light MERCEDES-BENZ C-CLASS COUPE 2015 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: C-CLASS COUPE, Model: MERCEDES-BENZ C-CLASS COUPE 2015Pages: 385, PDF Size: 13.12 MB

Page 337 of 385

Where will

Ifind...? Reflective safety jacket

Removing/replacing the reflective

safety jacket The reflective safety jackets are located in the

safety jacket compartments in the stowage

compartments.

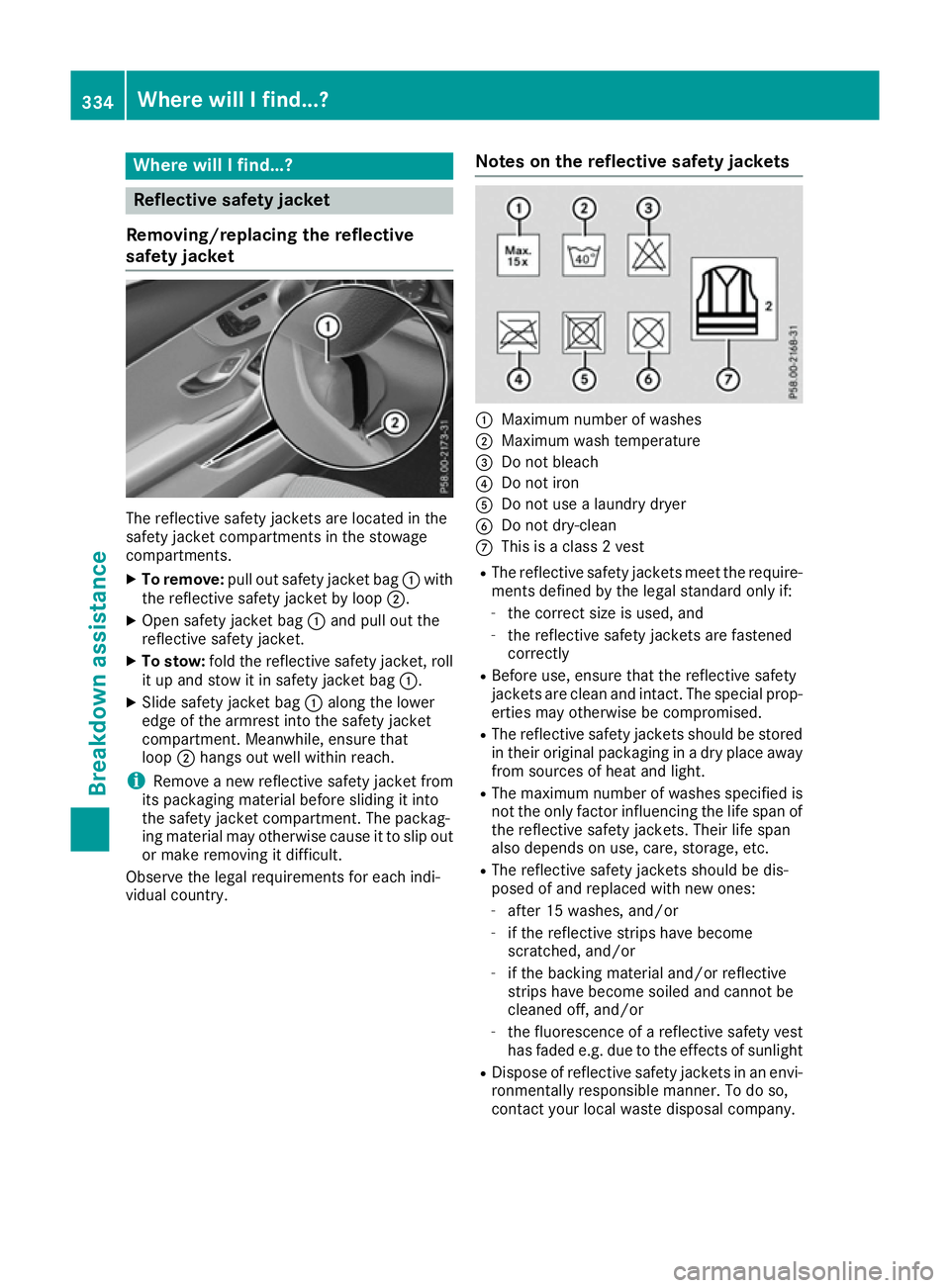

X To remove: pullout safety jacket bag :with

the reflective safety jacket by loop ;.

X Open safety jacket bag :and pul lout the

reflective safety jacket.

X To stow: fold the reflective safety jacket, roll

it up and stow it in safety jacket bag :.

X Slid esafety jacket bag :along the lower

edge of the armres tinto the safety jacket

compartment. Meanwhile, ensure that

loop ;hangs out wel lwithi nreach.

i Remove

anew reflective safety jacket from

its packaging material before sliding it into

the safety jacket compartment. The packag-

ing material may otherwise caus eittoslipo ut

or make removing it difficult.

Observe the lega lrequirements for each indi-

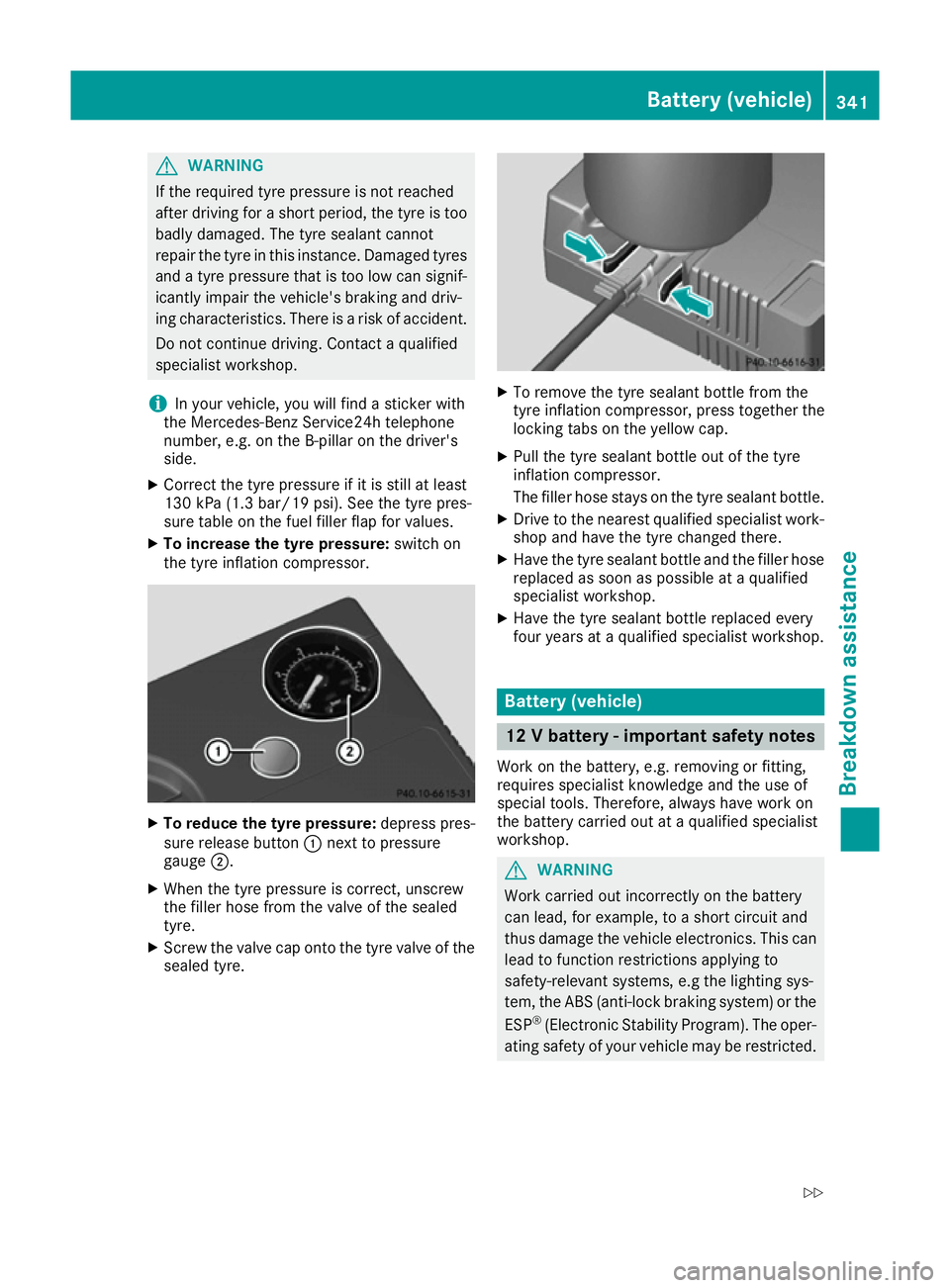

vidual country. Notes on the reflective safety jackets :

Maximum numbe rofwashes

; Maximum wash temperature

= Do not bleach

? Do not iron

A Do not use alaundry dryer

B Do not dry-clean

C This is aclass2v est

R The reflective safety jackets meet the require-

ments defined by the lega lstandard only if:

- the correct size is used, and

- the reflective safety jackets are fastened

correctly

R Before use ,ensure that the reflective safety

jackets are clea nand intact. The special prop-

erties may otherwise be compromised.

R The reflective safety jackets should be stored

in their original packaging in adry place away

from sources of hea tand light.

R The maximu mnumberofw ashes specified is

not the only factor influencing the life spa nof

the reflective safety jackets. Thei rlife span

als od epends on use ,care, storage ,etc.

R The reflective safety jackets should be dis-

pose dofa nd replaced with new ones:

- after 15 washes, and/or

- if the reflective strips have become

scratched ,and/or

- if the backing material and/or reflective

strips have become soiled and cannot be

cleaned off, and/or

- the fluorescence of areflective safety vest

has fade de.g. due to the effects of sunlight

R Dispos eofreflective safety jackets in an envi-

ronmentall yresponsibl emanner. To do so,

contact you rloca lwaste disposal company. 334

Where will

Ifind...?Breakdown assistance

Page 342 of 385

If you come into contact with the tyre sealant,

observe the following:

R Rinse off the tyre sealant from yours kin

immediately with water.

R If the tyre sealant comes into contact with

youre yes,immediately rinse them thor-

oughlyw ith clean water.

R If tyre sealant is swallowed, immediately

rinse yourm outh out thoroughl yand drink

plenty of water. Do not induce vomiting,

and seek medica lattention immediately.

R Immediately change out of clothing which

has come into contact with tyre sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

! Do not operate the tyre inflation compres-

sor for longer than ten minutes at atime with-

out abreak. It may otherwise overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

Complyw ith the manufacturer's safety instruc-

tions on the sticker on the tyre inflation com-

pressor.

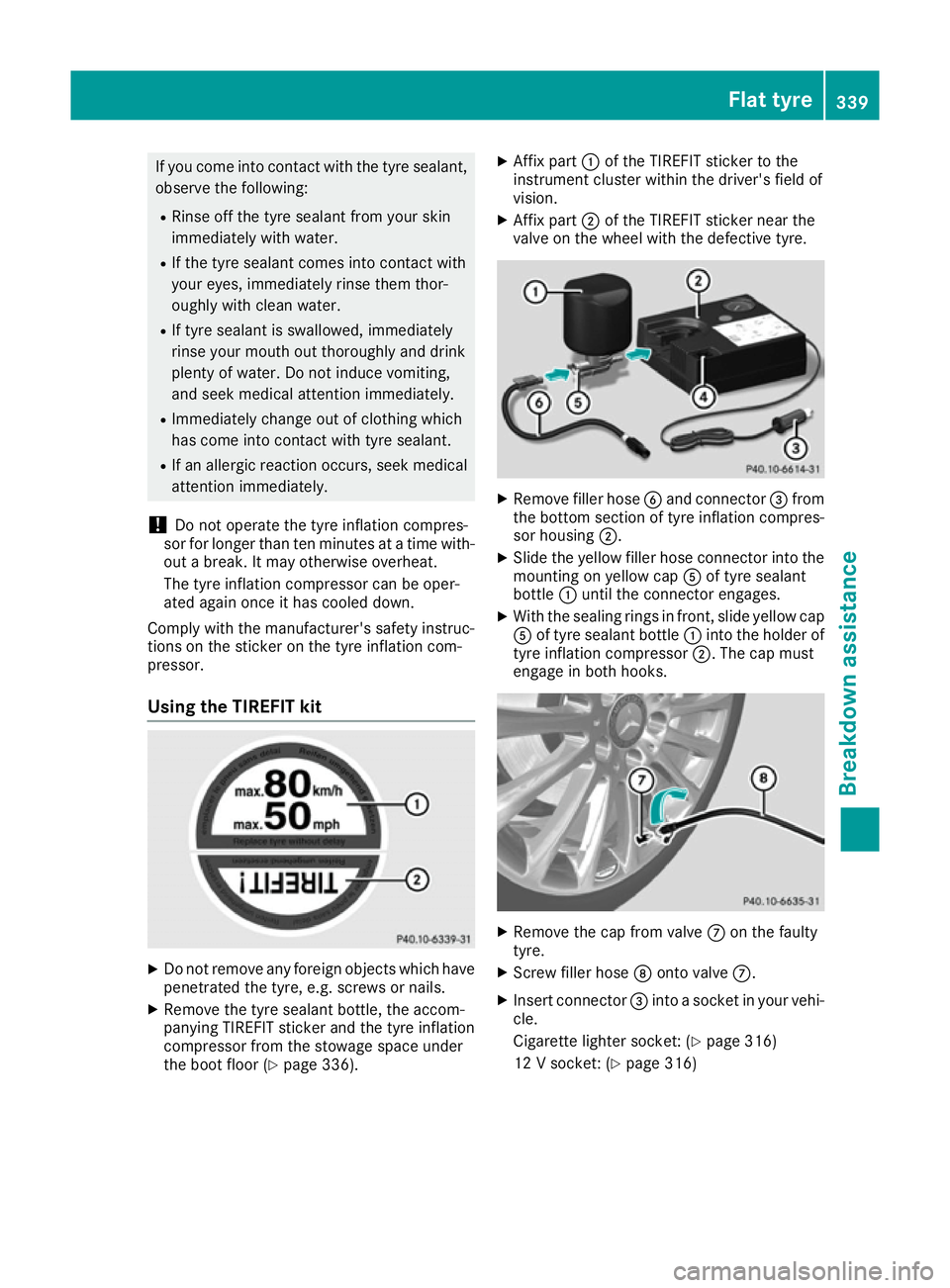

Usingt he TIREFITk it X

Do not remove any foreign objects which have

penetrated the tyre, e.g. screws or nails.

X Remove the tyre sealant bottle, the accom-

panying TIREFIT sticker and the tyre inflation

compressor from the stowage space under

the boot floor (Y page 336). X

Affix part :of the TIREFIT sticker to the

instrument cluster within the driver's field of

vision.

X Affix part ;of the TIREFIT sticker near the

valve on the wheel with the defective tyre. X

Remove fillerh oseBand connector =from

the bottom section of tyre inflation compres- sor housing ;.

X Slide the yellow fillerh ose connector into the

mounting on yellow cap Aof tyre sealant

bottle :until the connector engages.

X With the sealing rings in front, slidey ellow cap

A of tyre sealant bottle :into the holderof

tyre inflation compressor ;.The cap must

engage in both hooks. X

Remove the cap from valve Con the faulty

tyre.

X Screw fillerh oseDonto valve C.

X Insert connector =into asocket in yourv ehi-

cle.

Cigarette lighter socket: (Y page 316)

12 Vsocket: (Y page 316) Flat tyre

339Breakdowna ssistance Z

Page 343 of 385

Observe the notes on the cigarette lighter

(Y page 316). Observe the notes on sockets

(Y page 316).

X Turn the key to position 1in the ignition lock

(Y page 145).

X Press on and off switch ?on the tyre inflation

compressor to ON.

The tyre inflation compressor is switched on.

The tyre is inflated.

First, tyre sealant is pumped into the tyre. The pressure may briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tyre inflation com-

pressor during this phase.

X Let the tyre inflation compressor run for a

maximum of ten minutes. The tyre should

then have attained apressure of at least

200 kPa (2.0 bar/29 psi).

If ap ressure of 200 kPa (2.0 bar/29 psi) has

been attained after ten minutes, see "Tyre pres- sure reached" (Y page 340).

If at yre pressure of 200 kPa (2.0 bar/29 psi) has

not been attained after ten minutes, see "Tyre

pressure not reached" (Y page 340).

If tyre sealant leaks out, make sure you clean the

affected area as quickly as possible.Itisp ref-

erable to use clear water.

If you get tyre sealant on your clothing, have it

cleaned as soon as possible with perchloroethy- lene.

Tyre pressure not reached If

at yre pressure of 200 kPa (2.0 bar/29 psi) has

not been attained after ten minutes:

X Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of the

faulty tyre.

Please note that tyre sealant may leak out

when unscrewing the filler hose.

X Very slowly drive forwards or reverse approx-

imately 10 m.

X Pump up the tyre again.

After amaximum of ten minutes, the tyre

pressure must be at least 200 kPa (2.0 bar/

29 psi). G

WARNING

If the required tyre pressure is not reached

after the specified time, the tyre is too badly

damaged.T he tyre sealant cannot repair the tyre in this instance. Damaged tyres and

atyre

pressure that is too low can significantly

impair the vehicle's braking and driving char-

acteristics. There is arisk of accident.

Do not continue driving. Contact aqualified

specialist workshop.

Tyre pressure reached G

WARNING

At yre temporarily sealed with tyre sealant

impairs the driving characteristics and is not

suitablef or higher speeds. There is arisk of

accident.

You should therefore adapty our driving style

accordingly and drive carefully.Don ot exceed

the specified maximum speed with atyre that

has been repaired using tyre sealant.

The maximum permissibles peed foratyre

sealed with tyre sealant is 80 km/h. The upper

part of the TIREFIT sticker must be affixed to the

instrument cluster where it will be easilys een by

the driver.

! After use, excess tyre sealant may run out of

the filler hose. This could cause stains.

Therefore, place the filler hose in the plastic

bag which contained the TIREFIT kit. H

Environmental note

Have the used tyre sealant bottle disposed of

professionally,e .g. ataqualified specialist

workshop.

If at yre pressure of 200 kPa (2.0 bar/29 psi) has

been attained after ten minutes:

X Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of the

faulty tyre.

X Stow the tyre sealant bottle, the tyre inflation

compressor and the warning triangle.

X Pull away immediately.

X Stop after driving for approximately ten

minutes and check the tyre pressure with the

tyre inflation compressor.

The tyre pressure must now be at least

130 kPa (1.3 bar/19 psi). 340

Flat tyreBreakdown assistance

Page 344 of 385

G

WARNING

If the required tyre pressure is not reached

after driving for ashort period, the tyre is too

badly damaged. The tyre sealant cannot

repair the tyre in this instance. Damaged tyres and atyre pressure that is too low can signif-

icantly impair the vehicle's braking and driv-

ing characteristics. There is arisk of accident.

Do not continue driving. Contact aqualified

specialist workshop.

i In yourv

ehicle, you willf indasticker with

the Mercedes-Benz Service24h telephone

number, e.g. on the B-pillar on the driver's

side.

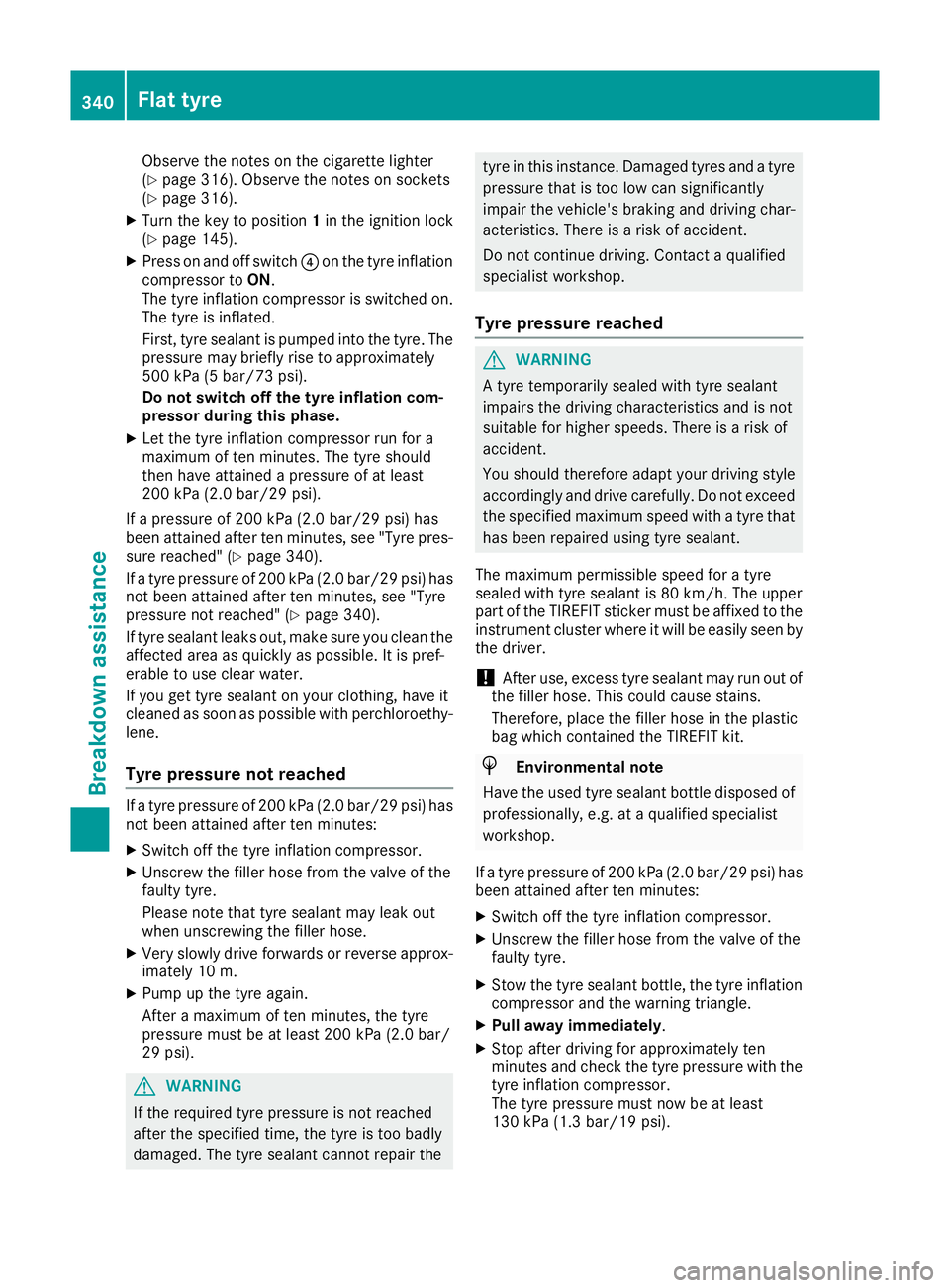

X Correct the tyre pressure if it is still at least

130 kPa (1.3 bar/19 psi) .See the tyre pres-

sure table on the fuel filler flap for values.

X To increase the tyre pressure: switch on

the tyre inflation compressor. X

To reduce the tyre pressure: depress pres-

sure release button :next to pressure

gauge ;.

X When the tyre pressure is correct, unscrew

the filler hose from the valve of the sealed

tyre.

X Screw the valve cap onto the tyre valve of the

sealed tyre. X

To remove the tyre sealant bottle from the

tyre inflation compressor, press together the

locking tabs on the yellow cap.

X Pullt he tyre sealant bottle out of the tyre

inflation compressor.

The filler hose stays on the tyre sealant bottle.

X Drive to the neares tqualified specialist work-

shop and have the tyre changed there.

X Have the tyre sealant bottle and the filler hose

replaced as soon as possible at aqualified

specialist workshop.

X Have the tyre sealant bottle replaced every

four years at aqualified specialist workshop. Battery (vehicle)

12

Vb attery -important safety notes

Work on the battery ,e.g. removing or fitting,

requires specialist knowledge and the use of

special tools. Therefore, alwaysh ave work on

the battery carrie dout at aqualified specialist

workshop. G

WARNING

Work carrie dout incorrectly on the battery

can lead, for example, to ashort circui tand

thus damage the vehicl eelectronics. This can

leadtof unction restrictions applying to

safety-relevant systems ,e.g the lighting sys-

tem, the ABS (anti-lock braking system) or the

ESP ®

(Electronic Stability Program). The oper-

ating safety of yourv ehiclemay be restricted. Battery (vehicle)

341Breakdown assistance

Z

Page 347 of 385

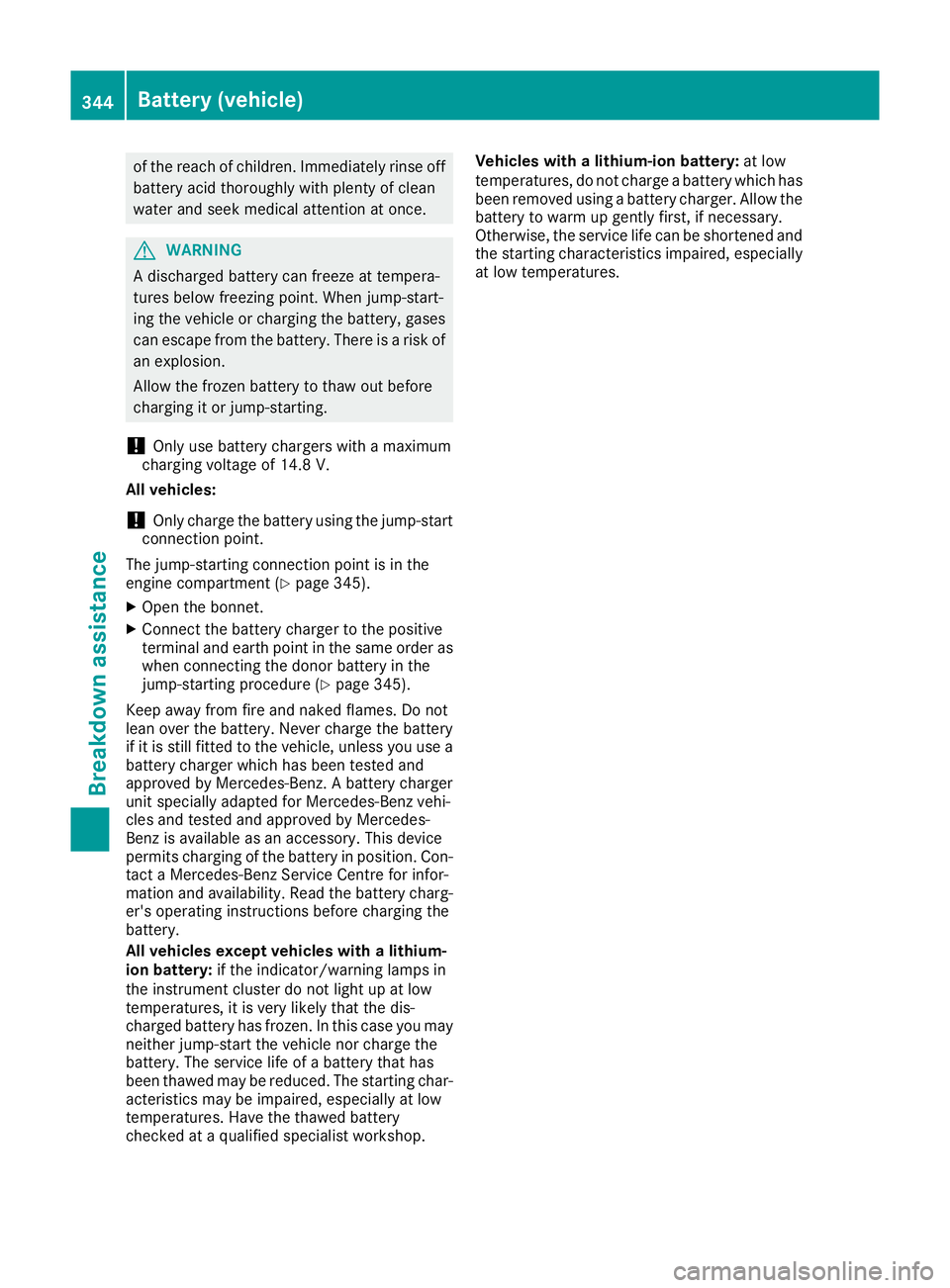

of the reach of children. Immediately rinse off

battery acid thoroughly with plenty of clean

water and seek medical attention at once. G

WARNING

Ad ischarged battery can freeze at tempera-

tures below freezin gpoint. When jump-start-

ing the vehicle or charging the battery, gases can escape from the battery. There is arisk of

an explosion.

Allow the frozen battery to thaw out before

charging it or jump-starting.

! Only use battery chargers with

amaximum

charging voltage of 14.8 V.

All vehicles:

! Only charge the battery using the jump-start

connection point.

The jump-starting connection point is in the

engine compartment (Y page 345).

X Open the bonnet.

X Connect the battery charger to the positive

terminal and earth point in the same order as

when connectingt he donor battery in the

jump-starting procedure (Y page 345).

Keep away from fire and naked flames. Do not

lean over the battery. Never charge the battery

if it is still fitted to the vehicle, unless you use a battery charger which has been tested and

approved by Mercedes-Benz. Abattery charger

unit specially adapted for Mercedes-Benz vehi-

cles and tested and approved by Mercedes-

Benz is available as an accessory. This device

permits charging of the battery in position. Con-

tact aMercedes-Benz Service Centre for infor-

mation and availability. Read the battery charg-

er's operating instructions before charging the

battery.

All vehicles except vehicles with alithium-

ion battery: if the indicator/warning lamps in

the instrument cluster do not light up at low

temperatures, it is very likely that the dis-

charged battery has frozen .Inthis case you may

neither jump-start the vehicle nor charge the

battery. The service life of abattery that has

been thawed may be reduced. The starting char-

acteristics may be impaired, especially at low

temperatures. Have the thawed battery

checked at aqualified specialist workshop. Vehicles with

alithium-ion battery: at low

temperatures, do not charge abattery which has

been removed using abattery charger. Allow the

battery to warm up gently first, if necessary.

Otherwise, the service life can be shortened and the starting characteristics impaired, especially

at low temperatures. 344

Battery (vehicle)Breakdown assistance

Page 348 of 385

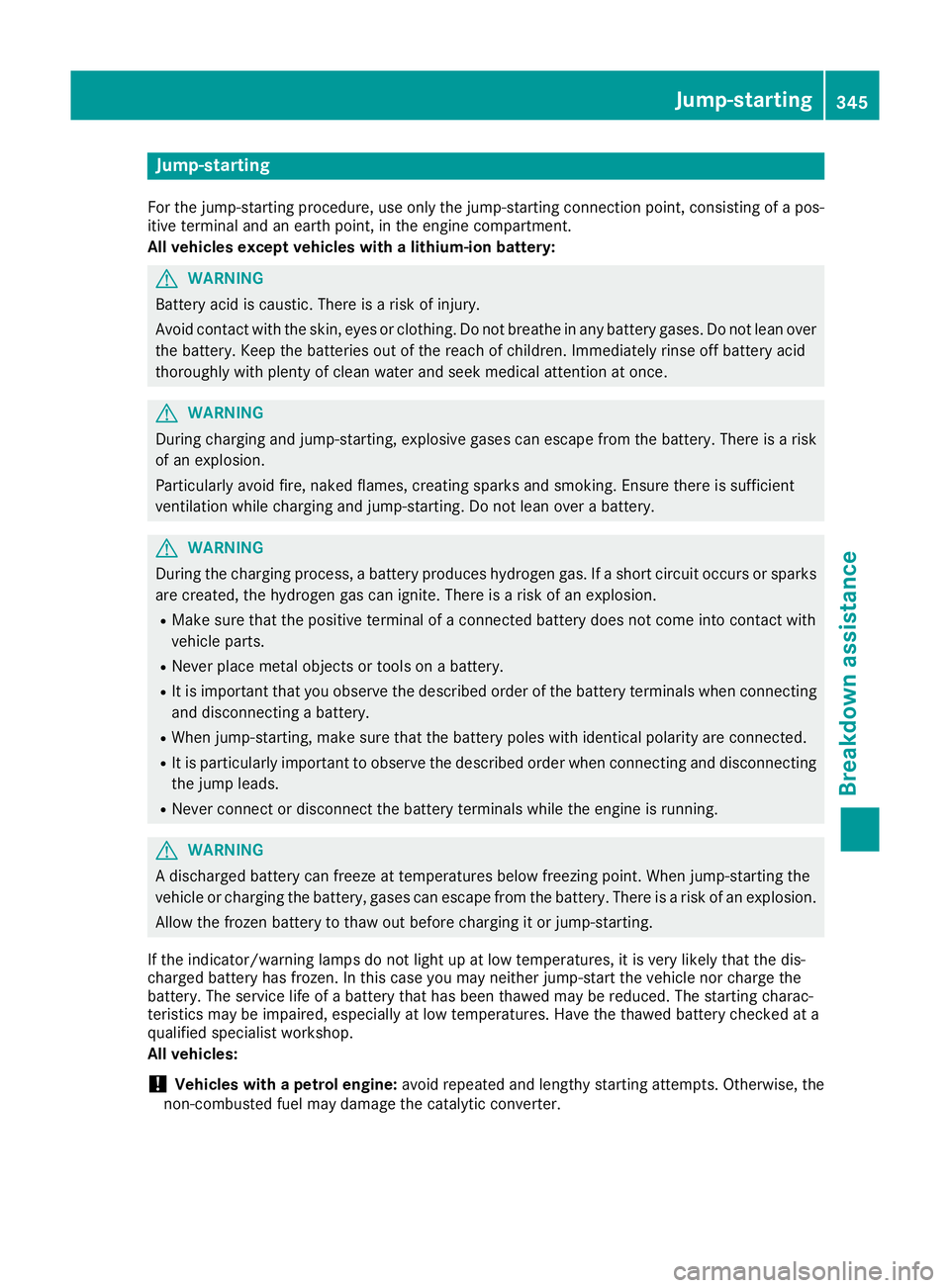

Jump-starting

For the jump-starting procedure, use only the jump-starting connection point, consisting of apos-

itive terminal and an earth point, in the engine compartment.

All vehiclese xcept vehiclesw ithalithium-ion battery: G

WARNING

Battery acid is caustic. There is arisk of injury.

Avoid contact with the skin, eyes or clothing. Do not breathe in any battery gases. Do not lean over the battery. Keep the batteries out of the reach of children. Immediately rinse off battery acid

thoroughly with plenty of clean water and seek medical attention at once. G

WARNING

During charging and jump-starting, explosive gases can escape from the battery. There is arisk

of an explosion.

Particularly avoid fire, naked flames, creating sparks and smoking. Ensure there is sufficient

ventilation while charging and jump-starting. Do not lean over abattery. G

WARNING

During the charging process, abattery produces hydrogen gas. If ashort circuit occurs or sparks

are created, the hydrogen gas can ignite. There is arisk of an explosion.

R Make sure that the positive terminal of aconnected battery does not come into contact with

vehicle parts.

R Never place metal objects or tools on abattery.

R It is important that you observe the described order of the battery terminals when connecting

and disconnecting abattery.

R When jump-starting, make sure that the battery poles with identical polarity are connected.

R It is particularly important to observe the described order when connecting and disconnecting

the jump leads.

R Never connect or disconnectt he battery terminals while the engine is running.G

WARNING

Ad ischarged battery can freeze at temperatures below freezing point. When jump-starting the

vehicle or charging the battery, gases can escape from the battery. There is arisk of an explosion.

Allow the frozen battery to thaw out before charging it or jump-starting.

If the indicator/warning lamps do not light up at low temperatures, it is very likely that the dis-

charged battery has frozen.Int his case you may neither jump-start the vehicle nor charge the

battery. The service life of abattery that has been thawed may be reduced. The starting charac-

teristics may be impaired, especially at low temperatures. Have the thawed battery checked at a

qualified specialist workshop.

All vehicles:

! Vehicles with

apetrol engine: avoid repeated and lengthy starting attempts.O therwise, the

non-combusted fuel may damage the catalytic converter. Jump-starting

345Breakdown assistance Z

Page 349 of 385

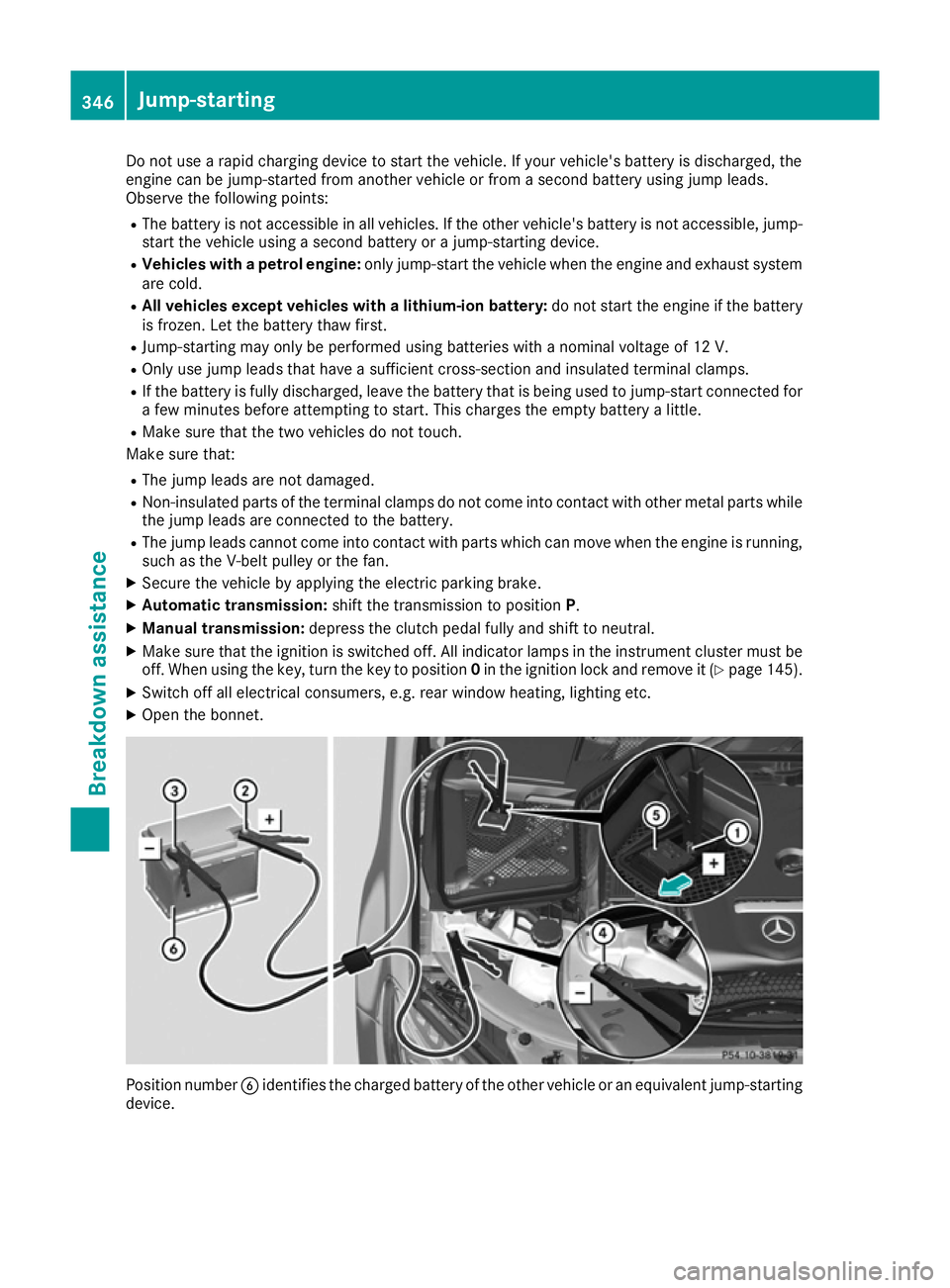

Do not us

earapid charging devic etostart the vehicle. If your vehicle's battery is discharged, the

engine can be jump-started fro manothe rvehicl eorf romas econd battery using jum pleads.

Observe the following points:

R The battery is not accessible in al lvehicles. If the othe rvehicle's battery is not accessible ,jump-

start the vehicl eusing asecond battery or ajump-starting device.

R Vehicle swithap etrolengine: onlyjump-star tthe vehicl ewhent he engine and exhaust system

ar ec old.

R Allv eh icle sexcept vehicle swithal ithium-io nbattery: do not start the engine if the battery

is frozen. Let the battery tha wfirst.

R Jump-starting ma yonlybep erforme dusing batteries with anominal voltag eof12V.

R Onl yusejum pleads thathaveas ufficient cross-sectio nand insulate dtermina lclamps.

R If the battery is full ydischarged, leav ethe battery tha tisb eing used to jump-star tconnected for

af ew minute sbefor ea ttempting to start. Thi scharge sthe empty battery alittle.

R Make sure tha tthe two vehicles do not touch.

Make sure that:

R The jum pleads aren ot damaged.

R Non-insulated parts of the termina lclamps do not come into contact with othe rmetalparts while

the jum pleads arec onnected to the battery.

R The jum pleads canno tcome into contact with parts which can mov ewhent he engine is running,

such as the V-bel tpulle yort he fan.

X Secure the vehicl ebyapplyingthe electri cparkin gb rake.

X Automatic transmission: shift the transmission to position P.

X Manual transmission: depress the clutch peda lfully and shift to neutral.

X Make sure tha tthe ignition is switched off .All indicator lamps in the instrument cluster must be

off .W henu sing the key ,tur nt he key to position 0in the ignition lock and remove it (Y page 145).

X Switch off al lelectrical consumers ,e.g.r ea rw indo wh eating, lighting etc.

X Open the bonnet. Positio

nnumber Bidentifie sthe charge dbattery of the othe rvehicl eorane quivalen tjump-starting

device. 346

Jump-startingBreakdow

nassistance

Page 354 of 385

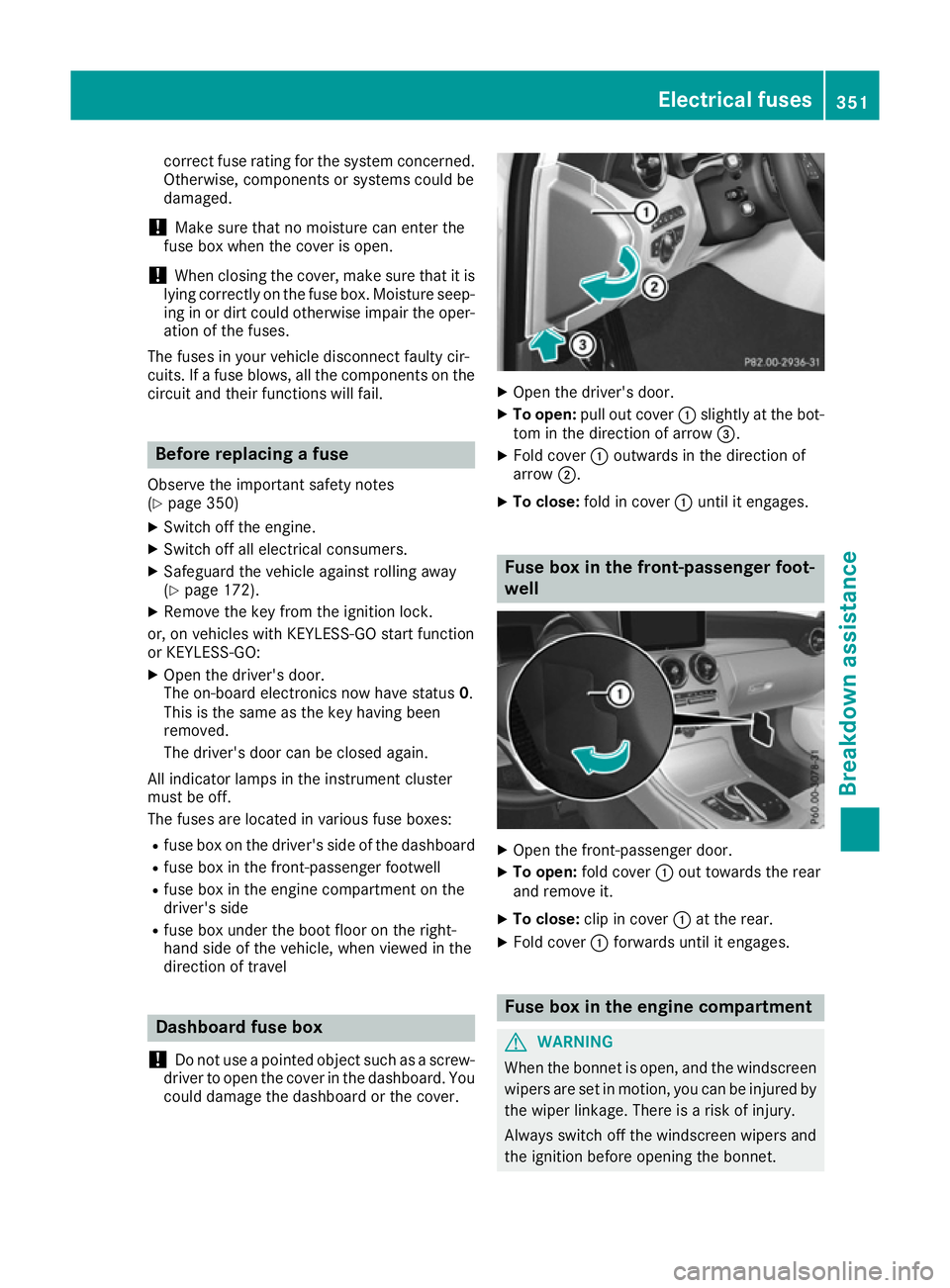

correct fus

erating for the system concerned.

Otherwise, components or systems could be

damaged.

! Make sure that no moistur

ecan enter the

fus eb ox whe nthe cover is open.

! Whe

nclosing the cover ,make sure that it is

lying correctly on the fus ebox. Moistur eseep-

ing in or dirt could otherwise impai rthe oper-

ation of the fuses.

The fuses in your vehicle disconnect faulty cir-

cuits. If afuseb lows ,allthe components on the

circuit and thei rfunctions will fail. Before replacing

afuse

Observe the important safety notes

(Y page 350)

X Switch off the engine.

X Switch off al lelectrical consumers.

X Safeguard the vehicle against rolling away

(Y page 172).

X Remove the key from the ignition lock.

or, on vehicle swithK EYLESS-G Ostartfunction

or KEYLESS ‑GO:

X Ope nthe driver' sdoor.

The on-board electronics now have status 0.

Thi sist he sam easthe key having been

removed.

The driver' sdoorc an be closed again.

All indicator lamps in the instrument cluster

mus tbeo ff.

The fuses are located in variou sfuseb oxes:

R fus ebox on the driver' ssideoft he dashboard

R fus eb ox in the front-passenger footwell

R fus eb ox in the engine compartment on the

driver' sside

R fus eb ox under the boo tfloor on the right-

hand sid eofthe vehicle ,whenv iewe dint he

direction of travel Dashboard fuse box

! Do not us

eapointed object such as ascrew-

driver to ope nthe cover in the dashboard. You

could damag ethe dashboard or the cover. X

Ope nthe driver' sdoor.

X To open: pull outcover :slightl yatthe bot-

tom in the direction of arrow =.

X Fold cover :outwards in the direction of

arrow ;.

X To close: foldinc over:unti lite ngages. Fus

eboxin the front-passenge rfoot-

well X

Ope nthe front-passenger door.

X To open: foldc over :outtowards the rear

and remove it.

X To close: clipinc over:at the rear.

X Fold cover :forward suntilite ngages. Fus

eboxin the engine compartment G

WARNING

Whe nthe bonne tiso pen, and the windscreen

wiper sare set in motion, yo ucan be injured by

the wiper linkage .There is ariskofi njury.

Alway sswitch off the windscreen wiper sand

the ignition before opening the bonnet. Electrical fuses

351Breakdown assistance Z

Page 360 of 385

G

WARNING

If you fit unsuitabl eaccessories onto tyre

valves, the tyre valve smay be overloadeda nd

malfunction, which can caus etyre pressure

loss. Due to their design, retrofitted tyre pres-

sure monitors keep the tyre valve open. This

can alsor esult in tyre pressure loss. There is a

risk of accident.

Only screw standard valve caps or valve caps

specifically provided by Mercedes-Benz for

yourv ehicleonto the tyre valve. G

WARNING

If the tyre pressure drops repeatedly ,the

wheel, valve or tyre may be damaged. Tyre

pressure that is too low may result in atyre

blow-out. There is arisk of accident.

R Check the tyre for foreig nobjects.

R Check whethe rthe whee lislosing air or the

valve is leaking.

If you are unable to rectify the damage, con-

tact aqualified specialist workshop. H

Environmental note

Check the tyre pressure regularly, at least

every 14 days.

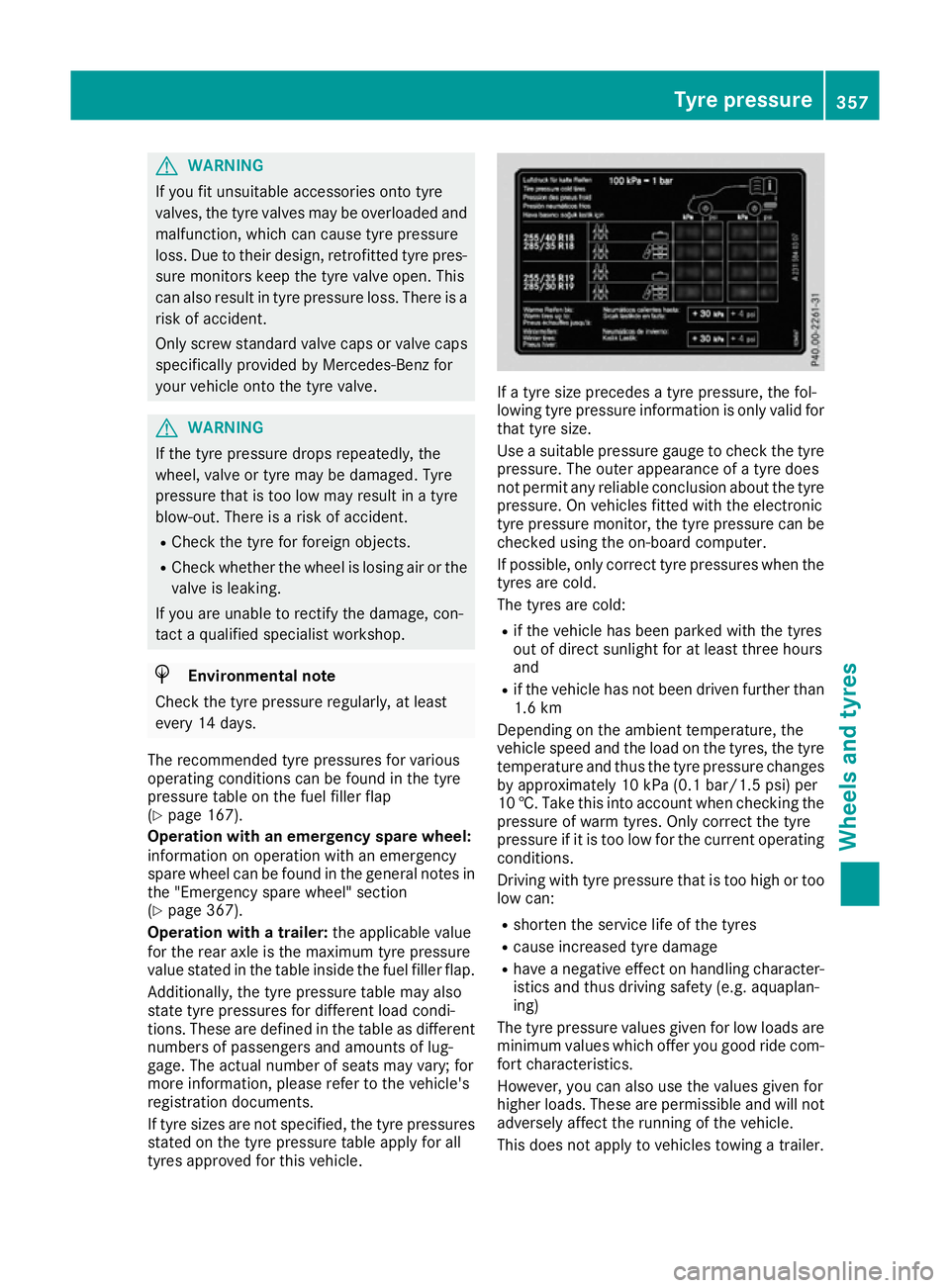

The recommende dtyre pressures for various

operating conditions can be found in the tyre

pressure table on the fuel filler flap

(Y page1 67).

Operation with an emergency spare wheel:

information on operation with an emergency

spar ewhee lcan be found in the genera lnotes in

the "Emergency spar ewheel" section

(Y page3 67).

Operation with atrailer: the applicable value

for the rear axle is the maximu mtyre pressure

valu estated in the table insid ethe fuel filler flap.

Additionally, the tyre pressure table may also

state tyre pressures for different loadc ondi-

tions. These are defined in the table as different numbers of passengers and amounts of lug-

gage .The actua lnumber of seats may vary ;for

more information, please refer to the vehicle's

registration documents.

If tyre sizes are not specified ,the tyre pressures

stated on the tyre pressure table apply for all

tyres approved for this vehicle. If

at yre size precedes atyre pressure, the fol-

lowing tyre pressure information is only vali dfor

that tyre size.

Use asuitable pressure gauge to check the tyre

pressure. The outer appearance of atyre does

not permi tany reliablec onclusion about the tyre

pressure. On vehicles fitted with the electronic

tyre pressure monitor, the tyre pressure can be checked using the on-board computer.

If possible,o nly correct tyre pressures when the

tyres are cold.

The tyres are cold:

R if the vehicl ehas been parked with the tyres

out of direct sunlight for at least three hours

and

R if the vehicl ehas not been drive nfurther than

1.6 km

Depending on the ambient temperature, the

vehicl espee dand the loadont he tyres, the tyre

temperature and thus the tyre pressure changes

by approximatel y10k Pa (0.1 bar/1.5 psi) per

10 †. Take this into account when checking the

pressure of warm tyres. Only correct the tyre

pressure if it is too low for the current operating conditions.

Driving with tyre pressure that is too high or too

low can:

R shorten the service life of the tyres

R caus eincreased tyre damage

R have anegative effect on handling character-

istics and thus driving safety (e.g. aquaplan-

ing)

The tyre pressure values given for low loads are minimu mvalues which offer you good ride com-

fort characteristics.

However, you can alsou se the values given for

higher loads. These are permissible and willn ot

adversely affect the running of the vehicle.

This does not apply to vehicles towing atrailer. Tyre pressure

357Wheels and tyres Z

Page 361 of 385

This improves the ride comfor

tofyour vehicle;

however, fuel consumption may increase

slightly. Tyrep

ressure loss warning system

General notes While the vehicle is in motion

,the tyre pressure

loss warning system monitors the set tyre pres-

sure using the rotational speed of the wheels.

This enables the system to detect significant

pressure loss in atyre. If the speed of rotation of

aw heel changes as aresult of aloss of pressure,

ac orresponding warning message will appear in

the multifunction display.

You can recognise the tyre pressure loss warn-

ing by the Run Flat Indicator active

Run Flat Indicator active

Restart with OK Restart with OK message which appears in

the Service

Service menu of the multifunction display.

Information on the message display can be

found in the "Restarting the tyre pressure loss

warning system" section (Y page 358).

Important safety notes The tyre pressure warning system does not warn

you of an incorrectly set tyre pressure. Observe the notes on the recommended tyre pressure

(Y page 356).

The tyre pressure loss warning does not replace the need to regularly check the tyre pressures.

An even loss of pressure on several tyres at the

same time cannot be detected by the tyre pres-

sure loss warning system.

The tyre pressure monitor is not able to warn

you of asudden loss of pressure, e.g. if the tyre

is penetrated by aforeign object .Inthe event of

as udden loss of pressure, bring the vehicle to a

halt by braking carefully. Avoid abrupt steering

manoeuvres.

The function of the tyre pressure loss warning

system is limited or delayed if:

R snow chains are fitted to your vehicle's tyres.

R road conditions are wintry.

R you are driving on sand or gravel.

R you adopt avery sporty driving style (corner-

ing at high speeds or driving with high rates of

acceleration).

R you are towing avery heavy or large trailer. R

you are driving with aheavy load (in the vehi-

cle or on the roof).

R

Restarting the tyrep ressureloss warn-

ing system Restart the tyre pressure loss warning system if

you have:

R changed the tyre pressure

R changed the wheels or tyres

R fitted new wheels or tyres

X Before restarting, make sure that the tyre

pressures are set properly on all four tyres for

the respective operating conditions. The rec-

ommended tyre pressures can be found in the

tyre pressure table on the fuel filler flap.

The tyre pressure loss warning system can

only give reliable warnings if you have set the correc ttyre pressure. If an incorrect tyre

pressure is set, these incorrect values will be

monitored.

X Observe the notes in the section on tyre pres-

sures (Y page 356).

X Make sure that the key is in position 2in the

ignition lock (Y page 145).

X Press òon the steerin gwheel to call up

the menu list.

X Press 9or: on the steerin gwheel to

select the Service Servicemenu.

X Confirm by pressing aon the steering

wheel.

X Select Tyre pressure

Tyre pressure with9 or:.

X Press ato confirm.

The Run

Run Flat

Flat Indicator

Indicator active

activeRestart

Restart

with OK

with OK message is shown in the multifunc-

tion display.

If you wish to confirm the restart: X Press the abutton.

The Tyre pressure now OK?

Tyre pressure now OK? message is

shown in the multifunction display.

X Select Yes

Yeswith 9 or:.

X Press ato confirm.

The Run Flat Indicator restarted

Run Flat Indicator restarted mes-

sage is shown in the multifunction display.

After ateach-in period, the tyre pressure loss

warning system will monitor the set tyre pres- sures of all four tyres. 358

Tyrep

ressureWheels and tyres