fuses MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 20 of 1164

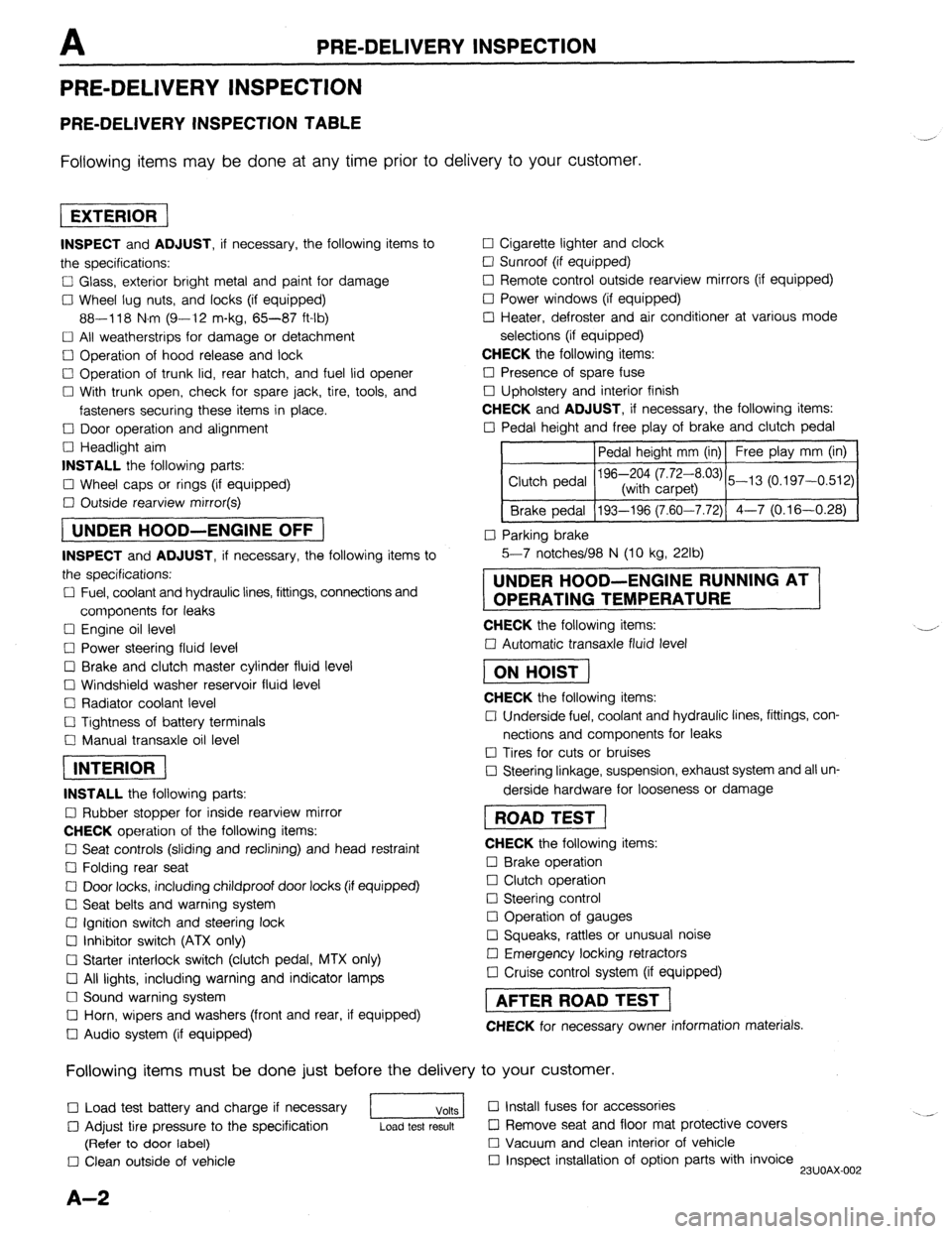

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 761 of 1164

POWER DOOR LOCK SYSTEM s

Power door lock system does not operate

(All doors)

I

Check ROOM 10A and DOOR OK NG VB: Battery voltage - Repair harness and replace fuses

1

Check for battery voltage at terminal-wire (L/R) of door

lock switch connector NG

Repair harness (Fuse box-Door lock switch)

1 OK

Check terminal voltage above connector with switch

each condition

Locked

Unlocked (G/R) wire

Va

ov (G/O) wire

ov

VB

1 OK

Check door lock switch (Refer to page S-26)

Disconnect door lock timer and relay connector:

check for battery voltage at terminal-wire (W/G) NO

- Repair harness (Fuse box-Door lock timer and relay) OK

Check terminal voltage above connector with switch

each condition

Lot ked

Unlocked

VB

ov (G/O) wire

ov

VB

1 OK

NO

Repair harness =

(Door lock switch-Door lock timer and relay)

1

Check for continuity of above connector terminal-wire

(B) to ground Repair harness (Door lock timer and relay-Ground)

I OK

Connect battery voltage to terminal-wire (G) and ground

terminal-wire (R) of door lock timer and relay; check that NGT Broken harness (Door lock timer and relay-Door lock

doors lock control) or defective door lock control

Reverse above connection; check that doors unlock (Refer to inspection; page S-26)

I OK F Check door lock timer and relay (Refer to page S-26)

23uosx-007 One door lock does not operate

t

Check door lock control (Refe Replace door lock control (Refer to pages S-13, 14, 19)

I OK __ Repair harness

- (Door lock timer and relay-Door lock control)

03uosx-030

s-25

Page 841 of 1164

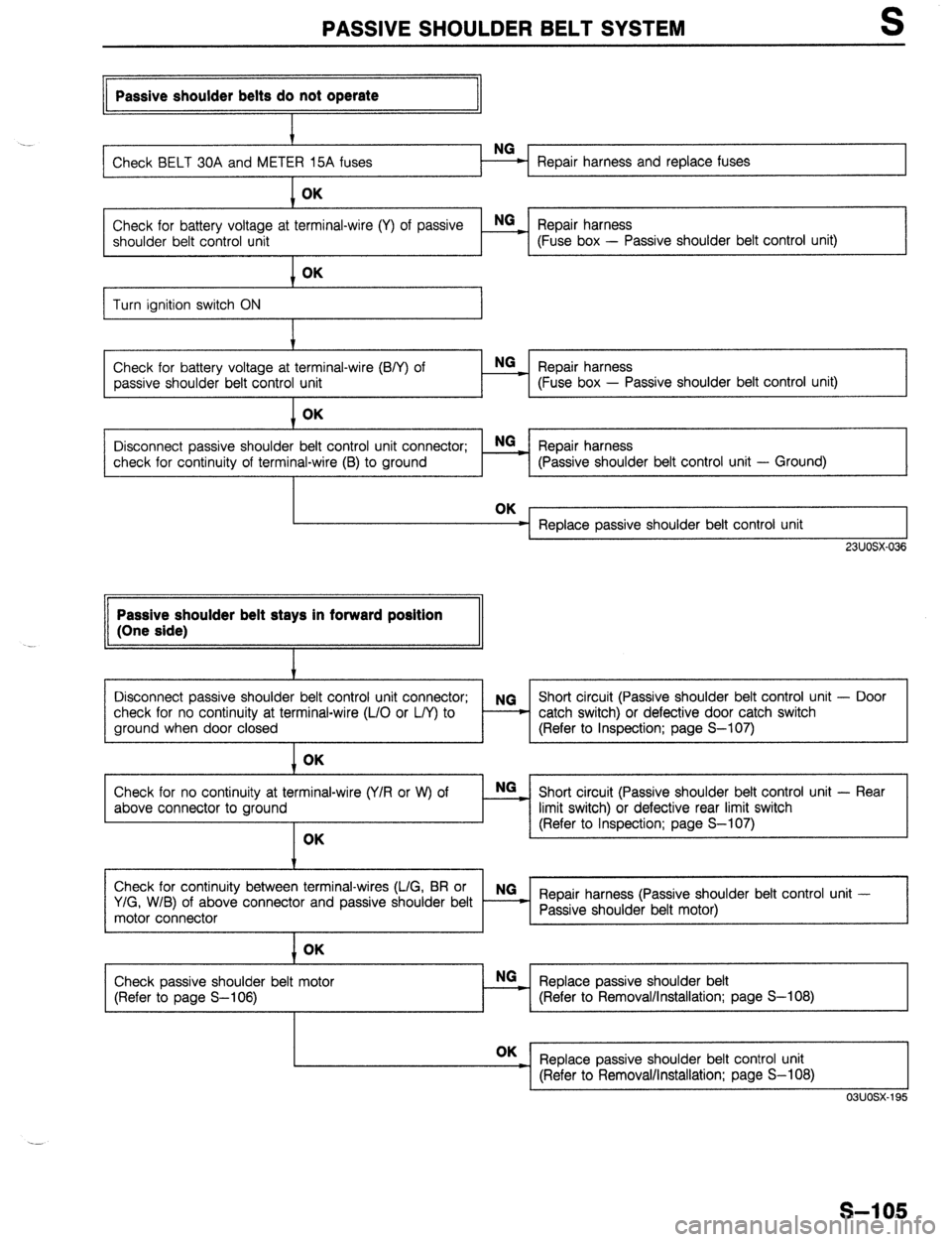

PASSIVE SHOULDER BELT SYSTEM S

II Passive shoulder belts do not operate

II

. .

Repair harness and replace fuses OK

Check for battery voltage at terminal-wire (Y) of passive E Repair harness

shoulder belt control unit (Fuse box - Passive shoulder belt control unit)

I

Turn ignition switch ON

Check for battery voltage at terminal-wire (B/Y) of

passive shoulder belt control unit OK

NG

Repair harness _

- (Fuse box - Passive shoulder belt control unit)

Disconnect passive shoulder belt control unit connector; NGz Repair harness

check for continuity of terminal-wire (B) to ground (Passive shoulder belt control unit - Ground)

Replace passive shoulder belt control unit

, 23UOSX-036 Passive shoulder belt stays in forward position

(One side)

I

Disconnect passive shoulder belt control unit connector; NG Short circuit (Passive shoulder belt control unit - Door

check for no continuity at terminal-wire (L/O or L/Y) to - - catch switch) or defective door catch switch

ground when door closed (Refer to Inspection; page S-107) OK

Check for no continuity at terminal-wire (Y/R or W) of

above connector to ground OK E Short circuit (Passive shoulder belt control unit - Rear

limit switch) or defective rear limit switch

(Refer to Inspection; page S-107)

Check for continuity between terminal-wires (L/G, BR or NG

Y/G, W/B) of above connector and passive shoulder belt Repair harness (Passive shoulder belt control unit -

motor connector Passive shoulder belt motor)

I

1 OK

Check passive shoulder belt motor

(Refer to page S-106) Replace passive shoulder belt NO

:

(Refer to Removal/Installation; page S-l 08) OK

_ Replace passive shoulder belt control unit

I (Refer to Removal/Installation; page S-l 08) L I

03uosx-195

S-l 05

Page 857 of 1164

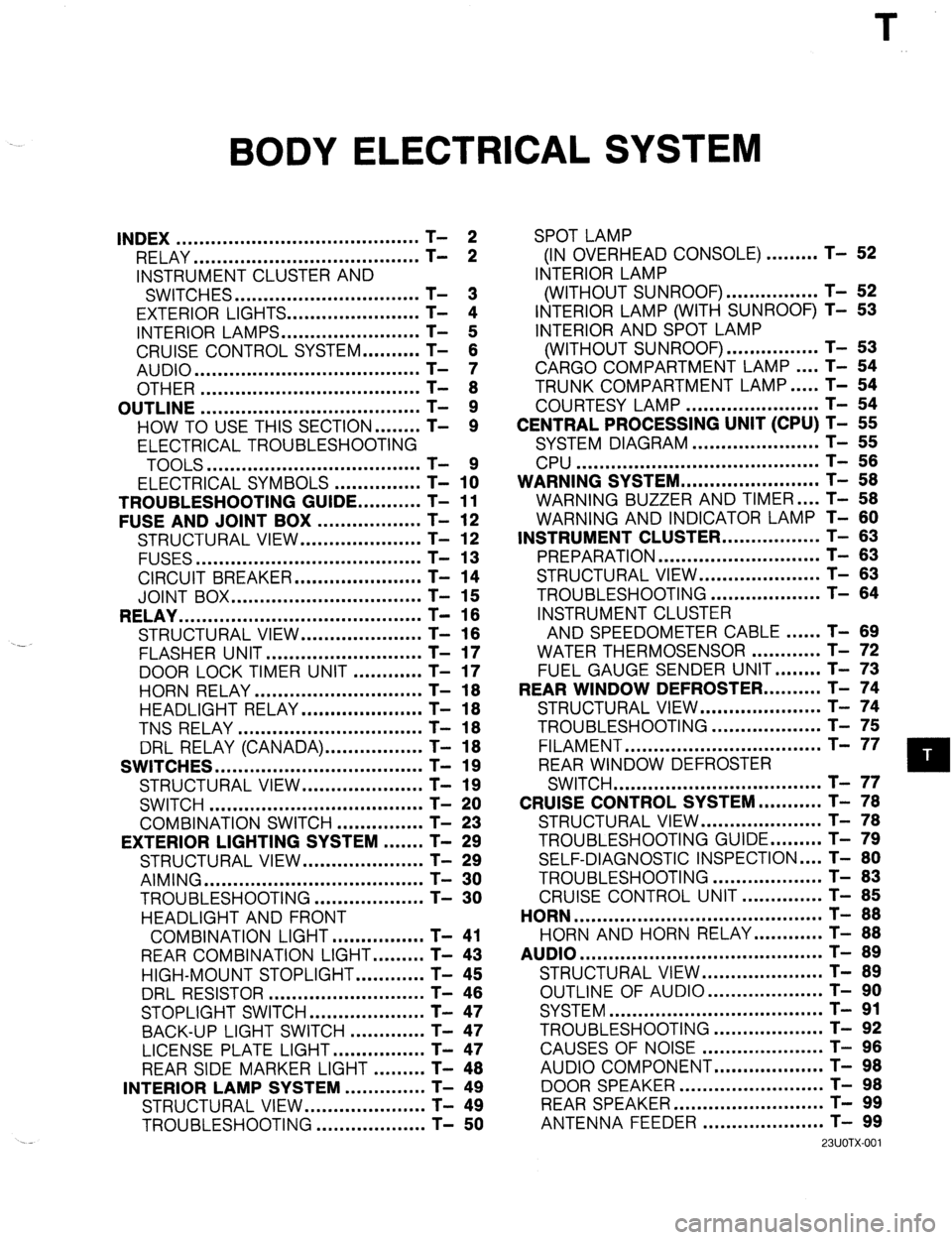

BODY ELECTRICAL SYSTEM

INDEX .......................................... T- 2

RELAY ....................................... T- 2

INSTRUMENT CLUSTER AND

SWITCHES ................................ T- 3

EXTERIOR LIGHTS.. ..................... T- 4

INTERIOR LAMPS.. ...................... T- 5

CRUISE CONTROL SYSTEM.. ........ T- 6

AUDIO ....................................... T- 7

OTHER ...................................... T- 8

OUTLINE ...................................... T- 9

HOW TO USE THIS SECTION.. ...... T- 9

ELECTRICAL TROUBLESHOOTING

TOOLS .....................................

ELECTRICAL SYMBOLS - ............... T- 1x

TROUBLESHOOTING GUIDE.. .........

T- 11

FUSE AND JOINT BOX ..................

T- 12

STRUCTURAL VIEW.. ...................

T- 12

FUSES ....................................... T- 13

CIRCUIT BREAKER.. ....................

T- 14

JOINT BOX ................................. T- 15

RELAY .......................................... T- 16

STRUCTURAL VIEW.. ...................

T- 16

.-

FLASHER UNIT ........................... T- 17

DOOR LOCK TIMER UNIT ............

T- 17

HORN RELAY ............................. T- 18

HEADLIGHT RELAY.. ................... T- 18

TNS RELAY ................................ T- 18

DRL RELAY (CANADA). ................ T- 18

SWITCHES .................................... T- 19

STRUCTURAL VIEW.. ................... T- 19

SWITCH ..................................... T- 20

COMBINATION SWITCH ...............

T- 23

EXTERIOR LIGHTING SYSTEM ....... T- 29

STRUCTURAL VIEW.. ...................

T- 29

AIMING ...................................... T- 30

TROUBLESHOOTING.. .................

T- 30

HEADLIGHT AND FRONT

COMBINATION LIGHT.. ..............

T- 41

REAR COMBINATION LIGHT.. ....... T- 43

HIGH-MOUNT STOPLIGHT.. .......... T- 45

DRL RESISTOR ........................... T- 46

STOPLIGHT SWITCH.. .................. T- 47

BACK-UP LIGHT SWITCH ............. T- 47

LICENSE PLATE LIGHT.. ..............

T- 47

REAR SIDE MARKER LIGHT ......... T- 48

INTERIOR LAMP SYSTEM ..............

T- 49

STRUCTURAL VIEW.. ...................

T- 49

TROUBLESHOOTING ...................

T- 50 SPOT LAMP

(IN OVERHEAD CONSOLE) ......... T- 52

INTERIOR LAMP

(WITHOUT SUNROOF). ............... T- 52

INTERIOR LAMP (WITH SUNROOF) T- 53

INTERIOR AND SPOT LAMP

(WITHOUT SUNROOF). ............... T- 53

CARGO COMPARTMENT LAMP.. .. T- 54

TRUNK COMPARTMENT LAMP.. ... T- 54

COURTESY LAMP ....................... T- 54

CENTRAL PROCESSING UNIT (CPU) T- 55

SYSTEM DIAGRAM ...................... T- 55

CPU .......................................... T- 56

WARNING SYSTEM.. ...................... T- 58

WARNING BUZZER AND TIMER .... T- 58

WARNING AND INDICATOR LAMP T- 60

INSTRUMENT CLUSTER.. ............... T- 63

PREPARATION ............................ T- 63

STRUCTURAL VIEW ..................... T- 63

TROUBLESHOOTING ................... T- 64

INSTRUMENT CLUSTER

AND SPEEDOMETER CABLE.. .... T- 89

WATER THERMOSENSOR ............ T- 72

FUEL GAUGE SENDER UNIT.. ...... T- 73

REAR WINDOW DEFROSTER.. ........ T- 74

STRUCTURAL VIEW.. ................... T- 74

TROUBLESHOOTING ................... T- 75

FILAMENT .................................. T- 77

REAR WINDOW DEFROSTER

SWITCH .................................... T- 77

CRUISE CONTROL SYSTEM.. ......... T- 78

STRUCTURAL VIEW.. ................... T- 78

TROUBLESHOOTING GUIDE.. ....... T- 79

SELF-DIAGNOSTIC INSPECTION .... T- 80

TROUBLESHOOTING ................... T- 83

CRUISE CONTROL UNIT .............. T- 85

HORN ........................................... T- 88

HORN AND HORN RELAY.. .......... T- 88

AUDIO .......................................... T- 89

STRUCTURAL VIEW.. ................... T- 89

OUTLINE OF AUDIO.. .................. T- 90

SYSTEM ..................................... T- 91

TROUBLESHOOTING ................... T- 92

CAUSES OF NOISE ..................... T- 96

AUDIO COMPONENT.. ................. T- 98

DOOR SPEAKER .........................

REARSPEAKER .......................... ;-

- !3;

ANTENNA FEEDER ..................... T- 99

23UOTX-001

Page 869 of 1164

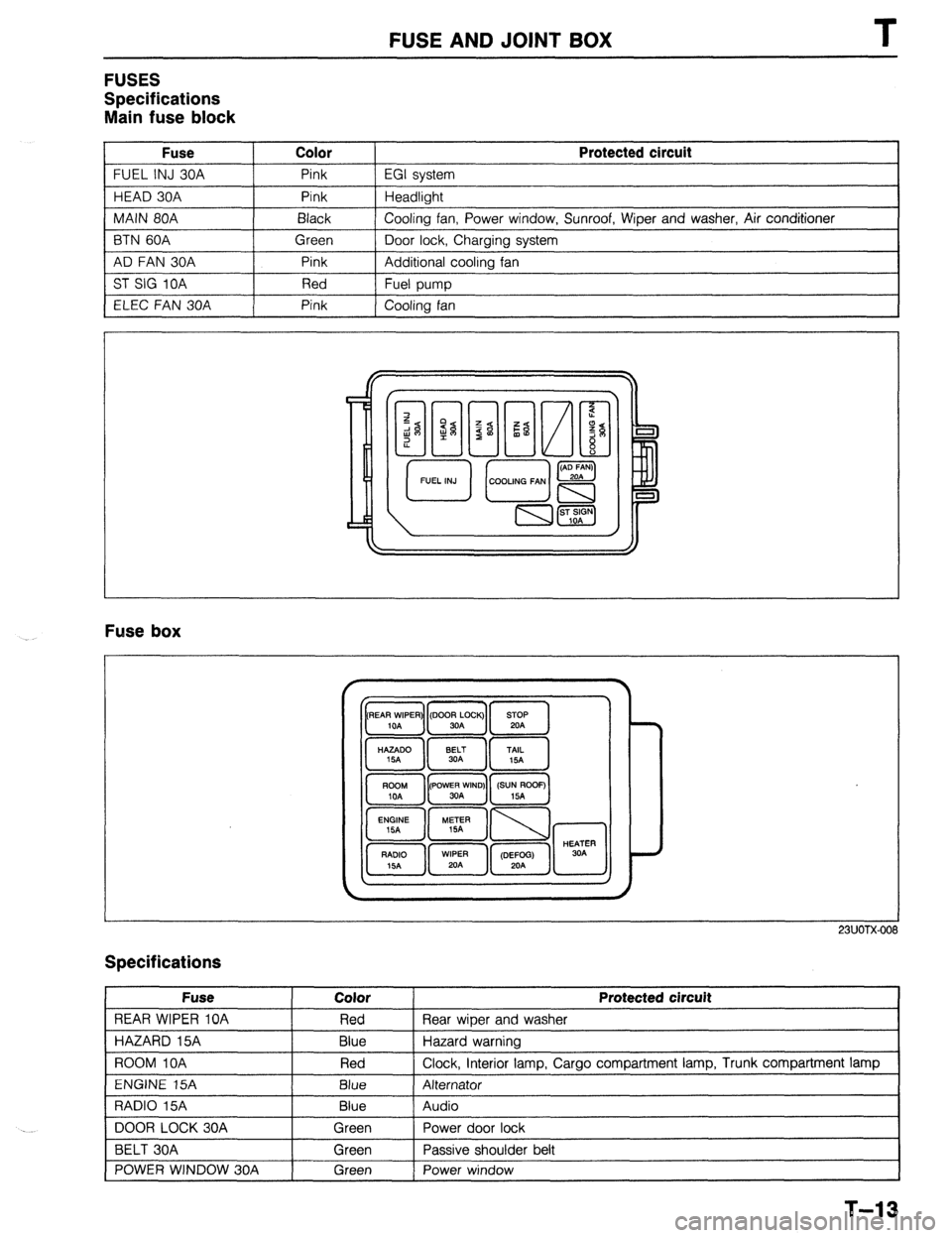

FUSE AND JOINT BOX

FUSES

Specifications

Main fuse block

Fuse Color

FUEL INJ 30A Pink

HEAD 30A Pink

MAIN 80A Black

BTN 60A Green

AD FAN 30A Pink

ST SIG 10A Red

ELEC FAN 30A Pink Protected circuit

EGI system

Headlight

Cooling fan, Power window, Sunroof, Wiper and washer, Air conditioner

Door lock, Charging system

Additional cooling fan

Fuel pump

Cooling fan

Fuse box

23UOTX-001

Specifications

Fuse

REAR WIPER 10A

HAZARD 15A

ROOM IOA

ENGINE 15A

RADIO 15A

DOOR LOCK 30A

BELT 30A

POWER WINDOW 30A Color

Red

Blue

Red

Blue

Blue

Green

Green

Green Protected circuit

Rear wiper and washer

Hazard warning

Clock, interior lamp, Cargo compartment lamp, Trunk compartment lamp

Alternator

Audio

Power door lock

Passive shoulder belt

Power window

1

T-13

Page 968 of 1164

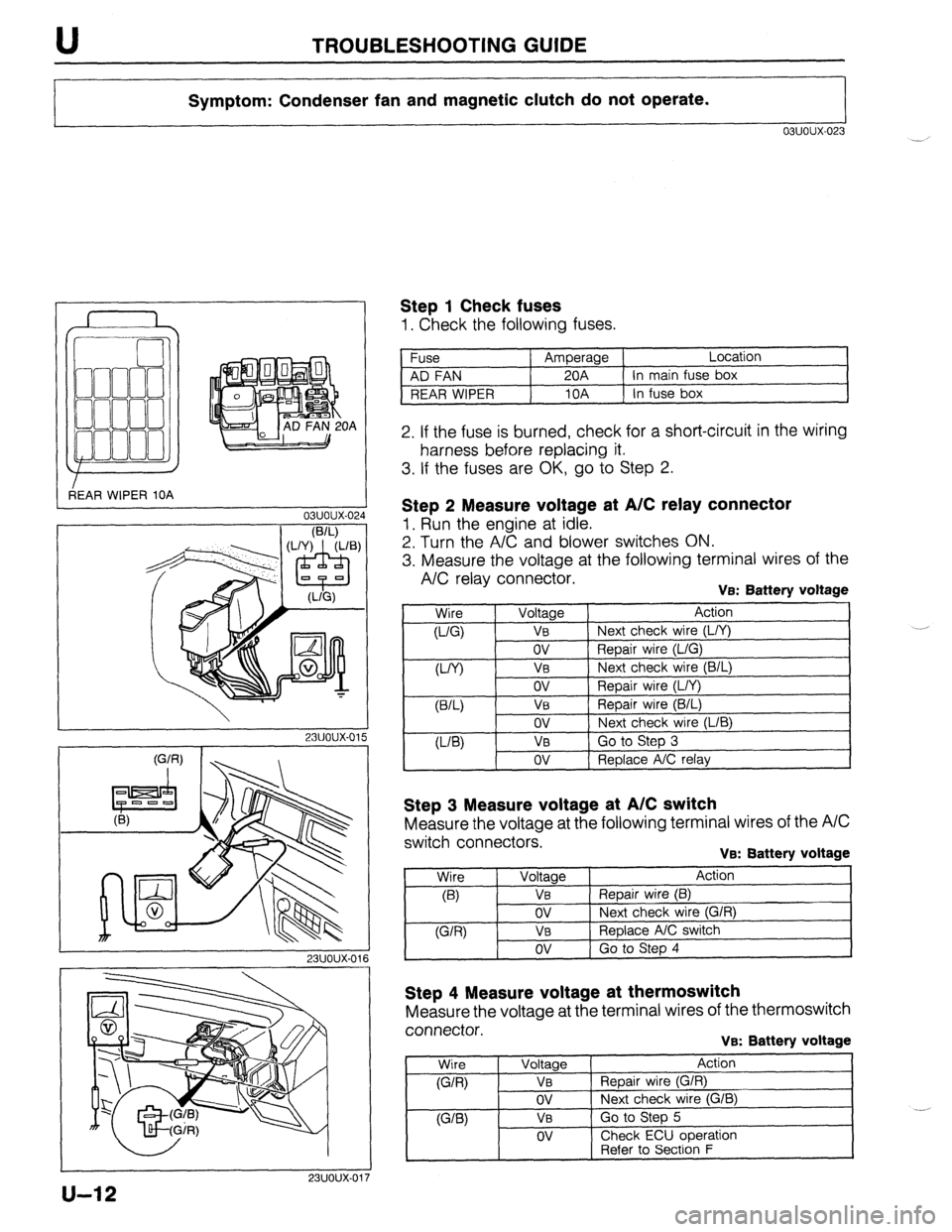

TROUBLESHOOTING GUIDE

Symptom: Condenser fan and magnetic clutch do not operate.

03uoux-023

r

3EAR WIPER 10A OA

L

03uoux-02.

I

1 Step 1 Check fuses

1. Check the following fuses.

Fuse Amperage Location

AD FAN 20A In main fuse box

REAR WIPER 10A In fuse box

2. If the fuse is burned, check for a short-circuit in the wiring

harness before replacing it.

3. If the fuses are OK, go to Step 2.

I

23uoux-011

Step 2 Measure voltage at A/C relay connector

1. Run the engine at idle.

2. Turn the A/C and blower switches ON.

3. Measure the voltage at the following terminal wires of the

A/C relay connector. VEX Battery voltage

,

Wire

0-Q

W) Voltage Action

VB Next check wire (L/Y)

ov Repair wire (L/G)

V0 Next check wire (B/L)

ov

VB

ov

VB

ov Repair wire (L/Y)

Repair wire (B/L)

Next check wire (LIB)

Go to Step 3

Replace A/C relay

Step 3 Measure voltage at A/C switch

Measure the voltage at the following terminal wires of the A/C

switch connectors.

VB: Battery voltage

Step 4 Measure voltage at thermoswitch

Measure the voltage at the terminal wires of the thermoswitch

connector.

VB: Battery voltage

Wire

(G/R)

WB)

Voltage

VB

ov

VB

OV

Action

Repair wire (G/R)

Next check wire (G/B)

Go to Step 5

Check ECU ooeration

1 -. [ Refer to Secti6n F

u-12

Page 1058 of 1164

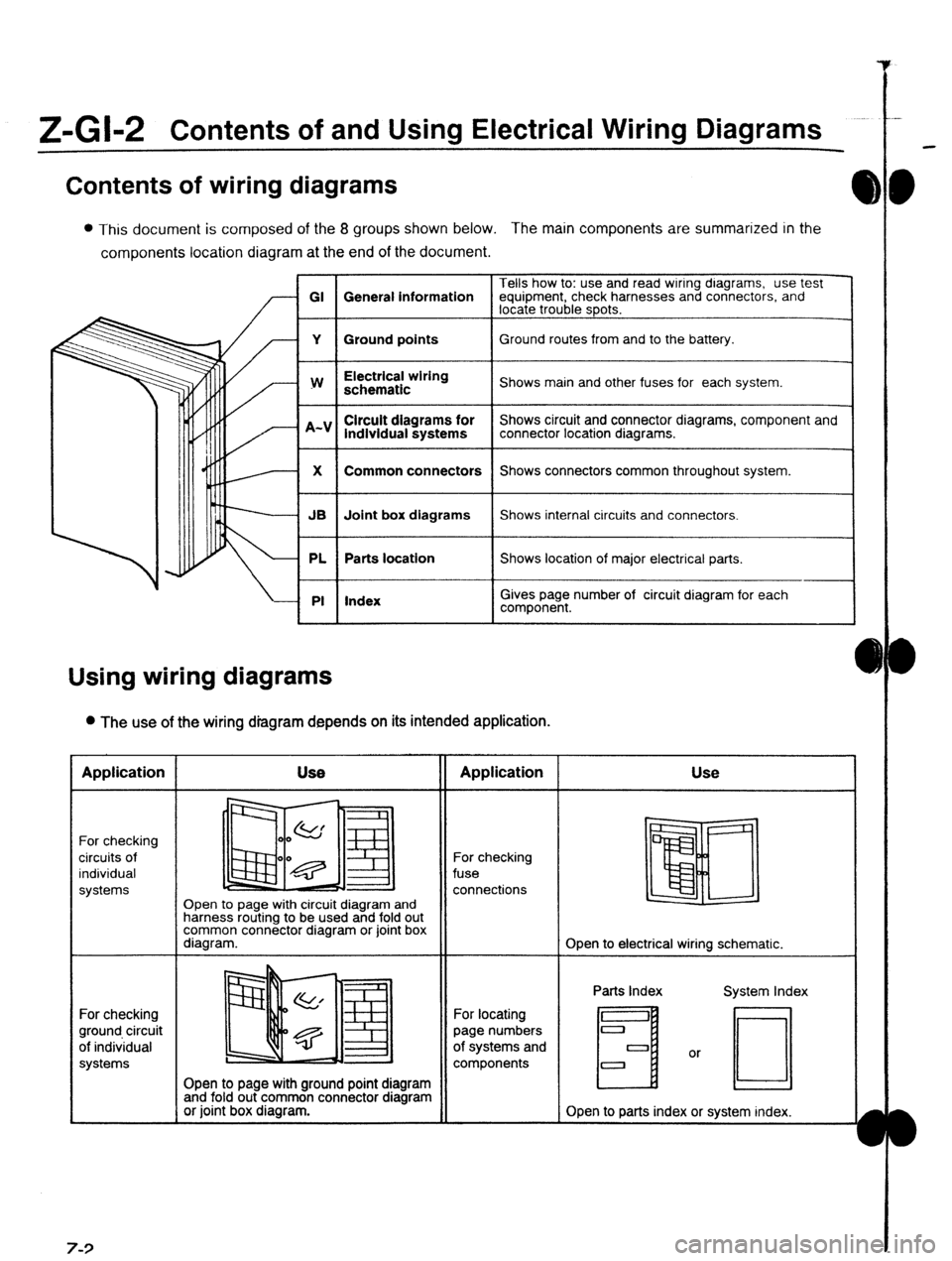

Z-Gl-2 Contents of and Using Electrical Wiring Diagrams

Contents of wiring diagrams

l This document is composed of the 8 groups shown below. The main components are summarized in the

components location diagram at the end of the document.

Tells how to: use and read wiring dragrams, use test

GI General information equipment, check harnesses and connectors, and

locate trouble spots.

Y Ground points Ground routes from and to the battery.

I

w

I Electrical wiring

schematic

I Shows main and other fuses for each system.

lndlvidual systems

I Shows circuit and connector diagrams, component and

connector location diagrams.

1

X

I Common connectors

I Shows connectors common throughout system.

I

JB Joint box diagrams Shows internal circuits and connectors.

PL Parts location Shows location of major electrical parts.

PI Index

I

I

Gives page number of circuit diagram for each

component.

Using wiring diagrams

l The use of the wiring diagram depends on its intended application. Application

For checking

circuits of

individual

systems

For checking

ground circuit

of individual

systems 7-3 Use

II Application

Open to page with circuit diagram and

harness routing to be used and fold out

common connector diagram or joint box

diagram. For checking

fuse

connections Use

Open to electrical wiring schematic.

Open to page with ground point diagram

and fold out common connector diagram

or joint box diagram. For locating

page numbers

of systems and

components Parts Index

H

Open to parts index or system index.

Page 1064 of 1164

Z-Gl-8 Reading Wiring Diagrams

Svmbols I

Symbol Meaning Symbol Meaning

Battery (I, Generates electricity through Resistance l A resistor with a constant value

chemical reaction l Mainly used to protect electrical

l Supplies direct current to circuits components in circuits by maintaining

rated voltage

l Reading resistance values

Ground (1)

l Connecting point to vehicle body or No.1 Cobr band

-A- other ground wire where current flows -No.2 Cobr band

from positive to negative terminal of -No.3 Cobr band

battery No.4 Cobr band

1

l Ground (1) indicates a ground point to Flnt color. Rerkrancs

body through wire harness

Ground (2) l Gound (2) indicates point where

component is grounded directly to body

Remark

oCurrent wilt not flow through a circuit if

ground is faulty

Fuse (1)

(box)

Fuse (2)

l Melts when current flow exceeds that

specified for circuit, stopping current

flow

Precautions

o Do not replace with fuses exceeding

specified capacity

(Cartridge)

vlain fuse/Fusible

l Electrical switching component

a Turns on when voltage is applied to Motor

0 Converts electrical energy into

mechanical energy

Transistor (2)

coiibmr (Cl

l Reading code l Pulls in and expels gases and liquids

Lamp

Number of terminals O:Low- frequency NPN

l Emits light and generates heat when

Cigarette lighter

current flows through filament a Electrical coil that generates heat

Page 1067 of 1164

Troubleshootina Z-GM 1

Precautions when servicing electrical system

l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way as this may damage the vehicle or cause a fire

due to shorting or overcapacity of a circuit.

l Always disconnect the negative (- ) battery cable first and 0 Replace blown fuses with ones having the same designated

reconnect It last when disconnecting the battery. capacity.

1OA

15A

Zaution

l Be sure that the ignition and other switches are OFF

before disconnecting or connecting the battery

terminals.

Failure to do so may damage the semi-conductor

components. Caution l Replacing a fuse with one of a larger capacity than

designated may damage components or cause an electrical

fire.

l Secure harnesses with a clamp when provided to take Up l Tape areas of the

a Be sure that the harness

any slack. harness that may rub or

is not caught or damaged

bump against sharp

when mounting

edges to protect it from

components.

damage.

Caution

l Clamp all harnesses near vibrating components(e.g.

the engine) to remove any slack and prevent Contact

due to vibration.

l Do not handle roughly or drop electrical components.

l Disconnect heat sensitive

parts (e.g. relays, ECU)

when performing

maintenance where

temperatures may exceed l Make sure that the

connectors are securely

connected when

installed.

80°C (176°F) (i.e.welding).

oid