LED MERCEDES-BENZ E43AMG 2017 W213 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E43AMG, Model: MERCEDES-BENZ E43AMG 2017 W213Pages: 482, PDF Size: 6.31 MB

Page 343 of 482

&WARNING Risk of accident caused by

re peated drop in tire pressure

If th e tire pressure drops repeatedl y,the

wheel, valve or tire may be damaged.

Insuf ficient tire pressure can cause the tires

to bur st.

#Inspect the tire for signs of fore ign

objects.

#Check whe ther the wheel or valve has a

leak.

#If yo u are unab leto rectify the damage,

conta ct aqualified specialist workshop.

Yo u can find information on tire pressure forth e

ve hicle's factor y-ins talled tires on thefo llowing

labels:

RTi re and Loading Info rmation placard on the

B‑pillar of your vehicle (→page 345).

RTire pressure table on the inside of the fuel

fi ller flap (→page 341).

Observ eth e maximum tire pressure

(

→page 352). Use a suitable pressure

gauge tocheck the tire

pressure. The outer appearance of a tire does

not permit any reliable conclusion about the tire

pressure.

Ve hicles with a tire pressure monitoring sys‐

te m: You can also check the tire pressure using

th e on-board computer.

Only cor rect tire pressure when the tires are

cold. Conditions for cold tires:

RThe vehicle has been par ked with the tires

out of direct sunlight for at least th ree hours.

RThe vehicle has tr aveled less than 1 mile

(1.6 km).

A rise in the tire temp erature of 18°F (10 °C)

increases the tire pressure byappr ox.10 kPa

(0.1 bar/1.5 psi). Take this into account when

ch ecking the tire pressure of warm tires.

The tire pressure re commendedfor increased

load/speed in the tire pressure table can af fect

th eride comfort.

&

WARNING Risk of accident from unsuita‐

ble accessori es onthe tire valves

If yo u mount unsuitable accessories onto tire

va lves, the tire valves may be overloaded and

malfunction, which can cause tire pressure

loss. Tire pressure monitoring sy stems for

re trofitting will cause the tire valve toremain

open. This can also result in tire pressure

loss.

#Only scr ewstandard valve caps or valve

caps specifically appr ovedby

Mercedes-Benz foryo ur vehicle onto

th e tire valve.

Ti re pressure table

The tire pressure table is on the inside of the

fuel filler flap.

% The data shown in the images is example

data.

Wheels and tires 34

1

Page 346 of 482

The system checks the tire pressure of the tires

ins talled on theve hicle bymeans of a tire pres‐

sure sensor.

New tire pressure sensor, e.g. in winter tires, are

automatically taught-in thefirs t time they are

driven.

The tire pressure appears in the multifunction

display (

→page 202).

If th ere is a subs tantial pressure loss or if the

tire temp erature is excessive, a warning will be

given:

RVi a display messages (→page 409).

RViath eh warning lamp in the instrument

clus ter (→page 440).

It is the driver's responsibility toset the tire

pressure tothere commended cold tire pressure

suitable forth e operating situation. Set the tire

pressure for cold tires using a tire pressure

ga uge. Notethat the cor rect tire pressure forth e

cur rent operating situation must firs t be taught-

in to the tire pressure monitor.

In most cases, the tire pressure monitoring sys‐

te m will auto matically update the new refere nce va

lues af teryo u ha vechanged the tire pressure.

Yo u can, ho wever,also update there fere nce val‐

ues byrestarting the tire pressure monitoring

sy stem manually (

→page 345).

Sy stem limitations

The t

ire pressure monitoring sy stem does not

issue a warning:

RIfth e tire pressure is set incor rectly.

RIfth ere is a sudden pressure loss caused, for

ex ample, byafo re ign object penetrating the

tire.

RIf th ere is a malfunction caused byano ther

ra dio signal source.

Be sure toalso observ eth efo llowing fur ther

re lated subjects:

RNo tes on tire pressure (→page 339)

Checking the tire pressure with the tire pres‐

sure moni toring sy stem

Requ irements

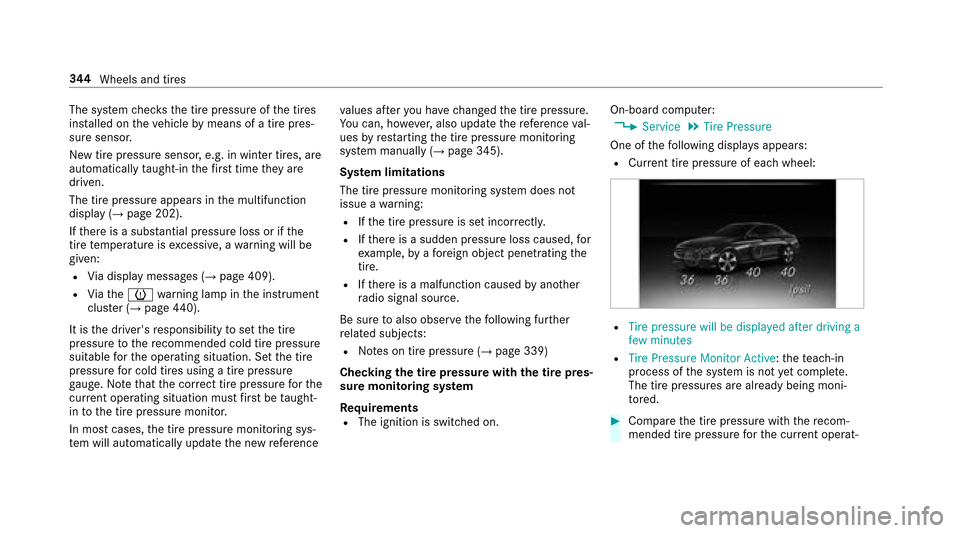

RThe ignition is switched on. On-board computer:

,�6�H�U�Y�L�F�H.�7�L�U�H �3�U�H�V�V�X�U�H

One of thefo llowing displa ysappears:

RCur rent tire pressure of ea chwheel:

R�7�L�U�H �S�U�H�V�V�X�U�H �Z�L�O�O �E�H �G�L�V�S�O�D�\�H�G �D�I�W�H�U �G�U�L�Y�L�Q�J �D

�I�H�Z �P�L�Q�X�W�H�V

R�7�L�U�H �3�U�H�V�V�X�U�H �0�R�Q�L�W�R�U �$�F�W�L�Y�H: thete ach-in

process of the sy stem is not yet comple te.

The tire pressures are already being moni‐

to re d.

#Compare the tire pressure with there com‐

mended tire pressure forth e cur rent operat‐

34 4

Wheels and tires

Page 352 of 482

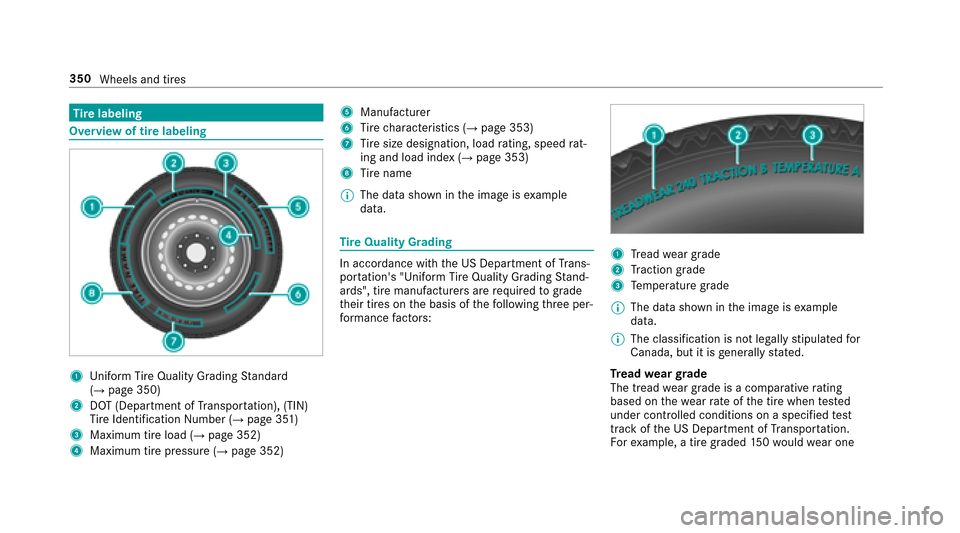

Tire labeling

Overview of tire labeling

1Uni form Ti reQuality Grading Standard

(→page 350)

2DOT (Department of Transpor tation), (TIN)

Ti re Identification Number (→page 351)

3Maximum tire load (→page 352)

4Maximum tire pressure (→page 352)

5Manufacturer

6Tire characteristics (→page 353)

7Tire size designation, load rating, speed rat‐

ing and load ind ex(→page 353)

8Tire name

% The da tashown in the image is example

data.

Ti re Quality Grading

In accordance with the US Department of Trans‐

por tation's "Unifo rm TireQuality Grading Stand‐

ards", tire manufacturers are requ ired tograde

th eir tires on the basis of thefo llowing thre e per‐

fo rm ance factors:1Tread weargrade

2Traction grade

3Te mp erature grade

% The data shown in the image is example

data.

% The classification is not legally stipulated for

Canada, but it is general lystated.

Tr ead weargrade

The tread wear grade is a comparative rating

based on thewe arrate ofthe tire when tested

under controlled conditions on a specified test

track of the US Department of Transpor tation.

Fo rex ample, a tire graded 150wo uld wear one

350

Wheels and tires

Page 353 of 482

and one-half times aswell on the go vernment

course as a tire graded 100.

The relative per form ance of tires depends upon

th e actual conditions of their use, ho wever,and

may depart significantly from the norm due to

va riations in driving habits, service practices and

dif fere nces in road characteristics and climate

conditions.

Tr action grade

&

DANG ER Risk of accident due toinade‐

qu ate traction

The traction grade assigned tothis tire is

based on stra ight-ahead braking traction

te sts, and does not include either accelera‐

tion, cornering, hydroplaning or peak traction

ch aracteristics.

#Alw ays adapt your drivin gst yle and

drive at a speed tosuit the pr evailing

traf fic and weather conditions.

* NO

TEDama getothe driv etra in from

wheelspin

#Av oid wheelspin.

The traction grades – from highest tolowest –

are AA, A,B and C. Those grades represent the

tire's ability tostop on wet pa vement as meas‐

ured under controlled conditions on specified

go vernment test sur faces made of asphalt and

concr ete.

Te mp erature grade

&

WARNING Risk of accident from tire

ove rheating and tire failure

The temp erature grade forth is tire is es tab‐

lished for a tire that is proper ly inflated and

not overloaded. Excessive speed, underinfla‐

tion, or excessive loading, either separately

or in combination, can cause excessive heat

build-up and possible tire failure.

#Obser vethere commended tire pres‐

sure s and regularly check the tire pres‐

sure of all tires including the spare

wheel.

#Ad just the tire pressure as necessar y.

Thetemp erature grades are A (the highest), B

and C. They represent the tire's resis tance tothe

ge neration of heat and its ability todissipate

heat when tested under controlled conditions on

a specified indoor laboratory test wheel. Sus‐

ta ined high temp eratures can cause the material

of the tire todegenerate and reduce tire life. Fur‐

th ermore, excessive temp eratures can lead to

sudden tire failure. Grade C cor responds toa

le ve l of per form ance which all passenger car

tires must meet under therequ irements of the

US Department of Transpor tation.

DO T,Tire Identification Number (TIN)

US tire regulations stipulate that eve rytire man‐

ufactu rer or retreader must imprint a TIN in or

on the side wall of each tire produced.

Wheels and tires 351

Page 358 of 482

Uniform Tire Quality Grading Standards: a

uniform standard tograde thequ ality of tires

with rega rd totread quality, tire traction and

te mp erature characteristics. The quality grading

assessment is made bythe manufacturer follow‐

ing specifications from theU. S. go vernment. The

qu ality grade of a tire is imprinted on the side

wa ll of the tire.

Re commended tire pressure :th ere commen‐

ded tire pressure is the tire pressure specified

fo rth e tires mounted totheve hicle at thefa c‐

to ry.

The tire and information table conta insthere c‐

ommended tire pressure for cold tires, the maxi‐

mum permissible load and the maximum permis‐

sible vehicle speed.

The tire pressure table conta insthere commen‐

ded tire pressure for cold tires under various

operating conditions, i.e. loading and/or speed

of theve hicle.

Increased vehicle weight due tooptional

equipment: the combined weight of all standard

and optional equipment available forth eve hicle, re

ga rdless of whe ther it is actually ins talled on

th eve hicle or not.

Rim: the part of the wheel on which the tire is

mounted.

GA WR (Gross Axle Weight Rating): the GAWR

is the maximum gross axle load. The actual load

on an axle must ne verexc eed the gross axle

we ight rating. The gross axl e

we ight rati

ng can

be found on theve hicle identification plate on

th e B‑pillar on the driver's side.

Speed rating: the speed rating is pa rtof the tire

identification. It specifies the speed range for

which a tire is appr oved.

GV W (Gross Vehicle Weight): the gross vehicle

we ight comprises thewe ight of theve hicle

including fuel, tools, the spare wheel, accesso‐

ri es ins talled, occupants, luggage and the trailer

dr aw bar nose weight, if applicable. The gross

ve hicle weight must not exceed the gross vehicle

we ight rating GVWR as specified on theve hicle

identification plate on the B‑pillar on the driver's

side.

GV WR (Gross Vehicle Weight Rating): the

GV WR is the maximum permitted gross weight of

the fully laden vehicle (weight of theve hicle

including all accessories, occupants, fuel, lug‐

ga ge and the trailer dr awbar nose weight if appli‐

cable). The gross vehicle weight rating is speci‐

fi ed on theve hicle identification plate on the

B‑pillar on the driver's side.

Maximum weight of the laden vehicle: the

maximum weight is the sum of the unladen

we ight of theve hicle, thewe ight of the accesso‐

ri es, the maximum load and thewe ight of

optional equipment ins talled at thefa ctor y.

Kilopascal (kPa): metricunit for tire pressure .

6.9 kPa cor responds to1 psi. Ano ther unit for

tire pressure is bar.100 kilop ascal (kPa

) equals

1 bar.

Load index: in additiontothe load-bearing

index, the load index may also be imprinted on

th e side wall of the tire. This specifies the load-

bearing capacity of the tire more precisel y.

Curb weight: thewe ight of a vehicle with stand‐

ard equipment including the maximum capacity

of fuel, oil and coolant. It also includes the air

conditioning sy stem and optional equipment if

356

Wheels and tires

Page 359 of 482

these are ins talled on theve hicle, but does not

include passengers or luggage.

Maximum tire load: the maximum tire load is

th e maximum permissible weight in kilog rams or

lbs for which a tire is appr oved.

Maximum permissible tire pressure: maxi‐

mum permissible tire pressure for one tire.

Maximum load on one tire: maximum load on

one tire. This is calculated bydividing the maxi‐

mum axle load of one axle bytwo.

PSI (pounds per square in ch):standard unit of

measurement for tire pressure .

Aspect ratio: ratio between tire height and tire

width in pe rcent.

Ti re pressure: pressure inside the tire applying

an outward forc eto eve rysquare inch of the tire.

The tire pressure is specified in pounds per

square inch (psi), in kilopascals (kPa) or in bar.

The tire pressure should only be cor rected when

th e tires are cold.

Cold tire pressure: the tires are cold when the

ve hicle has been par kedfo r at least 3 hours without direct sunlight on

the tires or theve hicle

has been driven for less than 1 mile (1.6 km).

Ti re contact sur face: the part of the tire that

comes into con tact wi th thero ad.

Ti re bead: the purpose of the tire bead is to

ensure that the tire sits securely on the wheel

ri m. There are se veralst eel wires in the bead to

pr eve nt

the t

ire from coming loose from the

wheel rim.

Side wall:the part of the tire between the tread

and the tire bead.

We ight of optional equipment: the combined

we ight of the optional equipment weighing more

th an there placed standard parts and more than

5 lbs (2.3 kg).This optional equipment, such as

high-per form ance brakes, le vel control sy stem, a

ro of luggage rack or high-per form ance batte ries,

is not included in the curb weight and thewe ight

of the accessories.

TIN (Tire Identification Number): a unique

identification number which can be used bya

tire manufactu rerto identify tires, forex ample,

in a product recall, and thus identify the pur‐

ch asers. The TIN is made up of the manufactur‐ er's identity code, tire size, tire type code and

th

e manufacturing date.

Load-bearing index: the load-bearing index

(also load index) is a code that con tains the max‐

imum load-bearing capacity of a tire.

Tr action: traction is the grip resulting from fric‐

tion between the tires and thero ad sur face.

We ar indicator: narrow bars (tread wear bars)

th at are distributed overth e tire conta ct surface.

If th e tire tread is le vel with the bars, thewe ar

limit of 1/ 16in (1.6 mm) has been reached.

Distribution of vehicle occupants: distribution

of vehicle occupants

over design

ated seat posi‐

tions in a vehicle.

Maximum permissible pa yload weight: nomi‐

nal load and luggage load plus 150 lb (68 kg)

multiplied bythe number of seats in theve hicle.

Wheels and tires 357

Page 360 of 482

Changing a wheel

Notes on selecting, mounting and replacing

tires

Yo u can ask for information rega rding permitte d

wheel/tire combinations at an authorized

Mercedes-Benz Center.

& WARNING Risk of accident due toincor‐

re ct dimensions of wheels and tires

If wheels and tires of the wrong size are

ins talled, the wheel brakes or wheel suspen‐

sion components may be damaged.

#Alw aysre place wheels and tires with

th ose that fulfill the specifications of

th e original part.

When replacing wheels, make sure tofit th e

cor rect:

RDesignation

RModel

When replacing tires, make sure toins tallth e

cor rect:

RDesignation

RManufactu rer

RModel

&

WARNING Risk of injury thro ugh exceed‐

ing the specified tire load rating or the

permissible speed rating

Exceeding the specified tire load rating or

th e permissible speed rating may lead totire

damage andtothe tires bur sting.

#Therefore, only use tire types and sizes

appr ovedfo ryo ur vehicle model.

#Obser vethe tire load rating and speed

ra ting requ ired foryo ur vehicle.

* NO

TEDama getovehicle and tires due to

non-app rove d tire types and sizes

Fo r saf etyre asons, only use wheels, tires

and accessories which havebeen appr oved

fo ryo ur vehicle byMercedes-Benz.

These tires ha vebeen specially adap tedfo r

use with the control sy stems, e.g. ABS or

ESP

®, and are mar ked as follo ws :

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

(run-flat tires only for cer tain wheels)

RMO1 = Mercedes-Benz Original (only cer‐

tain AMG tires)

Cer tain characteristics, e.g. handling, vehicle

noise emissions or fuel consum ption, may

ot herwise be adversely af fected. In addition,

when driving wi tha load, tire dimension var‐

iations could cause the tires tocome into

contact wi th the body and axle components.

This could result in damage tothe tires or the

ve hicle.

358

Wheels and tires

Page 368 of 482

&WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/

wheel nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing.

#Ne ver oil or grease theth re ads.

#In theeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y.

#Have the damaged wheel bolts or dam‐

aged hub thre ads replaced.

#Do not continue driving.

#Obser vethe information on thech oice of

tires (→page 358).

Fo r tires with a specified direction of rotation, an

ar row onthe side wall of the tire indicates the

cor rect dire ction of rotation. Observ eth e direc‐

tion of rotation when mounting.

#Slide the wheel tobe mounted onto the cen‐

te ring pin and push it on.

&

WARNING Risk of injury from tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip.

#Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground.

#Fo r saf etyre asons, Mercedes-Benz recom‐

mends that you only use wheel bolts which

ha ve been appr oved for Mercedes-Benz vehi‐

cles, as well as forth e wheel in question.

* NO

TEDama getopaintwork of the wheel

ri m when scr ewing on thefirs t wheel bolt

If th e wheel has too much play when scr ew‐

ing in thefirs t wheel bolt, the wheel rim paint

can be dama ged.

#Press the wheel firm lyagainst the

wheel hub when scr ewing on thefirs t

wheel bolt.

#Ti ghten the wheel bolts until they are finger-

tight.

#Un scr ew the centering pin.

#Tighten the last wheel bolt until it is finger-

tight.

#Lo we rth eve hicle(→page 366).

Lo weri ngtheve hicle af ter a wheel change

Re quirementsRThe new wheel has been mounted

(→page 365).

#Place thera tchet wrench onto the he xagon

nut of the jack so that the letters "AB" are

visible.

#To lowe r the vehicle: turnthera tchet

wrench of the jack counter-clockwise.

366

Wheels and tires

Page 370 of 482

Notes ontech nical data

The data stated only appliestovehicles with

st andard equipment. You can obtain fur ther

information from an authorized Mercedes-Benz

Center.

Ve hicle electronics

Tw o-w ayradios

Note s on installing two-w ayradios

&

WARNING Risk of accident from incor‐

re ctly car ried out workon the RF trans‐

mitter

The electromagnetic radiation from RF trans‐

mitters can inter fere with theve hicle elec‐

tronics if RF transmitters are manipulate d or

re trofitted inco rrectly.

This could jeopardize the operating saf etyof

th eve hicle.

#Yo u should ha veall workon electrical

and electronic components car ried out

at a qualified specialist workshop.

&

WARNING Risk of accident from incor‐

re ct ope ration of the RF transmit ter

If yo u operate RF transmit ters incor rectly in

th eve hicle, the electromagnetic radiation

could inter fere with the on-board electronics,

e.g.:

Rif th e RF transmit ter is not connected to

an exterior antenna

Rif th eex terior antenna is not cor rectly

mounted or is not a lo w-reflection type.

This could jeopardize the operating saf etyof

th eve hicle.

#Ha ve the lo w-reflection exterior

antenna ins talled at a qualified special‐

ist workshop.

#When operating RF transmitters in the

ve hicle, alw ays connect them tothe

lo w- reflection exterior antenna.

* NO

TEInva lidation of the operating per‐

mit due tofailure tocomply wi th the

instructions for ins tallation and use

The operating permit may be in validated if

th e instructions for ins tallation and use of RF

transmitters are not obser ved.

#Only use appr oved frequency bands.

#Obser vethe maximum permissible out‐

put po wer in these frequency bands.

#Only use appr oved antenna positions.

368

Tech nical da ta

Page 374 of 482

Operatingfluids

Note s on operating fluids

&

WARNING Risk of injury from operating

fl uids harmful to your health

Operating fluids maybe pois onous and harm‐

ful to yo ur health.

#Obser vethete xt on the original con‐

ta iners when using, storing or disposing

of operating fluids.

#Alw aysst ore operating fluids sealed in

th eir original conta iners.

#Alwayske ep children away from operat‐

ing fluids.

+ENV IRONMEN TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal

#Dispose of operating fluids in an envi‐

ro nmentally responsible manner.

Operating fluids include thefo llowing:

RFu els

RLubricants

RCoolant

RBrake fluid

RWi ndshield washer fluid

RClimate cont rol sy stem refrigerant

Only use products recommended byMercedes-

Benz. Damage caused byusing vehicle products

which ha venot been recommended is not cov‐

ered bythe Mercedes-Benz guarantee, warranty

or goodwill gestures.

Yo u can identify operating fluids appr ovedby

Mercedes-Benz bythefo llowing insc ript ion on

th e conta iners:

RMB-Freigabe (e.g. MB-Fr eigabe 229.51)

RMB-Approval (e.g. MB-App rova l 229.51) Fu

rther information on appr oved operating flu‐

ids:

RIn the Mercedes-Benz Specifications for

operating fluids at http://be vo.mercedes-

benz.com (byen tering the designation)

RAt aqu alified specialist workshop

&

WARNING Risk offire and explosion

caused byfuel

Fu els are highly inflammable.

#You must avoidfire , open flames, creat‐

ing spar ksand smoking.

#Before refueling, switch off the engine

and, if ins talled in your vehicle, thest a‐

tionary heater.

& WARNING Risk of injury from fuel

Fu els are poisonous and harmful to your

health

#Do not swallow fuel or let it come into

contact with skin, eyes or clo thing.

#Do not inhale fuel vapors.

37 2

Tech nical da ta