MERCEDES-BENZ G500 2002 W463 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: G500, Model: MERCEDES-BENZ G500 2002 W463Pages: 385, PDF Size: 30.37 MB

Page 311 of 385

308 Spare wheel, vehicle jack

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

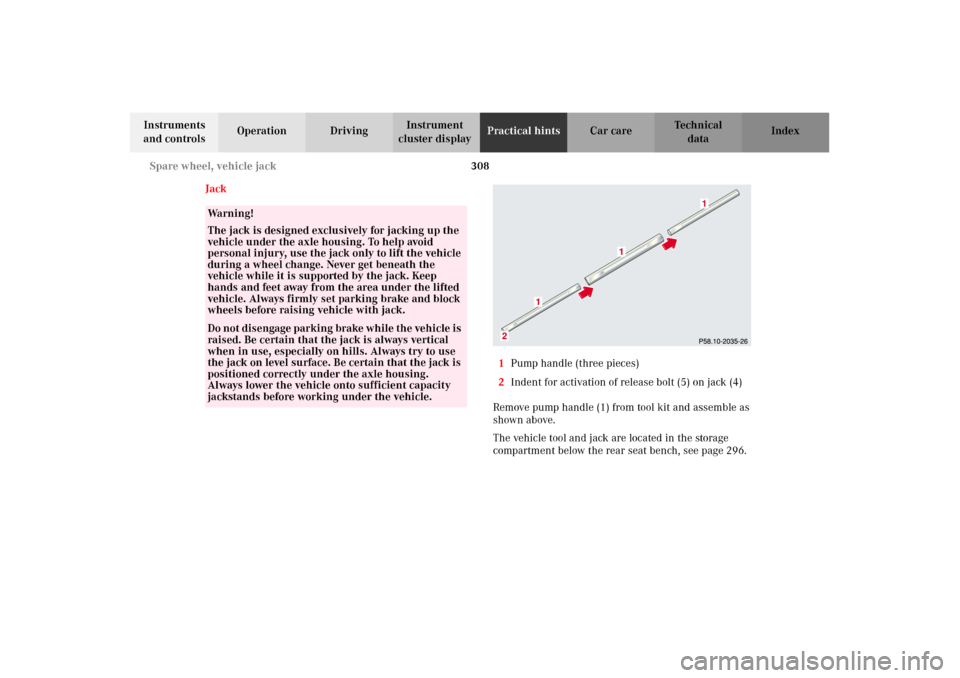

Jack

1Pump handle (three pieces)

2Indent for activation of release bolt (5) on jack (4)

Remove pump handle (1) from tool kit and assemble as

shown above.

The vehicle tool and jack are located in the storage

compartment below the rear seat bench, see page 296.

Wa r n i n g !

The jack is designed exclusively for jacking up the

vehicle under the axle housing. To help avoid

personal injury, use the jack only to lift the vehicle

during a wheel change. Never get beneath the

vehicle while it is supported by the jack. Keep

hands and feet away from the area under the lifted

vehicle. Always firmly set parking brake and block

wheels before raising vehicle with jack.Do n ot d is engage parki n g brake w hil e t he vehi c le i s

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be certain that the jack is

positioned correctly under the axle housing.

Always lower the vehicle onto sufficient capacity

jackstands before working under the vehicle.

J_G463.book Seite 308 Mittwoch, 19. September 2001 8:06 08

Page 312 of 385

309 Spare wheel, vehicle jack

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

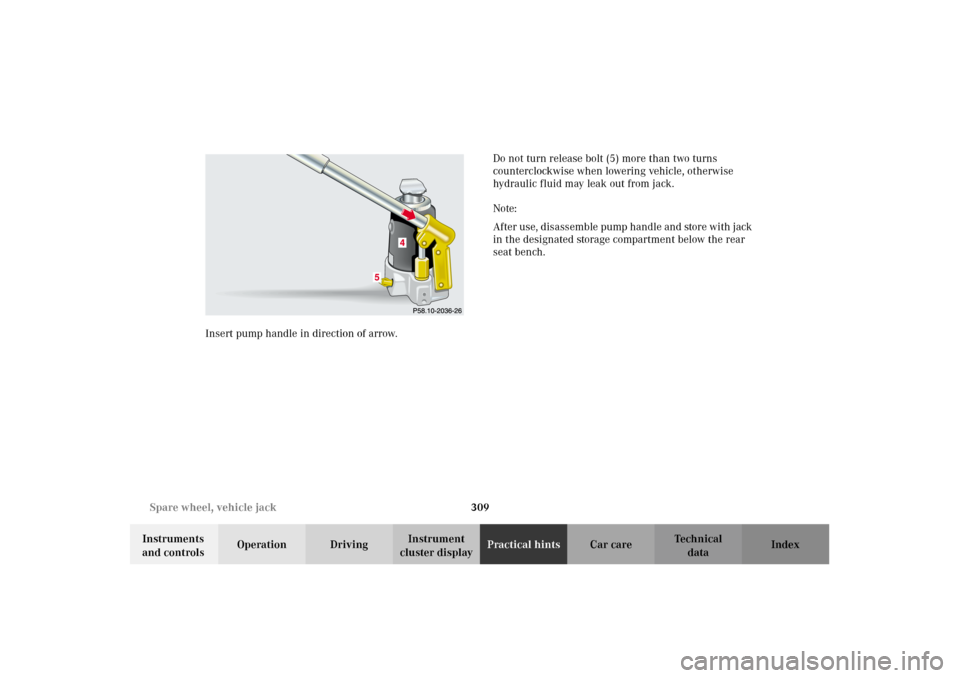

cluster displayPractical hintsCar care Index Insert pump handle in direction of arrow.Do not turn release bolt (5) more than two turns

counterclockwise when lowering vehicle, otherwise

hydraulic fluid may leak out from jack.

Note:

After use, disassemble pump handle and store with jack

in the designated storage compartment below the rear

seat bench.

J_G463.book Seite 309 Mittwoch, 19. September 2001 8:06 08

Page 313 of 385

310 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Wheels

Replace rims or tires with the same designation,

manufacturer and type as shown on the original part.

See your authorized Mercedes-Benz Light Truck Center

for further information.

See your authorized Mercedes-Benz Light Truck Center

for information on tested and recommended rims and

tires for summer and winter operation. They can also

offer advice concerning tire service and purchase.Tire replacement

Front and rear tires should be replaced in sets. Rims

and tires must be of the correct size and type. For

dimensions, see technical data on page 359.

We recommend that you break in new tires for

approximately 60 miles (100 km) at moderate speed.

It is imperative that the wheel mounting bolts be

fastened to a tightening torque of 97 ft.lb. (130 Nm)

whenever wheels are mounted.

For rim and tire specif ications, refer to technical data on

page 359.

Wa r n i n g !

Do not mix different tire construction types (i.e.

radial, bias, bias-belted) on your vehicle because

handling may be adversely affected and may result

in loss of control.

Wa r n i n g !

Worn, old tires can cause accidents. If the tire tread

is badly worn, or if the tires have sustained

damage, replace them.When replacing rims, use only genuine

Mercedes-Benz wheel bolts specified for the

particular rim type. Failure to do so can result in

the bolts loosening and possibly an accident.

J_G463.book Seite 310 Mittwoch, 19. September 2001 8:06 08

Page 314 of 385

311 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Rotating wheels

The wheels can be rotated according to the degree of

tire wear while retaining the same direction of travel.

Rotating, however, should be carried out as

recommended by the tire manufacturer, before the

characteristic tire wear pattern (shoulder wear on front

wheels and tread center wear on rear wheels) becomes

visible, as otherwise the driving properties deteriorate.

Important!

Unidirectional tires must always be mounted with arrow

on tire sidewall pointing in direction of vehicle forward

movement.Notes:

Thoroughly clean the inner side of the wheels any time

you rotate the wheels or wash the vehicle underside.

The use of retread tires is not recommended. Retread

tires may adversely affect the handling characteristics

and safety of the vehicle.

Dented or bent rims can cause tire pressure loss and

damage to the tire beads. For this reason, check rims for

damage at regular intervals. The rim flanges must be

checked for wear before a tire is mounted. Remove

burrs, if any.

Check and ensure proper tire inflation pressure after

rotating the wheels. For tire inflation pressure see

page 318.

J_G463.book Seite 311 Mittwoch, 19. September 2001 8:06 08

Page 315 of 385

312 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

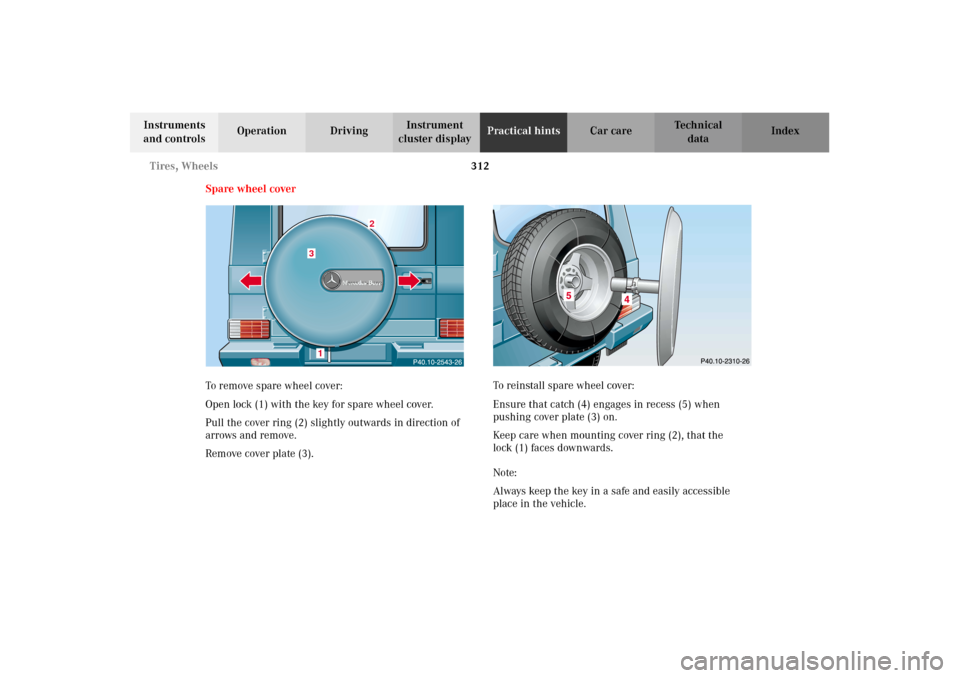

Spare wheel cover

To remove spare wheel cover:

Open lock (1) with the key for spare wheel cover.

Pull the cover ring (2) slightly outwards in direction of

arrows and remove.

Remove cover plate (3).To reinstall spare wheel cover:

Ensure that catch (4) engages in recess (5) when

pushing cover plate (3) on.

Keep care when mounting cover ring (2), that the

lock (1) faces downwards.

Note:

Always keep the key in a safe and easily accessible

place in the vehicle.

3

2

1

J_G463.book Seite 312 Mittwoch, 19. September 2001 8:06 08

Page 316 of 385

313 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

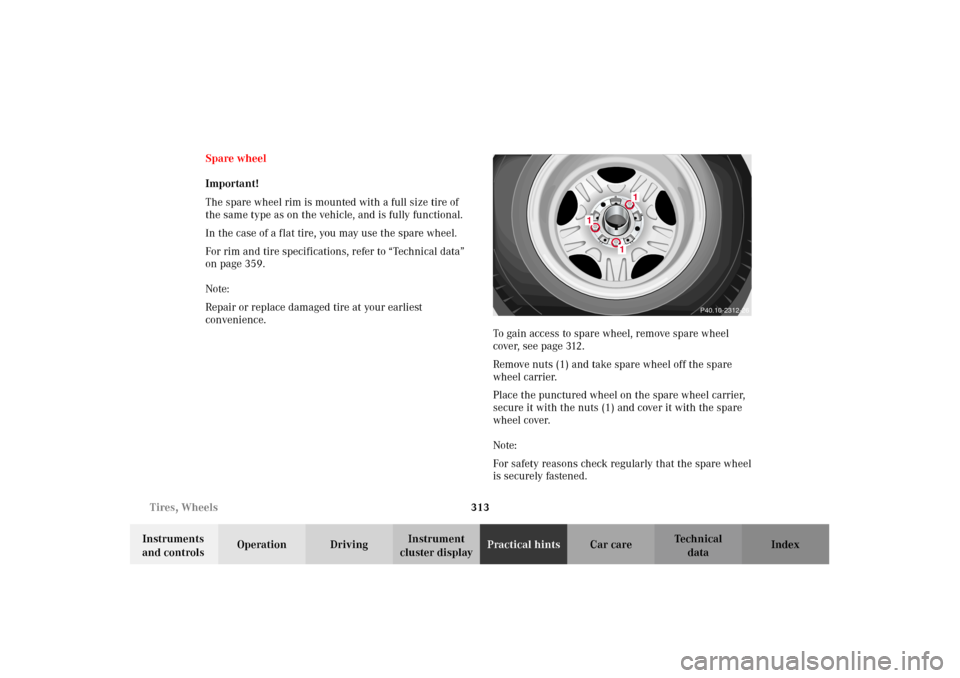

cluster displayPractical hintsCar care Index Spare wheel

Important!

The spare wheel rim is mounted with a full size tire of

the same type as on the vehicle, and is fully functional.

In the case of a flat tire, you may use the spare wheel.

For rim and tire specifications, refer to “Technical data”

on page 359.

Note:

Repair or replace damaged tire at your earliest

convenience.

To gain access to spare wheel, remove spare wheel

cover, see page 312.

Remove nuts (1) and take spare wheel off the spare

wheel carrier.

Place the punctured wheel on the spare wheel carrier,

secure it with the nuts (1) and cover it with the spare

wheel cover.

Note:

For safety reasons check regularly that the spare wheel

is securely fastened.

P40.10-2312-26

1

1

1

J_G463.book Seite 313 Mittwoch, 19. September 2001 8:06 08

Page 317 of 385

314 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

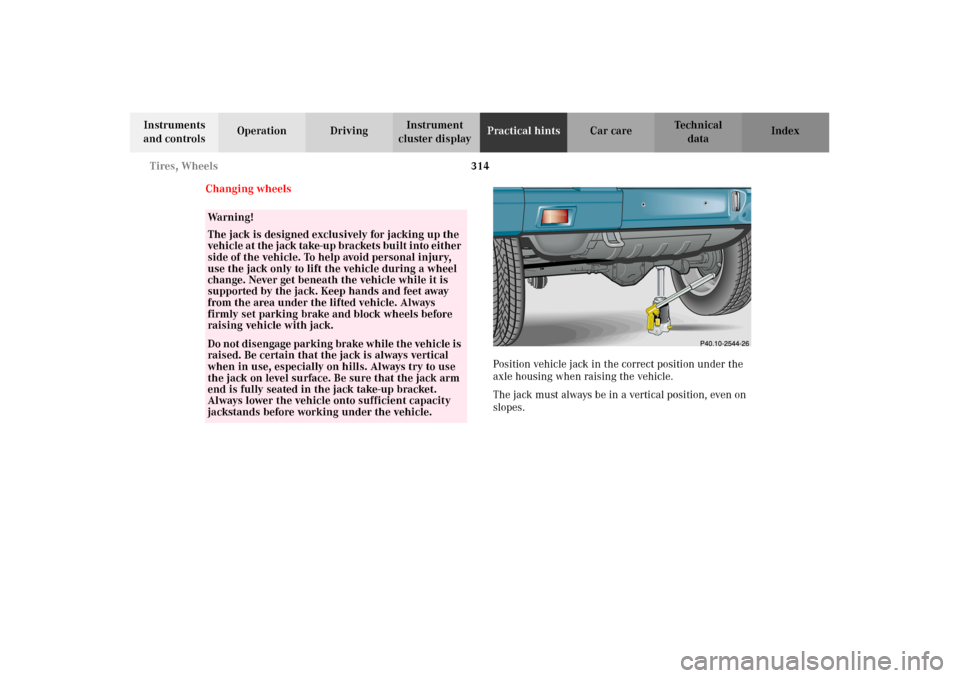

Changing wheels

Position vehicle jack in the correct position under the

axle housing when raising the vehicle.

The jack must always be in a vertical position, even on

slopes.

Wa r n i n g !

The jack is designed exclusively for jacking up the

vehi c le a t the j ack take-up b ra ckets b ui lt i nto eit her

side of the vehicle. To help avoid personal injury,

use the jack only to lift the vehicle during a wheel

change. Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet away

from the area under the lifted vehicle. Always

firmly set parking brake and block wheels before

raising vehicle with jack.Do n ot d is engage parki n g brake w hil e t he vehi c le i s

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

end is fully seated in the jack take-up bracket.

Always lower the vehicle onto sufficient capacity

jackstands before working under the vehicle.

J_G463.book Seite 314 Mittwoch, 19. September 2001 8:06 08

Page 318 of 385

315 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

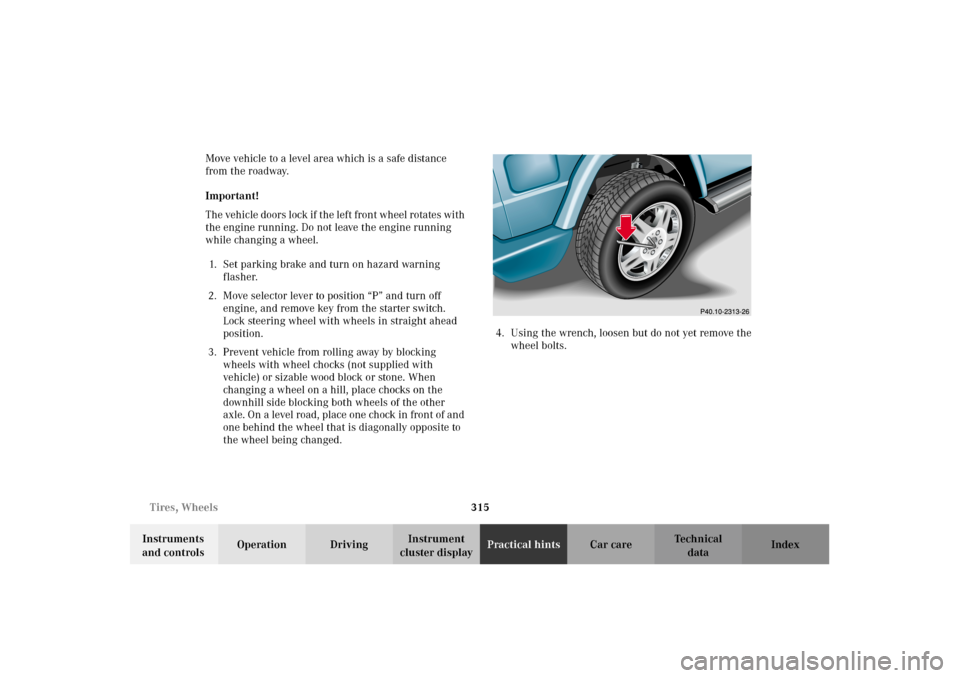

cluster displayPractical hintsCar care Index Move vehicle to a level area which is a safe distance

from the roadway.

Important!

The vehic le door s lock if t he lef t f ron t wheel r otate s with

the engine running. Do not leave the engine running

while changing a wheel.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine, and remove key from the starter switch.

Lock steering wheel with wheels in straight ahead

position.

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On a level road, place one chock in front of and

one behind the wheel that is diagonally opposite to

the wheel being changed.4. Using the wrench, loosen but do not yet remove the

wheel bolts.

J_G463.book Seite 315 Mittwoch, 19. September 2001 8:06 08

Page 319 of 385

316 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

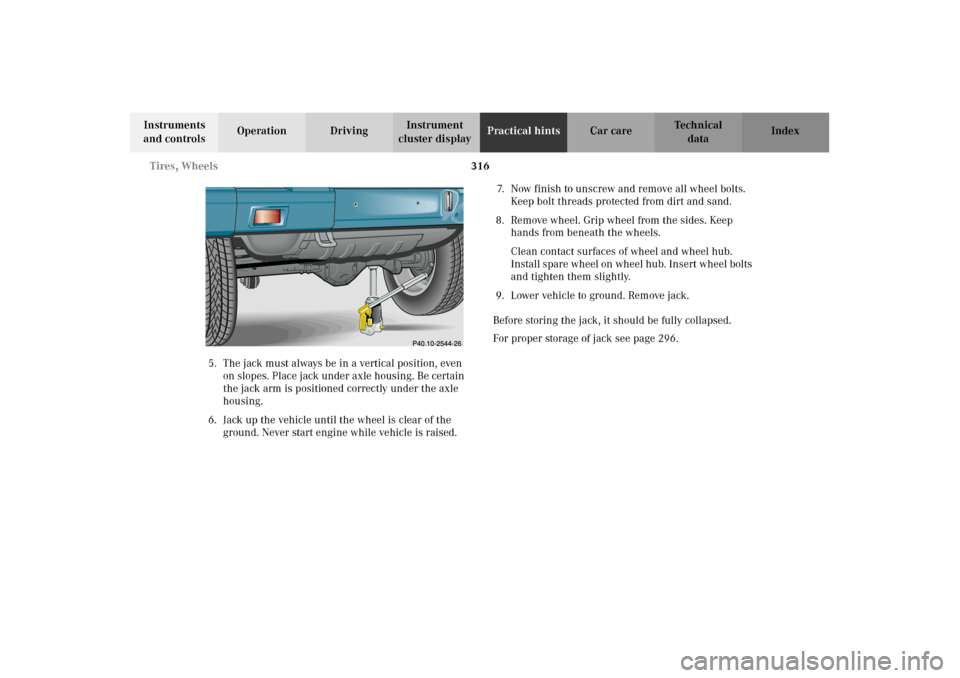

5. The jack must always be in a vertical position, even

on slopes. Place jack under axle housing. Be certain

the jack arm is positioned correctly under the axle

housing.

6. Jack up the vehicle until the wheel is clear of the

ground. Never start engine while vehicle is raised.7. Now finish to unscrew and remove all wheel bolts.

Keep bolt threads protected from dirt and sand.

8. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.

Clean contact surfaces of wheel and wheel hub.

Install spare wheel on wheel hub. Insert wheel bolts

and tighten them slightly.

9. Lower vehicle to ground. Remove jack.

Before storing the jack, it should be fully collapsed.

For proper storage of jack see page 296.

J_G463.book Seite 316 Mittwoch, 19. September 2001 8:06 08

Page 320 of 385

317 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

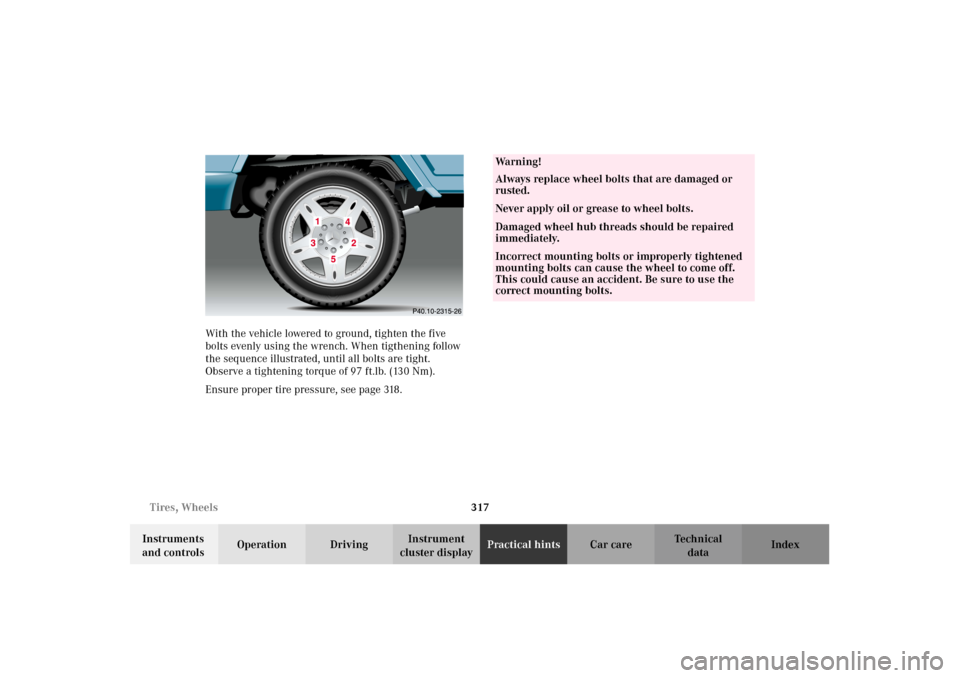

cluster displayPractical hintsCar care Index With the vehicle lowered to ground, tighten the five

bolts evenly using the wrench. When tigthening follow

the sequence illustrated, until all bolts are tight.

Observe a tightening torque of 97 ft.lb. (130 Nm).

Ensure proper tire pressure, see page 318.

Wa r n i n g !

Always replace wheel bolts that are damaged or

rusted.Never apply oil or grease to wheel bolts.Damaged wheel hub threads should be repaired

immediately.Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

This could cause an accident. Be sure to use the

correct mounting bolts.

J_G463.book Seite 317 Mittwoch, 19. September 2001 8:06 08