wheel alignment MERCEDES-BENZ GLS 2019 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLS, Model: MERCEDES-BENZ GLS 2019Pages: 398, PDF Size: 7.3 MB

Page 337 of 398

Vehicle tool kit

General notes The vehicle tool kit can be found in the stowage

well under the cargo compartment floor.

Apart from certain country-specific variations,

the vehicles are not equipped with a tire-change

tool kit. Some tools for changing a wheel are

specific to the vehicle. For more information on

which tools are required to perform a wheel

change on your vehicle, consult a qualified spe-

cialist workshop.

Necessary tire-changing tools can include, for

example:

R jack

R wheel chock

R lug wrench

R ratchet wrench

R alignment bolt

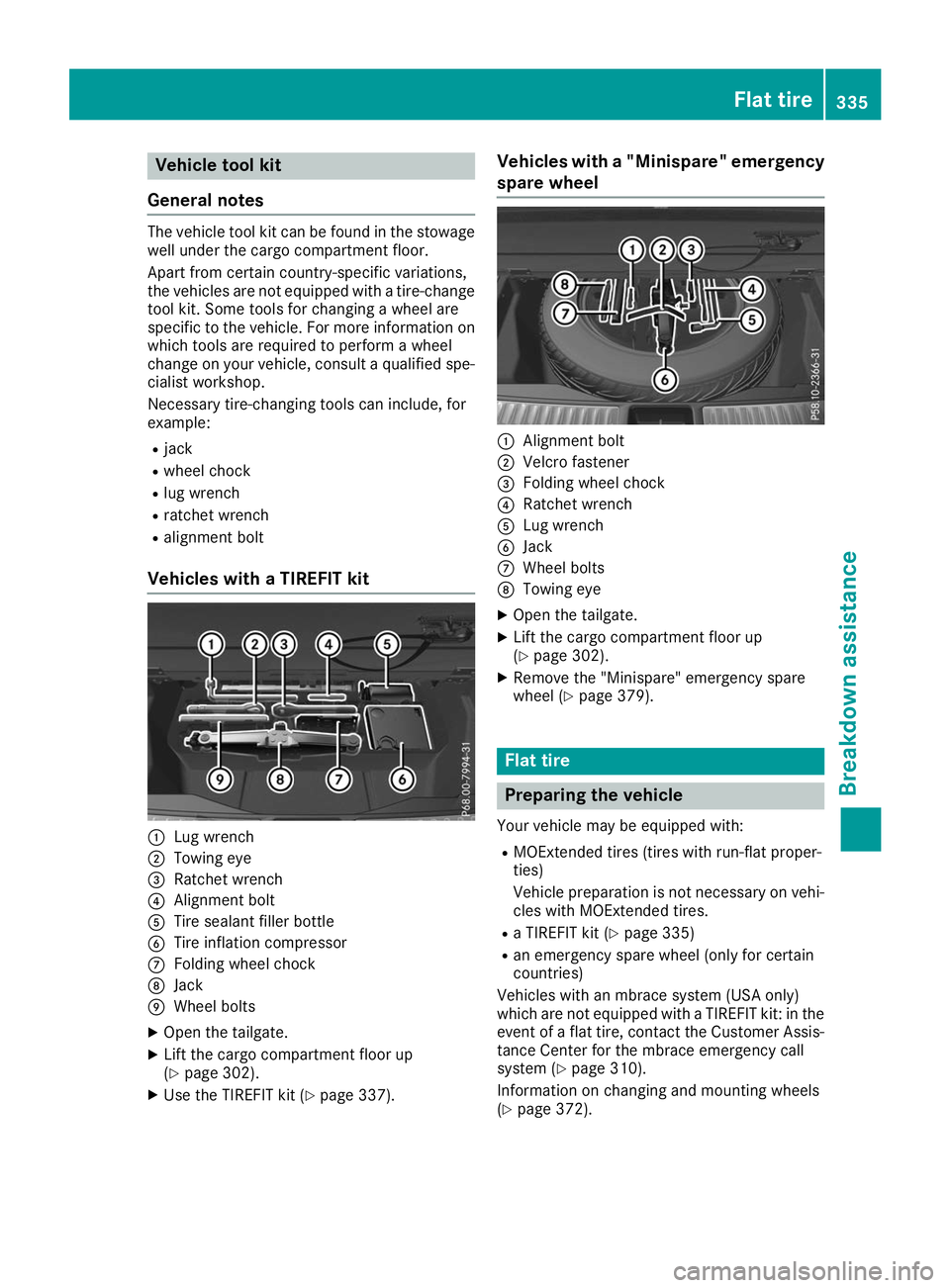

Vehicles with a TIREFIT kit 0043

Lug wrench

0044 Towing eye

0087 Ratchet wrench

0085 Alignment bolt

0083 Tire sealant filler bottle

0084 Tire inflation compressor

006B Folding wheel chock

006C Jack

006D Wheel bolts

X Open the tailgate.

X Lift the cargo compartment floor up

(Y page 302).

X Use the TIREFIT kit (Y page 337). Vehicles with a "Minispare" emergency

spare wheel 0043

Alignment bolt

0044 Velcro fastener

0087 Folding wheel chock

0085 Ratchet wrench

0083 Lug wrench

0084 Jack

006B Wheel bolts

006C Towing eye

X Open the tailgate.

X Lift the cargo compartment floor up

(Y page 302).

X Remove the "Minispare" emergency spare

wheel (Y page 379). Flat tire

Preparing the vehicle

Your vehicle may be equipped with: R MOExtended tires (tires with run-flat proper-

ties)

Vehicle preparation is not necessary on vehi-

cles with MOExtended tires.

R a TIREFIT kit (Y page 335)

R an emergency spare wheel (only for certain

countries)

Vehicles with an mbrace system (USA only)

which are not equipped with a TIREFIT kit: in the event of a flat tire, contact the Customer Assis-tance Center for the mbrace emergency call

system (Y page 310).

Information on changing and mounting wheels

(Y page 372). Flat tire

335Breakdown assis tance

Page 377 of 398

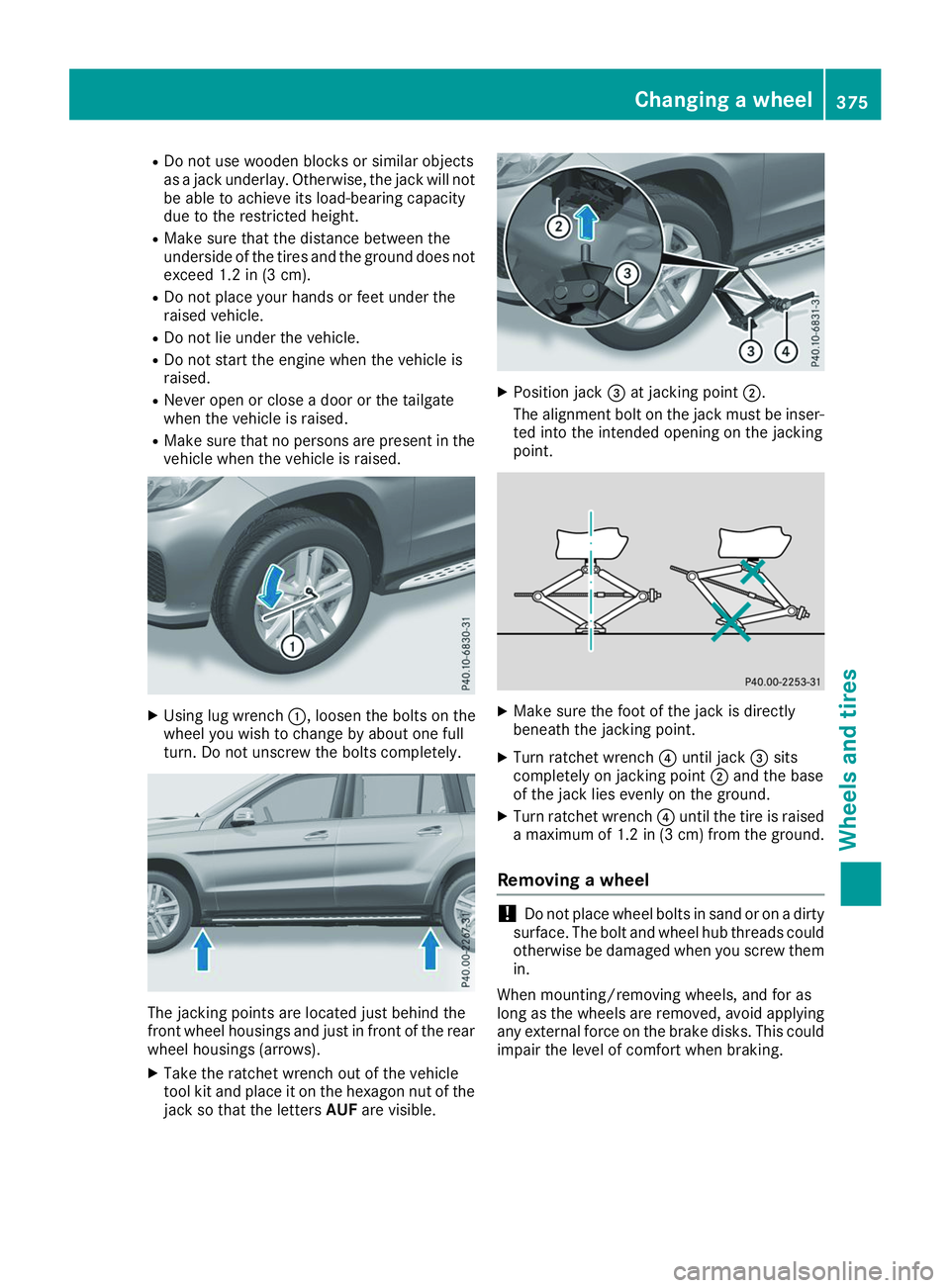

R

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not be able to achieve its load-bearing capacity

due to the restricted height.

R Make sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

R Do not place your hands or feet under the

raised vehicle.

R Do not lie under the vehicle.

R Do not start the engine when the vehicle is

raised.

R Never open or close a door or the tailgate

when the vehicle is raised.

R Make sure that no persons are present in the

vehicle when the vehicle is raised. X

Using lug wrench 0043, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely. The jacking points are located just behind the

front wheel housings and just in front of the rear wheel housings (arrows).

X Take the ratchet wrench out of the vehicle

tool kit and place it on the hexagon nut of the

jack so that the letters AUFare visible. X

Position jack 0087at jacking point 0044.

The alignment bolt on the jack must be inser- ted into the intended opening on the jacking

point. X

Make sure the foot of the jack is directly

beneath the jacking point.

X Turn ratchet wrench 0085until jack 0087sits

completely on jacking point 0044and the base

of the jack lies evenly on the ground.

X Turn ratchet wrench 0085until the tire is raised

a maximum of 1.2 in (3 cm) from the ground.

Removing a wheel !

Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying any external force on the brake disks. This could impair the level of comfort when braking. Changing a

wheel

375Wheels an d tires Z

Page 378 of 398

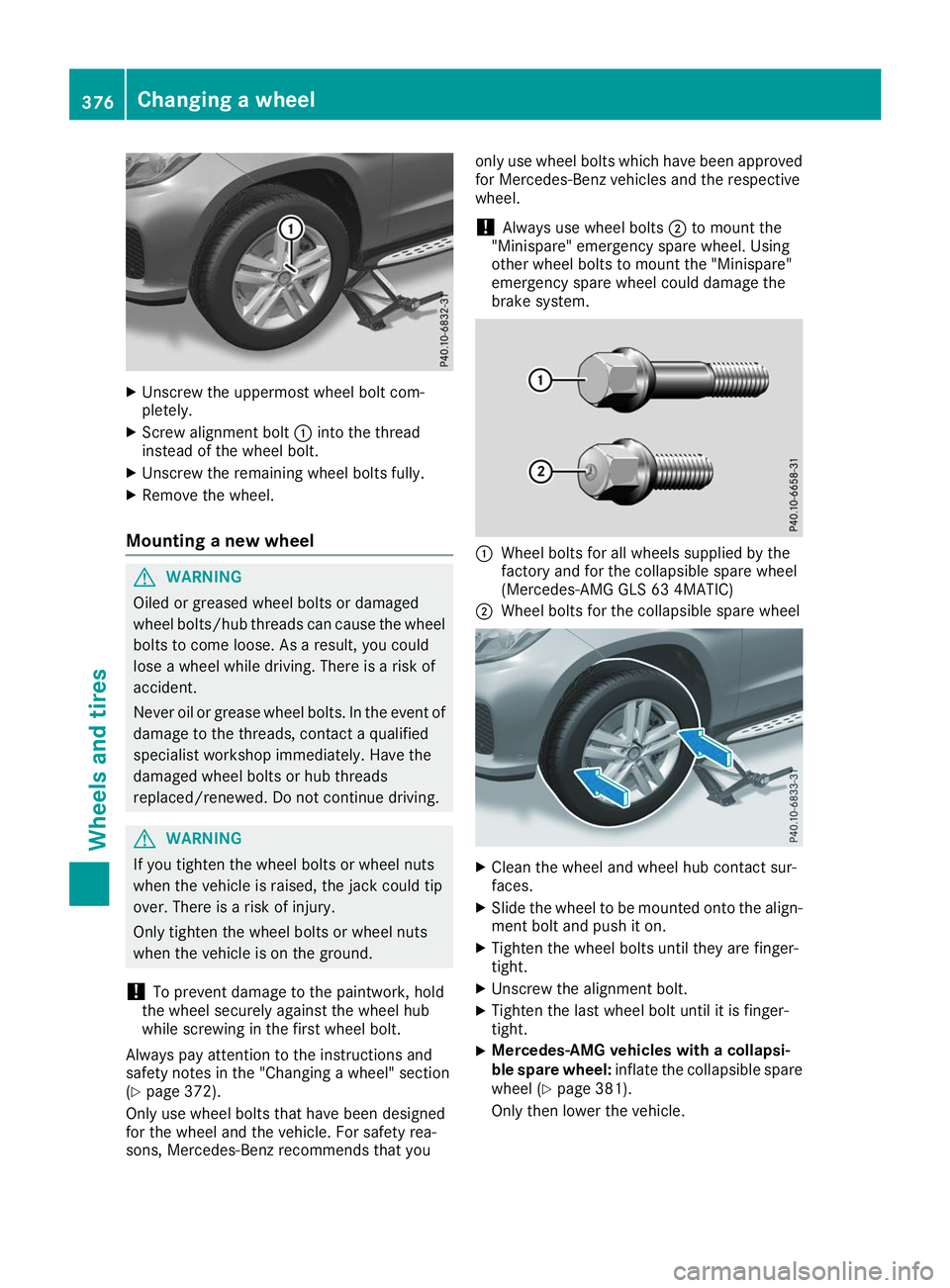

X

Unscrew the uppermost wheel bolt com-

pletely.

X Screw alignment bolt 0043into the thread

instead of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(Y page 372).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

! Always use wheel bolts

0044to mount the

"Minispare" emergency spare wheel. Using

other wheel bolts to mount the "Minispare"

emergency spare wheel could damage the

brake system. 0043

Wheel bolts for all wheels supplied by the

factory and for the collapsible spare wheel

(Mercedes-AMG GLS 63 4MATIC)

0044 Wheel bolts for the collapsible spare wheel X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the wheel to be mounted onto the align-

ment bolt and push it on.

X Tighten the wheel bolts until they are finger-

tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

X Mercedes-AMG vehicles with a collapsi-

ble spare wheel:

inflate the collapsible spare

wheel (Y page 381).

Only then lower the vehicle. 376

Changing a wheelWheels and tires