engine coolant MAZDA PROTEGE 1992 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 262 of 1164

E ELECTRIC COOLING FAN SYSTEM, FAN MOTOR

03UOEX-02

I

1

I

‘4

.

2

.:

)

SYSTEM INSPECTION

1. Jump across the fan test (TFA) terminal and the ground

(GND) terminal of the diagnosis connector.

2. Turn the ignition switch ON and verify that the fan operates.

If the fan does not operate, inspect the cooling fan system

components and wire harness. -.-

3. Remove the radiator cap and place a thermometer in the

radiator filler neck.

4. Start the engine.

5. Verify that the fan operates when the coolant temperature

reaches approx. 97OC (207OF).

If it does, check the water thermoswitch.

(Refer to page E-16.)

FAN MOTOR

INSPECTION

Single-Speed Type

1. Check that the battery is fully charged.

2. Disconnect the fan motor connector.

3. Connect the battery and an ammeter to the fan motor con-

nectar.

4. Verify that current is as specified.

Current (A)

B6 SOHC

BP SOHC

BP DOHC MTX ATX

6.6 f 1 6.6 f 1

6.6 f 1 -

6.6 f 1 -

5. If current is not within specification and/or the fan does not

turn smoothly, replace the fan motor.

Two-Speed Type

1. Check that the battery is fully charged.

2. Disconnect the fan motor connector.

3. Connect the battery and an ammeter to the fan motor con-

nectors for low-speed inspection. 4. Verify that the fan motor operates smoothly at the standard

current.

Current (A): 8.8 + 10% MAX

I

03UOEX-022

E-14

Page 263 of 1164

FAN MOTOR E

I-

i.- 5. Connect the battery, an ammeter, and switch to the fan mo-

tor connectors for high-speed inspection.

6. Verify that the fan motor operates smoothly at the standard

current or less with the switch ON.

Current (A): 13.3 + 10% MAX

7. If the fan motor is faulty, replace it.

---“-. --

REPLACEMENT

Caution

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure.

4. Install in the reverse order of removal.

7.8-11 N.m

7.8-11 N.m

(80-110 cm-kg,

1. Resonance chamber

4. Radiator cowling

2. Cooling fan connector

5.

Cooling fan

3. Radiator hose upper

6. Fan motor

E-l 5

Page 264 of 1164

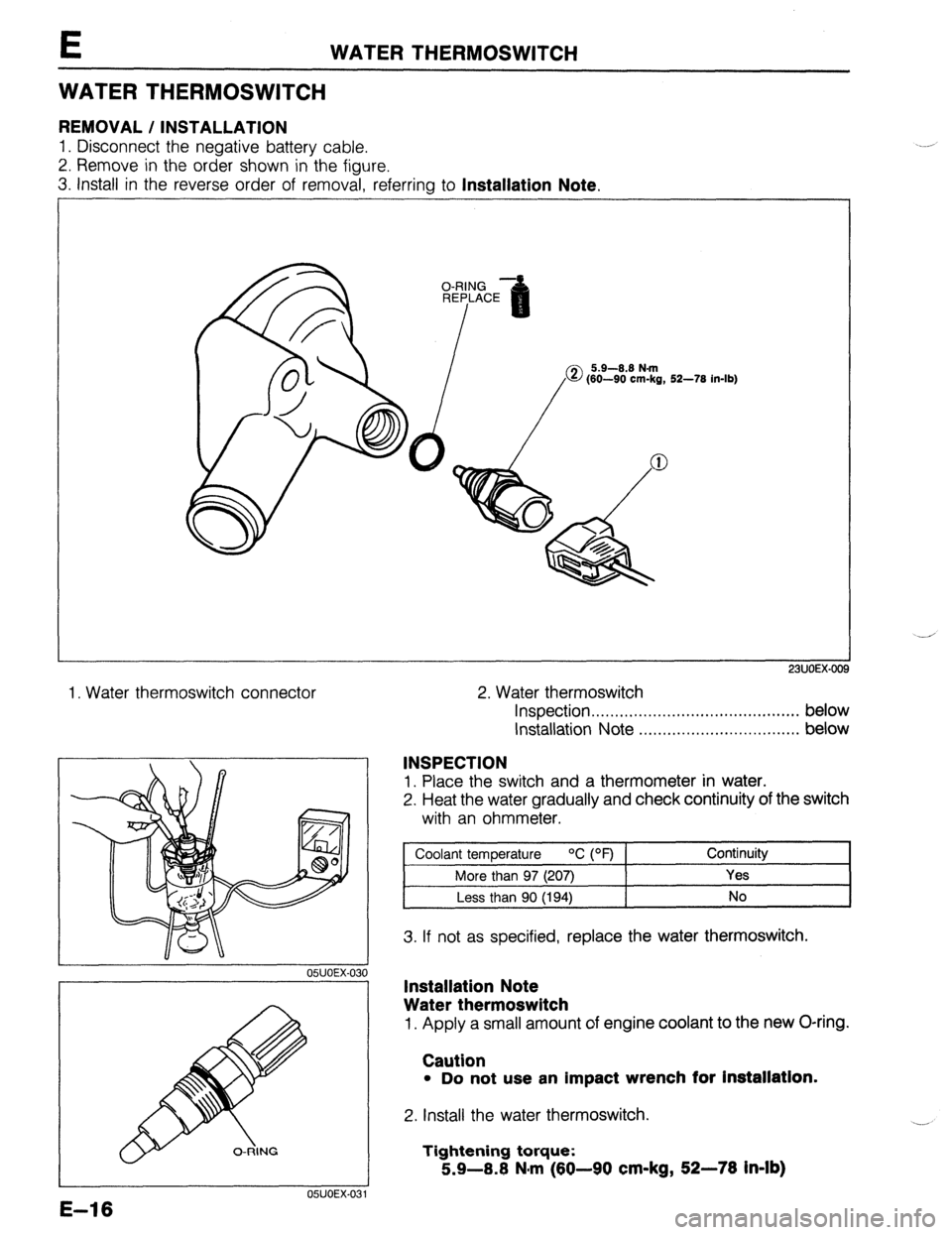

E WATER THERMOSWITCH

WATER THERMOSWITCH

REMOVAL / INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure.

3. Install in the reverse order of removal, referring to

Installation Note.

2. Water thermoswitch

23UOEX-OO!

1. Water thermoswitch connector

05UOEX-031

05UOEX.03

E-16

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

INSPECTION

1. Place the switch and a thermometer in water.

2. Heat the water gradually and check continuity of the switch

with an ohmmeter.

I Coolant temDerature

OC PF) 1 Continuity

I

More than 97 (207) Yes

Less than 90 (194) No

3. If not as specified, replace the water thermoswitch.

Installation Note

Water thermoswitch

1. Apply a small amount of engine coolant to the new O-ring.

Caution

l Do not use an impact wrench for Installation.

2. Install the water thermoswitch.

Tightening torque:

5.9-8.8 N#m (69-90 cm-kg, 52-78 in-lb)

Page 282 of 1164

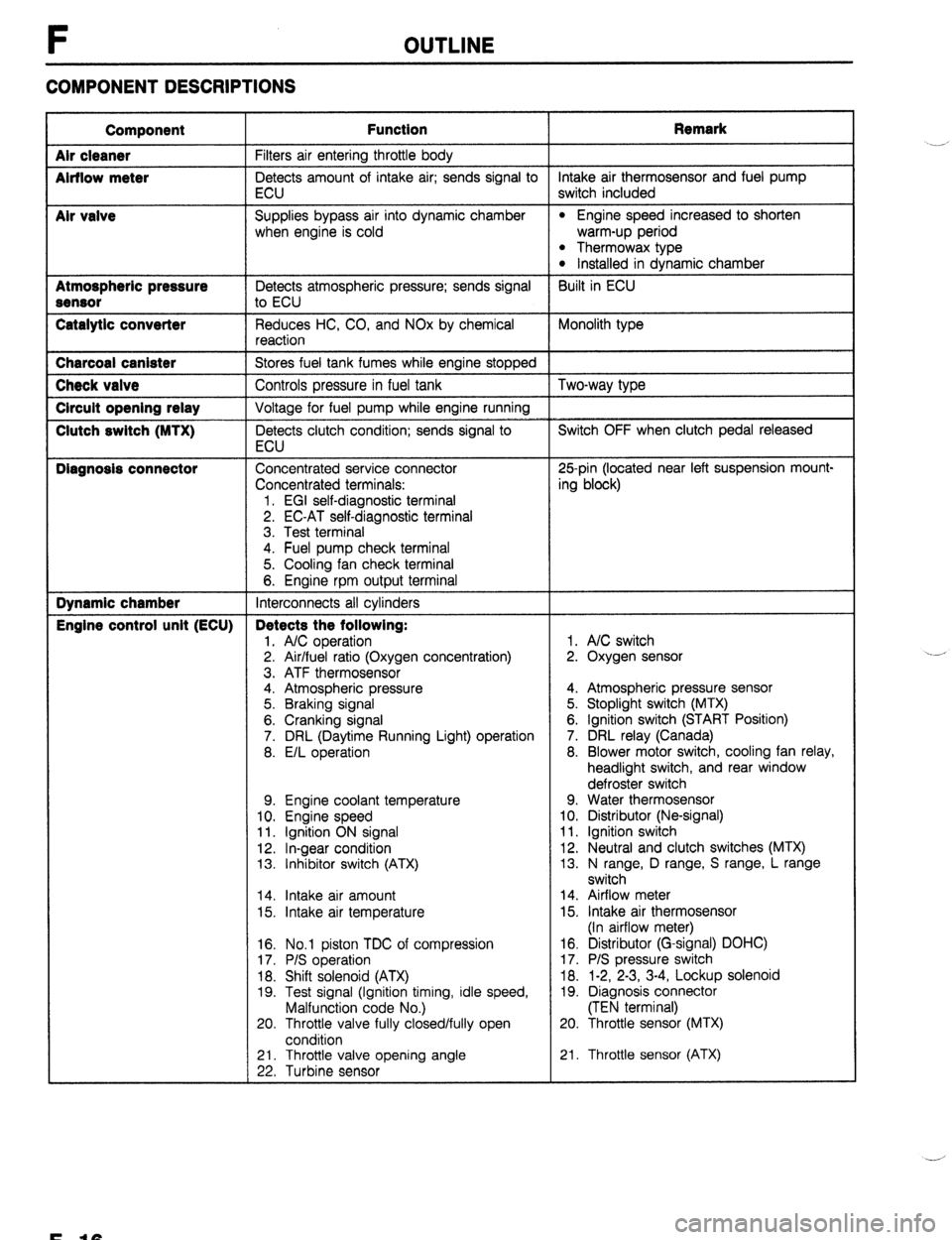

F OUTLINE

COMPONENT DESCRIPTIONS

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 284 of 1164

F OUTLINE

I Component

I Function

I Remark

I

Three-way

solenoid

valve vIcs*

Pressure

regulator

control

Controls vacuum to shutter valve actuator

Controls vacuum to pressure regulator Cuts vacuum when engine speed above

5.000 ram

Cuts vacuum just after starting when engine

hot starting Vacuum chamber

(DOHC)

Water thermosensor

Stores vacuum for use during wide open For WCS*

throttle

Detects coolant temperature; sends signal to

ECU

l WCS: Variable Inertia Charging System 23UOFX-013

F-l 8

Page 286 of 1164

F TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

ENGINE CONTROL OPERATION CHART

Note

Input Device and Engine Conditions

l The data in this chart is for reference only.

INPUT DEVICES APPROX,- SENSORS

MATE TIME G& THROTTLE SENSOR

(BASED ON TRIBUTOR

WATER INTAKE

10-16°C, (G. OXYGEN AIRFLOW AIR

VT

POW

.50-6OOF

SIGNAL)” ;;;;;f- SENSOR METER

AMBIENT) (Ne-SIGNAL) THERMO- TERMINAL TERMINAL yE\MINAL

CONDITIONS SENSOR (ATX)

WX)

A

c

CRANKING

-COLD ENGINE Signal has Signal has Signal has Signal has Slgnal has Slgnal has

l COLD AIR zero no affect no effect no effect no effect no effect

no effect

. COLD COOLANT on ECU on ECU on ECU on ECU on ECU

on ECU

Cool to A A

COLD START

warm: Low volume Closed Closed

Closed

-FAST IDLE

One

Medium airflow: throttle: throttle:

l COLD AIR

minute

voltage High volt-

Low volt- Low volt- throttle.

Low volt-

* COLD COOLANT

(3.5” and :zo:o, ,,Pbove 1’,“,“$; a(ogi-O,8”) ;149&“) we W)

dropping) to high

(68OF)]:

COLD DRIVEAWAY voltage A

Above

-PART THROTTLE Two (O-0.9”) 2.3”

l COLD AIR minutes

l COLD COOLANT

v v ,,

Warm: Medi- Sensor Moderate II

WARM DRIVEAWAY

volume air-

-PART THROTTLE Three N&IGNAL um voitage hot:

flow: Low

l WARM AIR minutes Sends all Vvwrox switching l WARM COOLANT cylinders 0.7V and

from high to medium

Part Part

TDC signal dropping) voltage voltage

throttle: throttle.

)

A (0.9V) (1 .o-3.5”)

to ECU

.“~ Medium Medium

HOT CRUISE

s voltage voltage

Open

l WARM AIR G-

SIGNAL”’ to low (0.8-3.0”) (4.5-5.5”) throttle:

l WARM COOLANT High

Sends No. voltage

1 cylinder (0.1”) voltage

1 (battery

TDC (com-

1 I voltage)

HOT ACCELERATION pression)

-60% THROTTLE signal to

Moderate

ECU

to strong

High Cool lo warm

voltage ;$,“,” Of j-20-4OT

f t

HOT ACCELERATION

More’ than Hot: Low (0.9”) Low (-4-‘04”F)l: W,ds open

voltage 1.5-4.3v

throttle: Wide open

-WIDE OPEN

four voltage

High volt- throttle

THROTTLE (0.5-1.5V)

minutes (Below High

0.5”) age (Above

voltage (OV)

t 1 3.OV)

I,

A 1. /I

DECELERATION

-CLOSED THROTTLE

HOT CURB IDLE

-EXTENDED

HOT ENGINE

SHUTDOWN Low

voltage

(0”) Low Closed Closed

Closed

volume throttle: throttle.

throttle.

of airflow:

~~~~!$$ (Above Low Low

Low

voltage voltage

voltage

to low 3.OV) (0.2-0.N) (4.5-5 5V) (OV)

voltage

(0.75%

t t 1 0.25”)

r v 1 I I

Sensor

hot: Low

OFF OFF voltage

-

(0.1”) until OFF OFF OFF OFF

OFF

sensw

COOIS

._-

Page 288 of 1164

F TROUBLESHOOTING GUIDE

Output Devices and Engine Conditions

Note

. The data in this chart is for reference only.

INJECTOR

CONDITIONS

CRANKING

-COLD ENGINE

l COLD AIR l COLD COOLANT

COLD START

-FAST IDLE

l COLD AIR l COLD COOLANT

COLD DRIVEAWAY

-PART THROTTLE

l COLD AIR l COLD COOLANT

WARM DRIVEAWAY

-PART THROTTLE

. WARM AIR

l WARM COOLANT

HOT CRUISE

l WARM AIR l WARM COOLANT Zero

One

mrnute

Two

minutes

Three

minutes

I AIR

INJECTION “AL”E

INJECTION TlMlNG

A

All A

cylinders

each

ignition

pulse

1

Rich Open:

coolant

tem-

perature:

Below

40%

(104OF)

,

I/

Rich and

2-group” 1’

lean l-group” /I

,

i

HOT ACCELERATION

-60% THROTTLE

-lOT ACCELERATION

-WIDE OPEN

THROTTLE

Closed ISC

VALVE

1, THREE-WAY

SOLENOID SOLENOID

VALVE VALVE

(PURGE

(PRESSURE

CONTROL) REGULATOR

CONTROL)‘3

c

OFF

(Purge

cut)

Large

1

, AK

RELAY

amount or

bypass air

OFF

(Vacuum

to

pressure

regulator)

After start-

rng: ON dur-

ing hot start

only (Vacu-

um cut)

OFF

l 2 SOHC, *’ BP

F-22

Page 292 of 1164

F TROUBLESHOOTING GUIDE

Troubleshooting chart

6 I

CRANKS NORMALLY BUT HARD TO START - WHEN ENGINE COLD

*Engine cranks at normal speed but requires excessive crankmg time before starting

IESCRIP-

l Batterv in normal condition

llON l Restans OK after warmup l Engine runs normally at idle [If Idle condrtron is not OK, refer to “Rough idle” (Nos. S-12)]

TROUBLESHOOTING HINTS]

B Air/Fuel mrxture too rrch @Air/Fuel mixture too lean

l Arrflow meter stickrng l Fuel iniectron control malfunction

l Aw cleaner element clogged

*Idle weed control malfunction (Correction for coolant temperature)

0 Poor atomizatron

- ~~ ~~ *Low RVP (summer) fuel is used rn cold weather >

f INSPECTION T Check If “00” is displayed on Self-Diagnosis

Checker wth Ignition switch ON -

Yes

No CT page F-73

SYSTEM SELECT: 1

“SELECT SW: A

Check if ECU terminal voltages are OK

(Especially 1C. 2D. and 2Q)

cc page F-144

Check If engine starts easily when throttle valve -

Yes

-

NO

-

Yes ACTION

Go to next step

Malfunctlon Code No. dlsplayed

Check for cause (Refer to specified

check sequence)

“58” flashes CT- page F-79

Check ECU terminal 1F voltage

Speciflcetlon: Battery voltage CT page F-144

(Ignition ewltch ON)

+ If OK, replace ECU CT page F-143

e If. not OK, check wrring between

ECU and Self-Diagnoos Checker

Go to next step

Check for cause CI page F-145

(-!hnrlr ,‘ ICP ..-I..- .^ nv

c+ page F-103

13UOFX-009

DESCRIPTION:

Further describes the symptom. Confirm that the chart addresses the actual symptom before beginning

troubleshooting.

TROUBLESHOOTING HINTS:

This describes the possible point of malfunction.

STEP:

This shows the order of troubleshooting. Proceed with troubleshooting as indicated.

INSPECTION:

This describes an inspection to quickly determine the malfunction of parts. If a detailed procedure is necessary

to perform the INSPECTION, refer to the page shown by the “~7” mark.

ACTION:

This recommends the appropriate action to take as a result (Yes/No) of the INSPECTION. How to perform

the action is described on the reference page shown by the “~7” mark.

OWOFX-016

F-26

Page 298 of 1164

F TROUBLESHOOTING GUIDE

3 CRANKS NORMALLY BUT WILL NOT START (PARTIAL COMBUSTION) - WHEN ENGINE COLD

DESCRIP- *Engine cranks at normal speed but shows only partial combustion and will not continue to run

TION

l Battery in normal condition

*Fuel in tank

[TROUBLESHOOTING HINTS]

0 Air/Fuel mixture too rich

*Air cleaner element clogged

l Airflow meter stuck @ Low engine compression

@ Air/Fuel mixture too lean

l Fuel injection control malfunction

(Correction for coolant temperature)

*Low fuel line pressure

*Air leakage of intake air system

Checker with ignition switch ON

CT page F-83

w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST w page F-149

Fuel line pressure:

285-314 kPa (2.7-3.2 kg/cm’, 38-48 psi) If fuel line pressure quickly in-

creases, check pressure regulator CF- page F-129

d If fuel line pressure gradually in-

creases check for clogging be-

I pump and pressure

Check if fuel return hose is clogged or

F-32

Page 300 of 1164

F TROUBLESHOOTING GUIDE

4

CRANKS NORMALLY BUT WILL NOT START (PARTIAL COMBUSTION) - AFTER WARM-UP *Engine cranks at normal speed and shows partial combustion but will not continue to run after running and

DESCRIP- hot soaked

TION *Battery in normal condition

*Engine starts normally when cold

[TROUBLESHOOTING HINTS] 3 Air/Fuel mixture too rich

@ Vapor lock

l Insufficient fuel injection control

*Fuel pressure not held in fuel line after engine stopped

(Correction for coolant temperature)

*High RVP (winter) fuel used in warm weather

l Injector fuel leakage @ Pressure regulator control system malfunction [BP]

switch ON, then check if en

D‘ page F-134

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 36-46 psi) ne pressure w

+ If fuel line pressure quickly in-

if fuel return hose is clogged

or

F-=34