lock MERCEDES-BENZ CLS COUPE 2018 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: CLS COUPE, Model: MERCEDES-BENZ CLS COUPE 2018Pages: 589, PDF Size: 10.95 MB

Page 410 of 589

Re

moving the fire extinguisher &

WARNING Risk of accident due toan

incor rectly secu redfire extinguisher in

th e driver's foot we ll

A fire extinguisher in the driver's foot we ll

may impede pedal tra vel or block a

depressed pedal.

This jeopardises the operating and road

saf ety of theve hicle.

Moreo ver,th efire extinguisher can be flung

around in the driver's foot we ll and injure the

driver or other vehicle occupants. #

Alw aysst ore and secure thefire extin‐

guisher in the brac ket du ring the jour‐

ne y. #

Do not remo vethefire extinguisher

while driving. #

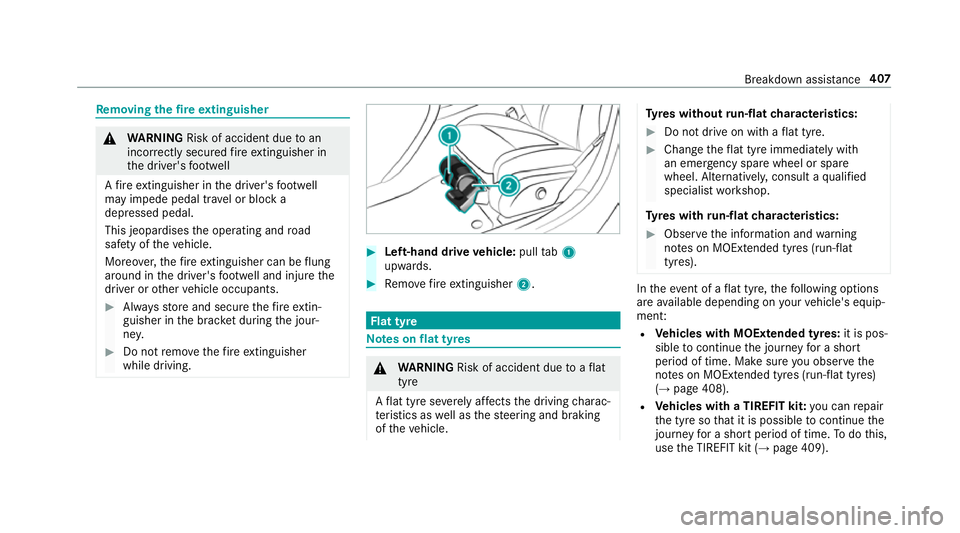

Left-hand drive vehicle: pulltab1

upwards. #

Remo vefire extinguisher 2. Flat tyre

Note

s onflat tyres &

WARNING Risk of accident due toaflat

tyre

A flat tyre se verely affects the driving charac‐

te rist ics as well as thesteering and braking

of theve hicle. Ty

res without run-flat characteristics: #

Do not drive on with a flat tyre. #

Chan getheflat tyre immediately with

an emer gency spa rewheel or spare

wheel. Alternativel y,consult a qualified

specialist workshop.

Ty res with run-flat characteristics: #

Obse rveth e information and warning

no tes on MOExtended tyres (run-flat

tyres). In

theeve nt of a flat tyre, thefo llowing options

are available depending on your vehicle's equip‐

ment:

R Vehicles with MOExtended tyres: it is pos‐

sible tocontinue the journey for a short

period of time. Make sure you obse rvethe

no tes on MOExtended tyres (run-flat tyres)

(→ page 408).

R Vehicles with a TIREFIT kit: you can repair

th e tyre so that it is possible tocontinue the

jou rney for a short period of time. Todo this,

use the TIREFIT kit (→ page 409). Breakdown assis

tance 407

Page 416 of 589

&

WARNING Risk of accident due tothe

specified tyre pressure not being ach‐

ie ved

If th e specified tyre pressure is not achie ved

af te r a brief drive, the tyre is too badly dam‐

aged. The tyre sealant cannot repair the tyre

in this ins tance.

Dama ged tyres and a tyre pressure that is

to o low can significantly impair braking and

handling characteristics. #

Do not drive on. #

Consult a qualified specialist workshop. Countries

that ha veMercedes-Benz

Service24h: you will find a sticke r with thete le‐

phone number, e.g. on the B‑pillar on the driver's

side. #

Cor rect the tyre pressure if it is still at least

13 0 kPa (1.3 bar/19 psi). See the tyre pres‐

sure table on the fuel filler flap forva lues. #

Toincrease the ty repressure: switch on

th e tyre inflation compressor. #

Toreduce the tyre pressure: press pres‐

su re re lease button 1next tomanome ter

2 . #

When the tyre pressure is cor rect, unscr ew

th efilling hose from theva lve of the sealed

tyre. #

Screw theva lve cap onto theva lve of the

sealed tyre. #

Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filling hose stay s on the tyre sealant bot‐

tle. #

Drive tothe nearest qualified specialist work‐

shop and ha vethe tyre, tyre sealant bottle

and filling hose replaced there. Batte

ry(vehicle) Note

s onthe12 V battery &

WARNING Risk of an accident due to

wo rkcar ried out incor rectly on the bat‐

te ry

Wo rkcar ried out incor rectly on the battery

can, forex ample, lead toa short circuit. This

can lead tofunction restrictions in saf ety-re l‐

eva nt sy stems, e.g. the lighting sy stem, ABS

(anti-lock braking sy stem) or ESP ®

(Elec‐

tronic Stability Prog ram). The operating

saf ety of your vehicle may be restricted.

Yo u could lose cont rol of theve hicle in the

fo llowing situations:

R when braking

R intheeve nt of ab rupt steering manoeu‐

vres and/or when theve hicle's speed is

not adap tedto thero ad conditions Breakdown assis

tance 413

Page 424 of 589

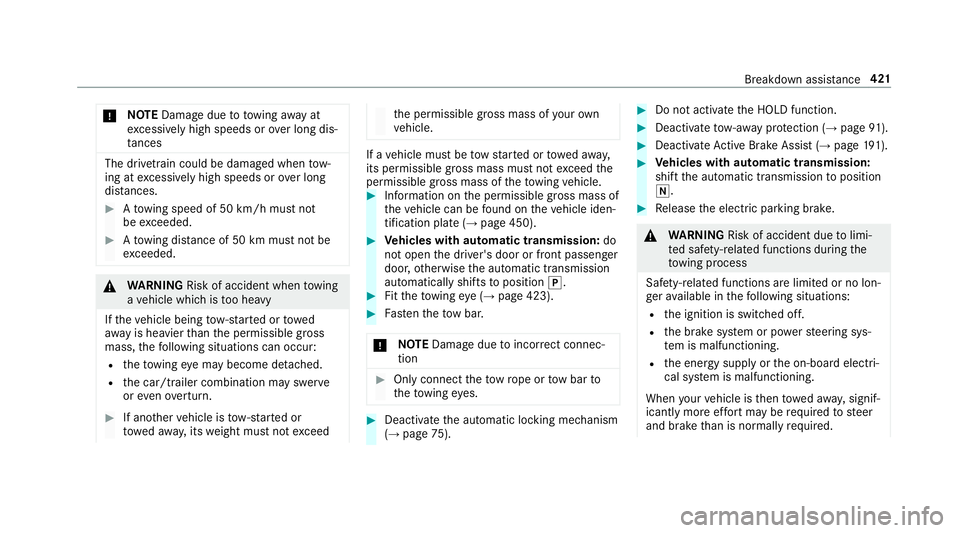

*

NO

TEDama gedue to to wing away at

exc essively high speeds or over long dis‐

ta nces The driv

etra in could be damaged when tow‐

ing at excessively high speeds or over long

dis tances. #

Atowing speed of 50 km/h must not

be exc eeded. #

Atowing dis tance of 50 km must not be

exc eeded. &

WARNING Risk of accident when towing

a ve hicle which is too heavy

If th eve hicle being tow- star ted or towed

aw ay is heavier than the permissible gross

mass, thefo llowing situations can occur:

R theto wing eye may become de tach ed.

R the car/t railer combination may swer ve

or eve nove rturn. #

If ano ther vehicle is tow- star ted or

to we daw ay, its weight must not exceed th

e permissible gross mass of your own

ve hicle. If a

vehicle must be tow star ted or towe daw ay,

its permissible gross mass must not exceed the

permissible gross mass of theto wing vehicle. #

Information on the permissible gross mass of

th eve hicle can be found on theve hicle iden‐

tification plate (→ page 450). #

Vehicles with automatic transmission: do

not open the driver's door or front passenger

door, otherwise the automatic transmission

automatically shifts toposition j. #

Fittheto wing eye (→ page 423). #

Fasten theto w bar.

* NO

TEDama gedue toincor rect connec‐

tion #

Only connect theto w rope or tow bar to

th eto wing eyes. #

Deactivate the automatic locking mechanism

(→ page 75). #

Do not activate the HOLD function. #

Deactivate tow- aw ay protection (→ page91). #

Deactivate Active Brake Assi st (→page 191). #

Vehicles with automatic transmission:

shift the automatic transmission toposition

i. #

Release the electric parking brake. &

WARNING Risk of accident due tolimi‐

te d saf ety-re lated functions during the

to wing process

Saf ety-re lated functions are limited or no lon‐

ge rav ailable in thefo llowing situations:

R the ignition is switched off.

R the brake sy stem or po werst eering sys‐

te m is malfunctioning.

R the energy supply or the on-board electri‐

cal sy stem is malfunctioning.

When your vehicle is then towe daw ay, signif‐

icantly more ef fort may be requ ired tosteer

and brake than is no rmally requ ired. Breakdown assis

tance 421

Page 426 of 589

*

NO

TEDama getotheve hicle from secur‐

ing it incor rectly #

After loading, theve hicle must be

secured on all four wheels. Otherwise,

th eve hicle could be damaged. #

A minimum dis tance of 20 cm up wards

and 10cm down wards must be kept to

th e transport platform. #

Secure theve hicle on all four wheels af ter

loading.

4MATIC vehicles/ vehicles with automatic

transmission #

Make sure that the front and rear axles come

to rest on the same transpor tation vehicle.

* NO

TEDama getothe driv etra in due to

incor rect positioning #

Do not position theve hicle abo vethe

connection point of the transport vehi‐

cle. To

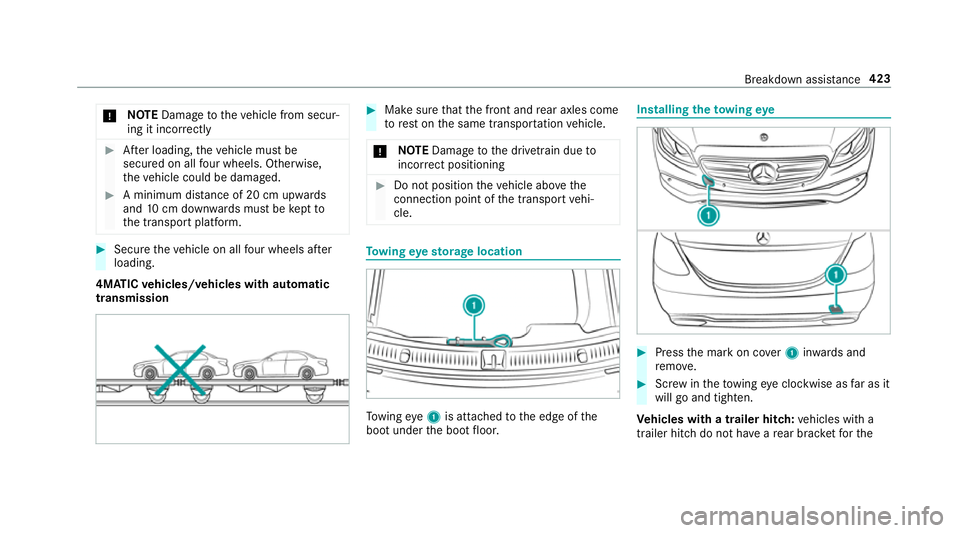

wing eyesto rage location To

wing eye1 is attached tothe edge of the

boot under the boot floor. Installing

theto wing eye #

Press the mark on co ver1 inwa rds and

re mo ve. #

Screw intheto wing eyeclockwise as far as it

will go and tighten.

Ve hicles with a trailer hitch: vehicles with a

trailer hitch do not ha veare ar brac ketfo rthe Breakdown assis

tance 423

Page 444 of 589

R

The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Apply the electric parking brake manually. #

Movethe front wheels tothest ra ight-ahead

position. #

Vehicles with automatic transmission:

shift into position j. #

Vehicles with le vel control sy stem: setthe

normal vehicle le vel (→ page 212). #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel you wish tochange. #

Remo vethe hub caps if necessary

(→ page 441). #

Raise theve hicle (→ page442). Re

moving and fitting hub caps Re

quirements:

R The vehicle is prepared for a wheel change

(→ page 440).

Plas tic hub cap #

Toremo ve:turn the cent recover of the hub

cap anti-clockwise and remo vethe hub cap. #

Tofit: make sure that the cent recover of the

hub cap is turned anti-clockwise. #

Position the hub cap and turn the cent re

co ver clockwise until the hub cap engages

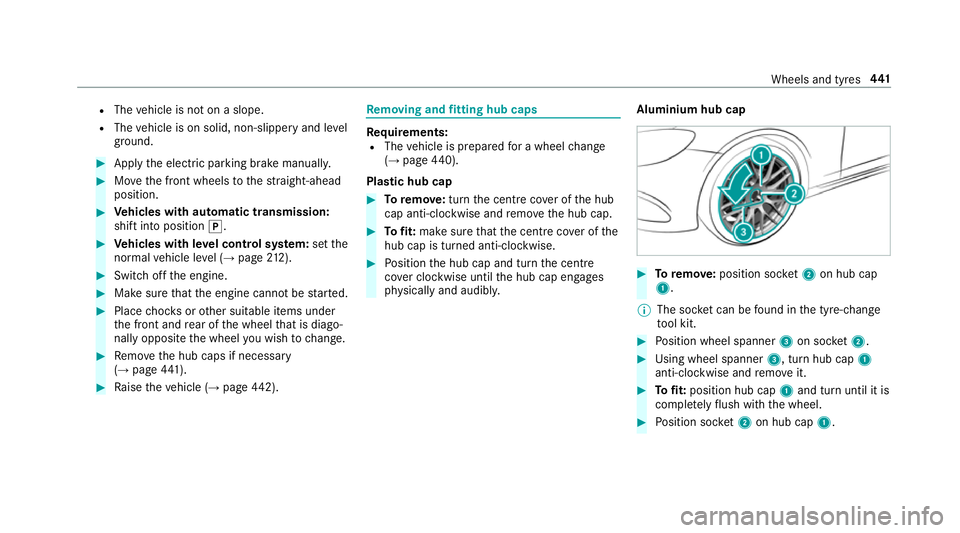

ph ysically and audibly. Aluminium hub cap #

Toremo ve:position soc ket2 on hub cap

1.

% The soc ket can be found in the tyre-change

to ol kit. #

Position wheel spanner 3on soc ket2. #

Using wheel spanner 3, turn hub cap1

anti-clo ckwise and remo veit. #

Tofit: position hub cap 1and turn until it is

comple tely flush with the wheel. #

Position soc ket2 on hub cap 1. Wheels and tyres

441

Page 445 of 589

#

Attach wheel spanner 3tosoc ket2 and

tighten the hub cap clockwise.

Specified tightening torq ue: 25 Nm. #

Raise theve hicle (→ page442). Ra

ising theve hicle when changing a wheel Re

quirements:

R There are no persons in theve hicle.

R The vehicle has been prepared for a wheel

ch ange (→ page440).

R The hub caps ha vebeen remo ved

( → page 441).

Impo rtant no tes on using the jack:

R Only use theve hicle-specific jack that has

been tested and appr oved byMercedes-Benz

to raise theve hicle.

R The jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle. R

The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

fl at, load-bearing, non-slip unde rlay.

R The foot ofthe jack must be positioned verti‐

cally under the jacking point. Ru

les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Do not lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or the boot

lid. #

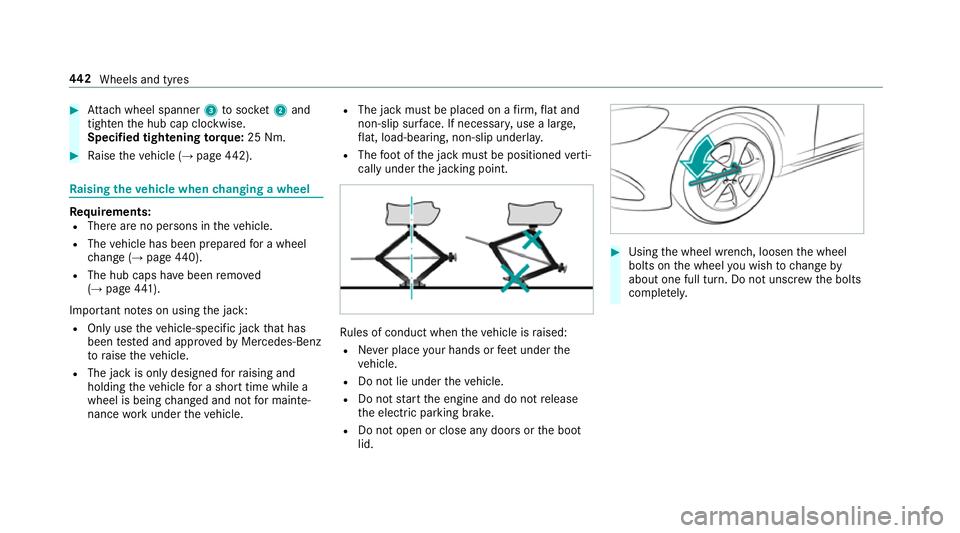

Using the wheel wrench, loosen the wheel

bolts on the wheel you wish tochange by

about one full turn. Do not unscr ewthe bolts

comple tely. 442

Wheels and tyres

Page 446 of 589

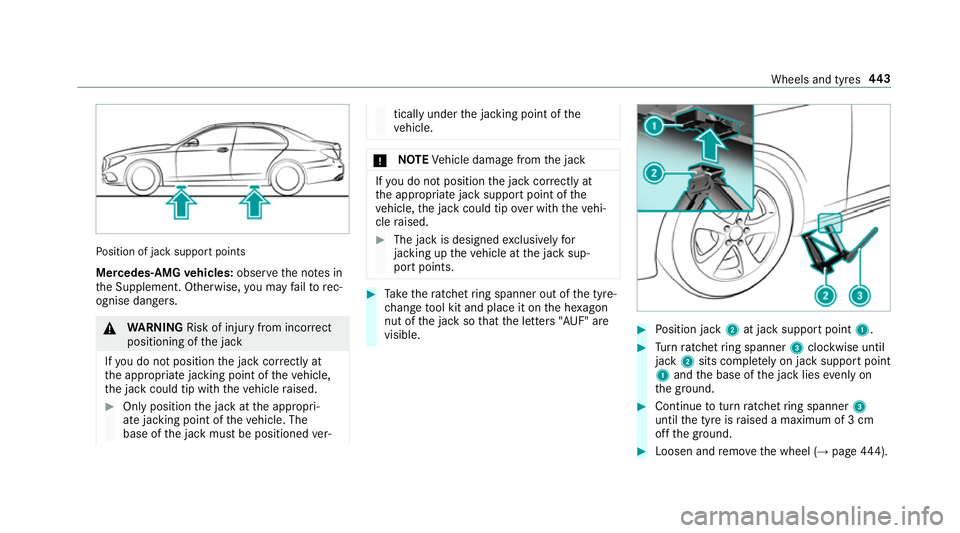

Po

sition of jack support points

Mercedes-AMG vehicles: observeth e no tes in

th e Supplement. Otherwise, you may failto rec‐

ognise dangers. &

WARNING Risk of inju ryfrom incor rect

positioning of the jack

If yo u do not position the jack cor rectly at

th e appropriate jacking point of theve hicle,

th e jack could tip with theve hicle raised. #

Only position the jack at the appropri‐

ate jacking point of theve hicle. The

base of the jack must be positioned ver‐ tically under

the jacking point of the

ve hicle. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at

th e appropriate jack support point of the

ve hicle, the jack could tip over with theve hi‐

cle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. #

Take thera tchet ring spanner out of the tyre-

ch ange tool kit and place it on the he xagon

nut of the jack so that the letters "AUF" are

visible. #

Position jack 2at jack support point 1. #

Turn ratchet ring spanner 3clockwise until

jack 2sits comple tely on ja cksupport point

1 and the base of the jack lies evenly on

th e ground. #

Continue toturn ratchet ring spanner 3

until the tyre is raised a maximum of 3 cm

off the ground. #

Loosen and remo vethe wheel (→ page444). Wheels and tyres

443

Page 448 of 589

#

Slide the wheel tobe mounted onto the cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

Be sure toobser vethe instructions and

saf ety no tes on "Changing a wheel"

(→ page 436). #

For saf etyre asons, on lyuse wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question. #

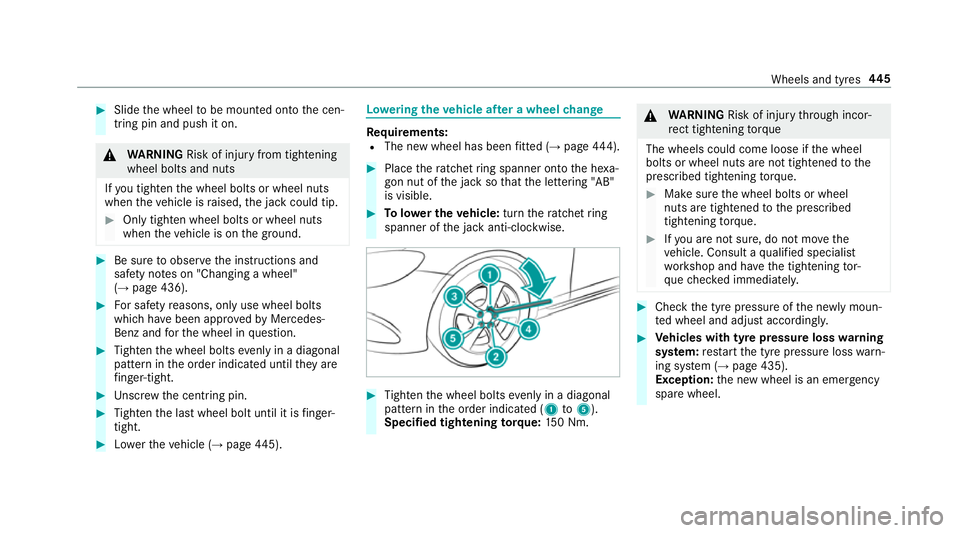

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated until they are

fi nger-tight. #

Unscr ew the cent ring pin. #

Tighten the last wheel bolt until it is finger-

tight. #

Lowe rth eve hicle (→ page445). Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted (→ page 444 ). #

Place thera tchet ring spanner onto the he xa‐

gon nut of the jack so that the lettering "AB"

is visible. #

Tolowe r the vehicle: turnthera tchet ring

spanner of the jack anti-clockwise. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated (1 to5 ).

Specified tightening torq ue: 150 Nm. &

WARNING Risk of inju rythro ugh incor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed tightening torque. #

Makesure the wheel bolts or wheel

nuts are tightened tothe prescribed

tightening torque. #

Ifyo u are not sure, do not mo vethe

ve hicle. Consult a qualified specialist

wo rkshop and ha vethe tightening tor‐

qu ech ecked immediately. #

Check the tyre pressure of the newly moun‐

te d wheel and adjust according ly. #

Vehicles with tyre pressure loss warning

sy stem: restart the tyre pressure loss warn‐

ing sy stem (→ page 435).

Exception: the new wheel is an emer gency

spa rewheel. Wheels and tyres

445

Page 464 of 589

tic su

rfaces, e.g. MB SummerFit or MB

Wi nterFit. *

NO

TEBlocked spr aynozzles caused by

mixing windscreen washer fluids #

Do not mix MB SummerFit and MB Win‐

te rFit with other windscreen washer flu‐

ids. Do not use distilled or de-ionised

water asthefill

le ve l sensor may be triggered er roneously.

Re commended windscreen washer fluid:

R Abo vefreezing point: e.g. MB SummerFit

R Below freezing point: e.g. MB WinterFit

Fo rth e cor rect mixing ratio, referto the informa‐

tion on the antif reeze contai ner.

Mix thewa sher fluid with the windscreen washer

fl uid all year round. Ve

hicle data Ve

hicle dimensions The heights speci

fied may vary as a result of the

fo llowing factors:

R tyres

R load

R condition of the suspension

R optional equipment Te

ch nical da ta461

Page 469 of 589

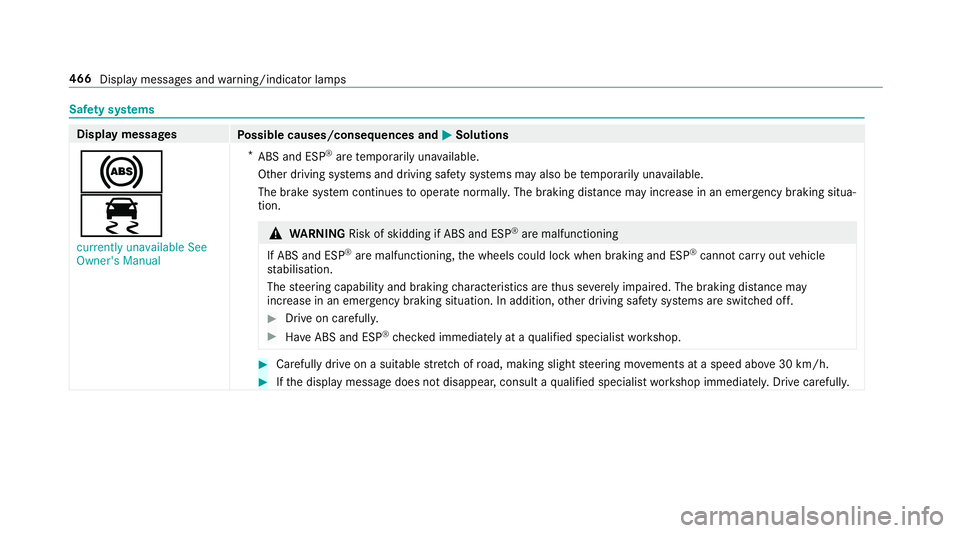

Saf

ety sy stems Display messages

Possible causes/consequences and M

MSolutions

!

÷ currently unavailable See

Owner's Manual *

ABS and ESP ®

are temp orarily una vailable.

Other driving sy stems and driving saf ety sy stems may also be temp orarily una vailable.

The brake sy stem continues tooperate normally. The braking dis tance may increase in an emergency braking situa‐

tion. &

WARNING Risk of skidding if ABS and ESP ®

are malfunctioning

If ABS and ESP ®

are malfunctioning, the wheels could lock when braking and ESP ®

cann otcar ryout vehicle

st abilisation.

The steering capability and braking characteristics are thus se verely impaired. The br aking distance may

increase in an emergency braking situation. In addition, other driving saf ety sy stems are switched off. #

Drive on carefull y. #

Have ABS and ESP ®

ch ecked immediately at a qualified specialist workshop. #

Carefully drive on a suitable stre tch of road, making slight steering mo vements at a speed abo ve30 km/h. #

Ifth e display message does not disappear, consult a qualified specialist workshop immediately. Drive carefully. 466

Display messages and warning/indicator lamps