clock MERCEDES-BENZ E-CLASS COUPE 2017 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-CLASS COUPE, Model: MERCEDES-BENZ E-CLASS COUPE 2017Pages: 541, PDF Size: 10.71 MB

Page 104 of 541

3

Stow age compartment in the front cent re

console wi tha USB port (depending on the

ve hicle's equipment)

4 Glovebox

Locking/unlocking thegl ove box

Obser vethe no tes on loading theve hicle

(→ page 99). #

Turn the emer gency key a quarter turn clock‐

wise 2(to lock) or anti-clockwise 1(to

unlock).

Opening the spectacles compa rtment

Obse rveth e no tes on loading theve hicle

(→ page 99). #

Toopen: press button 1. Th

rough-loading feature in there ar ben ch

seat Fo

lding there ar seat backrest forw ards &

WARNING Risk of inju ryifth ere ar

ben chseat/rear seat and seat backrest

are not engaged

If th ere ar ben chseat/rear seat and seat

backrest are not engaged they could fold for‐

wa rds, e.g. when braking suddenly or in the

ev ent of an accident.

R Ifth is is the case, theve hicle occupant

wo uld be forc ed into the seat belt bythe

re ar ben chseat/rear seat or bythe seat

backrest. The seat belt cann otprotect as

intended and could result in additional

injur y.

R Objects or loads in the boot cann otbe

re stra ined bythe seat backrest. #

Make sure that the seat backrest and

th ere ar ben chseat/rear seat are

engaged before everytrip. Seats and

stowing 101

Page 160 of 541

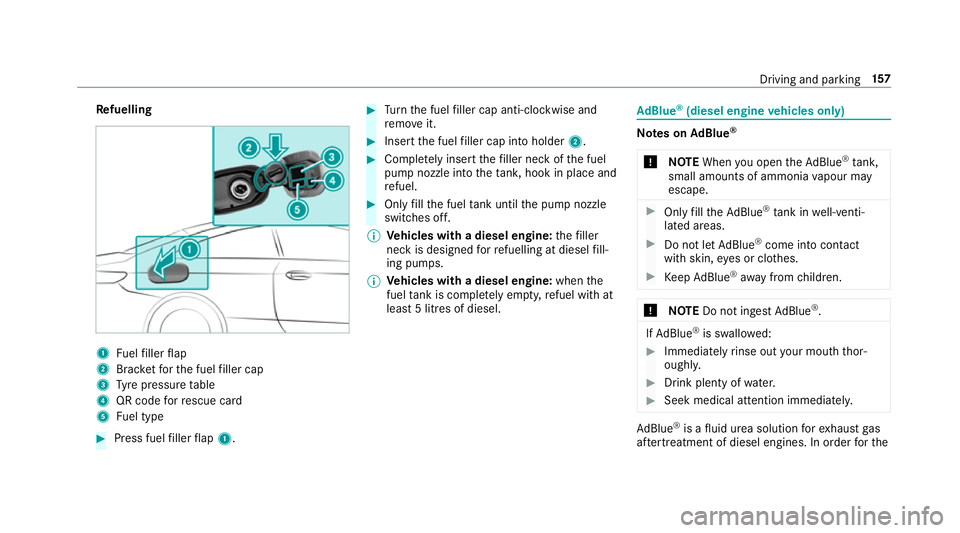

Re

fuelling 1

Fuelfiller flap

2 Brac ketfo rth e fuel filler cap

3 Tyre pressure table

4 QR code forre scue card

5 Fuel type #

Press fuel filler flap 1. #

Turn the fuel filler cap anti-clockwise and

re mo veit. #

Insert the fuel filler cap into holder 2. #

Comple tely inse rtthefiller neck of the fuel

pump nozzle into theta nk, hook in place and

re fuel. #

Only fill th e fuel tank until the pump nozzle

switches off.

% Vehicles with a diesel engine: thefiller

neck is designed forre fuelling at diesel fill‐

ing pumps.

% Vehicles with a diesel engine: whenthe

fuel tank is compl etely em pty, refuel with at

lea st5 litres of diesel. Ad

Blue ®

(diesel engine vehicles only) Note

s onAdBlue ®

* NOTEWhen you open theAd Blue ®

tank,

small amounts of ammonia vapour may

escape. #

Only fill th eAd Blue ®

tank in well-venti‐

lated areas. #

Do not let AdBlue ®

come into contact

wi th skin, eyes or clo thes. #

Keep AdBlue ®

aw ay from children. *

NOTEDo not ingest AdBlue ®

. If

Ad Blue ®

is swallo wed: #

Immediately rinse out your mouth thor‐

oughl y. #

Drink plenty of water. #

Seek medical attention immediately. Ad

Blue ®

is a fluid urea solution forex haust gas

af te rtre atment of diesel engines. In order forthe Driving and pa

rking 157

Page 162 of 541

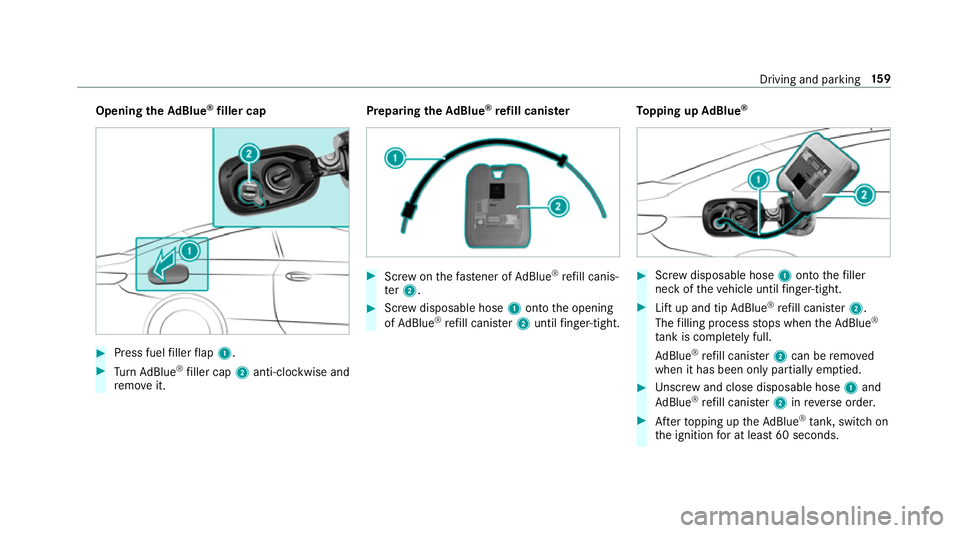

Opening

theAd Blue ®

filler cap #

Press fuel filler flap 1. #

Turn AdBlue ®

filler cap 2anti-clockwise and

re mo veit. Preparing

theAd Blue ®

re fill canis ter #

Screw onthefast ener of AdBlue ®

re fill canis‐

te r2. #

Screw disposable hose 1onto the opening

of Ad Blue ®

re fill canis ter2 until finger-tight. To

pping up AdBlue ® #

Screw disposable hose 1onto thefiller

neck of theve hicle until finger-tight. #

Lift up and tip AdBlue ®

re fill canis ter2.

The filling process stops when theAd Blue ®

ta nk is compl etely full.

Ad Blue ®

re fill canis ter2 can be remo ved

when it has been only partially em ptied. #

Unscr ew and close disposable hose 1and

Ad Blue ®

re fill canis ter2 inreve rse order. #

Afterto pping up theAd Blue ®

tank, switch on

th e ignition for at least 60 seconds. Driving and parking

15 9

Page 233 of 541

Re

quirements:

Before coupling up the trailer, the ball neck must

be fully extended and engaged in the securely

loc ked position.

Tr ailers with a 7-pin plug can be connec tedto

th eve hicle:

R adap ter plug

R adapte r cable

In order forth e trailer tobe recognised bythe

ve hicle:

R the electrical connection must be set up cor‐

re ctly

R the trailer lighting sy stem must be in working

order

The operation of thefo llowing sy stems depends

on the trailer being connected cor rectly:

R ESP ®

R Parking Assist PARKTRONIC

R Parking Pilot

R Blind Spot Assist or Active Blind Spot Assi st

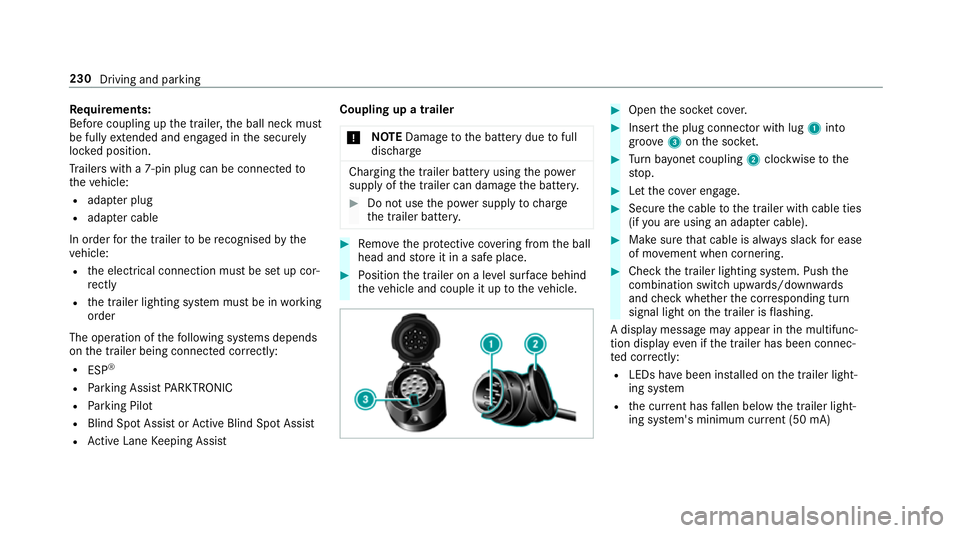

R Active Lane Keeping Assist Coupling up a trailer

* NO

TEDama getothe battery due tofull

discharge Charging

the trailer battery using the po wer

supply of the trailer can damage the batter y. #

Do not use the po wer supp lyto charge

th e trailer batter y. #

Remo vethe pr otective co vering from the ball

head and store it in a safe place. #

Position the trailer on a le vel sur face behind

th eve hicle and couple it up totheve hicle. #

Open the soc ket co ver. #

Insert the plug connector with lug 1into

groo ve3 onthe soc ket. #

Turn bayonet coupling 2clockwise tothe

st op. #

Let the co ver engage. #

Secure the cable tothe trailer with cable ties

(if you are using an adap ter cable). #

Make sure that cable is alw ays slack for ease

of mo vement when cornering. #

Check the trailer lighting sy stem. Push the

combination switch up wards/down wards

and check whe ther the cor responding turn

signal light on the trailer is flashing.

A display message may appear in the multifunc‐

tion display even if the trailer has been connec‐

te d cor rectly:

R LEDs ha vebeen ins talled on the trailer light‐

ing sy stem

R the cur rent has fallen below the trailer light‐

ing sy stem's minimum cur rent (50 mA) 230

Driving and pa rking

Page 361 of 541

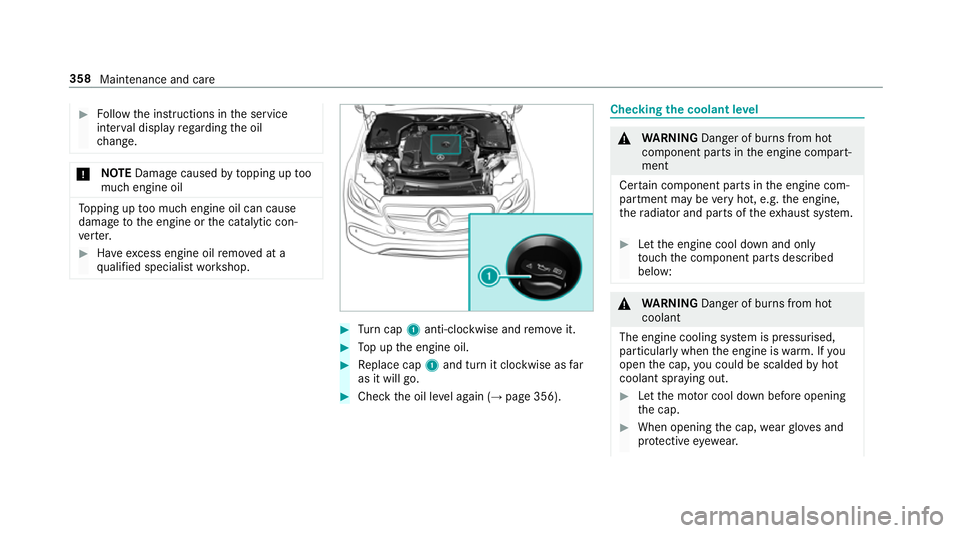

#

Follow the instructions in the service

inter val display rega rding the oil

ch ange. *

NO

TEDama gecaused bytopping up too

much engine oil To

pping up too much engine oil can cause

damage tothe engine or the catalytic con‐

ve rter. #

Have excess engine oil remo ved at a

qu alified specialist workshop. #

Turn cap 1anti-clockwise and remo veit. #

Top up the engine oil. #

Replace cap 1and turn it clockwise as far

as it will go. #

Check the oil le vel again (→ page 356). Checking

the coolant le vel &

WARNING Danger of bu rns from hot

component parts in the engine compart‐

ment

Cer tain component parts in the engine com‐

partment may be very hot, e.g. the engine,

th era diator and parts of theex haust sy stem. #

Let the engine cool down and only

to uch the component parts described

below: &

WARNING Danger of bu rns from hot

coolant

The engine cooling sy stem is pressurised,

particularly when the engine is warm. If you

open the cap, you could be scalded byhot

coolant spr aying out. #

Let the mo tor cool down before opening

th e cap. #

When opening the cap, wearglove s and

pr otective eyew ear. 358

Maintenance and care

Page 362 of 541

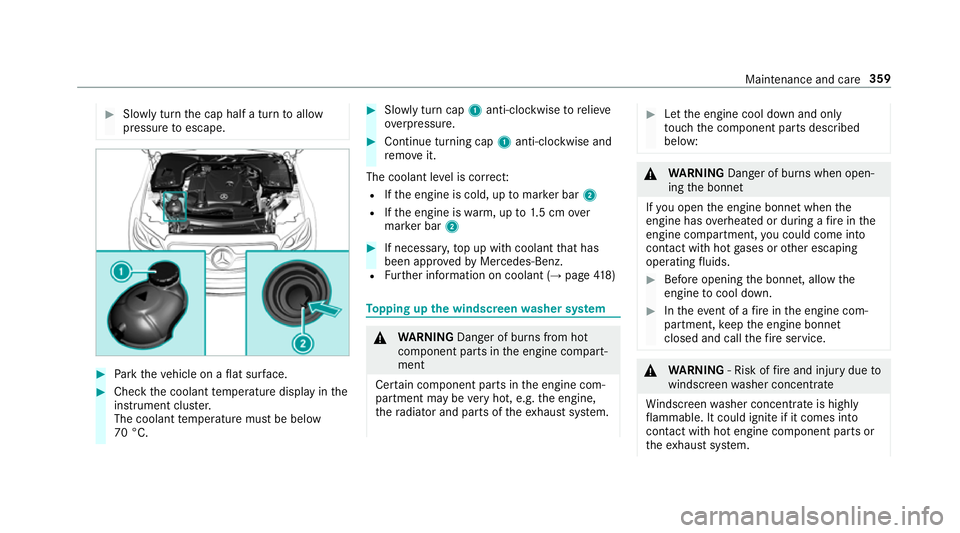

#

Slowly turn the cap half a turn toallow

pressure toescape. #

Park theve hicle on a flat sur face. #

Check the coolant temp erature display in the

instrument clus ter.

The coolant temp erature must be below

70 °C. #

Slowly turn cap 1anti-clockwise torelie ve

ov erpressure. #

Continue turning cap 1anti-clockwise and

re mo veit.

The coolant le vel is cor rect:

R Ifth e engine is cold, up tomar ker bar 2

R Ifth e engine is warm, up to1.5 cm over

mar ker bar 2 #

If necessar y,top up with coolant that has

been appr ovedby Mercedes-Benz.

R Further information on coolant (→ page418) To

pping up the windsc reen washer sy stem &

WARNING Danger of bu rns from hot

component parts in the engine compart‐

ment

Cer tain component parts in the engine com‐

partment may be very hot, e.g. the engine,

th era diator and parts of theex haust sy stem. #

Let the engine cool down and only

to uch the component parts described

below: &

WARNING Danger of bu rns when open‐

ing the bonn et

If yo u open the engine bonn etwhen the

engine has overheated or during a fire inthe

engine compartment, you could come into

contact with hot gases or other escaping

operating fluids. #

Before opening the bonn et, allow the

engine tocool down. #

Intheeve nt of a fire inthe engine com‐

partment, keep the engine bonn et

closed and call thefire service. &

WARNING ‑ Risk of fire and injury due to

windscreen washer concentrate

Wi ndsc reen washer concentrate is highly

fl ammable. It could ignite if it comes into

con tact wi thhot engine component parts or

th eex haust sy stem. Maintenance and care

359

Page 387 of 541

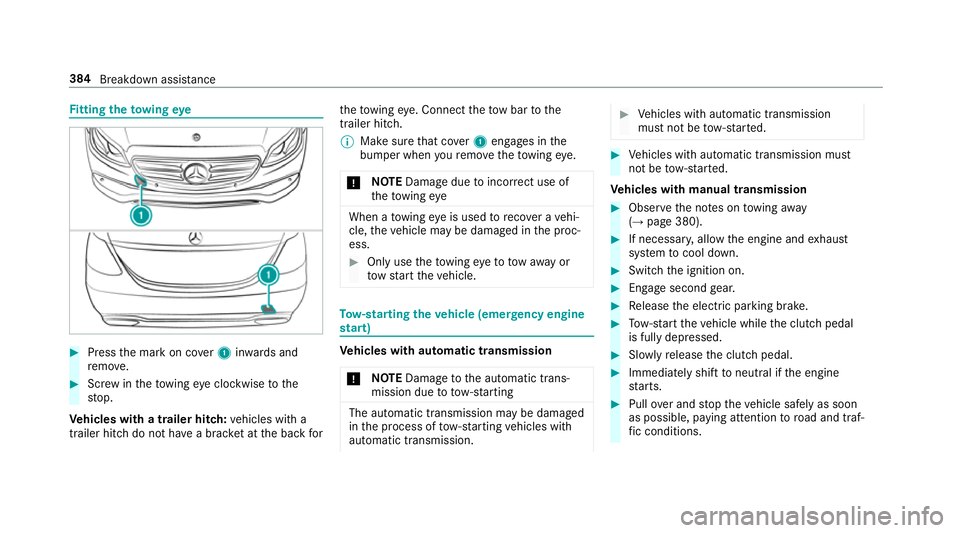

Fi

tting the towing eye #

Press the mark on co ver1 inwa rds and

re mo ve. #

Screw intheto wing eyeclockwise tothe

st op.

Ve hicles with a trailer hitch: vehicles with a

trailer hitch do not ha vea brac ket at the back forth

eto wing eye. Connect theto w bar tothe

trailer hitch.

% Makesure that co ver1 engages in the

bumper when youre mo vetheto wing eye.

* NO

TEDama gedue toincor rect use of

th eto wing eye When a

towing eye is used toreco ver a vehi‐

cle, theve hicle may be damaged in the proc‐

ess. #

Only use theto wing eyeto to waw ay or

to w start theve hicle. To

w- starting theve hicle (eme rgency engine

st art) Ve

hicles with automatic transmission

* NO

TEDama getothe automatic trans‐

mission due to tow-starting The automatic transmission may be damaged

in the process of tow- starting vehicles with

automatic transmission. #

Vehicles with automatic transmission

must not be tow- star ted. #

Vehicles with automatic transmission must

not be tow- star ted.

Ve hicles with manual transmission #

Obser vethe no tes on towing away

( → page 380). #

If necessar y,allow the engine and exhaust

sy stem tocool down. #

Switch the ignition on. #

Enga gesecond gear. #

Release the electric parking brake. #

Tow- start theve hicle while the clutch pedal

is fully depressed. #

Slowly release the clutch pedal. #

Immediately shift toneutral if the engine

st arts. #

Pull over and stop theve hicle safely as soon

as possible, paying attention toroad and traf‐

fi c conditions. 384

Breakdown assis tance

Page 404 of 541

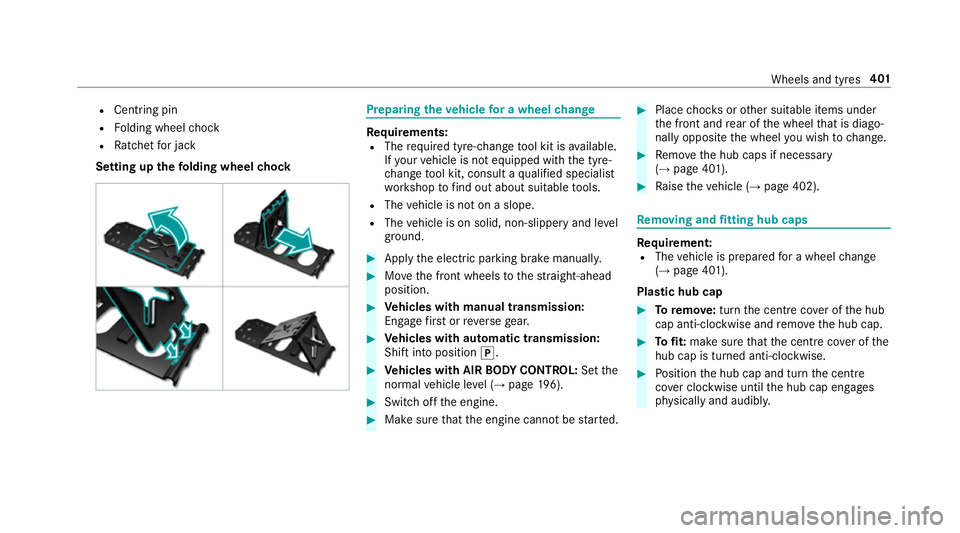

R

Centring pin

R Folding wheel chock

R Ratchet for jack

Setting up thefo lding wheel chock Prepa

ring theve hicle for a wheel change Re

quirements:

R The requ ired tyre-change tool kit is available.

If yo ur vehicle is not equipped with the tyre-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Apply the electric parking brake manually. #

Movethe front wheels tothest ra ight-ahead

position. #

Vehicles with manual transmission:

Engage firs t or reve rsege ar. #

Vehicles with automatic transmission:

Shift into position j. #

Vehicles with AIR BODY CONT ROL:Set the

normal vehicle le vel (→ page 196). #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel you wish tochange. #

Remo vethe hub caps if necessary

(→ page 401). #

Raise theve hicle (→ page 402). Re

moving and fitting hub caps Re

quirement:

R The vehicle is prepared for a wheel change

(→ page 401).

Pla stic hub cap #

Toremo ve:turn the cent recover of the hub

cap anti-clockwise and remo vethe hub cap. #

Tofit: make sure that the cent recover of the

hub cap is turned anti-clockwise. #

Position the hub cap and turn the cent re

co ver clockwise until the hub cap engages

ph ysically and audibly. Wheels and tyres

401

Page 405 of 541

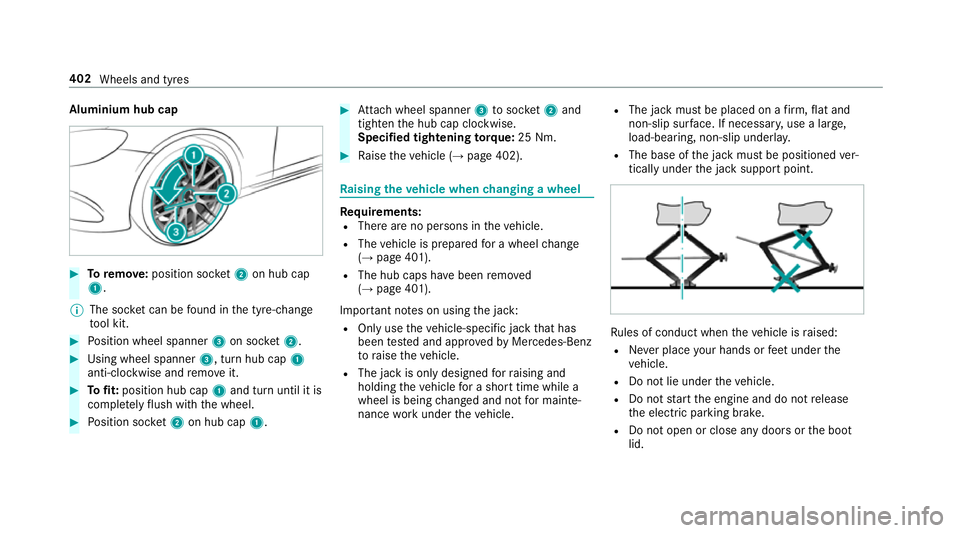

Aluminium hub cap

#

Toremo ve:position soc ket2 on hub cap

1.

% The soc ket can be found in the tyre-change

to ol kit. #

Position wheel spanner 3on soc ket2. #

Using wheel spanner 3, turn hub cap1

anti-clo ckwise and remo veit. #

Tofit: position hub cap 1and turn until it is

comple tely flush with the wheel. #

Position soc ket2 on hub cap 1. #

Attach wheel spanner 3tosoc ket2 and

tighten the hub cap clockwise.

Specified tightening torq ue: 25 Nm. #

Raise theve hicle (→ page 402). Ra

ising theve hicle when changing a wheel Re

quirements:

R There are no persons in theve hicle.

R The vehicle is prepared for a wheel change

(→ page 401).

R The hub caps ha vebeen remo ved

( → page 401).

Impor tant no tes on using the jack:

R Only use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle.

R The jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle. R

The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

load-bearing, non-slip underla y.

R The base of the jack must be positioned ver‐

tically under the jack support point. Ru

les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Do not lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or the boot

lid. 402

Wheels and tyres

Page 407 of 541

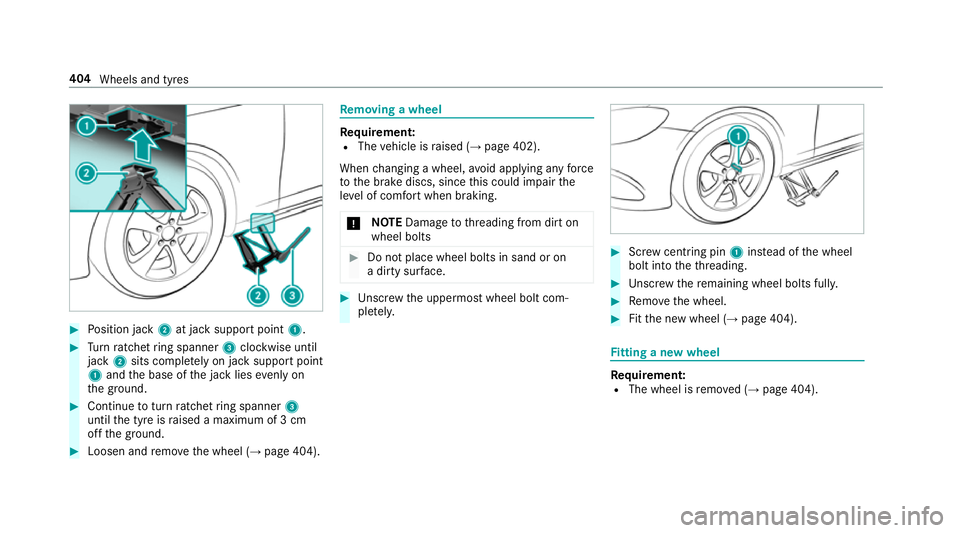

#

Position jack 2at jack support point 1.#

Turn ratchet ring spanner 3clockwise until

jack 2sits comple tely on ja cksupport point

1 and the base of the jack lies evenly on

th e ground. #

Continue toturn ratchet ring spanner 3

until the tyre is raised a maximum of 3 cm

off the ground. #

Loosen and remo vethe wheel (→ page 404). Re

moving a wheel Re

quirement:

R The vehicle is raised (→ page 402).

When changing a wheel, avoid applying any force

to the brake discs, since this could impair the

le ve l of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the uppermost wheel bolt com‐

ple tely. #

Screw centring pin 1instead of the wheel

bolt into theth re ading. #

Unscr ew there maining wheel bolts fully. #

Remo vethe wheel. #

Fitthe new wheel (→ page 404). Fi

tting a new wheel Re

quirement:

R The wheel is remo ved (→ page 404). 404

Wheels and tyres