brake sensor MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 281 of 1164

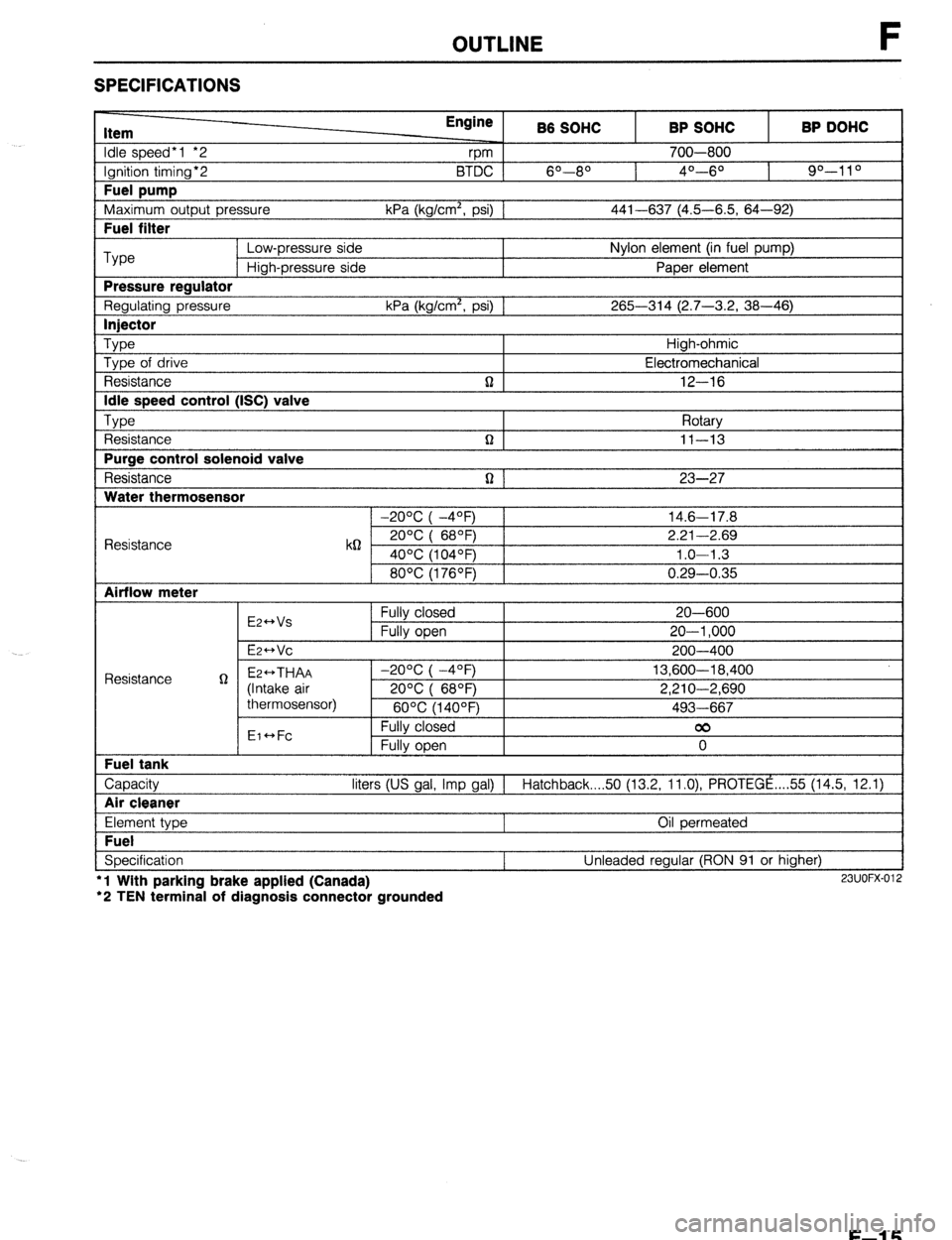

OUTLINE F

SPECIFICATIONS

Item

Idle speed*1 *2

Ignition timing*2

Fuel pump

Maximum outout Dressure Engine

rpm B6 SOHC

6O--80 BTDC 1

kPa (ka/cm’. osi1 1 BP SOHC

700-800

4O---6O BP DOHC

90-l 1 O

441-637 (4.5-6.5. 64-92) I

I Fuel filter I

Type Low-pressure side Nylon element (in fuel pump)

High-pressure side Paper element

Pressure reaulator

Regulating pressure kPa (kg/cm’, psi) 1 265-314 (2.7-3.2, 38-46)

I lniector I

Type Type of drive

Resistance

Idle speed control (ISC) valve

TvDe , ,

t Resistance

Purge control solenoid valve

Resistance

Water thermosensor n High-ohmic

Electromechanical

12-16

Rotarv

n I II-13 I

n 1 23-27

1 -20% I -4OFj 1 14.6-17.8

Resistance k62 2ooc i 68OF) 2.21-2.69

40°C (104OF) 1.0-l .3

80°C (176OF) 0.29-0.35

Airflow meter

E2++Vs

E2-Vc Fully closed

Fully open 20-600

20-l ,000

200-400

Capacity liters (US gal, Imp gal) 1 Hatchback 50 (13.2, ll.O), PROTEGE ,... 55 (14.5, 12.1)

I Air cleaner I

Element type

Fuel

Specification l

l Wlth parking brake applied (Canada)

‘2 TEN terminal of diagnosis connector grounded Oil permeated

Unleaded regular (RON 91 or higher) 23UOFX-012

F-l 5

Page 315 of 1164

TROUBLESHOOTING GUIDE F

12 ROUGH IDLE/ENGINE STALLS JUST AFTER STARTING

DESCRIP-

*Engine starts normally but vibrates excessively or stalls just after starting (acceleration from idle) TION

*Idle conditions are normal in the other conditions [TROUBLESHOOTING HINTS]

@ Fuel injection control system or idle speed control sys-

@ Idle speed misadjustment

tern malfunction @ Ignition timing misadjustment

*Start signal not input to ECU iTEl

-s-- 3

4

5 INSPECTION

-T- ACTION

Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM,SELECT: I

r -SELECT SW: A

Check if ECU terminal voltages are OK

MTX...Especially 1 N

ATX... Especially 1T w page F-150

Connect System Selector to diagnosis connector

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up w page F-78

Ignition timing (BTDC)

l BP DOHC : 9”-11 o l BP SOHC : 4O--6O

l B8 : 60-80

Check continuity between throttle sensor termi-

nals IDL and E CT page F-159

MTX

Clearance between throttle

lever and stopper

MTX O.lmm (0.004 in)

1 .Omm (0.039 in)

ATX 0.1 mm (0.004 in)

0.6mm (0.024 in) Continuity

Yes

No

Yes

No

Try known good ECU and check if condition

mproves w page F-149 Yes

No

Yes

Go to next step No

Check for cause Yes

In same condition as Step 3 inspection

and apply parking brake

Check for correct idle speed w page F-80

Idle speed: 700-800 rpm

No

Adjust Yes

Go to next step No

Adjust Go to next step Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal IF voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

d If OK, replace ECU w page F-149

* If not OK, check wiring between

ECU and Self-Diagnosis Checker c7 page F-151

3 If OK, go to next step

3 If not OK, adjust idle speed w page F-80

w page F-79

w page F-159

F-49

Page 374 of 1164

SELF-DIAGNOSIS FUNCTION

Throttle sensor

Depress accelerator pedal (not fully) and check that

monitor lamp illuminates

YES NO

PC: *Throttle sensor malfunction CT page F-169

*Short circuit in wire harness

from throttle sensor to ECU

*ECU terminal 1 N (MTX) 1T

(ATX) voltage incorrect CT page F-150

l ECU malfunction

Depress acceleration pedal fully and check that monitor

No : PC: *Throttle sensor malfunction w page F-169

lamp does not illuminate *Open circuit in wire harness

from throttle sensor to ECU

YES *ECU terminal 2L (MTX) or 21

(ATX) voltage incorrect a page F-154

Throttle sensor OK

Release accelerator pedal

23UOFX-090

Stoplight switch

Depress brake pedal

Check that monitor lamp illuminates

YES

Stoplight switch OK

Release brake pedal NO

PC: *Stoplight switch malfunction w Section T

*Open circuit in wire harness

1

from stoplight switch to ECU

*ECU terminal 10 (MTX) 1Q

(ATX) voltage incorrect CT page F-l 52

l ECU malfunction

23UOFX-091

Blower switch

---

Turn blower switch to 2nd or higher position

Check that monitor lamp illuminates

YES

Blower switch OK NO

__L PC: *Blower switch malfunction

*Open circuit in wire harness

from blower switch to ECU

l ECU terminal 1 S (MTX) 1 P

(ATX) voltage incorrect

l ECU malfunction p Section T

w page F-152

23UOFX-092

F-l 08

Page 418 of 1164

F CONTROL SYSTEM

VB: Battery voltage

erminal Input Output Connection to Test condition Corrsct voltage Remark

1M - - - - - -

IN 0 Throttle sensor Accelerator pedal released ov Ignition switch

(Idle switch)

Accelerator pedal depressed

VB ON

10 0

1P 0 Stoplight switch

P/S pressure

switch Brake pedal released

Brake pedal depressed

Ignition switch ON

P/S ON at idle

P/S OFF at idle ov

-

VEi

Va

ov

VS -

10 0 A/C switch A/C switch ON

A/C switch OFF Below 23 Ignition switch

VS ON and blower

motor ON

1R 0

IS 0 Fan switch

Blower control

switch Fan operating (Engine coolant tempera-

ture over 97% (207OF) or diagnosis con-

nector terminal TFA grounded)

Fan not operating (Idle)

Blower control switch OFF or 1st position

Blower control switch 2nd or higher po-

sition ov

-

V0

Ve ignition switch

ov ON

IT 0 Rear window

defroster switch Rear window defroster switch OFF

Rear window defroster switch ON ov

VB

Ignition switch ON

1u 0

iv 0 Headlight switch

Neutral/Clutch

switches Headlights ON

Headlights OFF

Neutral position or clutch pedal

depressed

Others V0

-

ov

ov

VB -

1 I lr----t

r-i

ul r

2Y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2’3 2A 1lJ 1s IQ 10 1M 1K 11 1G 1E 1~ 1A

22 2x 2v 2T 2R 2P 2N 2L 2J 34 2t= 2D 28 Ii/ fT 1R 1p IN 1L 1J 1H 1F 1D 18

F-l 52

Page 426 of 1164

CONTROL SYSTEM

VB: Battery voltage

erminal Input Output

Connection to Test condition Correct voltage

Remark

1L

0 A/C relay Ignition switch ON VB

A/C switch ON at idle Below 2.5V

A/C switch OFF at idle V0

-

1M 0

1N 0 Vehicle speed

sensor

P/S pressure

switch While driving 4--5v

Vehicle stopped 0 or 8V

Ignition switch ON

VB

P/S ON at idle

ov

P/S OFF at idle Vi3 -

-

10 0 A/C switch A/C switch ON

A/C switch OFF Below 2.5V ignition switch

VB ON and blower

motor ON

IP 0 Blower control

switch Blower control switch OFF or 1st position Ve ignition switch

Blower control switch 2nd or higher po- Below 1 .OV ON

sition

1Q 0

1R 0

1s 0

IT 0 Stoplight switch Brake pedal released Below 1 .OV

-

Brake pedal depressed VI3

Inhibitor switch N or P range ov Ignition switch

(P, N ranges) ON

Other range VI3

Cruise control main Normal condition

VB Ignition switch

switch ON

Set or Resume switch ON or vehicle speed Below 1 .OV

8 km/h (5 mph) lower than preset speed

(Driving vehicle cruise control operation)

Throttle sensor Accelerator pedal released Below 1 .OV Ignition switch

(Idle switch)

Accelerator pedal depressed V0 ON

1u - - -

- - -

1v - - - -

- -

2A 0 Distributor Ignition switch ON Approx. OV

(Ne-signal) or 5V -

Idle Approx. 2V

LY”“l I. A3 311 blFY.1.

J

- .*

F-160

Page 669 of 1164

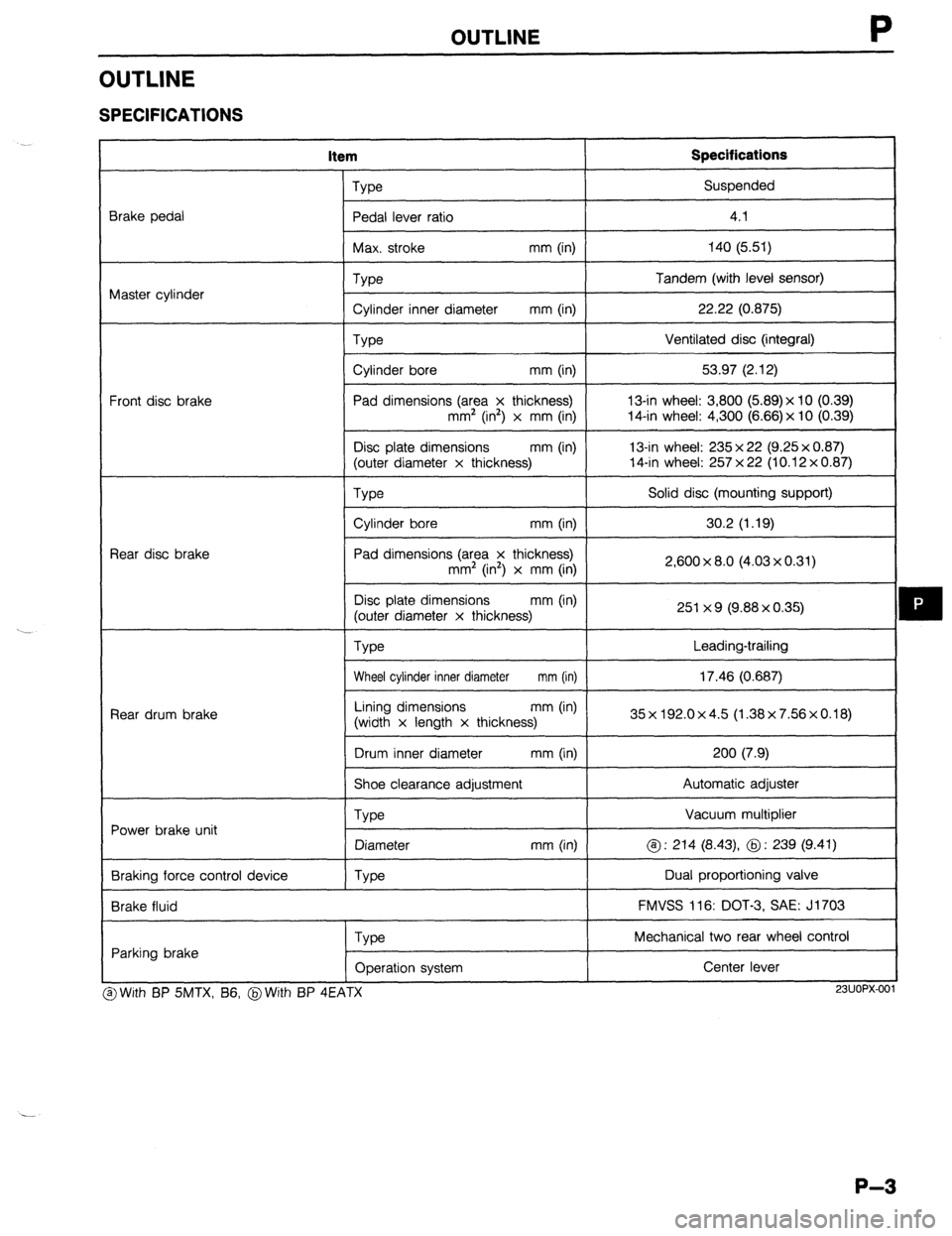

OUTLINE

OUTLINE

SPECIFICATIONS

item Specifications

Brake pedal

Master cylinder

Front disc brake

Rear disc brake

Rear drum brake

Power brake unit

Braking force control device

Brake fluid Type Suspended

Pedal lever ratio

I 4.1

I

Max. stroke mm (in) 140 (5.51)

I

Type

Cylinder inner diameter mm (in)

Type

Cylinder bore mm (in)

Pad dimensions (area x thickness)

mm’ (in2) x mm (in)

Disc plate dimensions mm (in)

(outer diameter x thickness) Tandem (with level sensor)

22.22 (0.875)

Ventilated disc (integral)

53.97 (2.12)

13-in wheel: 3,800 (5.89)x 10 (0.39)

14-in wheel: 4,300 (6.66) x 10 (0.39)

13-in wheel: 235 x 22 (9.25 x 0.87)

14-in wheel: 257 x 22 (10.12 x 0.87)

We

I Solid disc (mounting support)

I

Cylinder bore mm (in)

I 30.2 (1.19)

I

Pad dimensions (area x thickness)

mm2 (in’) x mm (in)

Disc plate dimensions mm (in)

(outer diameter x thickness)

Type 2,600 x 8.0 (4.03 x 0.31)

251 x 9 (9.88 x 0.35)

Leading-trailing

Wheel cylinder inner diameter mm (in) 17.46 (0.687)

I

Lining dimensions mm (in)

(width x length x thickness) 35x192.0x4.5 (1.38x7.56x0.18)

I

Drum inner diameter mm (in) 200 (7.9)

I

Shoe clearance adjustment Automatic adjuster

Vacuum multiplier

@ : 214 (8.43) @ : 239 (9.41)

Dual proportioning valve

FMVSS 116: DOT-3, SAE: J1703

Type

Diameter

Type mm (in)

Parking brake

Type

Operation system Mechanical two rear wheel control

Center lever I

3 With BP SMTX, B6, @With BP 4EATX

I I

23UOPX-001

P-3

Page 678 of 1164

P CONVENTIONAL BRAKE SYSTEM

Disassembly / Assembly / Inspection

1. After removing the brake fluid, disassemble in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

Caution

l Secure the master cylinder flange in a vise when necessary.

l Replace the piston assembly, if necessary.

l Do not let foreign material enter the cylinder, and do not scratch the inside of the cylinder

or the outer surface of the piston.

REP1 .ACE

0.98-1.47 (10-15, 8.7-13.0)

o R,NG ,,,dcE @.96-2.45 (20-25, 17.4-21.7)

- 3

N.m (cm-kg, in-lb)

1. Reservoir cap assembly 5. Bushing 9. Primary piston assembly

2. Float 6. Stopper screw 10. Secondary piston assembly

3. Screw 7. Fluid level sensor 11. Master cylinder body

4. Reservoir 8. Snap ring

P-12

Page 917 of 1164

WARNING SYSTEM T

13UOTX-07

63U15X-05

, I//

‘nF -

-

-

FUEL

13UOTX.08C

- CHARGE

13UOTX-08

13UOTX-08

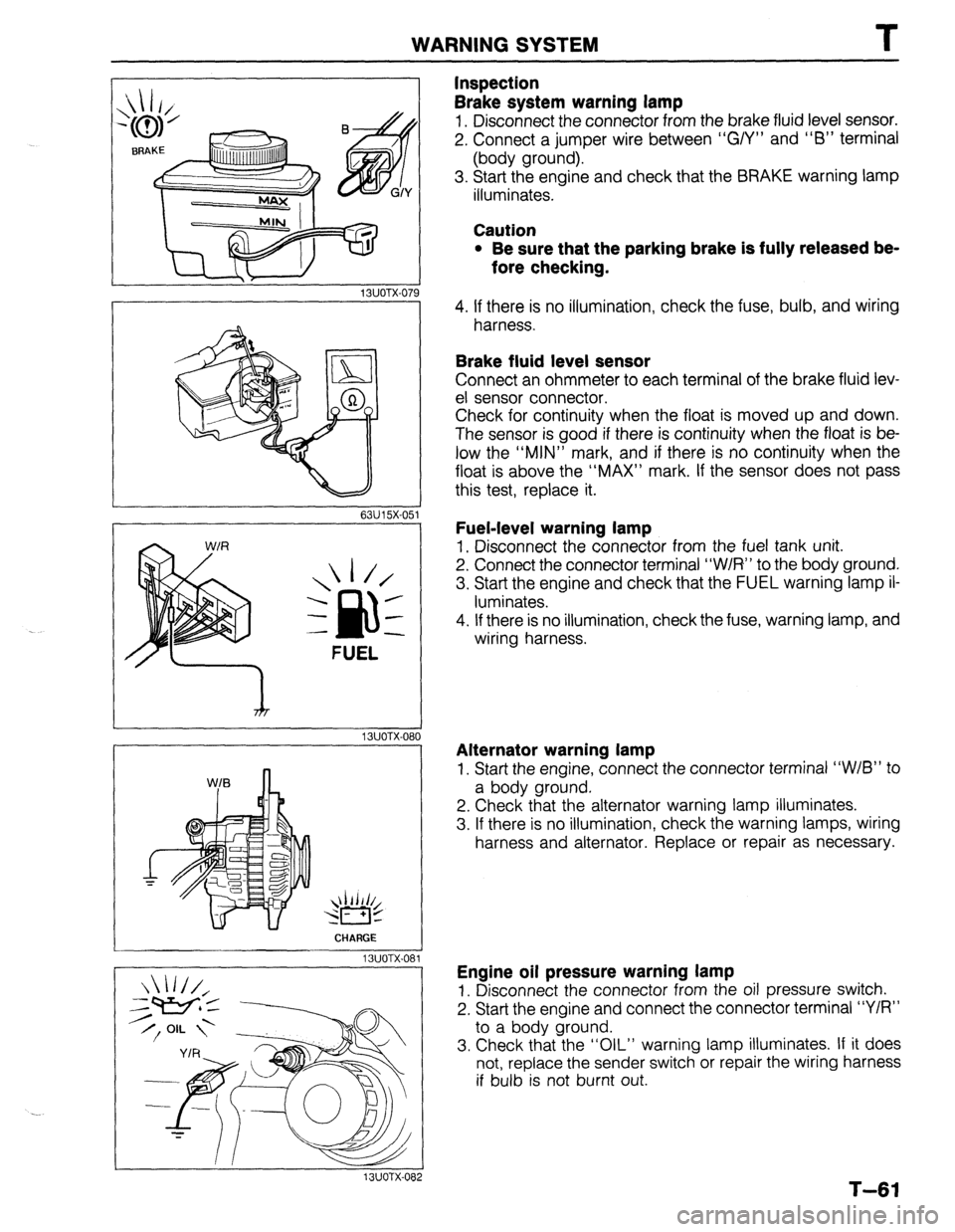

Inspection

Brake system warning lamp

1. Disconnect the connector from the brake fluid level sensor.

2. Connect a jumper wire between “G/Y” and “6” terminal

(body ground).

3. Start the engine and check that the BRAKE warning lamp

illuminates.

Caution

l Be sure that the parking brake is fully released be-

fore checking.

4. If there is no illumination, check the fuse, bulb, and wiring

harness.

Brake fluid level sensor

Connect an ohmmeter to each terminal of the brake fluid lev-

el sensor connector.

Check for continuity when the float is moved up and down.

The sensor is good if there is continuity when the float is be-

low the “MIN” mark, and if there is no continuity when the

float is above the “MAX” mark. If the sensor does not pass

this test, replace it.

Fuel-level warning lamp

1. Disconnect the connector from the fuel tank unit.

2. Connect the connector terminal “W/R” to the body ground.

3. Start the engine and check that the FUEL warning lamp il-

luminates.

4. If there is no illumination, check the fuse, warning lamp, and

wiring harness.

Alternator warning lamp

1. Start the engine, connect the connector terminal “W/B” to

a body ground.

2. Check that the alternator warning lamp illuminates.

3. If there is no illumination, check the warning lamps, wiring

harness and alternator. Replace or repair as necessary.

Engine oil pressure warning lamp

1. Disconnect the connector from the oil pressure switch.

2. Start the engine and connect the connector terminal “Y/R”

to a body ground.

3. Check that the “OIL” warning lamp illuminates. If it does

not, replace the sender switch or repair the wiring harness

if bulb is not burnt out.

T-61

Page 920 of 1164

2L BUZZER 2A 28 2C 2D 1A 3K l--r nnmn

I I‘ I

1C 3L 2E 2G IL iG 1F 1D tB

3F 38 3G 1E 3D

l-l rt

II l-l

l-l It II l-l 1J 11 1H

1G IF 1E 1D 1C 1B 1A 2L 2K 2J 21 2H 2G 2F 2E 2D 2C 28 2A

r-l It ,I 3L 3K 3J 31 3H 3G 3F 3E 3D 3C 3B 3A

Ter- I I minal Connected to 1 1A Combination switch

1B Ground

IC Fuel tank unit

1 ID 1 EGI control unit

I

II L 1J 1

L Ter-

minal Connected to

2A Speed sensor output

28 Light switch (high beam)

2C Turn switch (L)

20 Turn switch (R)

2E Ground

2F Ground

2L 1 IGI battery Ter-

minal Connected to

3A

38 Alternator

3c

30 Oil pressure switch

3E

3F Parking brake switch, Brake fluid switch

3G Passive shoulder belt control unit

3H h

I 31

3J

3K

IG2 battery

3L Water temperature gauge unit

Page 938 of 1164

CRUISE CONTROL SYSTEM

I

23UOTX-056

1 23UOTX-057

Inspection Procedure

Quick inspection of cruise control system

1. Locate the cruise control connector.

2. Connect a 1.4W test light between terminals f and d, with

connector attached to control unit. -1

Note

l There is no wire in terminal d of the connector. Push

the test light through the connector and touch the

corresponding pin on the control unit.

3. Turn the ignition switch to ON.

4. Verify that the MAIN switch is OFF. (The MAIN indicator lamp

is OFF.)

5. Press the RESUMElACCEL switch and the MAIN switch

simultaneously to activate the system inspection. (The MAIN

indicator lamp will come ON.)

6. Operate each switch as described below and verify the oper-

ation codes.

7. Press the MAIN switch to deactivate the system inspection.

(The MAIN indicator lamp will go OFF.)

Note

l The cruise control system will not operate when in

the self-diagnosis mode.

Operation Code Numbers

Inspection of cruise control system

The test light will flash if the system is operating correctly. If the light fails to flash, inspect the system.

Note

l Shift the selector lever to D or R range before operating the inspection. (For ATX)

l Shift to the gear except the neutral position. (For MTX)

Procedure

Press SET/COAST switch Pattern of output signal Code

(Test light) No. Actlon to inspect ON

n II 21 Inspect cruise control switch

(Refer to page T-21)

OFF

Press RESUMElACCEL switch

ON

n 22 inspect cruise control switch

(Refer to page T-21)

OFF

Depress brake pedal

ON

n ml 31 Inspect stoplight switches

(Refer to pages T-47 and

OFF T-88)

Turn ignition switch to ON and shift the ON 35 Inspect inhibitor switch

selector lever to P or N range (For ATX) (Refer to Section K) or clutch

Depress clutch pedal (For MTX) switch (Refer to Section F)

OFF

Drive vehicle above 40 km/h (25 mph) ON 37 Inspect speed sensor or wire

harness

OFF

I

1

. . . _

T-82