mixture of ethylene glycol

based coolant by referring to the table above.

Coolant capacity

MTX: 5.0 liters (5.3 US qt, 4.4 Imp qt)

ATX: 6.0 liters (6.3 US qt, 5.3 Imp qt)

6. Run the engine with the radiator cap removed until the up-

per radiator hose is hot.

7. With the engine idling, add coolant to the radiator until it

reaches the bottom of the filler neck.

8. Install the radiator cap.

03UOEX-010 -

E-6

Page 265 of 1164

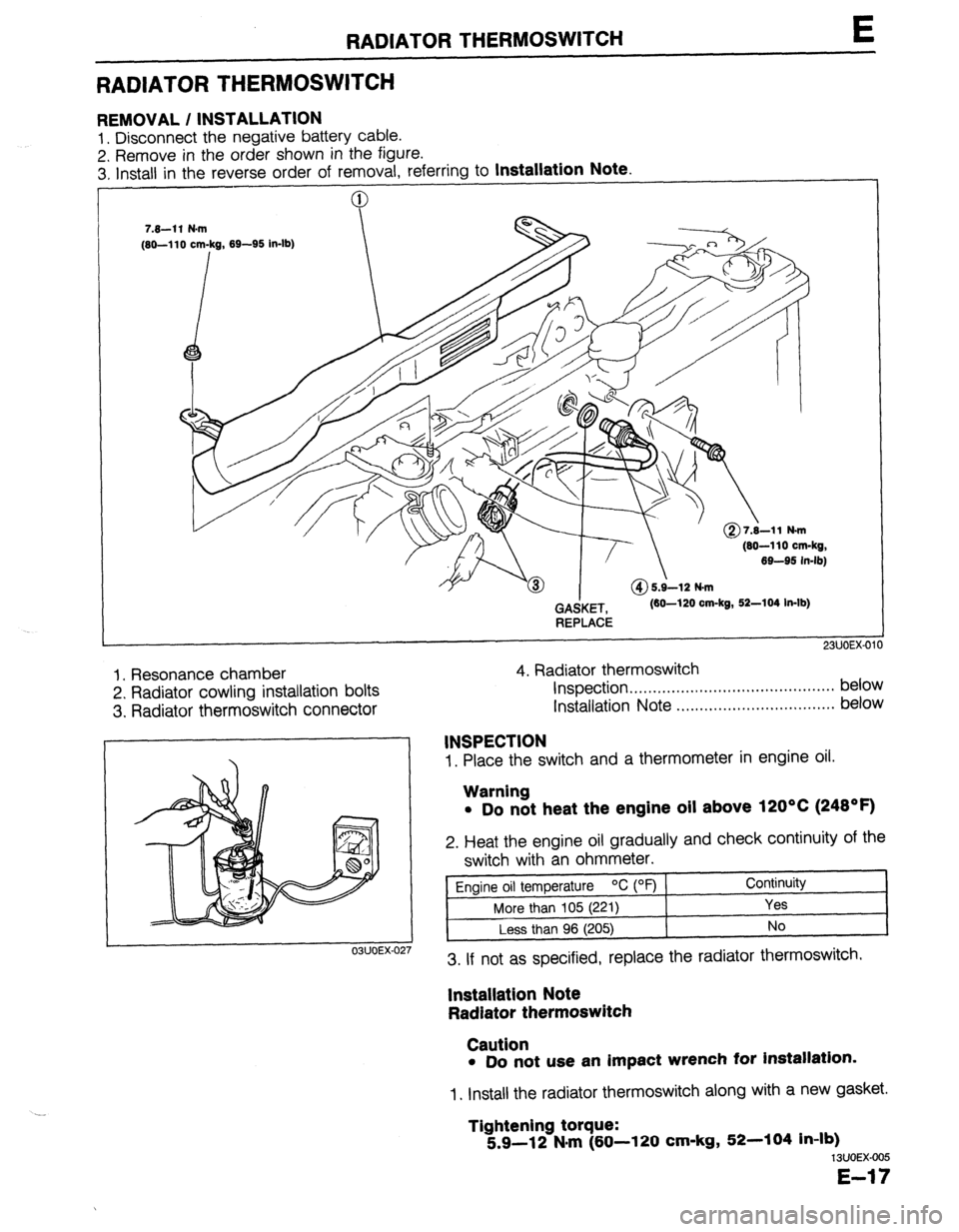

RADIATOR THERMOSWITCH E

RADIATOR THERMOSWITCH

REMOVAL / INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure.

3. Install in the reverse order of removal. referrina to

Installation Note.

(80-110 cm-kg,

69-95 in-lb)

GAdKET,

REPLACE (60-120 cm-kg, 52-104 In-lb)

1. Resonance chamber

2. Radiator cowling installation bolts

3. Radiator thermoswitch connector 4. Radiator thermoswitch

Inspection . . . . . . . . . . . . . . . ..*...,..,..................* below

Installation Note ..,.,........,.......,........,... below

1. Place the switch and a thermometer in engine oil.

03UOEX-02

INSPECTION

Warning

l Do not heat the engine oil above 120°C (248OF)

2. Heat the engine oil gradually and check continuity of the

switch with an ohmmeter.

Engine oil temperature OC (OF) Continuity

More than 105 (221)

Yes

Less than 96 (205) No

3. If not as specified, replace the radiator thermoswitch.

lnstallatlon Note

Radiator thermoswitch

Caution

l Do not use an impact wrench for installation.

1. Install the radiator thermoswitch along with a new gasket.

Tightening torque:

5.9-12 N#m (60-l 20 cm-kg, 52-104 in-lb)

13UOEX-005

E-17

Page 343 of 1164

![MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

27 MIL ALWAYS ON

DESCRIP- *Self-Diagnosis Checker does not indicate Malfunction Code No. but MIL always ON

TION

[TROUBLESHOOTING HINTS]

*Short circuit in wiring harness

l E MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

27 MIL ALWAYS ON

DESCRIP- *Self-Diagnosis Checker does not indicate Malfunction Code No. but MIL always ON

TION

[TROUBLESHOOTING HINTS]

*Short circuit in wiring harness

l E](/img/28/57077/w960_57077-342.png)

TROUBLESHOOTING GUIDE

27 MIL ALWAYS ON

DESCRIP- *Self-Diagnosis Checker does not indicate Malfunction Code No. but MIL always ON

TION

[TROUBLESHOOTING HINTS]

*Short circuit in wiring harness

l ECU malfunction

iTEF 1

1

-

s

Disconnect (Y/B) wire from ECU and check if

MIL goes off

‘YIB

ATX YIB

INSPECTION ACTION

Yes Replace ECU CT page F-149

No Check for short circuit in wiring be-

tween instrument cluster and ECU

23UOFX-042

28

MIL NEVER ON

IESCRIP- *Self-Diagnosis Checker indicates Malfunction Code No. of input device but MIL never ON

RON *Other indicator and warning lamps OK

:TROUBLESHOOTING HINTS]

b Bulb burned

‘Open circuit in wiring harness

m ECU malfunction

TEP INSPECTION

ACTION

1 Ground (Y/B) wire at ECU with jumper wire and

Yes Check connection of ECU connector

check if MIL comes on

MTX e If OK, replace ECU w page F-149

I- i -!~ !r--~r’:~;-‘;- --~_:- ,

1 i r 1 1 1 ;-.:,~;~$~& {-;&# ,$&]j 4 If not OK, repair ECU connector

! No

Check if bulb is OK

ATX 13 If OK, repair (Y/B) wire between

ECU and instrument cluster

e If not OK, replace bulb CT page T-83

23UOFX-043

29 A/C DOES NOT WORK

DESCRIP- *Blower fan operates but magnet clutch does not operate

TION

[TROUBLESHOOTING HINTS]

*Open or short circuit in wiring harness

*A/C relay, A/C switch, or magnetic clutch malfunction

l ECU malfunction

TEP/ INSPECTION ACTION

1 1 Check ECU

terminal 10 (MTX) 10 (ATX) voltage 1

Yes Check ECU terminal 1 J (MTX) 1 L (ATX)

OK

CT= page F-152

MTX

T7J++!;i”-

L

ATX

No voltage OK

CT page F-152

1-3 If OK, check A/C system

c3- page U-30

~3 If not OK, replace ECU CT page F-149

Check for cause w page F-153

F-77