parking brake MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 694 of 1164

P CONVENTIONAL BRAKE SYSTEM

REAR BRAKE (DRUM)

Quick Inspection, On-vehicle

1. Jack up the rear of the vehicle and support it with safety

stands.

2. Remove the wheels.

3. Remove the brake drum. (See below)

4. Verify the remaining thickness of the lining.

Thickness: l.Omm (0.04 in) min.

I

1 BUOPX-017

Removal / Inspection / Installation

1. Remove the lining in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

(18.0-24.0, 130-l 74)

N-m (m-kg, R-lb)

371 InPx-fll’

--_-. ,. -. 9

1. Screw

2. Brake drum

Inspection.. . . . . . . . page P-29

Installation Note

. . . . . . . . . . . . . . . . . . . . . . . page P-29

3. Return spring

4. Hold pin and spring

5. Anti-rattle spring

6. Brake shoe (leading side)

Inspection . . . . . . . . . . . . . . Above 7. Brake shoe (trailing side)

Inspection . . . . . . . . . . . . . . . . Above

8. Stopper spring and clip

9. Return spring

10. Parking brake cable

11. Operating lever assembly

12. Brake pipe

Removal Note . . page P-29 13. Bolt

14. Wheel cylinder

Disassembly I Inspection /

Assembly . . . . . . . page P-30

15. Wheel cylinder gasket

16. Hub cap

17. Locknut

18. Wheel hub

19. Backing plate

P-28

Page 696 of 1164

P CONVENTIONAL BRAKE SYSTEM

23UOPX-02

WHEEL CYLINDER

Disassembly / inspection / Assembly Caution

Take the following steps after installation:

l Add fluid and bleed the air. (Refer to page P-6.)

l Check for fluid leakage. (Refer to page P-6.)

l Depress the brake pedal a few times and check that

the rear brakes do not drag while rotating the wheel.

l Check the parking brake lever stroke.

(Refer to page P-31.)

Caution

l if a problem is found in the wheel cylinder or the piston, replace the wheel cylinder as an as-

sembly.

1. Disassemble the wheel cylinder in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

5.9-8.8 N-m

1. Dust boot

2. Piston

Inspect for corrosion and damage

3. Piston cup

4. Spring and caps

23UOPX-02

5. Rubber cup and bleeder screw

6. Steel ball

7. Wheel cylinder body

Inspect for corrosion and damage

P-30

Page 697 of 1164

PARKING BRAKE SYSTEM

PARKING BRAKE SYSTEM

TROUBLESHOOTING GUIDE

Problem

Brakes do not

release

Parking brake does

not hold well Possible cause

Improper return of parking brake cable or improper ad-

justment

Excessive lever stroke

Brake cable stuck or damaged

Brake fluid or oil on pad or lining

Hardening of pad / lining surface or poor contact Remedy Repair or adjust

Adjust

Repair or replace

Clean or replace

Grind or replace Page P-32

P-31

P-32

P-i,28

ONOPX-080

PARKING BRAKE SHOE

Removal / Inspection / Installation

Disc brake

Removal and Installation (Refer to page P-23)

Inspection (Refer to page P-25)

Drum brake

Removal and Installation (Refer to page P-28)

Inspection (Refer to page P-29)

03u0Px-081

13UOPX-021

03UOPX-08

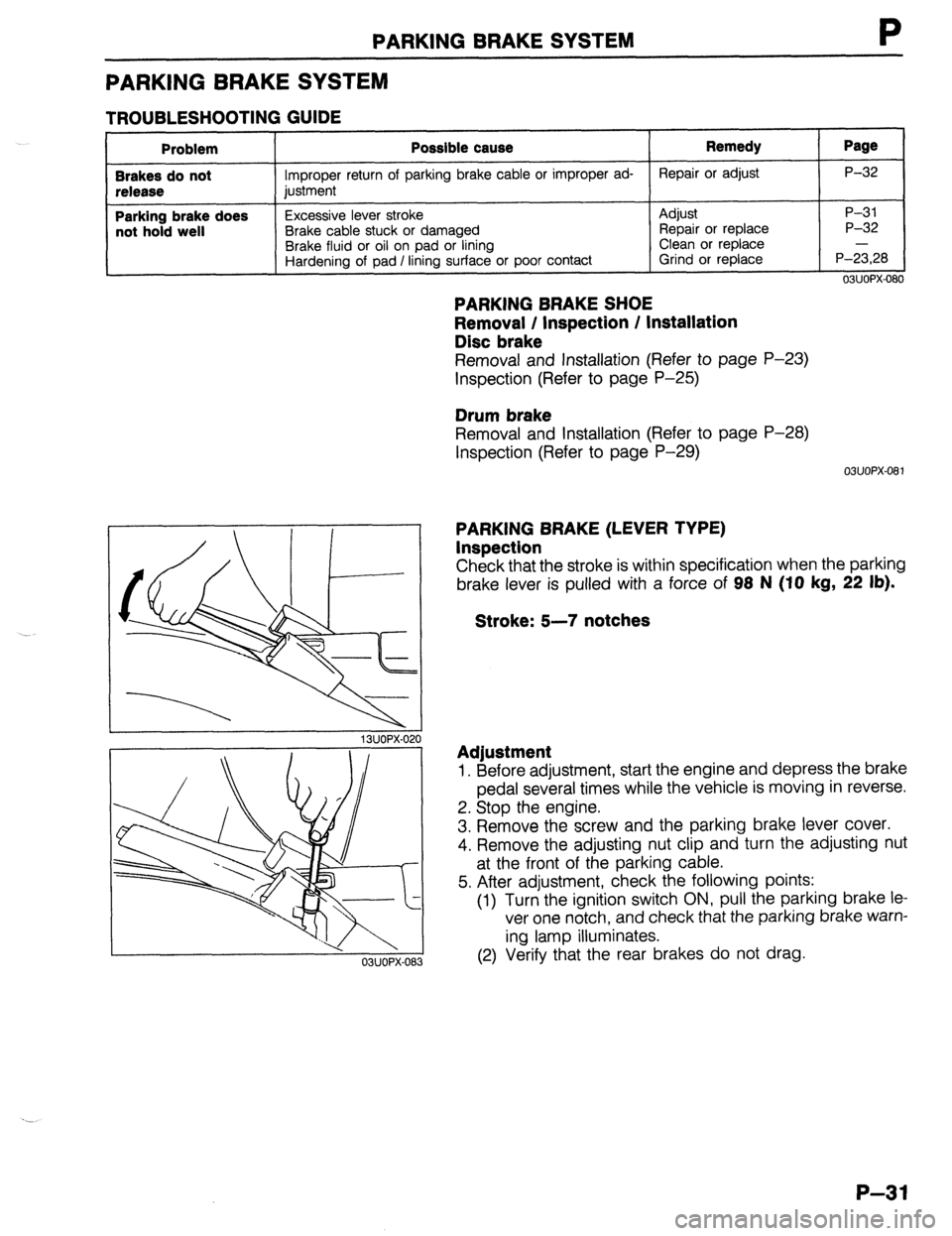

PARKING BRAKE (LEVER TYPE)

Inspection

Check that the stroke is within specification when the parking

brake lever is pulled with a force of 98 N (IO

kg, 22 lb).

Stroke: 5-7 notches

Adjustment

1. Before adjustment, start the engine and depress the brake

pedal several times while the vehicle is moving in reverse.

2. Stop the engine.

3. Remove the screw and the parking brake lever cover.

4. Remove the adjusting nut clip and turn the adjusting nut

at the front of the parking cable.

5. After adjustment, check the following points:

(1) Turn the ignition switch ON, pull the parking brake le

ver one notch, and check that the parking brake warn-

ing lamp illuminates.

(2) Verify that the rear brakes do not drag.

P-31

Page 698 of 1164

P PARKING BRAKE SYSTEM

PARKING BRAKE CABLE

Removal / Inspection / Installation

Caution

l Adjust the parking brake lever stroke.

l Depress the brake pedal a few times and check that the rear brakes do not drag while rotating

the wheels.

1. Remove the cable in the order shown in the figure.

2. Visually check each part, and replace it if necessary.

3. Install in the reverse order of removal.

16-23 (1.6-2.3, 12-17)

19-26 (1.9-2.6, 14-19)

N-m (m-kg, ft-lb)

03UOPX-08,

1. Rear console

3. Return spring 7. Clip

Removal / Installation

4. Front parking cable 8. Rear parking cable

. . . . . . . . . . . . . . . . . . . . . ..I. Section S 5. Nut (Disc brake type)

Inspect for damage and

2. Adjusting nut

6. Bolt (Drum brake type)

wear

P-32

Page 699 of 1164

PARKING BRAKE SYSTEM

PARKING BRAKE LEVER

Removal / Inspection / Installation

Caution

l Install the parking brake switch so that it contacts the parking brake lever when the lever is

fully released.

l Turn the ignition switch ON, and check that the parking brake warning lamp illuminates with

the lever pulled one notch.

1. Block the wheels firmly.

2. Release the parking brake.

3. Remove in the order shown in the figure.

4. Inspect all components and parts, Replace parts if necessary.

5. Install in the reverse order of removal.

6. After installation: Adiust the parking lever stroke. (Refer to paae P-31 .)

N.m (m-kg, R-lb)

23UOPX.022

1. Rear console 5. Parking brake switch

Removal / Installation . . . . . . . . . . . . . . . . . . . . . Section

S 6. Parking brake cap

2. Adjusting nut 7. Release button

3. Bolt 8. Parking lever spring

4. Parking brake lever assembly 9. Parking brake lever

Inspect for damage and wear

P-33

Page 889 of 1164

EXTERIOR LIGHTING SYSTEM T

Headlights either do not operate or are dim Low-High beam or passing flasher does not

J operate

Burnt out bulb or poor grounding J

03UOTX-049 Defective combination switch

03UOTX-050

(Canada) Daytime running lights (DRL) do not operate

Confirm that headlights operate with the light switch ON

(second position) OK

Turn OFF the light switch and turn ON the ignition

switch when parking level pulling

I

Check head 30A main fuse OK

Check DRL resistor OK Repair DRL resistor 10A fuse

Confirm battery voltage on R and L/G wire of the DRL NG

relay Repair harness (Fuse - DRL relay)

I

I

Check the DRL relay

Repair DRL relay

1 OK

Confirm battery voltage on (BRNV) wire of the DRL con-

trol unit NG

Repair harness (DRL relay - DRL control unit) OK

Confirm battery voltage on (L/G) wire of the DRL control NG

unit Repair harness (Rear wiper fuse - DRL control unit) OK

Confirm continuity of (G/R) wire of the DRL control unit x Repair harness (DRL control unit - Parking brake

to ground switch) or check the parking brake switch 1 OK

Confirm continuity on (B) wire of the DRL control unit to

NG

ground Repair harness (DRL control unit ground) OK

-1 NG

Confirm approx. 8V on the DRL resistor Repair harness (DRL control unit - DRL headlight)

I

Confirm battery voltage on (

Confirm approx. 8V on (R/W) wire of the DRL resistor Repair harness (DRL resistor - DRL relay)

Repair harness (DRL control unit - DRL resistor)

23UOTX-019

T-33

Page 917 of 1164

WARNING SYSTEM T

13UOTX-07

63U15X-05

, I//

‘nF -

-

-

FUEL

13UOTX.08C

- CHARGE

13UOTX-08

13UOTX-08

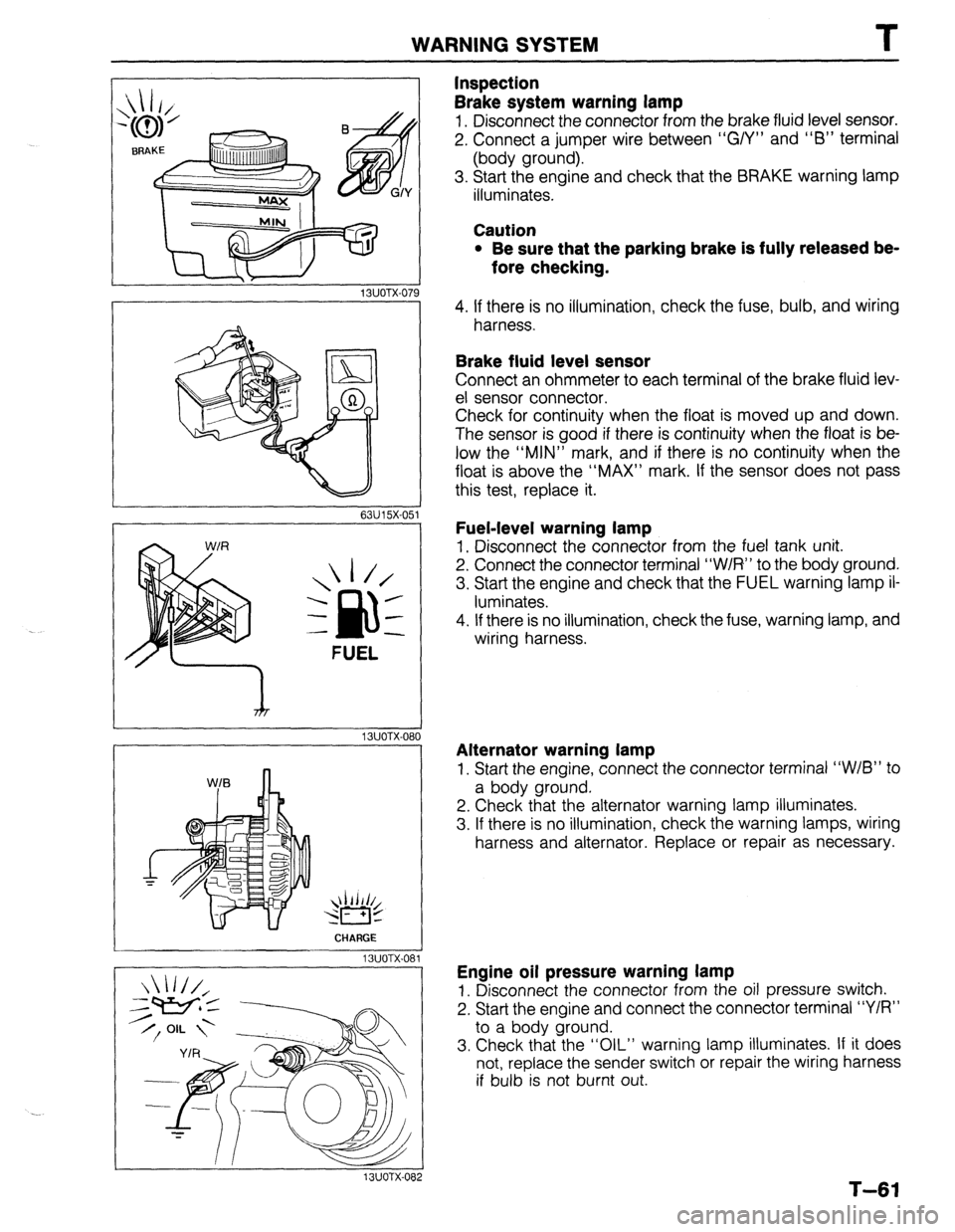

Inspection

Brake system warning lamp

1. Disconnect the connector from the brake fluid level sensor.

2. Connect a jumper wire between “G/Y” and “6” terminal

(body ground).

3. Start the engine and check that the BRAKE warning lamp

illuminates.

Caution

l Be sure that the parking brake is fully released be-

fore checking.

4. If there is no illumination, check the fuse, bulb, and wiring

harness.

Brake fluid level sensor

Connect an ohmmeter to each terminal of the brake fluid lev-

el sensor connector.

Check for continuity when the float is moved up and down.

The sensor is good if there is continuity when the float is be-

low the “MIN” mark, and if there is no continuity when the

float is above the “MAX” mark. If the sensor does not pass

this test, replace it.

Fuel-level warning lamp

1. Disconnect the connector from the fuel tank unit.

2. Connect the connector terminal “W/R” to the body ground.

3. Start the engine and check that the FUEL warning lamp il-

luminates.

4. If there is no illumination, check the fuse, warning lamp, and

wiring harness.

Alternator warning lamp

1. Start the engine, connect the connector terminal “W/B” to

a body ground.

2. Check that the alternator warning lamp illuminates.

3. If there is no illumination, check the warning lamps, wiring

harness and alternator. Replace or repair as necessary.

Engine oil pressure warning lamp

1. Disconnect the connector from the oil pressure switch.

2. Start the engine and connect the connector terminal “Y/R”

to a body ground.

3. Check that the “OIL” warning lamp illuminates. If it does

not, replace the sender switch or repair the wiring harness

if bulb is not burnt out.

T-61

Page 920 of 1164

2L BUZZER 2A 28 2C 2D 1A 3K l--r nnmn

I I‘ I

1C 3L 2E 2G IL iG 1F 1D tB

3F 38 3G 1E 3D

l-l rt

II l-l

l-l It II l-l 1J 11 1H

1G IF 1E 1D 1C 1B 1A 2L 2K 2J 21 2H 2G 2F 2E 2D 2C 28 2A

r-l It ,I 3L 3K 3J 31 3H 3G 3F 3E 3D 3C 3B 3A

Ter- I I minal Connected to 1 1A Combination switch

1B Ground

IC Fuel tank unit

1 ID 1 EGI control unit

I

II L 1J 1

L Ter-

minal Connected to

2A Speed sensor output

28 Light switch (high beam)

2C Turn switch (L)

20 Turn switch (R)

2E Ground

2F Ground

2L 1 IGI battery Ter-

minal Connected to

3A

38 Alternator

3c

30 Oil pressure switch

3E

3F Parking brake switch, Brake fluid switch

3G Passive shoulder belt control unit

3H h

I 31

3J

3K

IG2 battery

3L Water temperature gauge unit

Page 1023 of 1164

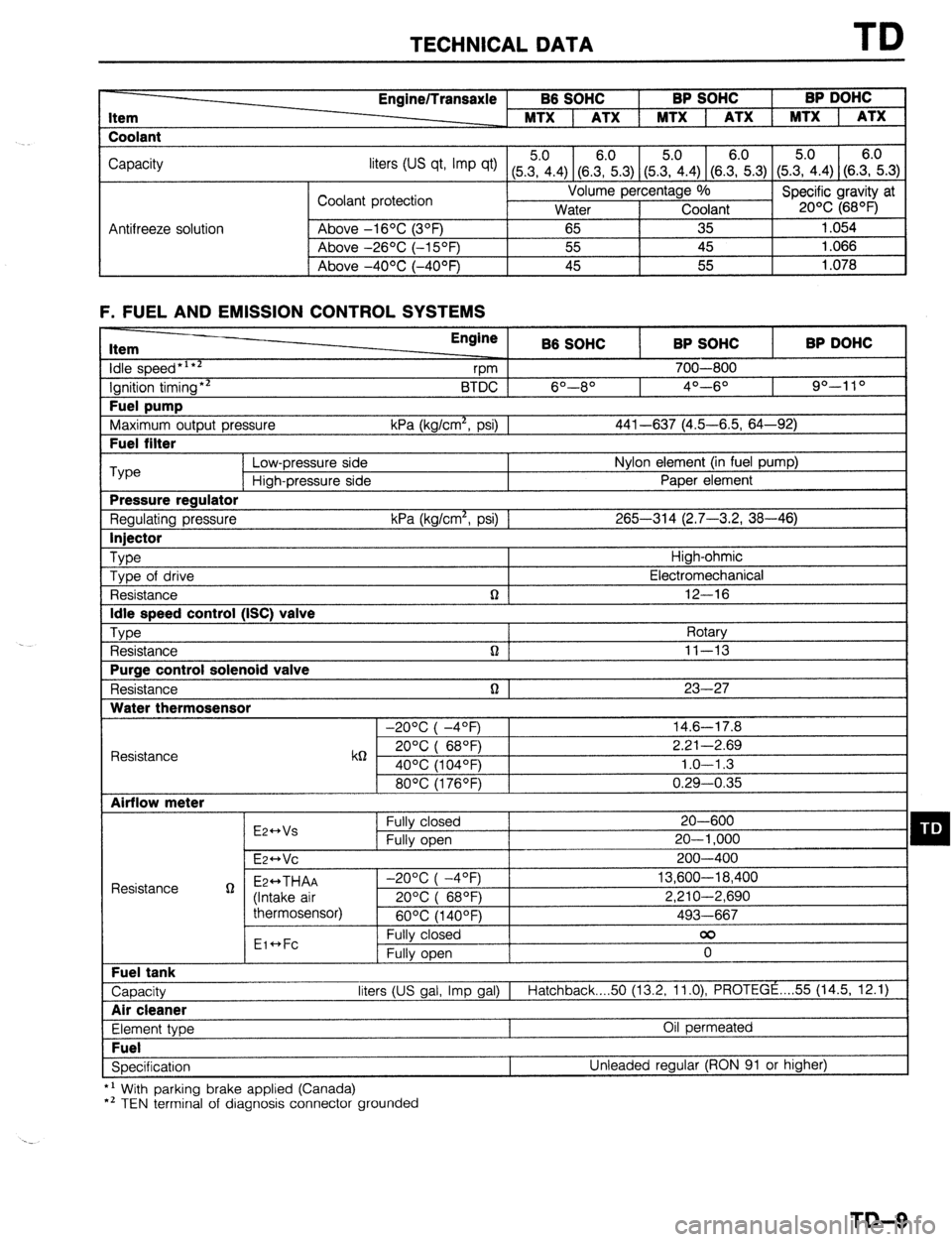

TECHNICAL DATA TD

Item

Coolant Engine/Transaxle B6 SOHC BP SOHC BP DOHC

MTX 1 ATX 1 MTX 1 ATX 1 MTX 1 ATX

Capacity

liters tus qt, Imp qt) (5Z.4) (8.E.3) (5&4) (SE.3) (5.?i.4) (S.E.3)

Coolant protection Volume percentage %

Specific gravity at

Water Coolant 20% (68OF)

Antifreeze solution Above -16OC (3OF)

65 35 1.054

Above -26OC (-15OF) 55 45 1.066

I Above -4OOC (-40°F) 45 55

1.078

F. FUEL AND EMISSION CONTROL SYSTEMS Item

idle speed*‘**

Ignition timing** Fuel pump

Maximum output pressure Fuel filter Engine

B6 SOHC BP SOHC BP DOHC

vm 700-800

BTDC 6O--8O 4O---6O 90-l 10

kPa (kg/cm*, psi) 1 441-637 (4.5-6.5, 64-92) ‘Type

Low-pressure side Nylon element (in fuel pump)

High-pressure side Paper element Pressure regulator

Regulating pressure kPa (kg/cm*, psi) 1 265-314 (2.7-3.2, 38-46) Injector

Type

High-ohmic

Type of drive Electromechanical

Resistance n 12-16 Idle speed control (ISC) valve

Type

Rotary

Resistance n ] 11-13 Purge control solenoid valve

Resistance n 1 23-27 Water thermosensor

-20°C( -4OF) 14.6-17.8

Resistance k6 20°C( 68QF) 2.21-2.69

40% (104OF) 1.0-l .3

80°C(1760F) 0.29-0.35 Airflow meter

E2++Vs Fully closed 20-600 q D Fully open 20-l ,000

E~HVC 200-400

Resistance g Ez++THAA -2O%(-4OF) 13,600-18,400

(Intake air 20%( 68OF) 2,210-2,690

thermosensor)

60°C(1400F) 493-667

Eic*Fc Fully closed 00

Fully open 0 Fuel tank

Capacity liters (US gal, Imp gal) I

Hatchback 50 (13.2, 11.0) PROTEGE . . . . 55 (14.5, 12.1) Air cleaner

Element type Oil permeated Fuel

Specification Unleaded regular (RON 91 or higher)

*’ With parking brake applied (Canada)

*’ TEN terminal of diagnosis connector grounded

TD-9

Page 1032 of 1164

TD TECHNICAL DATA

P. BRAKING SYSTEM

Item

3rake type

Brake pedal

Height mm (in)

Free play mm (in)

Reserve travel mm (in)

Clearance when pedal depressed at 589 N (60 kg, 132 lb)

Master cylinder

Type

Master cylinder

Bore diameter mm (in) 1

Front disc brake

We

Thickness of pad

mm (in) Standard

Minimum

Thickness of disc plate

mm (in) Standard

Minimum

Runout of disc plate mm (in)

Cylinder bore

mm (in) Specifications

Front . . . . . disc, Rear . . . . . disc or drum

193-196 (7.60-7.72)

4-7 (0.16-0.28)

70 (2.76) min

Tandem

22.22 (0.875)

Ventilated

10 (0.39)

2 (0.08)

22 (0.87)

20 (0.79)

0.1 (0.004)

53.97 (2.12)

Rear brake (drum)

We

Thickness of lining

I Drum inside diameter

1

tiheel cylinder bore

I Parking brake

Type

Parking brake lever notches Leading & trailing

mm (in) Standard 4.5 (0.18)

Minimum 1 (0.04)

mm (in) Standard 200 (7.90)

Maximum 201 (7.91)

mm (in) 17.46 (0.687)

Mechanical two-rear-wheel control

When lever is pulled at 98N (10 kg, 22 lb)

Power brake unit

Diameter mm (in) 5-7

(a): 214 (8.43) (b): 239 (9.41)

More than 1,177 (12, 171)/196 (20, 44)

Fluid pressure per treading force

kPa (kg/cm’, psi)/N (kg, lb) (4

@I at 0 mmHg (0 inHg)

More than 7,063 (72, 1,024)/l 96 (20, 44)

at 500 mmHg (19.7 inHg)

More than 1,517 (15, 213)/196 (20, 44)

at 0 mmHg (0 inHg)

More than 8,593 (88, 1,261)/196 (20, 44)

at 500 mmHg (19.7 inHg)

Rear wheel hydraulic control rystem

Type Dual proportioning valve

_-_.

. .- ,. . . . !

P.IF

Switching point (Master cylinder pressure)

KPa (kg/cm-, PSI) ) z,4~j3 (25, 356)

(a): BP engine with SMTX, B6 engine

(b): BP engine with 4EATX ..-

-’

TD-18