MERCEDES-BENZ E-CLASS SALOON 2008 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2008, Model line: E-CLASS SALOON, Model: MERCEDES-BENZ E-CLASS SALOON 2008Pages: 401, PDF Size: 6.89 MB

Page 321 of 401

Flat tyre

318 Make sure that the jack is placed on a firm,

non-slip, level surface. Do not use wooden

blocks or similar as jacking supports. Oth-

erwise, the jack will not be able to achieve

its load-bearing capacity due to the restric-

ted height.

Do not start the engine at any time while

the wheel is being changed.

Do not lie under the vehicle when it is being

supported by the jack. If you do not raise

the vehicle as described, it could slip off the

jack (e.g. if the engine is started or a door

or the boot lid/tailgate is opened or closed)

and you could sustain serious injuries. Using the TIREFIT kit

You can use the TIREFIT kit to seal small

punctures, particularly those in the tyre tread.

You can use TIREFIT in outdoor temperatures

down to -20 °C. G

Risk of accident

In the following situations, your safety is at

particular risk and TIREFIT is unable to pro-

vide breakdown assistance: R

if there are cuts or punctures in the tyre

greater than 4 mm

R if the wheel rim is damaged

R if you have driven at very low tyre pres-

sures or on a flat tyre

Do not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required.

Mercedes-Benz recommends that you use

a Mercedes-Benz Service Centre for this

purpose. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist work-

shop.

X Do not remove any foreign objects which

have penetrated the tyre, e.g. screws or

nails.

X Remove TIREFIT, the accompanying "max.

80 km/h "sticker and the electric air pump

from the stowage well underneath the

boot/luggage compartment floor

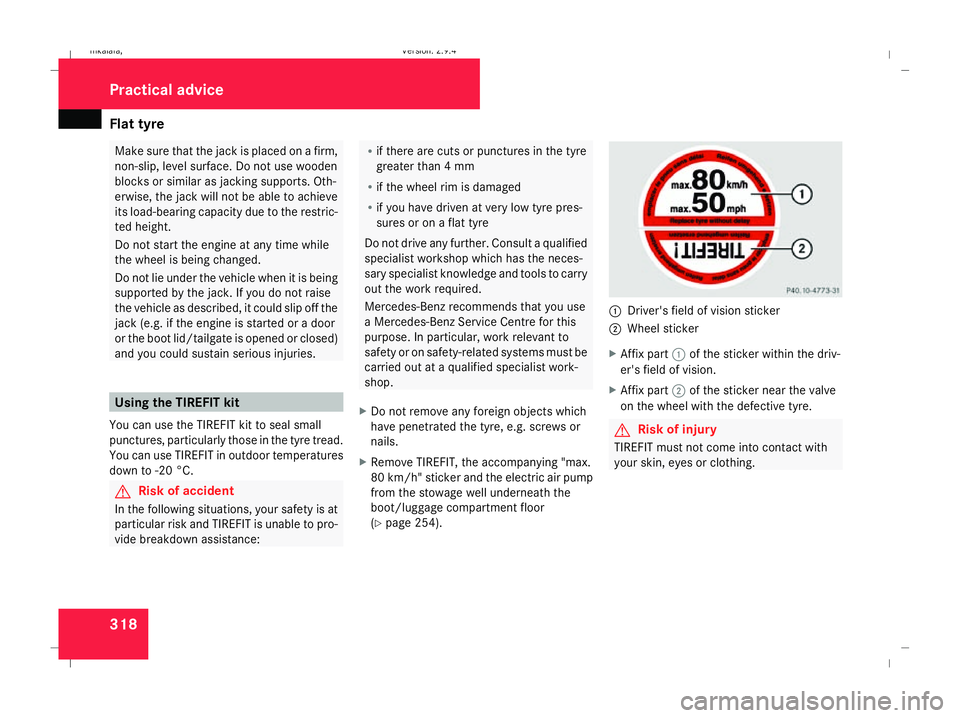

(Y page 254). 1

Driver's field of vision sticker

2 Wheel sticker

X Affix part 1of the sticker within the driv-

er's field of vision.

X Affix part 2of the sticker near the valve

on the wheel with the defective tyre. G

Risk of injury

TIREFIT must not come into contact with

your skin, eyes or clothing. Practical advice

211_AKB; 2; 5, en-GB

mkalafa

, Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 318Dateiname: 6515_3416_02_buchblock.pdf; preflight

Page 322 of 401

Flat tyre

319R

If TIREFIT comes into contact with your

eyes or skin, immediately rinse thor-

oughly with clean water.

R Change out of clothing which has come

into contact with TIREFIT immediately.

R If an allergic reaction occurs, consult a

doctor immediately.

Keep TIREFIT away from children.

R If TIREFIT is swallowed, immediately

rinse your mouth out thoroughly with

water and drink plenty of water.

R Do not induce vomiting. Consult a doctor

immediately.

R Do not inhale TIREFIT fumes.

i If TIREFIT leaks out, allow it to dry. It can

then be removed like a layer of film.

If you get TIREFIT on your clothing, have it

cleaned as soon as possible with perchloro-

ethylene. G

Risk of injury

Comply with the manufacturer's safety

instructions shown on the sticker on the

electric air pump. i

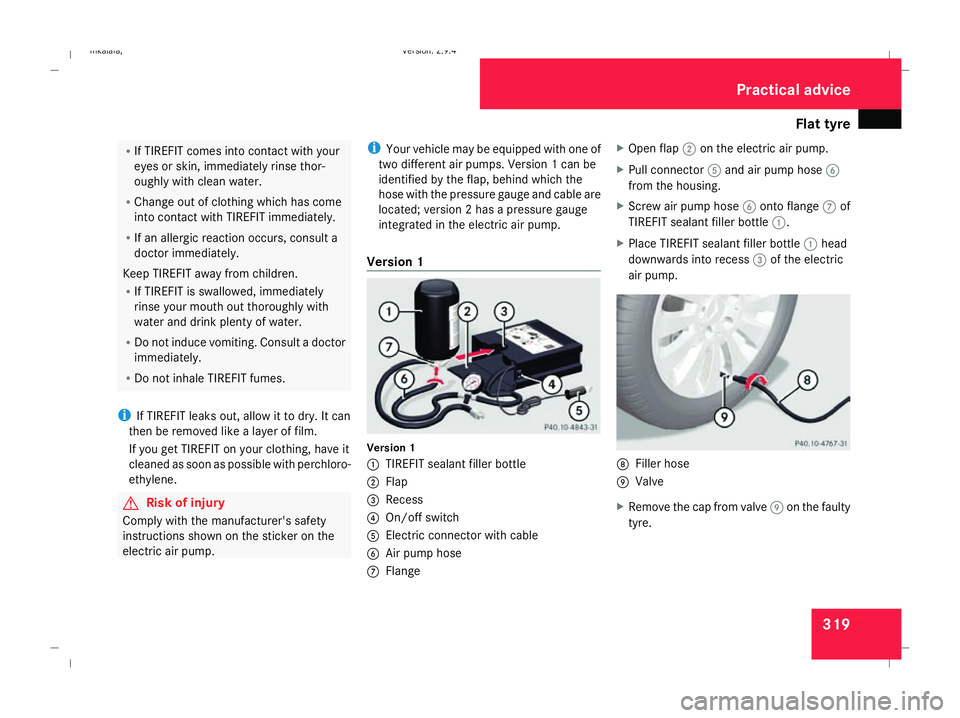

Your vehicle may be equipped with one of

two different air pumps. Version 1 can be

identified by the flap, behind which the

hose with the pressure gauge and cable are

located; version 2 has a pressure gauge

integrated in the electric air pump.

Version 1 Version 1

1

TIREFIT sealant filler bottle

2 Flap

3 Recess

4 On/off switch

5 Electric connector with cable

6 Air pump hose

7 Flange X

Open flap 2on the electric air pump.

X Pull connector 5and air pump hose 6

from the housing.

X Screw air pump hose 6onto flange 7of

TIREFIT sealant filler bottle 1.

X Place TIREFIT sealant filler bottle 1head

downwards into recess 3of the electric

air pump. 8

Filler hose

9 Valve

X Remove the cap from valve 9on the faulty

tyre. Practical advice

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 319 ZDateiname: 6515_3416_02_buchblock.pdf; preflight

Page 323 of 401

Flat tyre

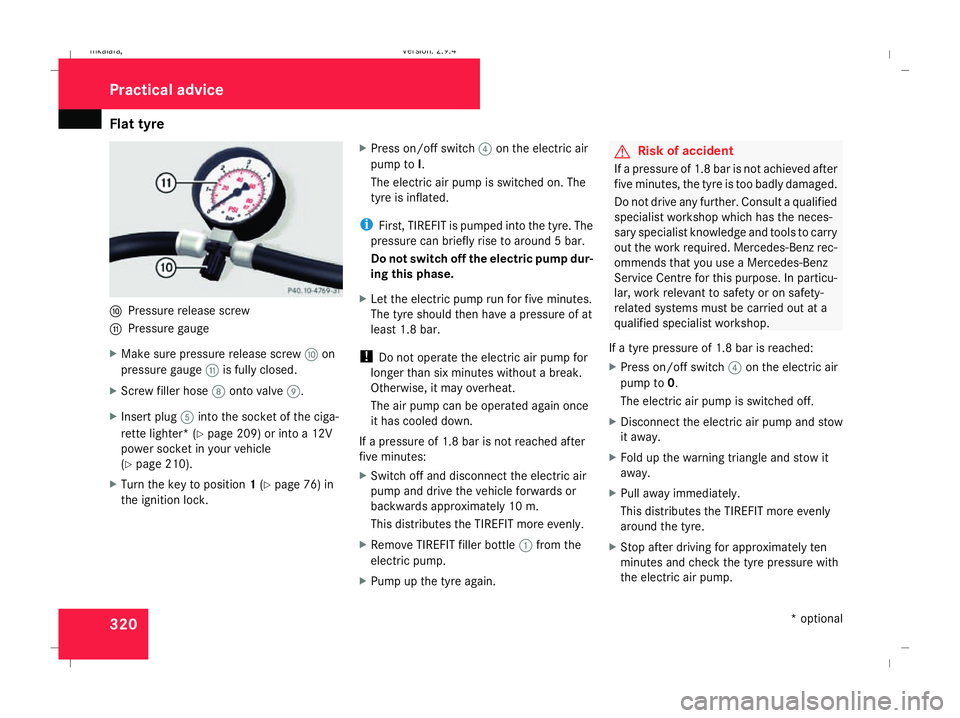

320a

Pressure release screw

b Pressure gauge

X Make sure pressure release screw aon

pressure gauge bis fully closed.

X Screw filler hose 8onto valve 9.

X Insert plug 5into the socket of the ciga-

rette lighter* (Y page 209) or into a 12V

power socket in your vehicle

(Y page 210).

X Turn the key to position 1(Y page 76) in

the ignition lock. X

Press on/off switch 4on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

i First, TIREFIT is pumped into the tyre. The

pressure can briefly rise to around 5 bar.

Do not switch off the electric pump dur-

ing this phase.

X Let the electric pump run for five minutes.

The tyre should then have a pressure of at

least 1.8 bar.

! Do not operate the electric air pump for

longer than six minutes without a break.

Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down.

If a pressure of 1.8 bar is not reached after

five minutes:

X Switch off and disconnect the electric air

pump and drive the vehicle forwards or

backwards approximately 10 m.

This distributes the TIREFIT more evenly.

X Remove TIREFIT filler bottle 1from the

electric pump.

X Pump up the tyre again. G

Risk of accident

If a pressure of 1.8 bar is not achieved after

five minutes, the tyre is too badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

qualified specialist workshop.

If a tyre pressure of 1.8 bar is reached:

X Press on/off switch 4on the electric air

pump to 0.

The electric air pump is switched off.

X Disconnect the electric air pump and stow

it away.

X Fold up the warning triangle and stow it

away.

X Pull away immediately.

This distributes the TIREFIT more evenly

around the tyre.

X Stop after driving for approximately ten

minutes and check the tyre pressure with

the electric air pump. Practical advice

* optional

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 320Dateiname: 6515_3416_02_buchblock.pdf; preflight

Page 324 of 401

Flat tyre

321G

Risk of accident

If the tyre pressure is now lower than

1.3 bar, the tyre is too badly damaged. Do

not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

qualified specialist workshop.

X If the tyre pressure is still at least 1.3 bar,

correct it (see fuel filler flap for values).

To increase the tyre pressure: switch on

the electric air pump.

To reduce the tyre pressure: open pres-

sure release screw aon pressure

gauge b.

X Drive to the nearest workshop and have the

tyre changed there.

X Have the TIREFIT kit replaced as soon as

possible at a qualified specialist workshop,

e.g. at a Mercedes-Benz Service Centre. G

Risk of accident

Do not exceed the maximum speed of 80

km/h.

The “max. 80 km/h” sticker must be affixed

within the driver's field of vision.

The vehicle's handling characteristics may

be affected. H

Environmental note

Have the used TIREFIT kit disposed of pro-

fessionally, e.g. at a Mercedes-Benz

Service Centre.

X Have the TIREFIT kit replaced every four

years at a qualified specialist workshop,

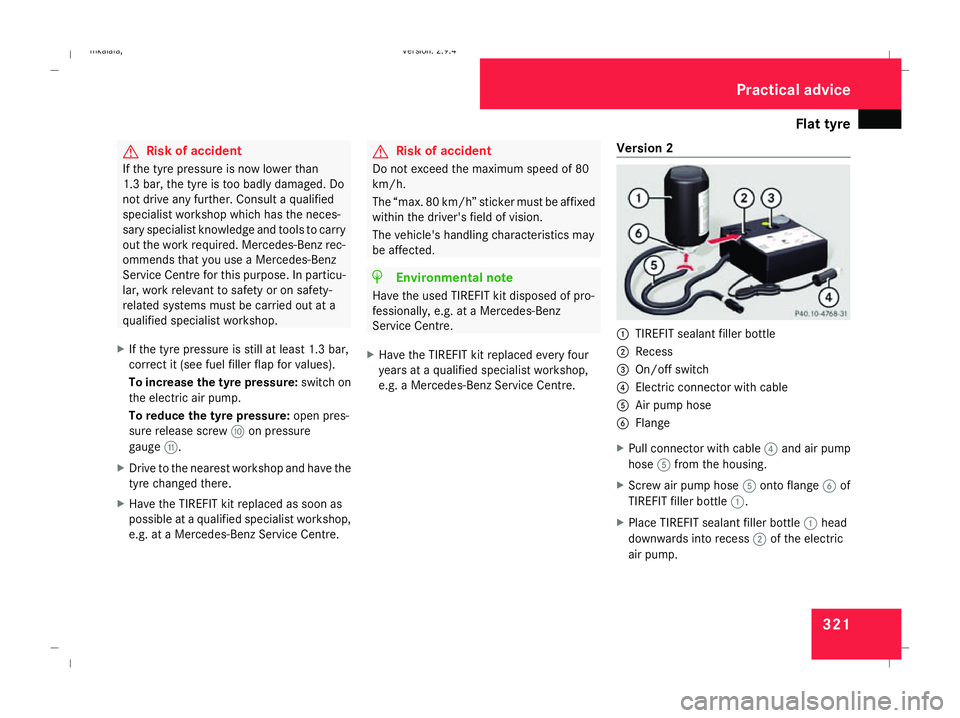

e.g. a Mercedes-Benz Service Centre. Version 2 1

TIREFIT sealant filler bottle

2 Recess

3 On/off switch

4 Electric connector with cable

5 Air pump hose

6 Flange

X Pull connector with cable 4and air pump

hose 5from the housing.

X Screw air pump hose 5onto flange 6of

TIREFIT filler bottle 1.

X Place TIREFIT sealant filler bottle 1head

downwards into recess 2of the electric

air pump. Practical advice

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 321 ZDateiname: 6515_3416_02_buchblock.pdf; preflight

Page 325 of 401

Flat tyre

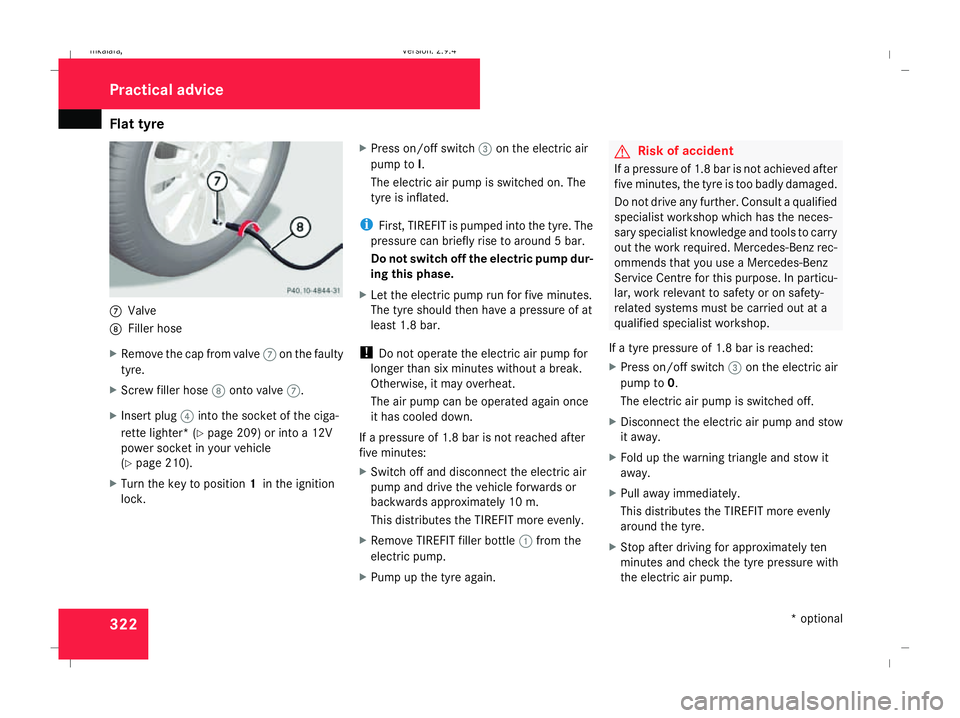

3227

Valve

8 Filler hose

X Remove the cap from valve 7on the faulty

tyre.

X Screw filler hose 8onto valve 7.

X Insert plug 4into the socket of the ciga-

rette lighter* (Y page 209) or into a 12V

power socket in your vehicle

(Y page 210).

X Turn the key to position 1in the ignition

lock. X

Press on/off switch 3on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

i First, TIREFIT is pumped into the tyre. The

pressure can briefly rise to around 5 bar.

Do not switch off the electric pump dur-

ing this phase.

X Let the electric pump run for five minutes.

The tyre should then have a pressure of at

least 1.8 bar.

! Do not operate the electric air pump for

longer than six minutes without a break.

Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down.

If a pressure of 1.8 bar is not reached after

five minutes:

X Switch off and disconnect the electric air

pump and drive the vehicle forwards or

backwards approximately 10 m.

This distributes the TIREFIT more evenly.

X Remove TIREFIT filler bottle 1from the

electric pump.

X Pump up the tyre again. G

Risk of accident

If a pressure of 1.8 bar is not achieved after

five minutes, the tyre is too badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

qualified specialist workshop.

If a tyre pressure of 1.8 bar is reached:

X Press on/off switch 3on the electric air

pump to 0.

The electric air pump is switched off.

X Disconnect the electric air pump and stow

it away.

X Fold up the warning triangle and stow it

away.

X Pull away immediately.

This distributes the TIREFIT more evenly

around the tyre.

X Stop after driving for approximately ten

minutes and check the tyre pressure with

the electric air pump. Practical advice

* optional

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 322Dateiname: 6515_3416_02_buchblock.pdf; preflight

Page 326 of 401

Flat tyre

323G

Risk of accident

If the tyre pressure is now lower than

1.3 bar, the tyre is too badly damaged. Do

not drive any further. Consult a qualified

specialist workshop which has the neces-

sary specialist knowledge and tools to carry

out the work required. Mercedes-Benz rec-

ommends that you use a Mercedes-Benz

Service Centre for this purpose. In particu-

lar, work relevant to safety or on safety-

related systems must be carried out at a

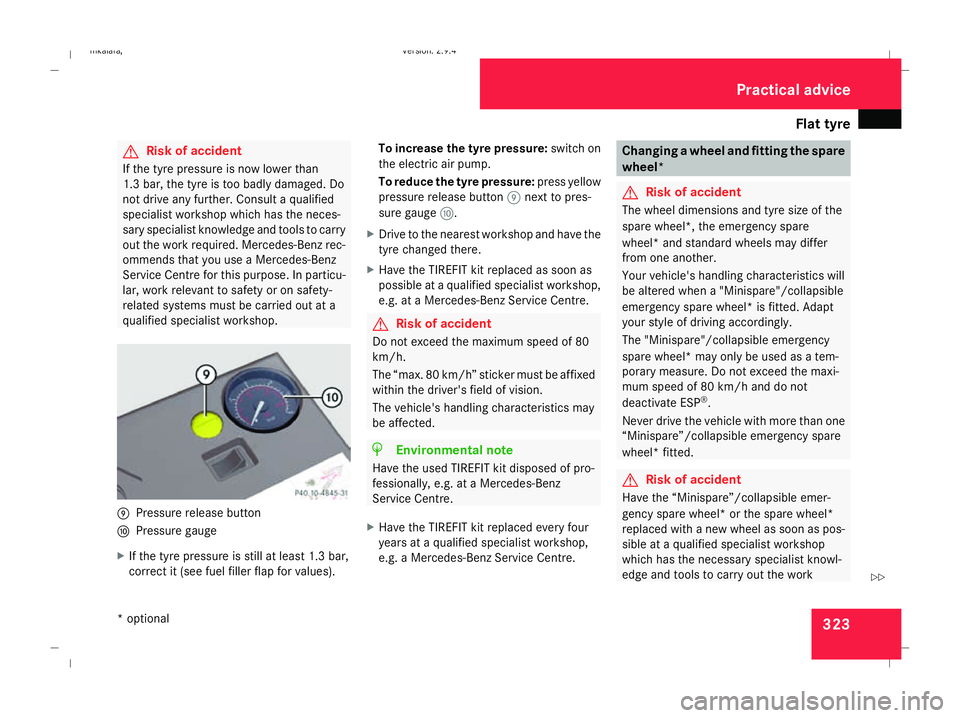

qualified specialist workshop. 9

Pressure release button

a Pressure gauge

X If the tyre pressure is still at least 1.3 bar,

correct it (see fuel filler flap for values). To increase the tyre pressure:

switch on

the electric air pump.

To reduce the tyre pressure: press yellow

pressure release button 9next to pres-

sure gauge a.

X Drive to the nearest workshop and have the

tyre changed there.

X Have the TIREFIT kit replaced as soon as

possible at a qualified specialist workshop,

e.g. at a Mercedes-Benz Service Centre. G

Risk of accident

Do not exceed the maximum speed of 80

km/h.

The “max. 80 km/h” sticker must be affixed

within the driver's field of vision.

The vehicle's handling characteristics may

be affected. H

Environmental note

Have the used TIREFIT kit disposed of pro-

fessionally, e.g. at a Mercedes-Benz

Service Centre.

X Have the TIREFIT kit replaced every four

years at a qualified specialist workshop,

e.g. a Mercedes-Benz Service Centre. Changing a wheel and fitting the spare

wheel*

G

Risk of accident

The wheel dimensions and tyre size of the

spare wheel*, the emergency spare

wheel* and standard wheels may differ

from one another.

Your vehicle's handling characteristics will

be altered when a "Minispare"/collapsible

emergency spare wheel* is fitted. Adapt

your style of driving accordingly.

The "Minispare"/collapsible emergency

spare wheel* may only be used as a tem-

porary measure. Do not exceed the maxi-

mum speed of 80 km/h and do not

deactivate ESP ®

.

Never drive the vehicle with more than one

“Minispare”/collapsible emergency spare

wheel* fitted. G

Risk of accident

Have the “Minispare”/collapsible emer-

gency spare wheel* or the spare wheel*

replaced with a new wheel as soon as pos-

sible at a qualified specialist workshop

which has the necessary specialist knowl-

edge and tools to carry out the work Practical advice

* optional

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 323 ZDateiname: 6515_3416_02_buchblock.pdf; preflight

Page 327 of 401

Flat tyre

324 required. Mercedes-Benz recommends

that you use a Mercedes-Benz Service

Centre for this purpose. In particular, work

relevant to safety or on safety-related sys-

tems must be carried out at a qualified

specialist workshop.

Preparing the vehicle X

Prepare the vehicle as described

(Y page 317).

X If a trailer is coupled, uncouple it.

X Place the wheels in the straight-ahead posi-

tion.

X Take out the following from the stowage

area beneath the boot/luggage compart-

ment floor:

R the "Minispare"/collapsible emergency

spare wheel* or the spare wheel*

R the vehicle tool kit

R the wheel chock

R the jack

X Secure the vehicle to prevent it from rolling

away.

On level ground: place chocks or similar

under the front and rear of the wheel that is diagonally opposite the wheel you wish

to change.

X On downhill gradients: place chocks or

similar under both wheels of the other axle.

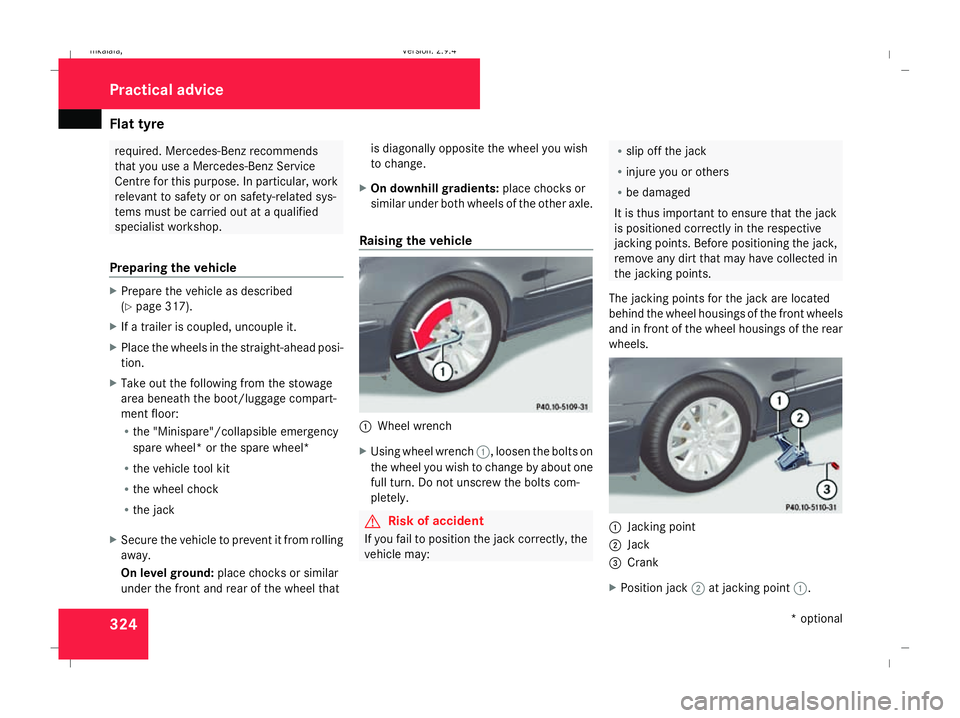

Raising the vehicle 1

Wheel wrench

X Using wheel wrench 1, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts com-

pletely. G

Risk of accident

If you fail to position the jack correctly, the

vehicle may: R

slip off the jack

R injure you or others

R be damaged

It is thus important to ensure that the jack

is positioned correctly in the respective

jacking points. Before positioning the jack,

remove any dirt that may have collected in

the jacking points.

The jacking points for the jack are located

behind the wheel housings of the front wheels

and in front of the wheel housings of the rear

wheels. 1

Jacking point

2 Jack

3 Crank

X Position jack 2at jacking point 1. Practical advice

* optional

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 324Dateiname: 6515_3416_02_buchblock.pdf; preflight

Page 328 of 401

Flat tyre

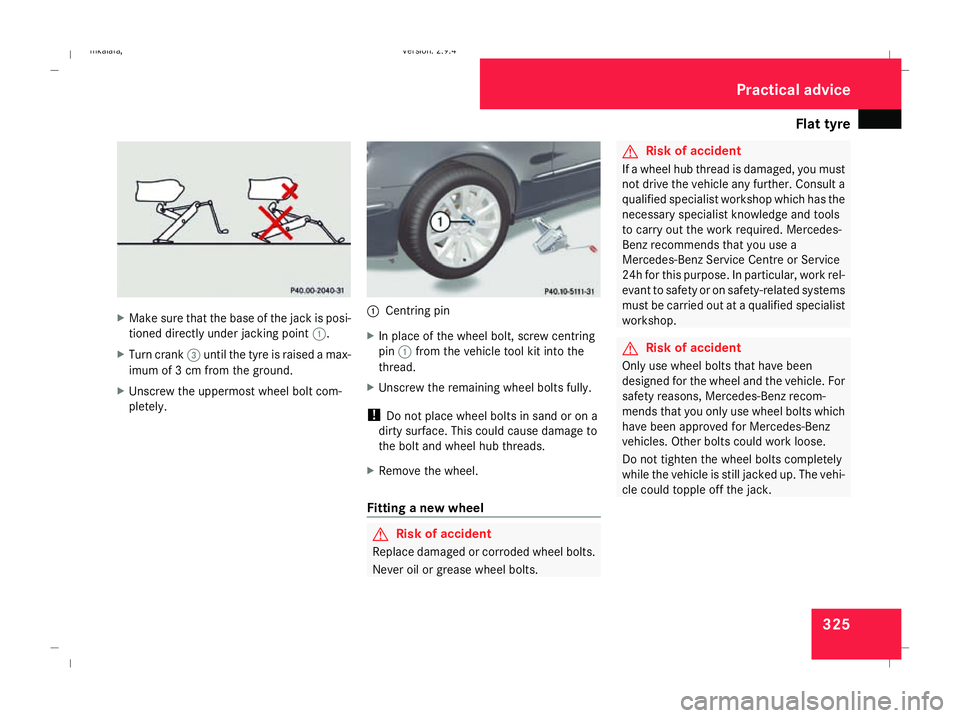

325X

Make sure that the base of the jack is posi-

tioned directly under jacking point 1.

X Turn crank 3until the tyre is raised a max-

imum of 3 cm from the ground.

X Unscrew the uppermost wheel bolt com-

pletely. 1

Centring pin

X In place of the wheel bolt, screw centring

pin 1from the vehicle tool kit into the

thread.

X Unscrew the remaining wheel bolts fully.

! Do not place wheel bolts in sand or on a

dirty surface. This could cause damage to

the bolt and wheel hub threads.

X Remove the wheel.

Fitting a new wheel G

Risk of accident

Replace damaged or corroded wheel bolts.

Never oil or grease wheel bolts. G

Risk of accident

If a wheel hub thread is damaged, you must

not drive the vehicle any further. Consult a

qualified specialist workshop which has the

necessary specialist knowledge and tools

to carry out the work required. Mercedes-

Benz recommends that you use a

Mercedes-Benz Service Centre or Service

24h for this purpose. In particular, work rel-

evant to safety or on safety-related systems

must be carried out at a qualified specialist

workshop. G

Risk of accident

Only use wheel bolts that have been

designed for the wheel and the vehicle. For

safety reasons, Mercedes-Benz recom-

mends that you only use wheel bolts which

have been approved for Mercedes-Benz

vehicles. Other bolts could work loose.

Do not tighten the wheel bolts completely

while the vehicle is still jacked up. The vehi-

cle could topple off the jack. Practical advice

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 325 ZDateiname: 6515_3416_02_buchblock.pdf; preflight

Page 329 of 401

Flat tyre

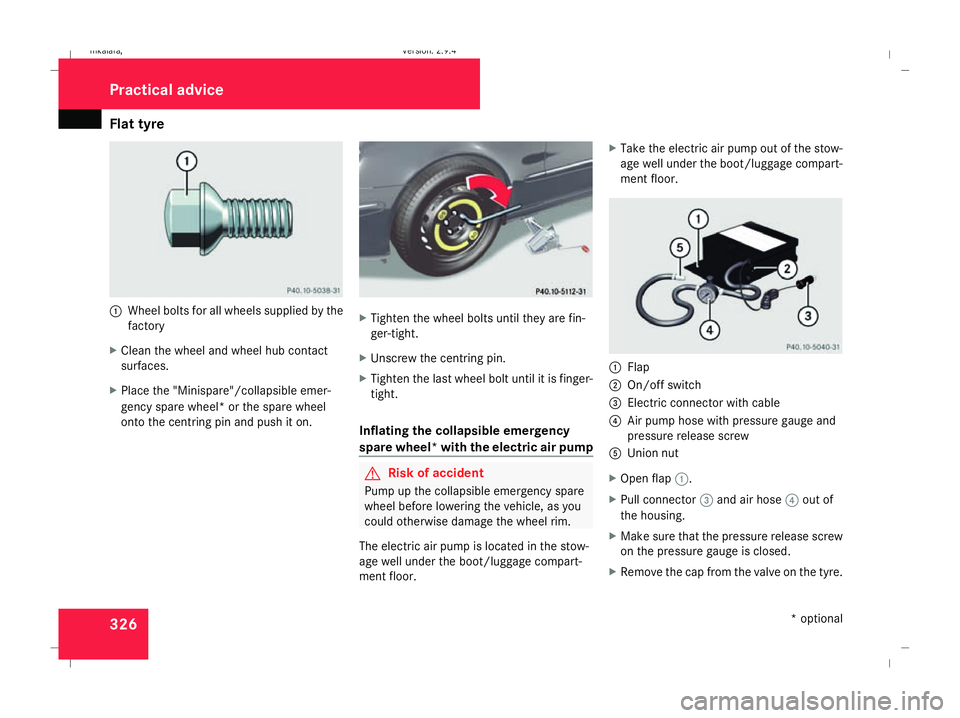

3261

Wheel bolts for all wheels supplied by the

factory

X Clean the wheel and wheel hub contact

surfaces.

X Place the "Minispare"/collapsible emer-

gency spare wheel* or the spare wheel

onto the centring pin and push it on. X

Tighten the wheel bolts until they are fin-

ger-tight.

X Unscrew the centring pin.

X Tighten the last wheel bolt until it is finger-

tight.

Inflating the collapsible emergency

spare wheel* with the electric air pump G

Risk of accident

Pump up the collapsible emergency spare

wheel before lowering the vehicle, as you

could otherwise damage the wheel rim.

The electric air pump is located in the stow-

age well under the boot/luggage compart-

ment floor. X

Take the electric air pump out of the stow-

age well under the boot/luggage compart-

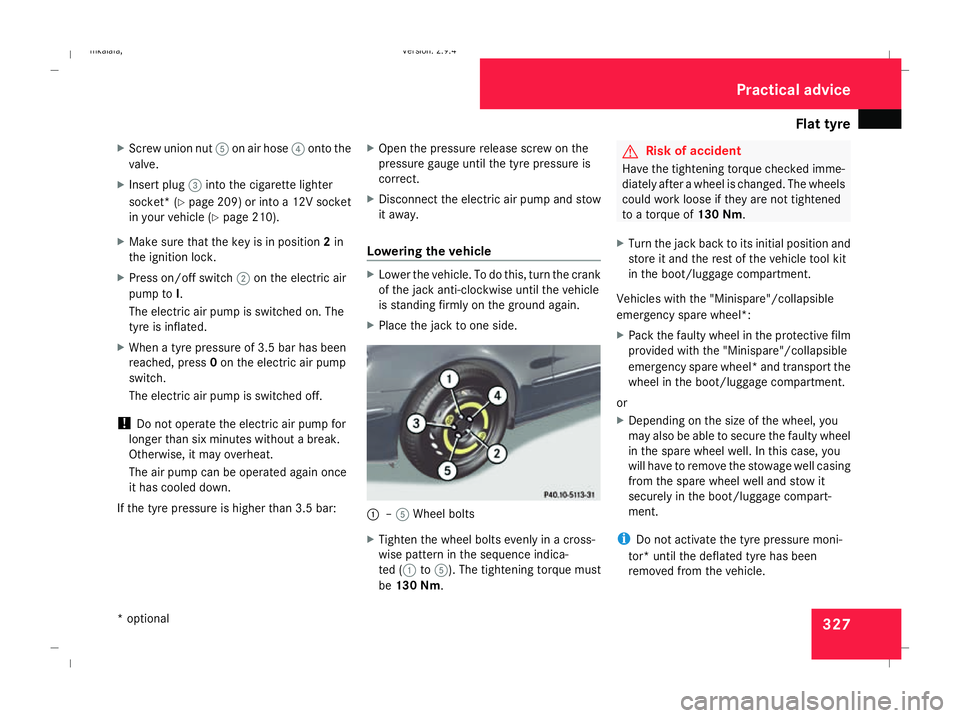

ment floor. 1

Flap

2 On/off switch

3 Electric connector with cable

4 Air pump hose with pressure gauge and

pressure release screw

5 Union nut

X Open flap 1.

X Pull connector 3and air hose 4out of

the housing.

X Make sure that the pressure release screw

on the pressure gauge is closed.

X Remove the cap from the valve on the tyre. Practical advice

* optional

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 326Dateiname: 6515_3416_02_buchblock.pdf; preflight

Page 330 of 401

Flat tyre

327

X

Screw union nut 5on air hose 4onto the

valve.

X Insert plug 3into the cigarette lighter

socket* ( Ypage 209) or into a 12V socket

in your vehicle (Y page 210).

X Make sure that the key is in position 2in

the ignition lock.

X Press on/off switch 2on the electric air

pump to I.

The electric air pump is switched on. The

tyre is inflated.

X When a tyre pressure of 3.5 bar has been

reached, press 0on the electric air pump

switch.

The electric air pump is switched off.

! Do not operate the electric air pump for

longer than six minutes without a break.

Otherwise, it may overheat.

The air pump can be operated again once

it has cooled down.

If the tyre pressure is higher than 3.5 bar: X

Open the pressure release screw on the

pressure gauge until the tyre pressure is

correct.

X Disconnect the electric air pump and stow

it away.

Lowering the vehicle X

Lower the vehicle. To do this, turn the crank

of the jack anti-clockwise until the vehicle

is standing firmly on the ground again.

X Place the jack to one side. 1

–5 Wheel bolts

X Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indica-

ted ( 1to5). The tightening torque must

be 130 Nm . G

Risk of accident

Have the tightening torque checked imme-

diately after a wheel is changed. The wheels

could work loose if they are not tightened

to a torque of 130 Nm.

X Turn the jack back to its initial position and

store it and the rest of the vehicle tool kit

in the boot/luggage compartment.

Vehicles with the "Minispare"/collapsible

emergency spare wheel*:

X Pack the faulty wheel in the protective film

provided with the "Minispare"/collapsible

emergency spare wheel* and transport the

wheel in the boot/luggage compartment.

or

X Depending on the size of the wheel, you

may also be able to secure the faulty wheel

in the spare wheel well. In this case, you

will have to remove the stowage well casing

from the spare wheel well and stow it

securely in the boot/luggage compart-

ment.

i Do not activate the tyre pressure moni-

tor* until the deflated tyre has been

removed from the vehicle. Practical advice

* optional

211_AKB; 2; 5, en-GB

mkalafa,

Version: 2.9.4 2008-02-29T16:57:07+01:00 - Seite 327 ZDateiname: 6515_3416_02_buchblock.pdf; preflight