engine coolant MAZDA PROTEGE 1992 Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 302 of 1164

F TROUBLESHOOTING GUIDE

5

CRANKS NORMALLY BUT HARD TO START - ALWAYS

DESCRIP- l Engine cranks at normal speed but requires excessive cranking time before starting

TION l Battery in normal condition

*Engine runs normally at idle [If idle condition not OK, refer to “Rough idle” (Nos. 8-12)J [TROUBLESHOOTING HINTS]

@ Air/Fuel mixture too lean

@ Air/Fuel mixture too rich l Fuel injection control malfunction

(Correction for coolant temperature) *Air cleaner element clogged

l Airflow meter stuck

*Low fuel line pressure

l Air leakage @ Poor ignition spark

;TEP INSPECTION ACTION

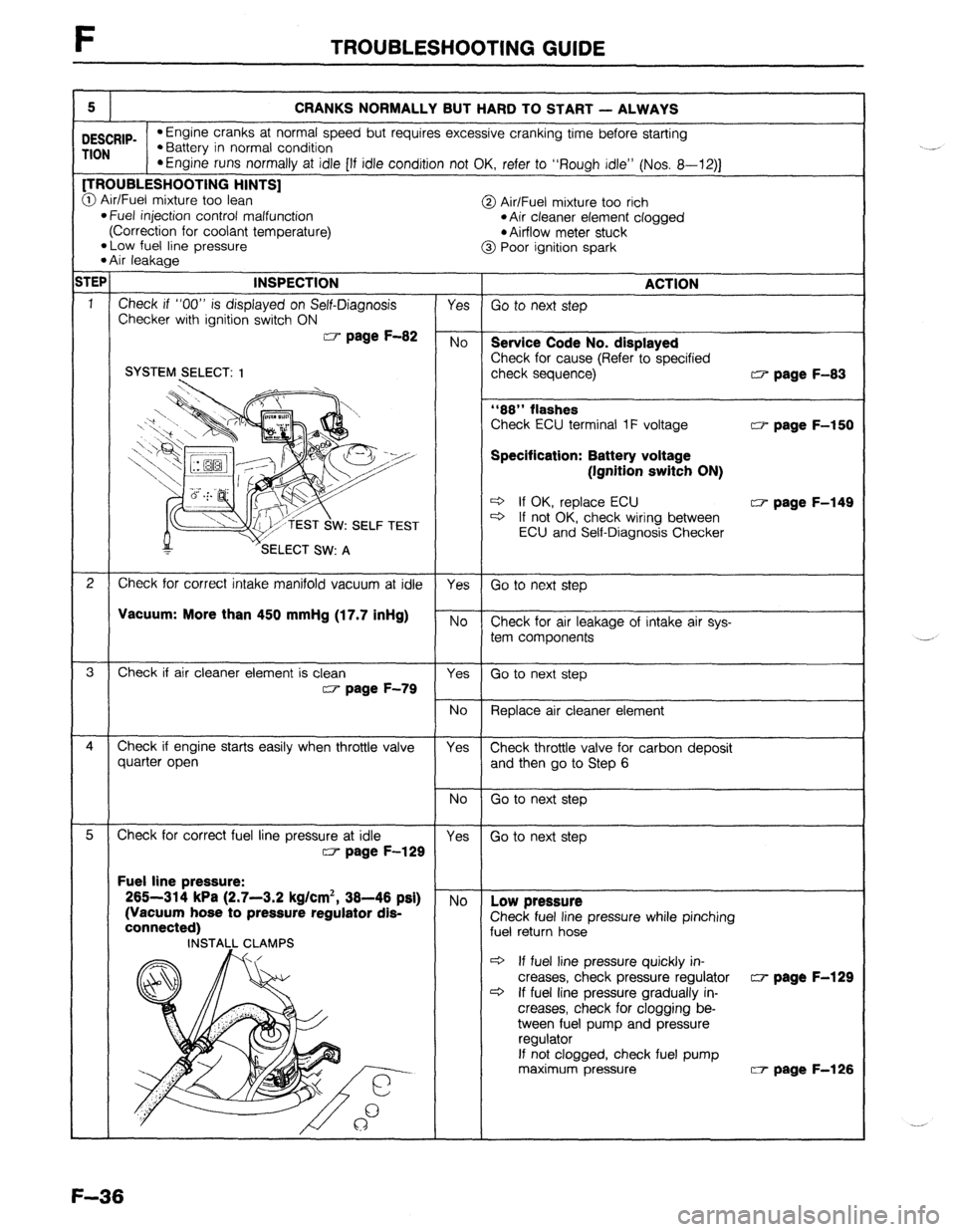

1

Check if “00” is displayed on Self-Diagnosis Yes Go to next step

Checker with ignition switch ON W page F-82 No

Service Code No. displayed

Check for cause (Refer to specified SYSTEM SELECT: 1 check sequence) w page F-83

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignitlon switch ON)

* If OK, replace ECU w page F-149

W: SELF TEST c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

2 Check for correct intake manifold vacuum at idle

Yes Go to next step

VsCUUm: More than 450 mmHg (17.7 inHg) No Check for air leakage of intake air sys-

tem components

3 Check if air cleaner element is clean

Yes Go to next step w page F-79

No

Replace air cleaner element

4 Check if engine starts easily when throttle valve Yes Check throttle valve for carbon deposit

quarter open and then go to Step 6 Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm*, 38-46 psi)

(Vacuum hose to pressure regulator dis-

pressure while pinching

c3 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

If not clogged, check fuel pump

maximum pressure W- page F-126

F-36

Page 304 of 1164

F TROUBLESHOOTING GUIDE

6 CRANKS NORMALLY BUT HARD TO START - WHEN ENGINE COLD

l Engine cranks at normal speed but requires excessive cranking time before starting )ESCRIP-

l Battery in normal condition UON

*Restarts OK after warm-up

*Engine runs normally at idle [If idle condition is not OK, refer to “Rough idle” (NOS. 8-124 [TROUBLESHOOTING HINTS]

3 Air/Fuel mixture too rich

@ Air/Fuel mixture too lean l Airflow meter sticking l Fuel injection control malfunction

*Air cleaner element clogged

(Correction for coolant temperature)

l Idle speed control malfunction

@ Poor atomization

*Low RVP (summer) fuel is used in cold weather

SYSTEM SELECT: 1

Check ECU terminal 1 F voltage CT- page F-150

Specification: Battery voltage

(Ignition switch ON)

c3 If OK, replace ECU CT page F-149 c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker Vacuum: More than 450 mmHg (17.7 inHg)

.

No

Check for air leakage of intake air sys-

tem components

5 Check if air cleaner element is clean Yes

Go to next step

~7 page F-79

No

Replace air cleaner element

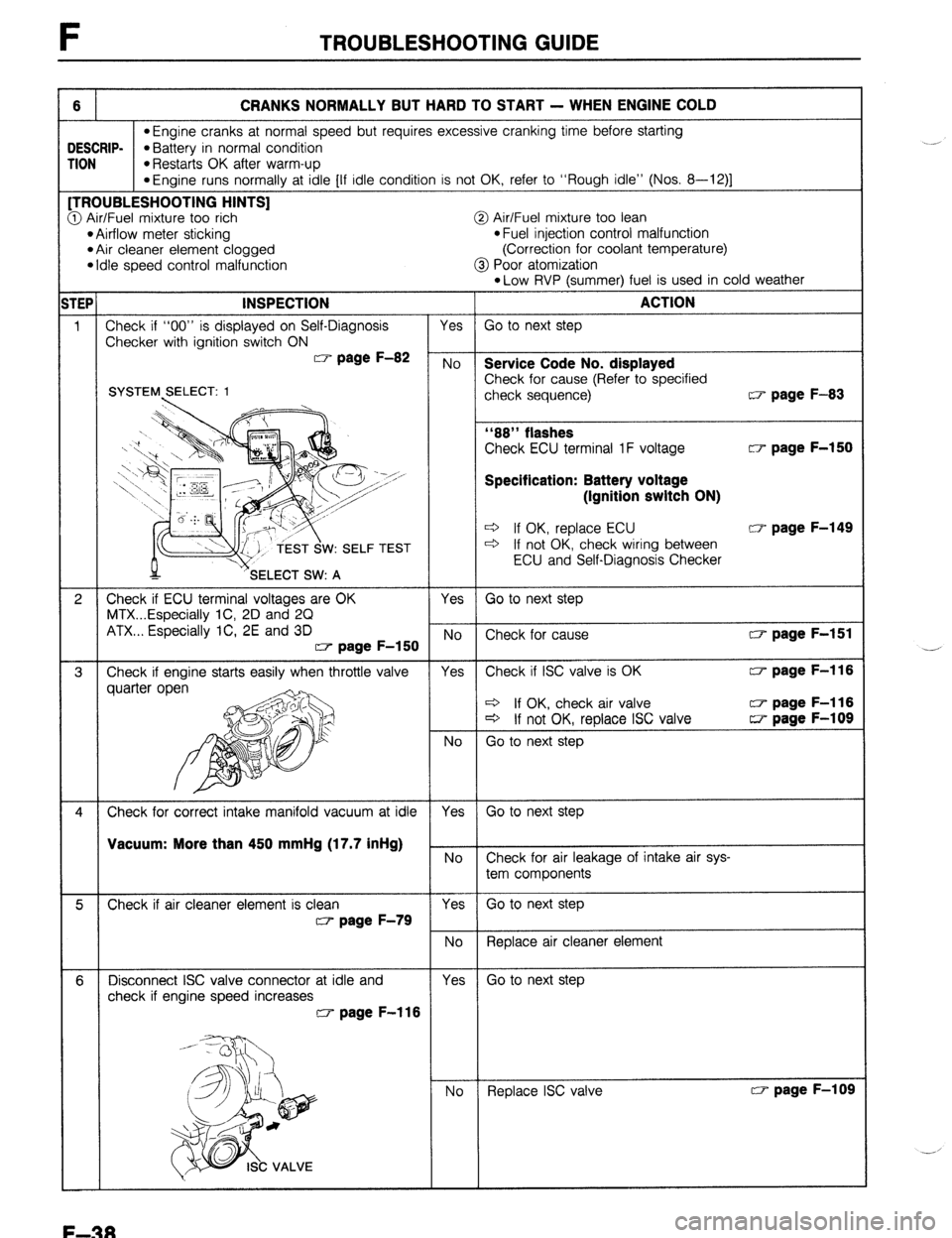

6 Disconnect ISC valve connector at idle and

Yes Go to next step

check if engine speed increases CT page F-l 16

No

Replace ISC valve CT page F-109

--’

F-38

Page 310 of 1164

F TROUBLESHOOTING GUIDE

9

ROUGH IDLE/ENGINE STALLS AT IDLE - BEFORE WARM-UP

DESCRIP-

*Engine speed low or engine stalls or vibrates excessively at idle during warm-up

TION

[TROUBLESHOOTING HINTS]

@ Low intake air amount

@ Low fuel injection control

l Airflow meter stuck

*Fuel injection control malfunction

*Air cleaner element clogged

(Correction for coolant temperature)

*Air valve

@ Poor atomization

*Low RVP (summer) fuel used in cold weather

w page F-83

W: SELF TEST Check ECU terminal 1F voltage

w page F-150

Specification: Battery voltage

(Ignition switch ON)

c3 If OK, replace ECU c3 page F-149

* If not OK, check wiring between

ECU and Self-Diagnosis Checker

Vacuum: More than 450 mmHg (17.7 inHg)

AX.. Especially 2B, 2E and 30

w page F-150

NO Check for cause CT page F-181

5 Disconnect ISC valve connector and check if en-

Yes Go to next step

gine speed increases after warm-up

CT page F-l 18

No Replace ISC valve c3 page F-109

F-44

Page 311 of 1164

TROUBLESHOOTING GUIDE F

s TEP INSPECTION ACTION

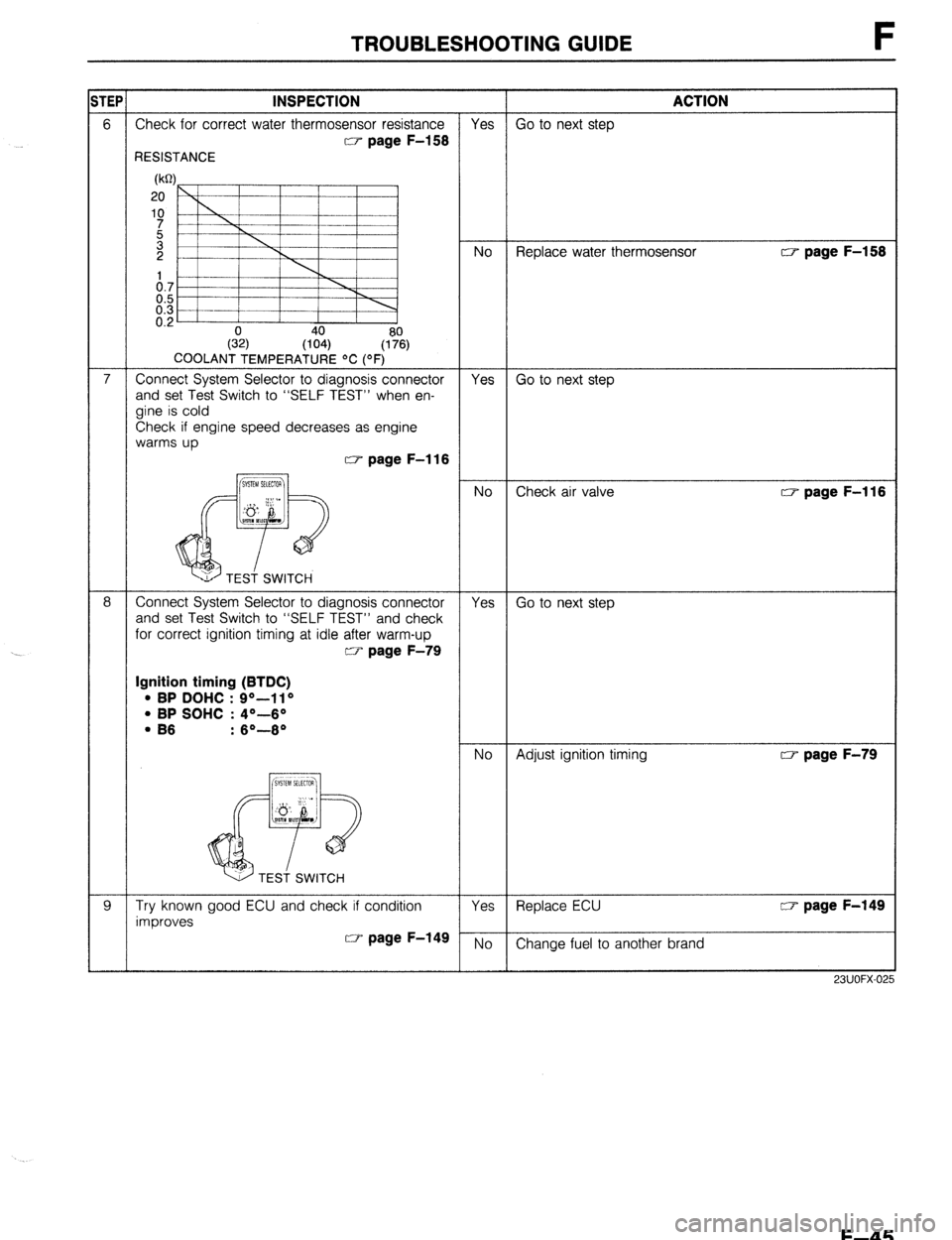

6 Check for correct water thermosensor resistance

Yes Go to next step

w page F-158

RESISTANCE

WI

20

‘70

I No Replace water thermosensor w page F-158

A.7

0.5

lE 41

(1400,

(1%) COOLANT TEMPERATURE OC (OF)

Connect System Selector to diagnosis connector

Check if engine speed decreases as engine

Ignition timing (BTDC)

l BP DOHC : go-11 * l BP SOHC : 4*-6O

23UOFX-OS

F-45

Page 312 of 1164

F TROUBLESHOOTING GUIDE

10

ROUGH IDLE/ENGINE STALLS AT IDLE - AFTER WARM-UP

DESCRIP-

rlON

*Engine runs normally at idle during warm-up but engine stalls or vibrates excessively after warm-up [TROUBLESHOOTING HINTS]

3 Idle speed control system malfunction @ Air/Fuel mixture too rich

3 Air/Fuel mixture too lean l Fuel injection control malfunction l Air leakage (Correction for coolant temperature)

*Low fuel line pressure @ Poor ignition

@ Low engine compression CT= page F-83

Check ECU terminal 1F voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU w page F-149 * If not OK, check wiring between

ECU and Self-Diagnosis Checker

Check for cause LY page F-151

Vacuum: More than 450 mmHg (17.7 inHg)

I.:.F page F-109

F-46

Page 316 of 1164

![MAZDA PROTEGE 1992 Service Manual F TROUBLESHOOTING GUIDE

13 HIGH IDLE SPEED AFTER WARM-UP

DESCRIP- l Idle speed excessive after warm-up

TION [TROUBLESHOOTING HINTS]

Excessive intake air supplied to engine

@I Throttle valve not f MAZDA PROTEGE 1992 Service Manual F TROUBLESHOOTING GUIDE

13 HIGH IDLE SPEED AFTER WARM-UP

DESCRIP- l Idle speed excessive after warm-up

TION [TROUBLESHOOTING HINTS]

Excessive intake air supplied to engine

@I Throttle valve not f](/img/28/57077/w960_57077-315.png)

F TROUBLESHOOTING GUIDE

13 HIGH IDLE SPEED AFTER WARM-UP

DESCRIP- l Idle speed excessive after warm-up

TION [TROUBLESHOOTING HINTS]

Excessive intake air supplied to engine

@I Throttle valve not fully closed

@ Idle speed control malfunction

l Air valve not closed l ISC valve stuck

l ISC valve connector disconnected l A/C, P/S, or E/L signal sent to ECU l Incorrect coolant temperature signal

stalled and operates freely w page F-l 14

@ If OK, go to Step 2

+ If not OK, clean, adjust or replace w page F-l 14

* If contaminated, clean throttle body Dashpot set speed: + If not contaminated, replace throttle

..*.............*..,........,... Approx. 3,000 rpm w page F-109

BP SOHC . . . . . . . . . . . . . . . . . . . . . . Approx. 2,700 rpm

BP DOHC . . . . . . . . . . . . . . . . . . . . . . Approx. 3,500 rpm

w page F-83

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

e If OK, replace ECU w page F-149

c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

Check for cause (Refer to specified

check sequence) w page F-108

W: SELF TEST

and Self-Diagnosis Checker

F-50

Page 344 of 1164

F ENGINE TUNE-UP

ENGINE TUNE-UP

PREPARATlON

SST

I

I I

49 BO19 9AO

System Selector For

inspection of igni-

tion timing and

idle speed

hA ‘I

03UOFX-04

03UOFX-04

03UOFX-04

NG POINT

03UOFX-04 03UOFX-045

BASIC INSPECTION

Engine Oil

1. Remove the engine oil level gauge and check the engine

oil level and oil condition.

2. Add or change the oil as necessary.

Coolant

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap before carefully

removing it.

1. Remove the coolant level gauge from the coolant reservoir.

2. Check that the coolant level is between the L and F marks

of the gauge.

3. Add coolant if necessary.

Battery

1. Check for corrosion on the terminals and for loose cable

connections. If necessary, clean the clamps and tighten

them firmly.

2. Check that the electrolyte level is between the UPPER LEV-

EL and LOWER LEVEL marks.

3. Add distilled water if necessary.

4. Check the specific gravity with a hydrometer.

Gravity: 1.27-l .29 (at 20% [68OF] )

Page 379 of 1164

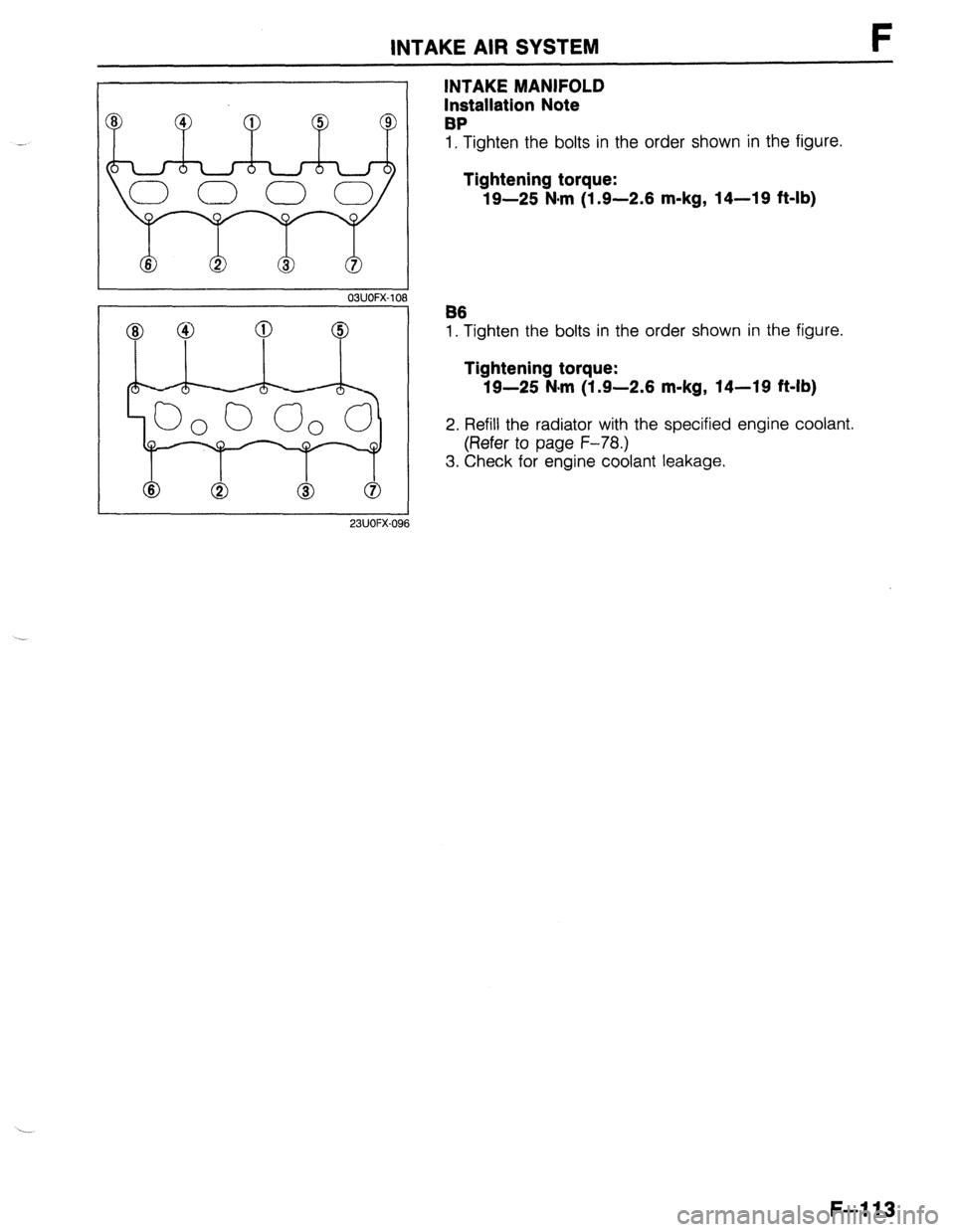

INTAKE AIR SYSTEM F

I 23UOFX-096

INTAKE MANIFOLD

Installation Note

BP

1, Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

B6

1. Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

2. Refill the radiator with the specified engine coolant.

(Refer to page F-78.)

3. Check for engine coolant leakage.

F-113

Page 382 of 1164

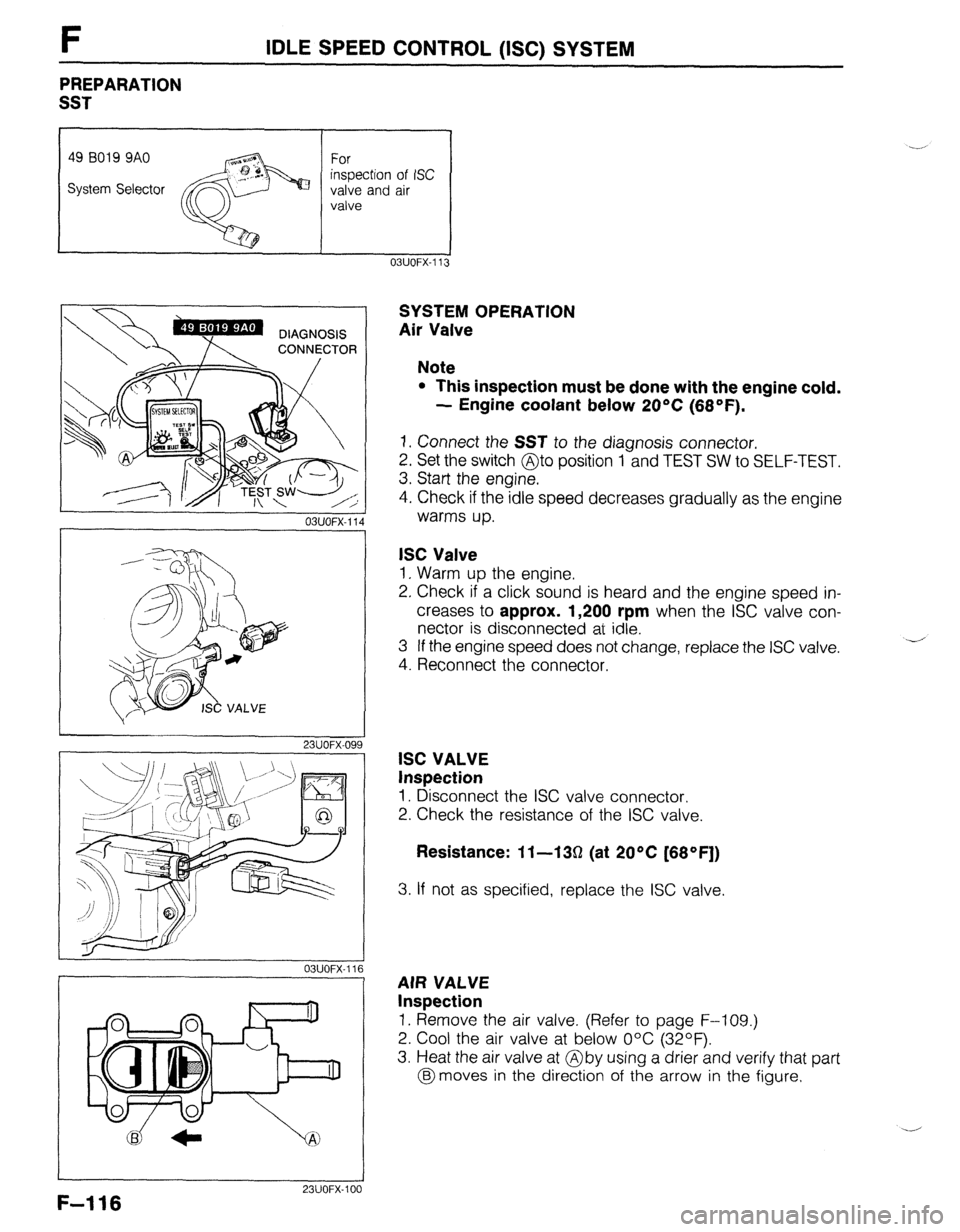

F IDLE SPEED CONTROL (ISC) SYSTEM

PREPARATION

SST

OBUOFX-113

OSUOFX-I 14

I

23UOFX-095

J 03UOFX-1 lf

23UOFX-101

F-116

SYSTEM OPERATION

Air Valve

Note

l This inspection must be done with the engine cold.

- Engine coolant below 20°C (68°F).

1. Connect the SST to the diagnosis connector.

2. Set the switch @to position 1 and TEST SW to SELF-TEST.

3. Start the engine.

4. Check if the idle speed decreases gradually as the engine

warms up.

ISC Valve

1. Warm up the engine.

2. Check if a click sound is heard and the engine speed in-

creases to approx. 1,200 rpm when the ISC valve con-

nector is disconnected at idle.

3 If the engine speed does not change, replace the ISC valve.

4. Reconnect the connector.

ISC VALVE

Inspection

1. Disconnect the ISC valve connector.

2. Check the resistance of the ISC valve.

Resistance: 11-130 (at 20°C [68*F])

3. If not as specified, replace the ISC valve.

AIR VALVE

Inspection

1. Remove the air valve. (Refer to page F-109.)

2. Cool the air valve at below O°C (32OF).

3. Heat the air valve at @by using a drier and verify that part

@moves in the direction of the arrow in the figure.

Page 400 of 1164

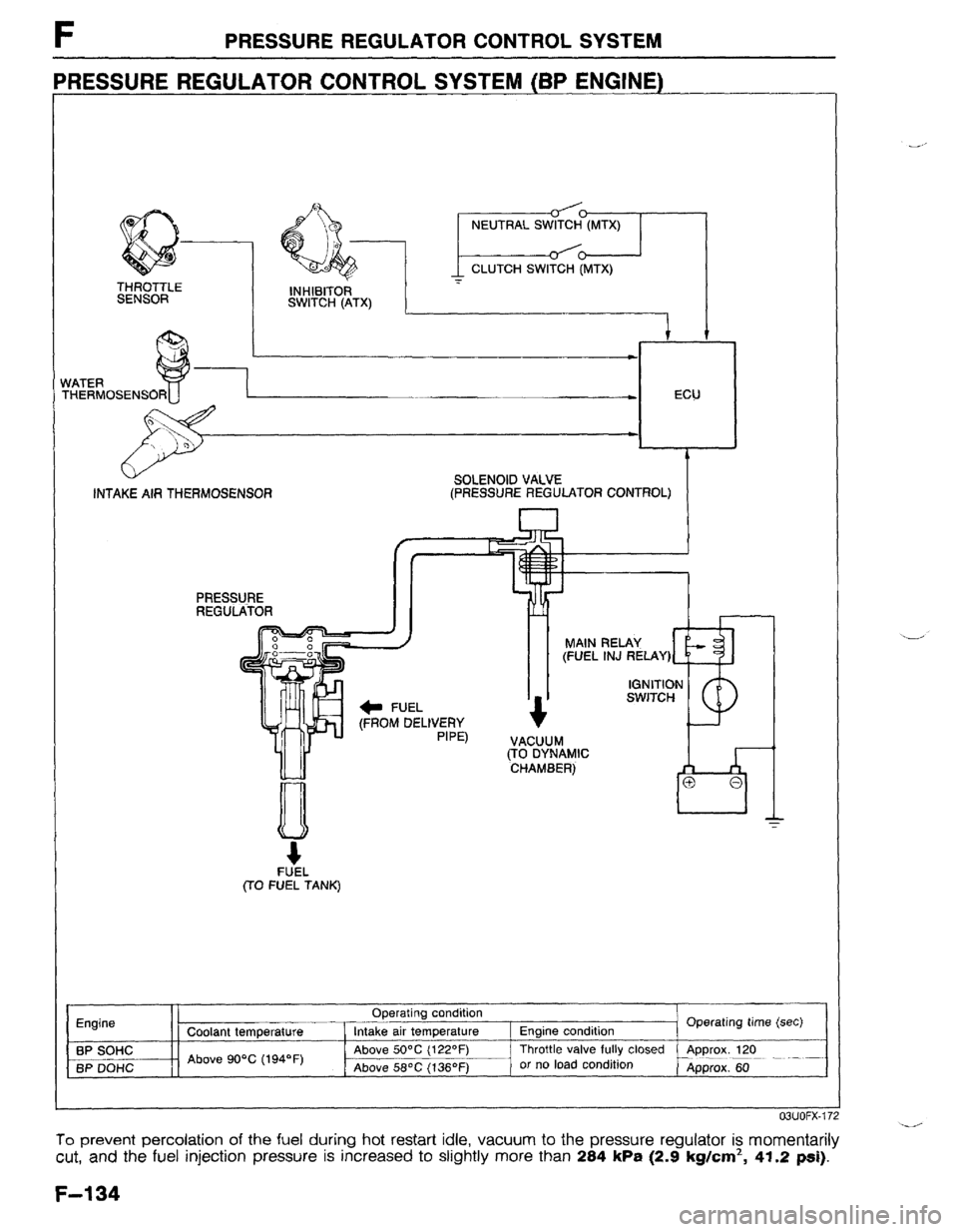

F PRESSURE REGULATOR CONTROL SYSTEM

PRESSURE REGULATOR CONTROL SYSTEM (BP ENGINE)

THERMOSEN

SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

(FROM DELIVERY

FUEL

(TO FUEL TANK)

Engine

BP SOHC

BP DOHC Coolant temperature

Above 90% (194*F) Operating condition

Intake air temperature

Above 50°C (122OF)

Above 58OC (136OF) Engine condition . Operating time (set)

Throttle valve fully closed

Approx. 120

or no load condition

Approx. 60

#.nr IAt-%/ 4 7

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator is momentarily

cut, and the fuel injection pressure is increased to slightly more than 284 kPa (2.9 kg/cm2, 41.2 psi).

F-l 34