key MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 3 of 1164

GENERAL INFORMATION

IMPORTANT INFORMATION ..................... GI- 2

BASIC ASSUMPTIONS ............................ GI- 2

SAFETY RISK ........................................ GI- 2

POSSIBLE LOSS OF WARRANTY ............. GI- 2

WARNING ON LUBRICANTS

AND GREASES .................................... GI- 2

HOW TO USE THIS MANUAL.. .................. GI- 3

PREPARATION ...................................... GI- 3

REPAIR PROCEDURE ............................. GI- 3

SYMBOLS ............................................. GI- 4

NOTES, CAUTIONS, AND WARNINGS.. ..... GI- 4

FUNDAMENTAL PROCEDURES.. ............... GI- 4

PROTECTION OF THE VEHICLE .............. GI- 4

A WORD

ABOUT SAFETY ....................... GI- 5

PREPARATION OF TOOLS

AND MEASURING EQUIPMENT.. ........... GI- 5

SPECIAL TOOLS .................................... GI- 5

REMOVAL OF PARTS ............................. GI- 5

DISASSEMBLY ...................................... GI- 5

REASSEMBLY ....................................... GI- 6

ADJUSTMENTS ..................................... GI- 7

RUBBER

PARTS AND TUBING ................

GI- 7

JACK AND SAFETY STAND POSITIONS.. .. GI- 6

VEHICLE LIFT (P-SUPPORT TYPE)

POSITIONS ............................................ GI- 6

TOWING .................................................. GI- 9

IDENTIFICATION NUMBER LOCATIONS ..... 61-10

UNITS ..................................................... GI-10

ABBREVIATIONS ..................................... GI-10

CAUTION ................................................ GI-1 1

INSTALLATION OF MOBILE

TWO-WAY RADIO SYSTEM .................... GI-11

REMOVAL OF IGNITION KEY ON

AUTOMATIC TRANSAXLE MODEL.. ........

GI-1 1

ELECTRICAL TROUBLESHOOTING TOOLS GI-12

CAUTION WITH ELECTRICAL PARTS ........

GI-13

03UGIX-001

Page 13 of 1164

CAUTION GI

CAUTION

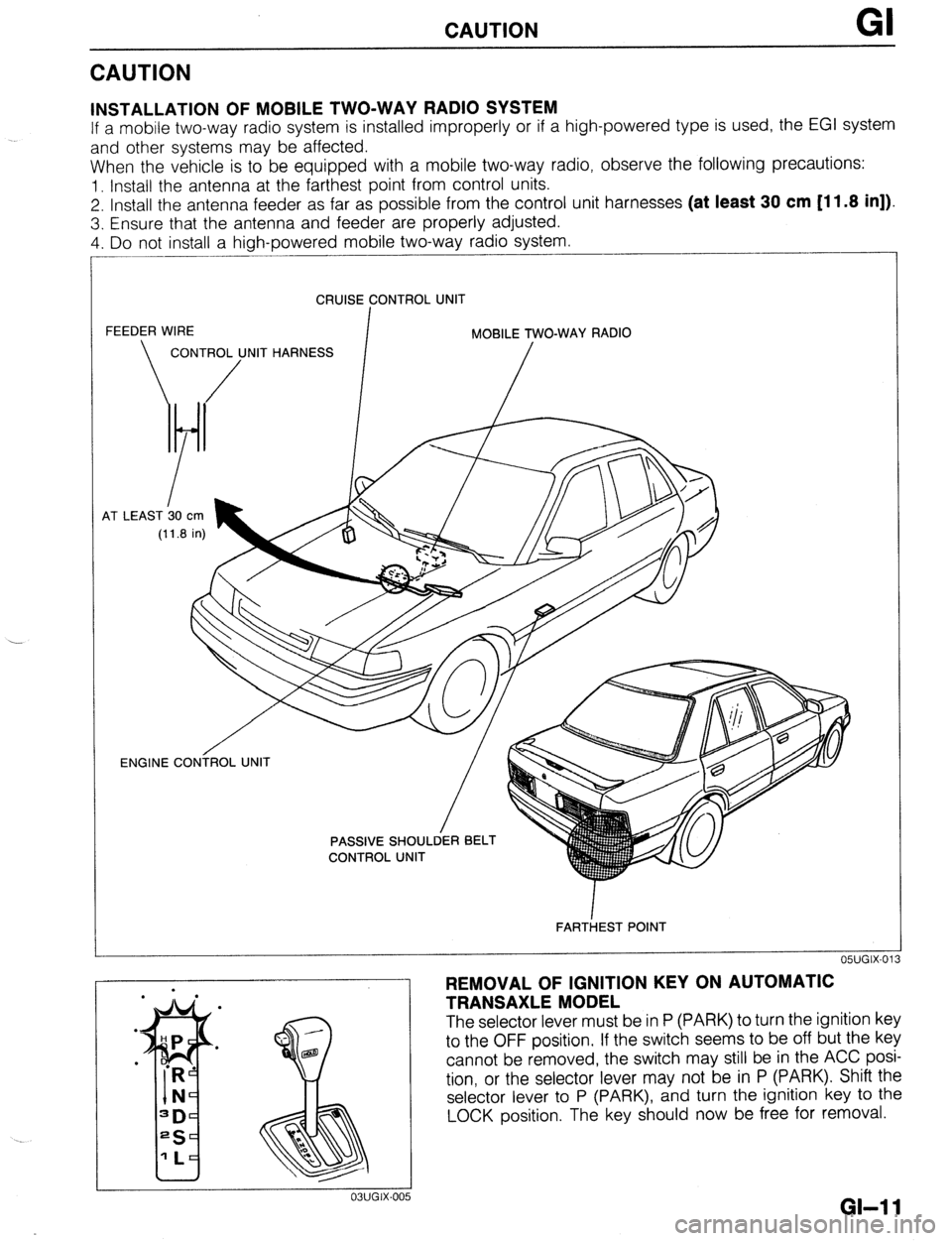

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a mobile two-way radio system is installed improperly or if a high-powered type is used, the EGI system

and other systems may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

1. Install the antenna at the farthest point from control units.

2. Install the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [11.8 in]).

3. Ensure that the antenna and feeder are properly adjusted.

4. Do not install a high-powered mobile two-way radio system.

CRUISE CONTROL UNIT

FEEDER WIRE

I MOBILE TWO-WAY RADIO

CONTROL UNIT HARNESS

/ /

4T LEAST b0

cm

(11.8 in)

OWGIX-013 ENGINE CONiROL UNIT

/

FARTiEST POINT

REMOVAL OF IGNITION KEY ON AUTOMATIC

TRANSAXLE MODEL

The selector lever must be in P (PARK) to turn the ignition key

to the OFF position. If the switch seems to be off but the key

cannot be removed, the switch may still be in the ACC posi-

tion, or the selector lever may not be in P (PARK). Shift the

selector lever to P (PARK), and turn the ignition key to the

LOCK position. The key should now be free for removal.

GI-1 1

Page 54 of 1164

Bl ON-VEHICLE MAINTENANCE

01 EOBX-056

23UOBi -0:

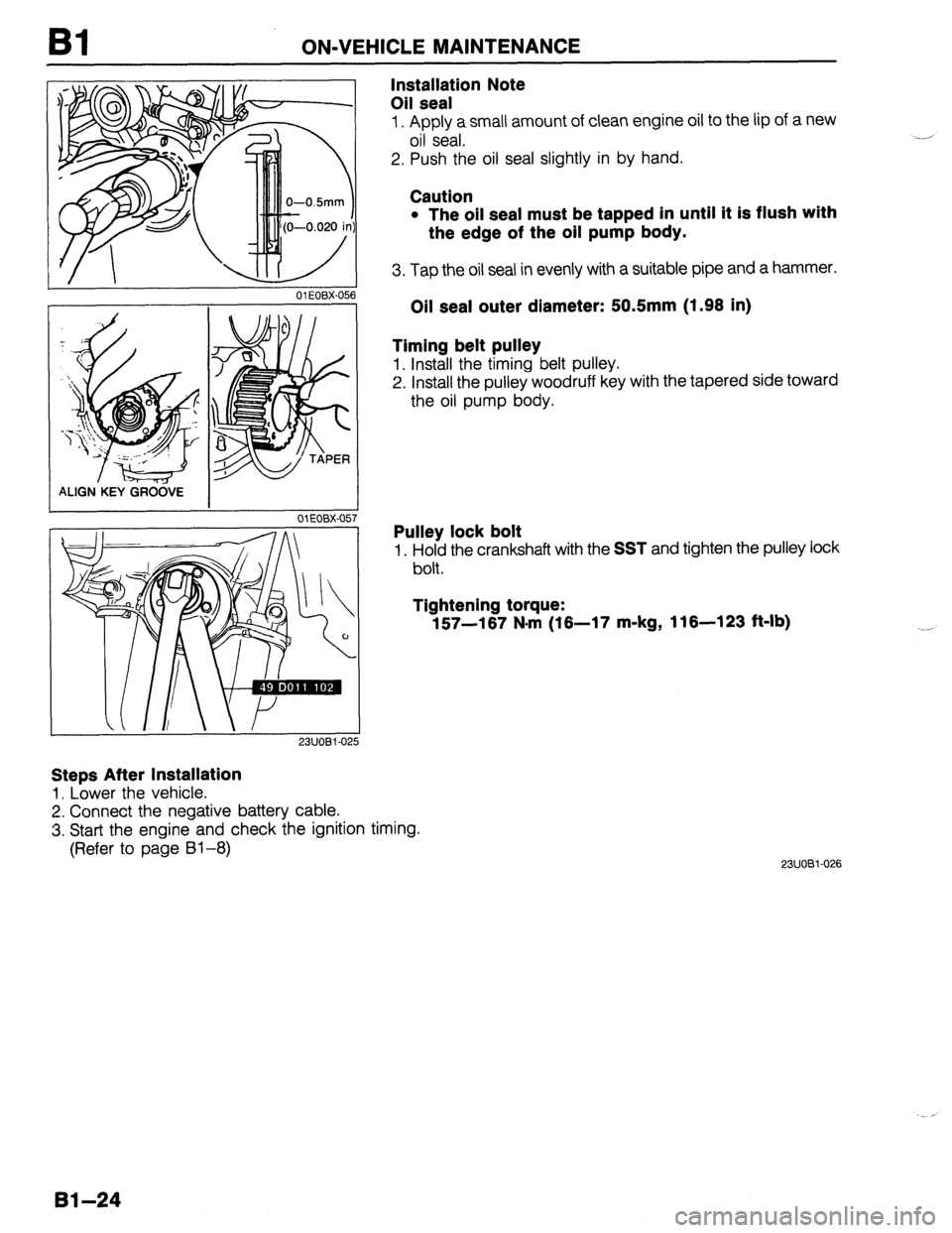

Steps After Installation

1. Lower the vehicle.

2. Connect the negative battery cable.

3. Start the engine and check the ignition timing.

(Refer to page 61-8)

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the oil pump body.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-167 N*rn (16-17 m-kg, 116-123 ft-lb)

23UOBi-026

Bl-24

Page 78 of 1164

Bl DISASSEMBLY

23UOBl-068

23UOBl-06!

I 2311081-070

23UOBl-071

Disassembly Note

Timing belt pulley

1. Hold the flywheel (MTX) or drive plate (ATX) with the SST

or equivalent.

2. Loosen the pulley lock bolt.

3. Remove the pulley lock bolt. -

4. Remove the timing belt pulley.

5. Remove the pulley Woodruff key.

2311081-059

Clutch cover (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Loosen the clutch cover lock bolts in two or three steps in

the order shown in the figure.

3. Remove the clutch cover.

-

Flywheel (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel lock bolts.

3. Remove the flywheel.

4. Remove the

SST or equivalent.

Backing plate, drive plate, and adapter (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

4. Remove the

SST or equivalent.

Bl-48

Page 159 of 1164

ON-VEHICLE MAINTENANCE

I 05UOBX-063

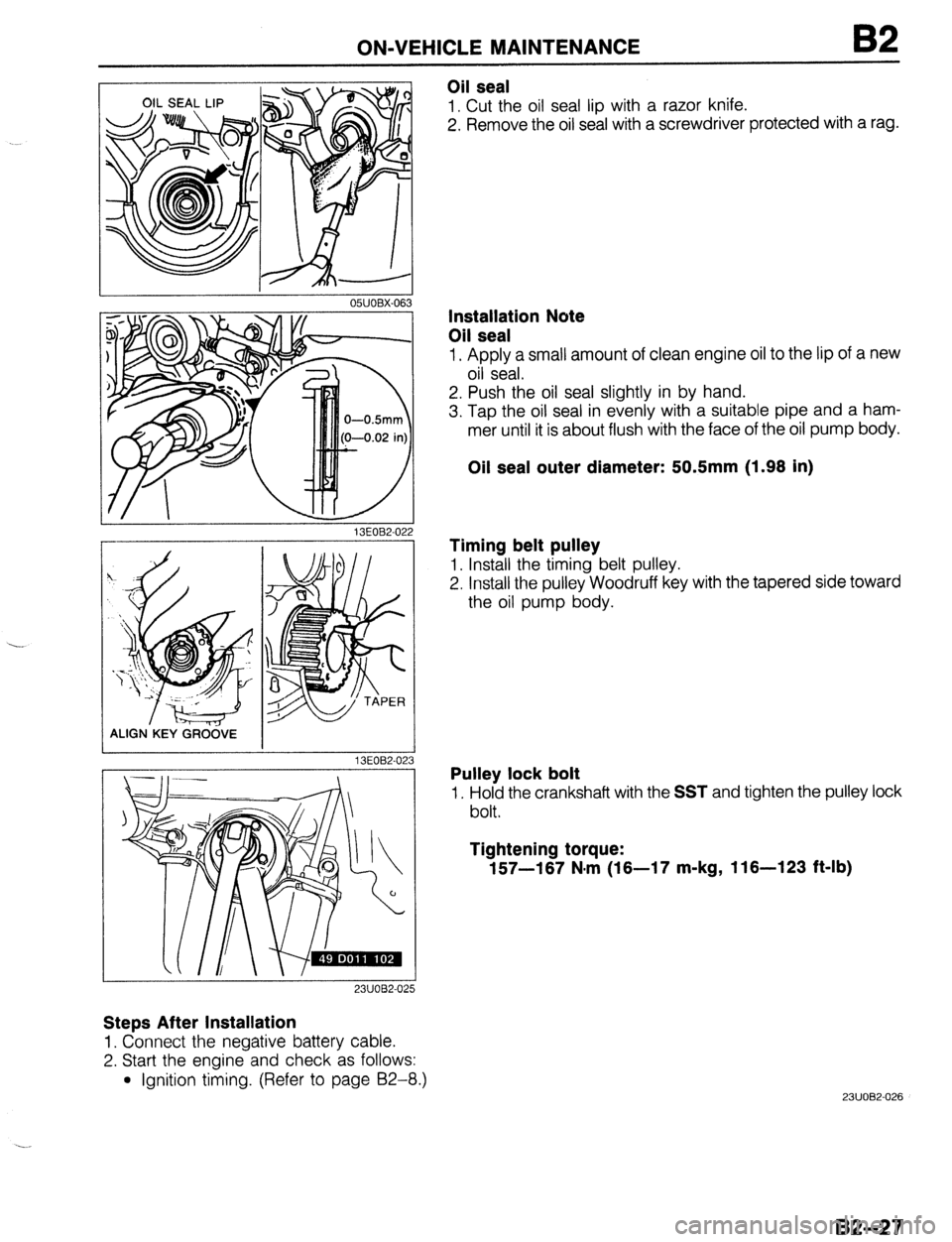

Oil seal

1. Cut the oil seal lip with a razor knife.

2. Remove the oil seal with a screwdriver protected with a rag.

13EOB2-02

ALIGN.KEY GRCi&E

13EOB2-02

23UOB2-025

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page 92-8.)

3

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

3. Tap the oil seal in evenly with a suitable pipe and a ham-

mer until it is about flush with the face of the oil pump body.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley Woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-187 N.m (18-17 m-kg, 116-123 ft-lb)

23UOB2-026

82-27

Page 181 of 1164

DISASSEMBLY

23UOW056

03UOB2-073

Disassembly Note

Timing belt pulley

1. Hold the flywheel or the drive plate with the SST or

equivalent.

2. Loosen the pulley lock bolt.

3. Remove the pulley lock bolt.

4. Remove the timing belt pulley.

5. Remove the pulley Woodruff key.

23UOB2-049

Flywheel (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel lock bolts.

3. Remove the flywheel.

Backing plate, drive plate, and adapter (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

Oil pan

1. Remove the oil pan mounting bolts.

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Remove the oil pan.

82-49

Page 210 of 1164

I32 ASSEMBLY

Qill’ ’ 23UOB2-050

03UOB2-10

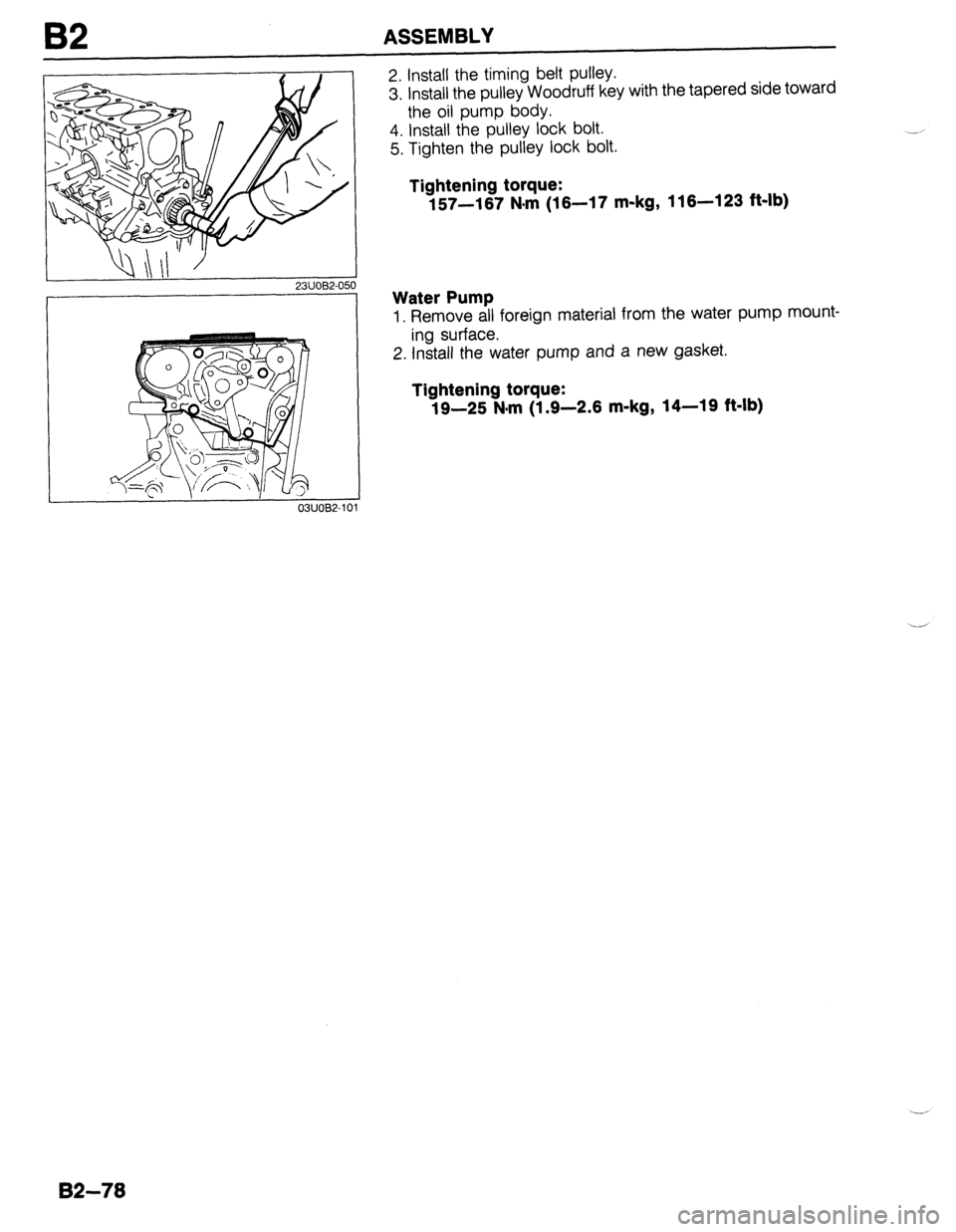

2. Install the timing belt pulley.

3. install the pulley Woodruff key with the tapered side toward

the oil pump body.

4. Install the pulley lock bolt.

5. Tighten the pulley lock bolt.

Tightening torque:

157-167 N#rn (16-17 m-kg, 116-123 ft-lb)

Water Pump

1. Remove all foreign material from the water pump mount-

ing surface.

2. Install the water pump and a new gasket.

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

82-78

Page 496 of 1164

Jl TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Problem

Shift lever won’t shift

smoothly or is hard

to shift

Too much play in

shift lever

I------

Difficult to shift

Won’t stay in gear

Abnormal noise

I

Possible cause

Seized shift lever ball

Seized change control rod joint

Bent change control rod

Worn change control rod bushing

Weak shift lever ball spring

Worn shift lever ball bushing

Bent change rod

No grease in transaxle control

Insufficient oil

Deterioration of oil quality

Wear or play of shift fork or shift rod

Worn synchronizer ring

Worn synchronizer cone of gear

Bad contact of synchronizer ring and cone of gear

Excessive longitudinal play of gears

Worn bearing

Worn synchronizer key spring

Excessive primary shaft gear bearing preload

improperly adjusted change guide plate

Bent change control rod

Worn change control rod bushing

Weak shift lever ball spring

improperly installed extension bar

Worn shift fork

Worn clutch hub

Worn clutch hub sleeve

Worn gear sliding part of both shaft gears

Worn gear sliding part of each gear

Worn steel sliding groove of control end

Weak spring pressing against steel ball

Excessive thrust clearance

Worn bearing

Improperly installed engine mount

Insufficient oil

Deterioration of oil quality

Worn bearing

Worn sliding surfaces of gears or shafts

Excessive gear backlash

Damaged gear teeth

Foreign material in gears

Damaged differential gear or excessive backlash Remedy Replace

Replace

Replace

Replace

Replace

Replace

Replace

Lubricate with grease

Add oil

Replace with oil of

specified quality

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Replace

Replace

Tighten

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Tighten

Add oil

Replace

Adjust or replace

Replace

Replace

Replace with oil of

specified quality

Replace

Adjust or replace Page Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl- 7

Jl- 7

Jl-14

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-36

Jl-17

Jl-56

Jl-56

Jl-56

Jl-56

Jl-14

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-14

Jl-14

Jl-22, 24

Jl-22, 24

Jl-48

Jl- 7

Jl- 7

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-53

03UOJl-OC --

-../

51-6

Page 505 of 1164

TRANSAXLE Jl

1, Rear cover

2. Locknut (Primary shaft)

Disassembly Note .,......,,.,......... page Jl-15

3. Stop plate

4. Locknut (Secondary shaft)

Disassembly Note ,..,....,,.,......... page Jl-15

5. 5th shift fork

6. Clutch hub assembly (5th)

Inspection . . . . . . . . . . . . . . . . ..*............... page J l-29

7. Synchronizer ring (5th)

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-27

8. 5th gear

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-28

9. Gear sleeve

Inspection . . . . . . . . . . . . . . . . ..*...*........... page Jl-28

10. Secondary 5th gear

11. Lock bolt and washer

12. Back-up light switch

13. Neutral switch

14. Transaxle case assembly

15. Magnet

16. Reverse idler shaft

17. Reverse idler gear

Inspection.. . . , . . . . . . . . . . . . . . . , , . , . . . . . . . . . . page J l-27

L ,

03UOJl-022

I

I I

03UOJl-023

18. 5th shift rod

19. 5th shift rod end

20. Pin

21. Crank lever shaft

22. Crank lever assembly

23. Shift fork and shift rod assembly

Disassembly Note ,.................... page Jl-16

24. Steel ball

25. Spring

26. Primary shaft gear assembly

27. Secondary shaft gear assembly

28. Differential assembly

29. Clutch housing

30. Synchronizer spring

31. Clutch hub sleeve

32. Synchronizer key

33. Clutch hub

34. 3rd/4th shift fork

35. Interlock sleeve

36. Control lever

37. lstl2nd shift fork

38. Control rod

39. Control end

03UOJl-021

Preinspection

5th gear thrust clearance

1. Measure the 5th gear thrust clearance with a dial indicator.

Clearance: 0.06-0.26mm (0.0024-0.0102 in)

Maximum : 0.31 mm (0.0122 in)

2. If the clearance exceeds the the maximum, check the con-

tact surfaces of 5th gear and the clutch hub. Replace worn

or damaged parts.

Disassembly note

Locknut

1, Mount the transaxle on the SST.

Jl-15

Page 512 of 1164

Jl TRANSAXLE

Primary Shaft Assembly

1. Measure the thrust clearances of all gears before disassembly, referring to Preinspection.

2. Disassemble in the order shown in the figure, referring to Disassembly Note.

REPLACE

1. Bearing

Disassembly Note.. . . . . . . . . . . . . . . . page Jl-23

Inspection.. . . .., . . . . . . . . . . . . . . . . . . . . . page J l-28

2.4th gear

Disassembly Note . . . . . . . . . . . . . . . . . . . . . page Jl-23

Inspection.. . . . . . . . . . . . . . . . . . . . . . . page J l-28

3. Synchronizer ring (4th)

Inspection.. . . . . . . . . . . . . . . . . . . . . . page J l-27

4. Retaining ring

5. Clutch hub assembly (3rd/4th)

Disassembly Note . . . . . . . . . . . . . . . . page Jl-23

inspection.. . . . . . . . . . . . . . . . . . . . . . . page J l-29

6. Synchronizer ring (3rd)

Disassembly Note . . . . . . . . . . . . . . . . . . . . page Jl-23

Inspection.. . . . .., . . . . . . ,.. . . . . . . . . page J l-27 7. 3rd gear

Disassembly Note.. . . . . . . . . . . . page J l-23

Inspection.. . . . . . . . . . . page J 1-28

8. Bearing

Disassembly Note.. . ., . . . page J l-23

9. Primary shaft

Inspection., . . . . . . . . . . . page J 1-27

10. Synchronizer spring

11. Clutch hub sleeve

12. Synchronizer key

13. Clutch hub

. . /’

Jl-22