wheel MERCEDES-BENZ METRIS 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2016Pages: 310, PDF Size: 7.28 MB

Page 291 of 310

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

!On vehicles equipped withatire pressure

monitor, electronic componentsa re located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at aqualified spe-

cialist workshop.

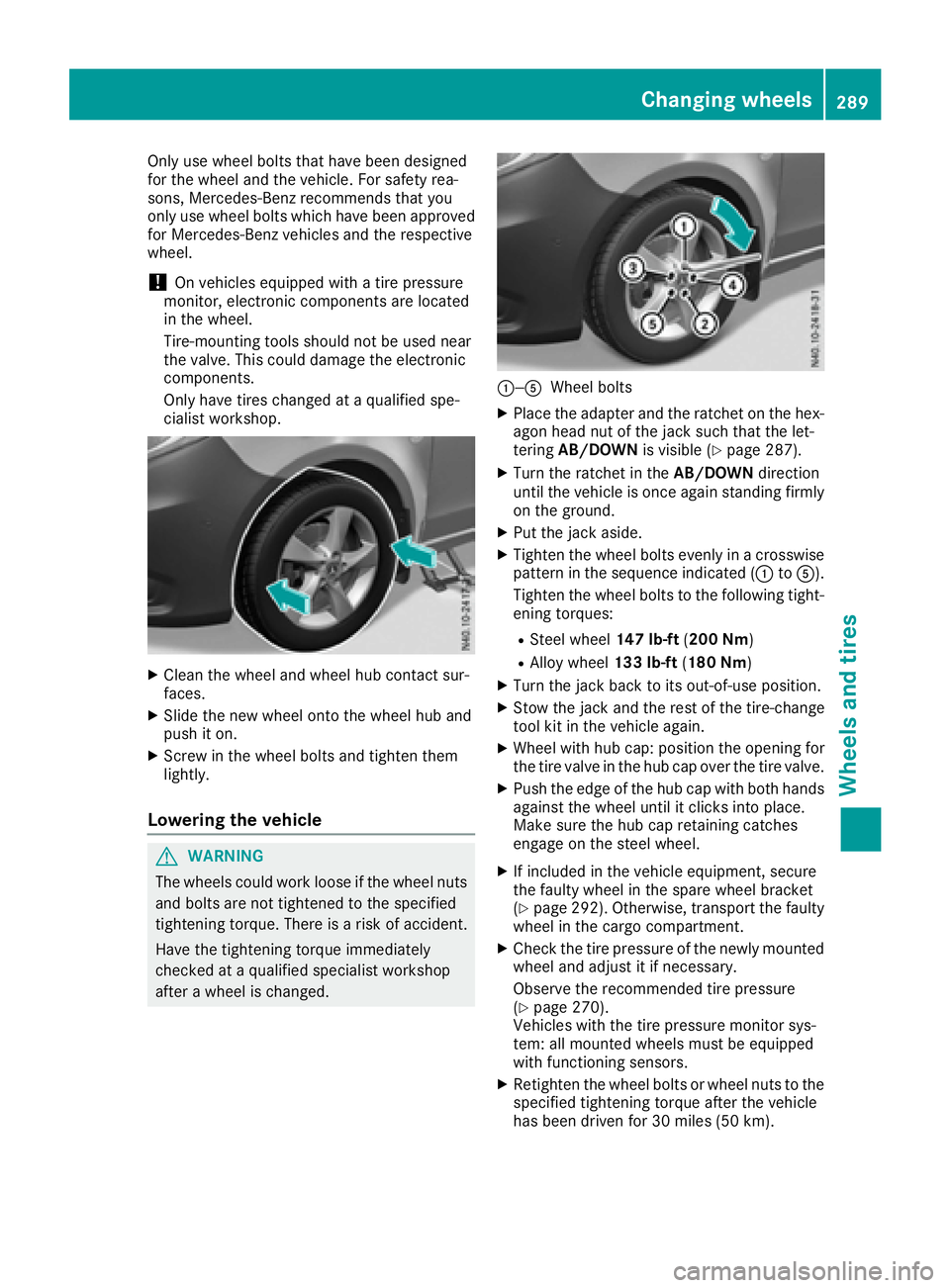

XCleant he wheel and wheel hub contact sur-

faces.

XSlide the new wheel onto the wheel hub and

push it on.

XScrew in the wheel bolts and tighten them

lightly.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is arisk of accident.

Have the tightening torque immediately

checked at aqualified specialist workshop

after awheel is changed.

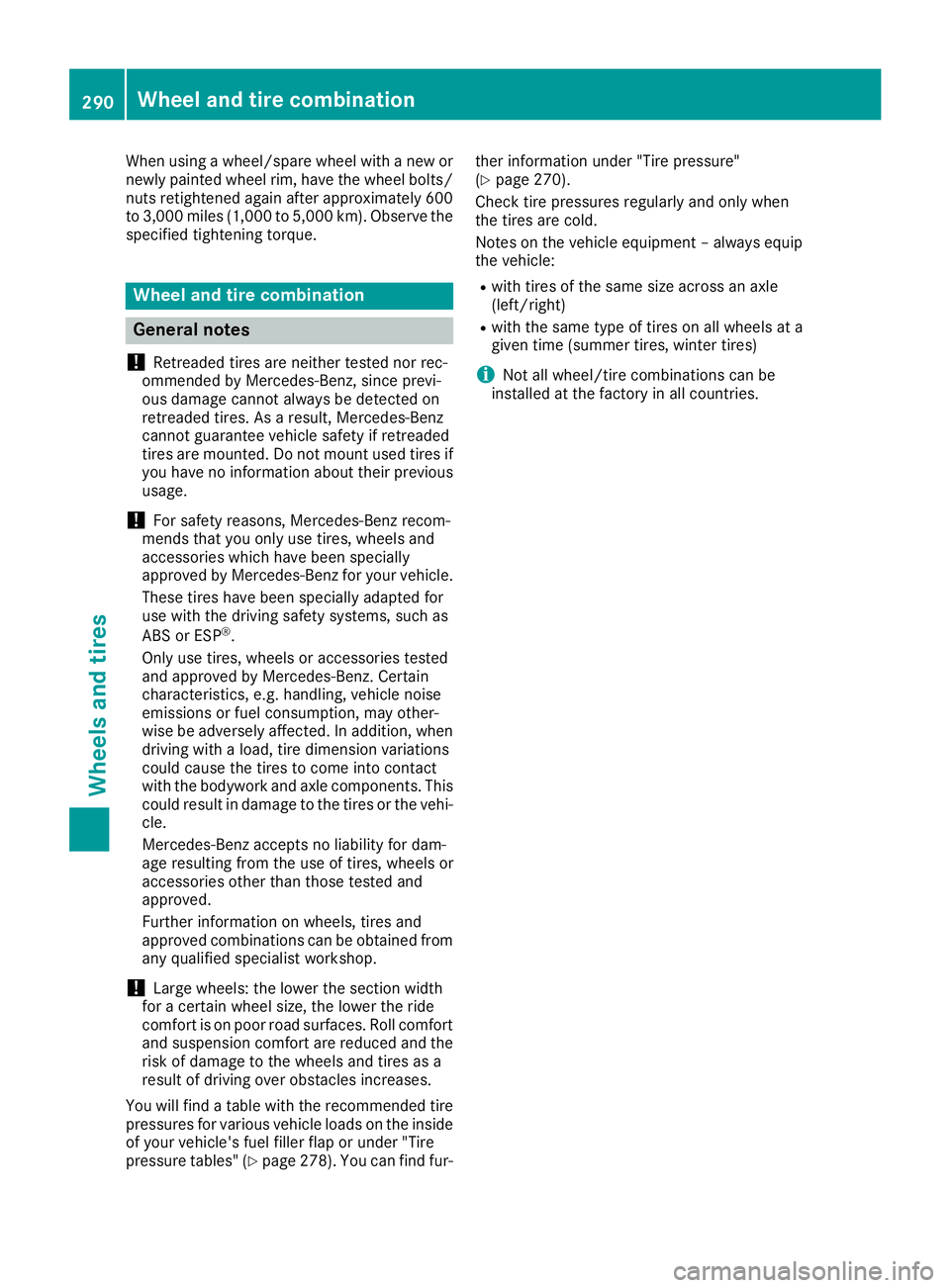

:—AWheel bolts

XPlace the adapter and the ratchet on the hex-

agon head nut of the jack such that the let-

tering AB/DOWN is visible (

Ypage 287).

XTurn the ratchet in the AB/DOWNdirection

until the vehicle is once agains tanding firmly

on the ground.

XPut the jack aside.

XTighten the wheel bolts evenly in acrosswise

pattern in the sequence indicated (: toA).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 147 lb-ft(200 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

XTurn the jack back to its out-of-use position.

XStow the jack and the rest of the tire-change

tool kit in the vehicle again.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XIf included in the vehicle equipment, secure

the faulty wheel in the spare wheel bracket

(

Ypage 292). Otherwise, transport the faulty

wheel in the cargo compartment.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 270).

Vehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functionings ensors.

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

Changing wheels289

Wheels and tires

Z

Page 292 of 310

When usingawheel/spare wheel with anew or

newly painted wheel rim, have the wheel bolts/

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

Wheel and tirec ombination

General notes

!

Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz,s ince previ-

ous damage cannot alwaysbed etected on

retreaded tires. As aresult, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if you have no information about their previous

usage.

!For safety reasons, Mercedes-Benz recom-

mends that you only use tires, wheels and

accessories which have been specially

approved by Mercedes-Benz for your vehicle.

These tires have been specially adapted for

use with the driving safety systems, such as

ABS or ESP

®.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz .Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with aload, tire dimension variations

could cause the tires to come into contact

with the bodywork and axle components. This

could result in damage to the tires or the vehi-

cle.

Mercedes-Benz acceptsnol iability for dam-

age resulting from the use of tires, wheels or

accessories other than those tested and

approved.

Further information on wheels, tires and

approved combinations can be obtained from

any qualified specialist workshop.

!Large wheels: the lower the section width

for acertain wheel size, the lower the ride

comfort is on poor road surfaces. Roll comfort and suspension comfort are reduced and the

risk of damage to the wheels and tires as a

result of driving over obstacles increases.

You will find atable with the recommended tire

pressures for various vehicle loads on the inside

of your vehicle's fuel filler flap or under "Tire

pressure tables" (

Ypage 278). You can find fur- ther information under "Tire pressure"

(

Ypage 270).

Check tire pressures regularly and only when

the tires are cold.

Notes on the vehicle equipment –alwayse quip

the vehicle:

Rwith tires of the same size across an axle

(left/right)

Rwith the same type of tires on all wheels at a

given time (summer tires, winter tires)

iNot all wheel/tire combinations can be

installed at the factory in all coun tries.

290Wheel and tirecombination

Wheels and tires

Page 293 of 310

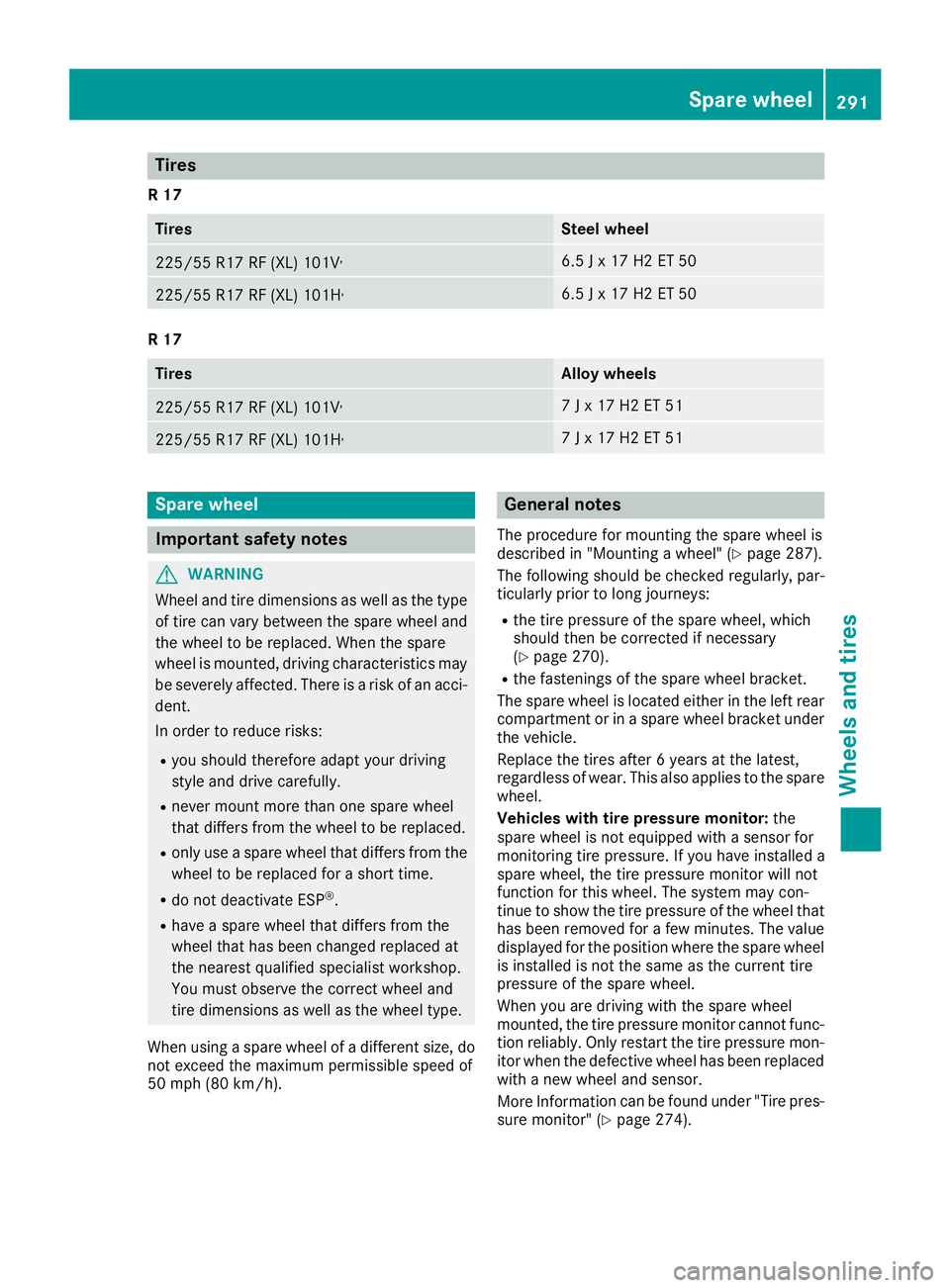

Tires

R17

TiresSteel wheel

225/55R 17RF (XL) 101V,6.5Jx17H2ET5 0

225/55 R17 RF (XL )101H,6.5 Jx17H2ET5 0

R17

TiresAllo ywheels

225/55 R17 RF (XL )101V,7Jx17H2ET5 1

225/55 R17 RF (XL )101H,7Jx17H2ET5 1

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can var ybetween the spare whee land

the whee ltobereplaced .Whent he spare

whee lismounted, driving characteristic smay

be severely affected. There is ariskofana cci-

dent.

In order to reduce risks:

Ryo us houl dtherefore adap tyou rd riving

style and drive carefully.

Rneve rmount more thano ne spare wheel

thatd iffer sfrom the whee ltobereplaced.

Ronlyuseaspare whee lthatd iffer sfrom the

whee ltober eplaced for ashort time.

Rdo not deactivate ESP®.

Rhave aspare whee lthatd iffer sfrom the

whee lthath asbeen changed replaced at

the neares tquali fied specialist workshop.

Yo um usto bserve the correct whee land

tire dimensions as well as the whee ltype.

Whe nusing aspare whee lofadifferent size, do

not exceed the maximump ermissibl espeed of

50 mph (80 km/h).

General notes

The procedure for mounting the spare whee lis

describe din"Mounting awheel "(Ypage 287).

The following shoul dbechecked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

shoul dthen be corrected if necessary

(

Ypage 270).

Rthe fastenings of the spare whee lbracket.

The spare whee lislocate deither in the left rear

compartment or in aspare whee lbracket under

the vehicle.

Replace the tire safter6y ears at the latest,

regardless of wear. Thi salsoa pplies to the spare

wheel.

Vehicles with tire pressure monitor: the

spare whee lisnot equipped with asensor for

monitoring tire pressure. If yo uhavei nstalle da

spare wheel, the tire pressure monitor will not

functio nfor this wheel. The system may con-

tinu etos howt he tire pressure of the whee lthat

hasb eenr emoved for afew minutes. The value

displayed for the position where the spare wheel

is installe disnot the same as the current tire

pressure of the spare wheel.

Whe nyou are driving with the spare wheel

mounted, the tire pressure monitor canno tfunc-

tio nr eliably. Only restart the tire pressure mon-

ito rw henthe defective whee lhas been replaced

with anew whee land sensor.

Mor eInformati on can be found under "Tire pres-

sure

monitor" (Ypage 274).

Spare wheel291

Wheel sand tires

Z

Page 294 of 310

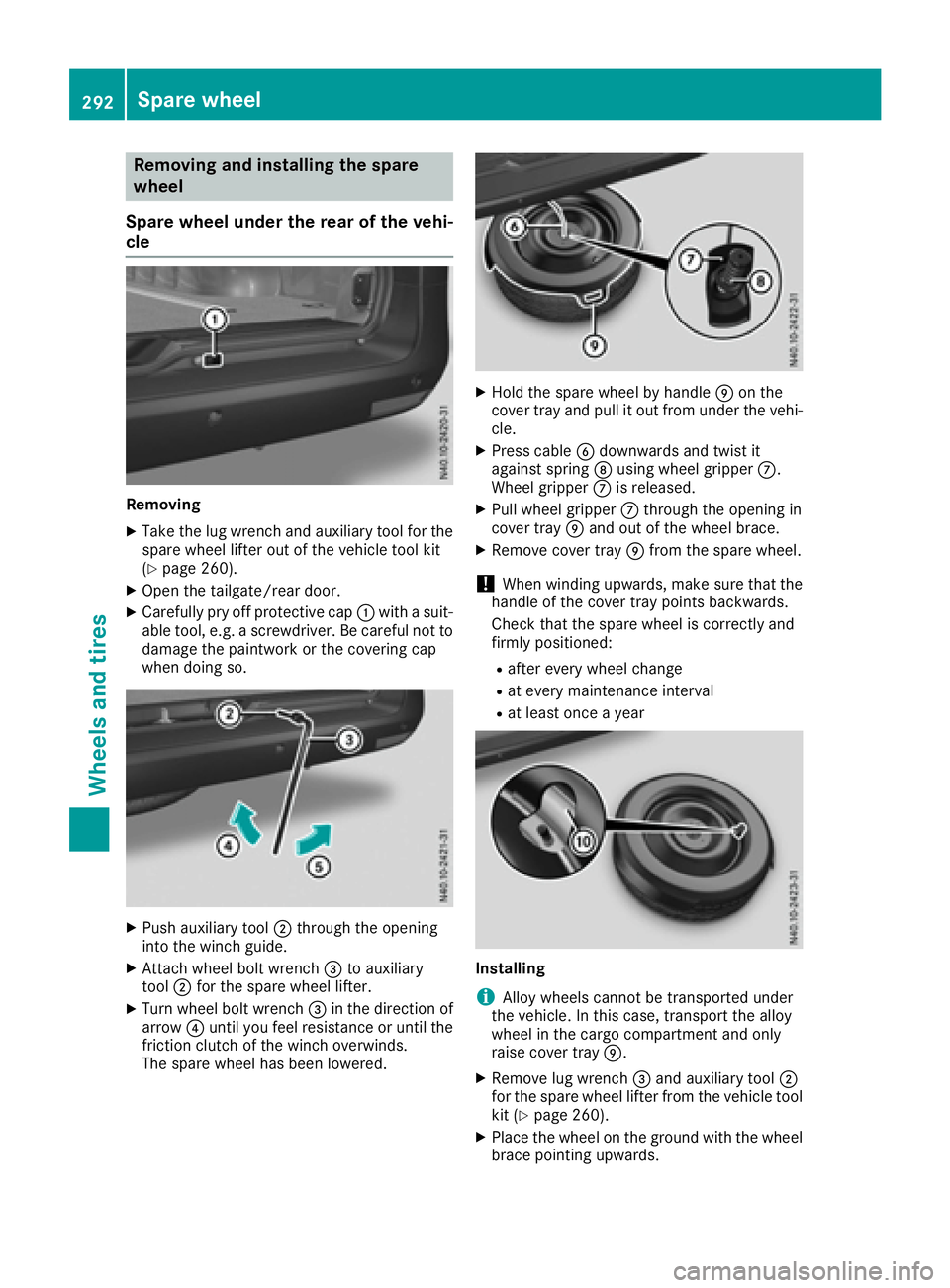

Removingand installing the spare

wheel

Spare wheel undert he rear of the vehi-

cle

Removing

XTake the lu gwrench and auxiliary tool for the

spare wheel lifter outoft he vehicletool kit

(

Ypage 260).

XOpe nthe tailgate/rea rdoor.

XCarefull ypry off protectiv ecap : with asuit-

able tool ,e.g. ascrewdriver. Be careful not to

damag ethe paintwork or the covering cap

when doing so.

XPush auxiliary tool ;through the opening

into the winch guide.

XAttach wheel bol twrench =to auxiliary

tool ;for the spare wheel lifter.

XTurn wheel bol twrench =in the direction of

arrow ?unti lyou fee lresistance or unti lthe

friction clutch of the winch overwinds.

The spare wheel hasb eenlowered.

XHoldt he spare wheel by handle Eon the

cove rtray and pull it outf rom under the vehi-

cle.

XPress cable Bdownwards and twist it

against spring Dusing wheel gripper C.

Wheel gripper Cis released.

XPull wheel gripper Cthrough the opening in

cove rtray Eand outoft he wheel brace.

XRemove cove rtray Efrom the spare wheel.

!Whe nwinding upwards ,make sure that the

handleoft he covertray points backwards.

Check that the spare wheel is correctly and

firmly positioned:

Rafte revery wheel change

Rat every maintenance interval

Rat leas tonce ayear

Installing

iAlloy wheel scanno tbetransported under

the vehicle. In this case, transpor tthe alloy

wheel in the carg ocompartment and only

raise cove rtray E.

XRemove lu gwrench =and auxiliary tool ;

for the spare wheel lifter from the vehicl etool

kit (

Ypage 260).

XPlace the wheel on the ground with the wheel brace pointing upwards.

292Spare wheel

Wheel sand tires

Page 295 of 310

XPlace cover trayEon the wheel so that the

recess for tire valve Fis above the valve.

XPress cover tray Eont othe wheel brace and

align the wheel so that the handle of cover

tray Efaces backwards.

XGuide wheel gripper Cat an angle on wire B

through the opening in cover tray Eand into

the wheel brace from above.

XSlide the wheel under the vehicle alittle.

XAttach lug wrench =to auxiliary tool ;for

the spare wheel lifter.

XTurn lug wrench =in the direction of arrow

A until you feel resistanc eand the friction

clutch of the winch overwinds in jerks.

The wheel is firmly secured to the underside

of the vehicle.

XPull lug wrench =and auxiliary tool ;for the

spare wheel lifter out of the opening for the

winch.

XClose the winch opening with covering

cap :.

XStow wheel bolt wrench =and auxiliary

tool ;for the spare wheel lifter in the vehicle

tool kit.

XClose the tailgate/rear door.

Sparew heel293

Wheels and tires

Z

Page 300 of 310

The following components of the different vehi-

cle versions influence fuel consumption:

Rtire sizes, tire tread, tire pressure, tire condi-

tion

Rtransmission ratios for the drive assemblies

Radditional equipment (e.g. air-conditioning

system, auxiliary heating system)

For these reasons, the actual consumption fig-

ures for your vehicle may deviate from the con-

sumption figures determined according to EU

Directive 80/1268/EE C.

Detail sonfuelconsumption can be calle dupin

the on-board computer:

Ron vehicles withou tsteerin gwheel buttons

(Ypage 171)

Ron vehicles with steerin gwheel buttons

(Ypage 178)

Engine oil

General notes

When handling engine oil, observe the important

safety note sonserviceproducts (Ypage 295).

The quality of the engine oi lusedisofd ecisive

importance for the engine's functionality and

operating life. Mercedes-Benz continually

approves engine oils based on comple xexperi-

ments according to the current state of the art.

Therefore ,onlyM ercedes-Benz approved

engine oils maybeu sedinM ercedes-Benz

engines. Mercedes-Benz recommends having

the oi lchange dataq ualified specialis twork-

shop. Informatio

nabout approved engine oils can be

obtained:

Rfroma ny Mercedes-Benz Commercial Van

Center

Ron the Internet at

http://bevo.mercedes-benz.co mbyenter ing

th ed esignation ,e.g.2 29.5 .

Mercedes-Ben zapprova lisindicate dont heoil

container by th einscriptio n„MB-Freigabe “or

„MB Approval“ and th ecorre spondin gdesigna-

tion ,e.g.M B-Freig abe or MB Approval 229.5.

Designation softheapprove dengineo ils for

your vehicl e

MB-Freigabe or MB

Approval229.5

Mercedes-Ben zrecommends that you only use

approve dmulti-grade engin eoils of th eSAE

classe sSAE 0W-30 and SA E0W-40 or

SA E5 W-30 and SA E5W-40. These engin eoils

ensur eoptimum lubrication eve natveryl ow

outside temperatures (

Ypage 299).

Whe ntoppin gup, we recommen dthaty ou only

use engin eoil of th esam egrade (MB-Freigabe

or MB Approvaldesignation )and SA Eclass as

th eo il filled at th elast oil change.

iIf th eengineo ils listed in th etable are no t

available, you may add th efollowin gengine

oils until th enexto il change:

RMB-Freigabe or MB Approval 229.1, or

ACE AA3

This mus tonlybea dded once and th eamount

mus tnotbe greate rtha n1q t(1.0l ).

Subsequentl yhavet he engin eoil changed at

th ee arliest possibl eopportunity.

!Using engin eoils of another grade qualit yis

no tp ermitted.

Capacities

!Do no tadd to omucho il. addin gtoo muc h

engin eoil can result in damage to th eengine

or to th ecatalytic converter. Hav eexces s

engin eoil siphoned off .

Oil change includin goil filter

Engin eoilApprox. 2USgal

(7.75 l)

298Service products and capacities

Technical data

Page 305 of 310

Vehicledata

General notes

The following section contains important tech-

nica ldataf or your vehicle. Additionalv ehicle-

specifi cand equipment-dependent technical

data, such as vehicl eweigh ts, can be found in

your vehicl eregistration papers.

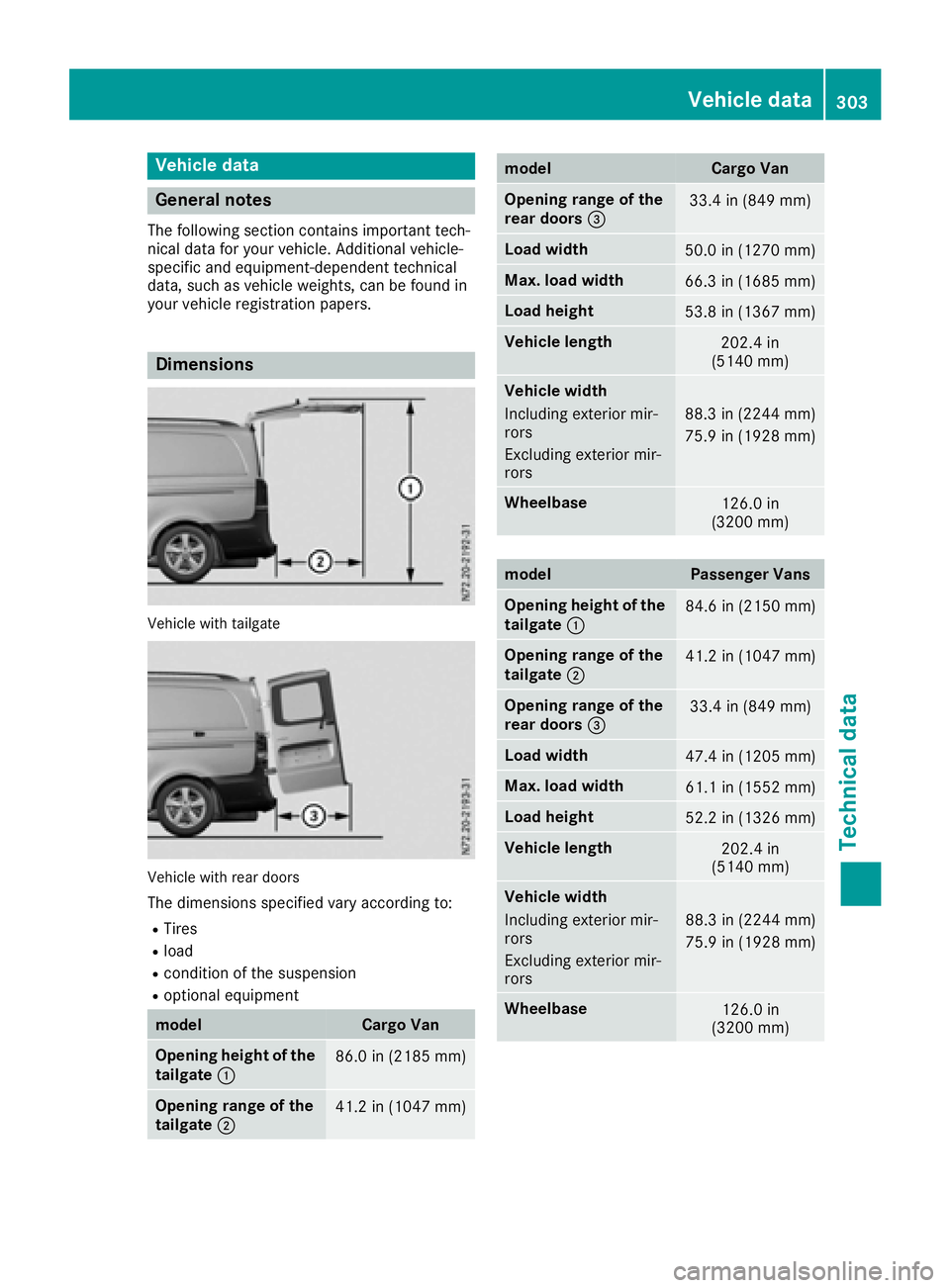

Dimensions

Vehicl ewitht ailgate

Vehicl ewithr eard oors

The dimensions specified var yaccording to:

RTires

Rload

Rcondition of the suspension

Roptional equipment

modelCarg oVan

Opening height of the

tailgate :86.0 in (2185 mm)

Opening rang eofthe

tailgate ;41.2 in (1047 mm)

modelCargoVan

Opening rang eofthe

rear doors =33.4 in (849 mm)

Load width50.0 in (1270 mm)

Max. load width66.3 in (1685 mm)

Load height53.8 in (1367 mm)

Vehiclelengt h202.4 in

(514 0mm)

Vehicl ewidth

Including exterio rmir-

rors

Excluding exterio rmir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(320 0mm)

modelPassenger Vans

Opening height of the

tailgate :84.6 in (2150 mm)

Opening rang eofthe

tailgate ;41.2 in (1047 mm)

Opening rang eofthe

rear doors =33.4 in (849 mm)

Load width47.4 in (1205 mm)

Max. load width61.1 in (1552 mm)

Load height52.2 in (1326 mm)

Vehiclelengt h202.4 in

(514 0mm)

Vehicl ewidth

Including exterio rmir-

rors

Excluding exterio rmir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(320 0mm)

Vehicl edata303

Technica ldata

Z