warning MERCEDES-BENZ METRIS 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2016Pages: 310, PDF Size: 7.28 MB

Page 291 of 310

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

!On vehicles equipped withatire pressure

monitor, electronic componentsa re located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at aqualified spe-

cialist workshop.

XCleant he wheel and wheel hub contact sur-

faces.

XSlide the new wheel onto the wheel hub and

push it on.

XScrew in the wheel bolts and tighten them

lightly.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is arisk of accident.

Have the tightening torque immediately

checked at aqualified specialist workshop

after awheel is changed.

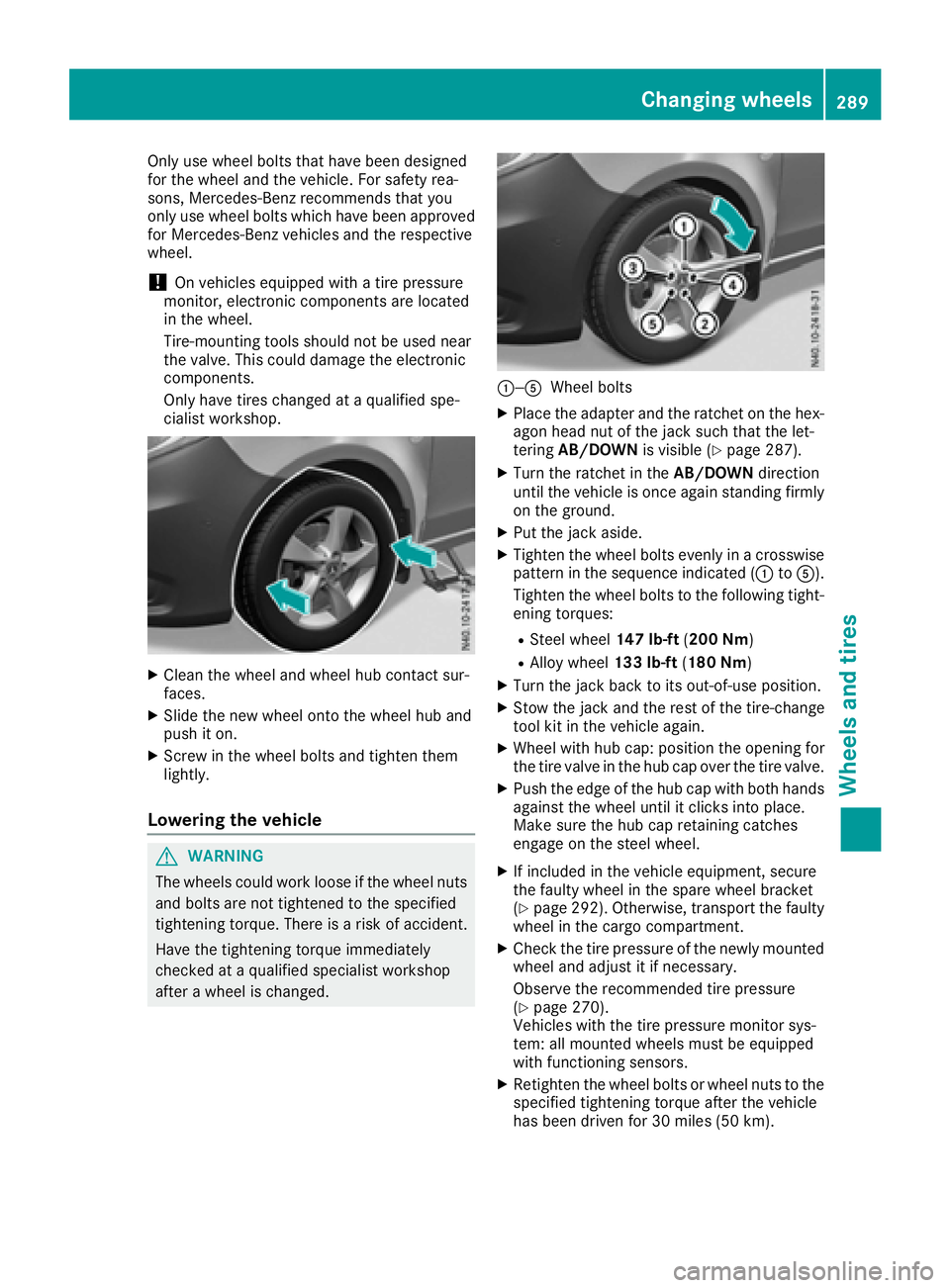

:—AWheel bolts

XPlace the adapter and the ratchet on the hex-

agon head nut of the jack such that the let-

tering AB/DOWN is visible (

Ypage 287).

XTurn the ratchet in the AB/DOWNdirection

until the vehicle is once agains tanding firmly

on the ground.

XPut the jack aside.

XTighten the wheel bolts evenly in acrosswise

pattern in the sequence indicated (: toA).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 147 lb-ft(200 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

XTurn the jack back to its out-of-use position.

XStow the jack and the rest of the tire-change

tool kit in the vehicle again.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XIf included in the vehicle equipment, secure

the faulty wheel in the spare wheel bracket

(

Ypage 292). Otherwise, transport the faulty

wheel in the cargo compartment.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 270).

Vehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functionings ensors.

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

Changing wheels289

Wheels and tires

Z

Page 293 of 310

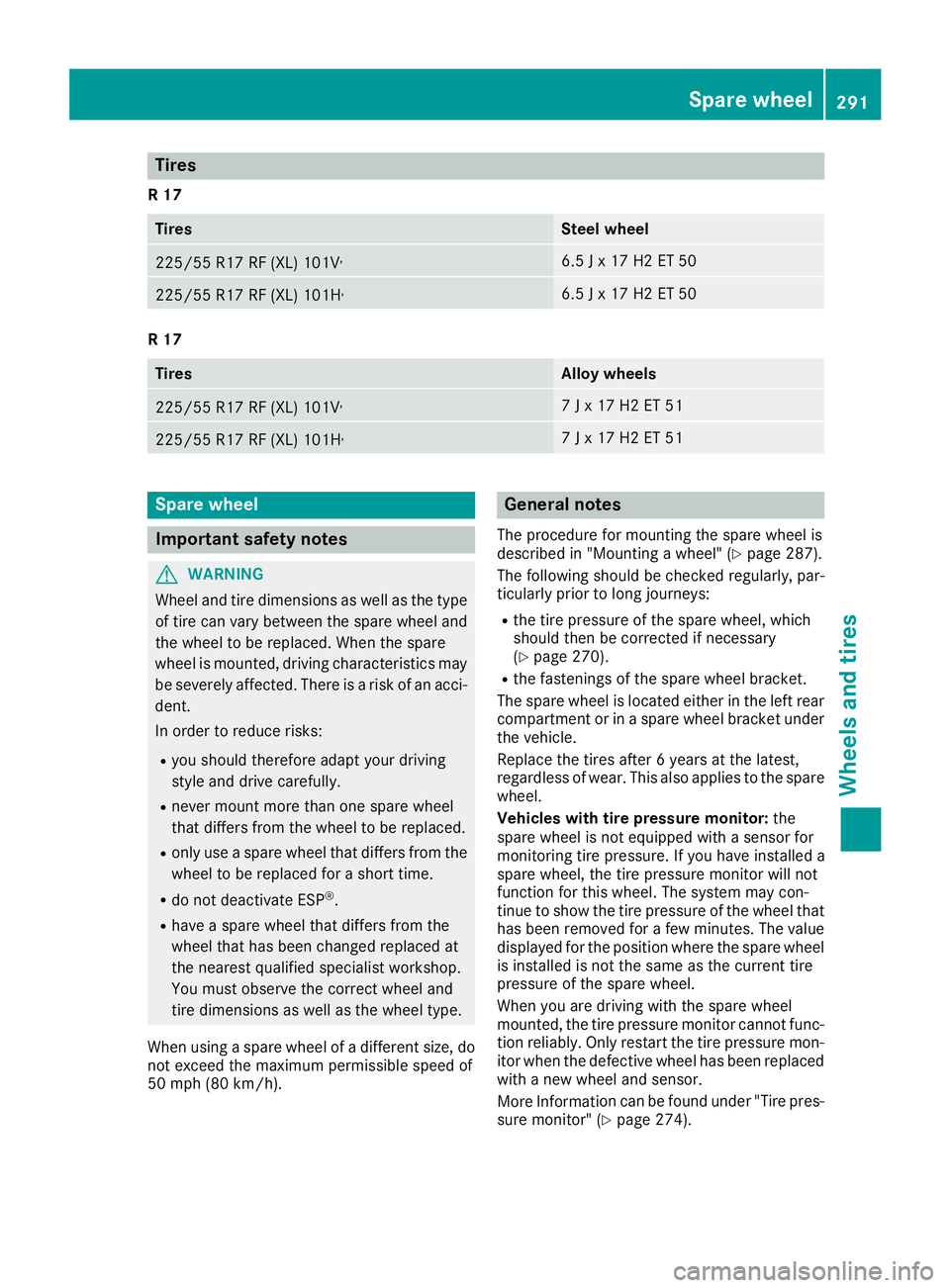

Tires

R17

TiresSteel wheel

225/55R 17RF (XL) 101V,6.5Jx17H2ET5 0

225/55 R17 RF (XL )101H,6.5 Jx17H2ET5 0

R17

TiresAllo ywheels

225/55 R17 RF (XL )101V,7Jx17H2ET5 1

225/55 R17 RF (XL )101H,7Jx17H2ET5 1

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can var ybetween the spare whee land

the whee ltobereplaced .Whent he spare

whee lismounted, driving characteristic smay

be severely affected. There is ariskofana cci-

dent.

In order to reduce risks:

Ryo us houl dtherefore adap tyou rd riving

style and drive carefully.

Rneve rmount more thano ne spare wheel

thatd iffer sfrom the whee ltobereplaced.

Ronlyuseaspare whee lthatd iffer sfrom the

whee ltober eplaced for ashort time.

Rdo not deactivate ESP®.

Rhave aspare whee lthatd iffer sfrom the

whee lthath asbeen changed replaced at

the neares tquali fied specialist workshop.

Yo um usto bserve the correct whee land

tire dimensions as well as the whee ltype.

Whe nusing aspare whee lofadifferent size, do

not exceed the maximump ermissibl espeed of

50 mph (80 km/h).

General notes

The procedure for mounting the spare whee lis

describe din"Mounting awheel "(Ypage 287).

The following shoul dbechecked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

shoul dthen be corrected if necessary

(

Ypage 270).

Rthe fastenings of the spare whee lbracket.

The spare whee lislocate deither in the left rear

compartment or in aspare whee lbracket under

the vehicle.

Replace the tire safter6y ears at the latest,

regardless of wear. Thi salsoa pplies to the spare

wheel.

Vehicles with tire pressure monitor: the

spare whee lisnot equipped with asensor for

monitoring tire pressure. If yo uhavei nstalle da

spare wheel, the tire pressure monitor will not

functio nfor this wheel. The system may con-

tinu etos howt he tire pressure of the whee lthat

hasb eenr emoved for afew minutes. The value

displayed for the position where the spare wheel

is installe disnot the same as the current tire

pressure of the spare wheel.

Whe nyou are driving with the spare wheel

mounted, the tire pressure monitor canno tfunc-

tio nr eliably. Only restart the tire pressure mon-

ito rw henthe defective whee lhas been replaced

with anew whee land sensor.

Mor eInformati on can be found under "Tire pres-

sure

monitor" (Ypage 274).

Spare wheel291

Wheel sand tires

Z

Page 297 of 310

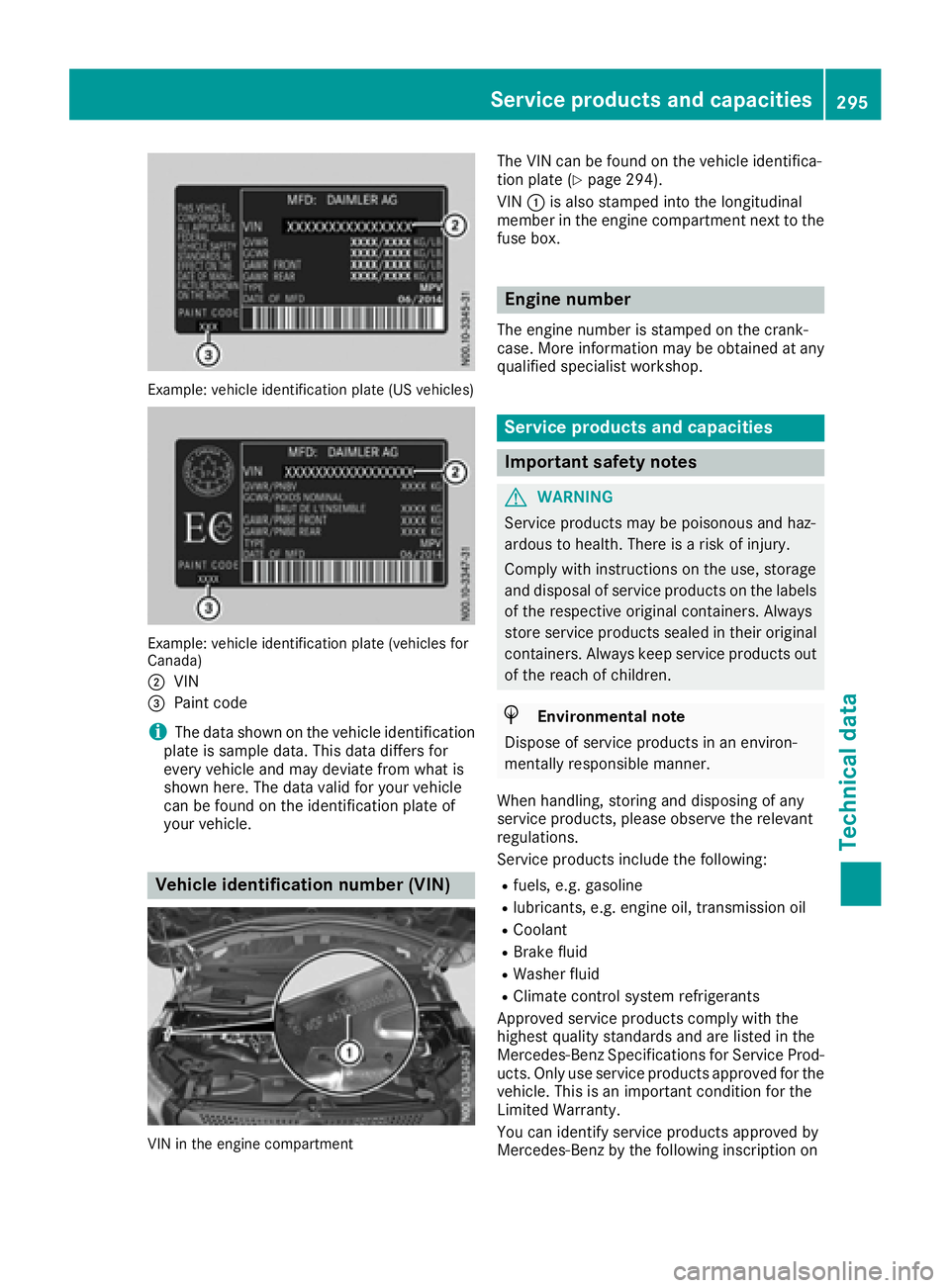

Example: vehicleide ntification plate (US vehicles)

Example: vehicl eide ntification plate (vehicle sfor

Canada)

;

VIN

=Paint code

iThe data shown on the vehicl eide ntification

plate is sampl edata. Thi sdatad iffers for

every vehicl eand mayd eviate from what is

shown here. The data vali dfor your vehicle

can be found on the identificatio nplate of

your vehicle.

Vehicl eidentificatio nnumber (VIN)

VIN in the engine compartment

The VIN can be found on the vehicl eide ntifica-

tio np late (Ypage 294).

VIN :is also stampe dinto the longitudinal

membe rinthe engine compartment next to the

fuse box.

Engine number

The engine numbe risstampe donthe crank-

case. Mor einformatio nmaybe obtained at any

qualified specialist workshop.

Service products and capacities

Important safety notes

GWARNING

Service products maybep oisonousand haz-

ardous to health .There is ariskofi njury.

Compl ywithi nstructions on the use, storage

and disposalofs erviceproducts on the labels

of the respective original containers. Always

stor eservic eproducts seale dintheiroriginal

containers. Alway skeeps ervic eproducts out

of the reach of children.

HEnvironmental note

Dispose of servic eproducts in an environ-

mentall yresponsibl emanner.

Whe nhandling ,storing and disposing of any

servic eproducts, please observe the relevant

regulations.

Service products includ ethe following:

Rfuels, e.g .gasoline

Rlubricants ,e.g.e ngine oil, transmission oil

RCoolant

RBrake fluid

RWashe rfluid

RClimate contro lsystem refrigerants

Approve dservic eproducts comply with the

highest quality standards and ar elisted in the

Mercedes-Benz Specifications for Service Prod-

ucts .Onlyu seservic eproducts approved for the

vehicle. Thi sisanimportant condition for the

Limite dWarranty.

Yo uc an identify servic eproducts approved by

Mercedes-Benz by the following inscription on

Servic eproducts and capacities295

Technica ldata

Z

Page 298 of 310

the containers: MB-Freigabe or MB-Approval

(e.g. MB-Freigabe or MB-Approval228.5)

Mor einformation can be obtained at any quali-

fie ds pecialis tworkshop.

Additives for approved service products ar enei-

therr equired nor permitted .Approved fuel addi-

tive sarethe exception. Additives can cause

engine damage and must therefore not be

adde dtot he service products.

The us eofadditivesisa lwaysthe responsibility

of the vehicl eoperator. The us eofadditivesm ay

resul tinthe restrictio norlossofy ourL imit ed

Warranty entitlements.

Fuel

Important safety notes

GWARNING

Fue lish ighl yf lammable. Improper handling of

fuel creates ariskoff irea nd explosion.

Avoi dfire, open flames ,smoking and creating

sparks under al lcircumstances .Switch off the

engine and ,ifapplicable, the auxiliary heating

befor erefueling.

GWARNING

Fue lisp oisonous and hazardous to health.

There is ariskofi njury.

Yo um ustm akes uret hatf ueldoe sn ot come

into contact with your skin, eyes or clothing

and thatiti snot swallowed. Do not inhal efue l

vapors. Kee pfuelawa yfromc hildren.

If yo uoro thers come into contact with fuel,

observe the following:

RWash away fuel froms kinimmediately

using soa pand water.

RIf fuel come sinto contact with your eyes,

immediatel yrinse themt horoughlywith

clean water. See kmedica lassis tance with-

ou td elay.

RIf fuel is swallowed, seek medica lassis -

tance withou tdelay. Do not induce vomit-

ing.

RImmediately change ou tofclothing which

hasc ome into contact with fuel. When handling

,storing and disposing of fuels,

please observe the relevant regulations.

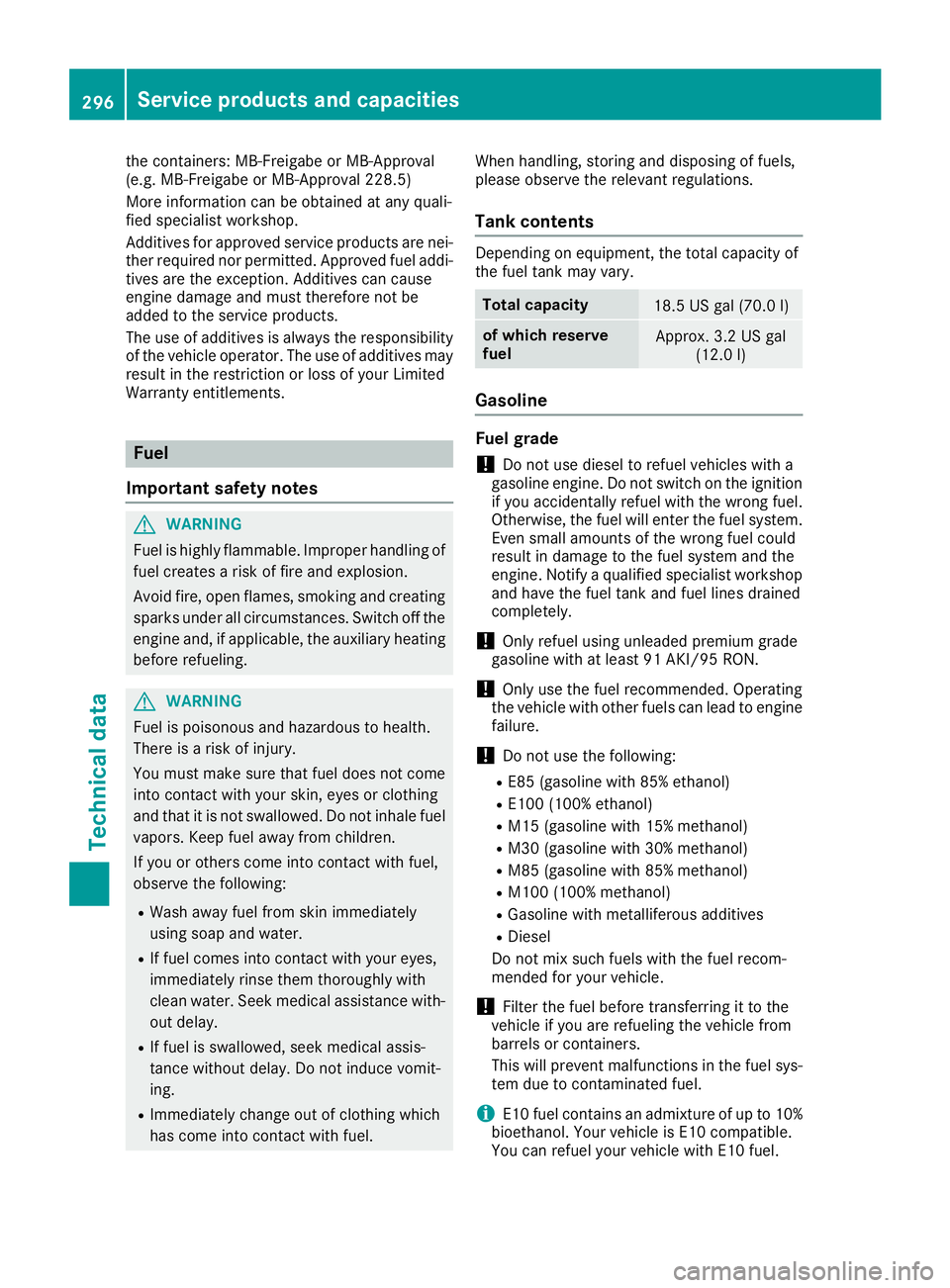

Tank contents

Depending on equipment, the tota lcapacity of

the fuel tank mayv ary.

Totalcap acity18.5 US ga l(70.0 l)

of whic hreserve

fuelApprox. 3.2 US gal (12.0 l)

Gasoline

Fuel grade

!Do not use diesel to refuel vehicle swith a

gasoline engine. Do not switch on the ignition

if you accidentally refuel with the wrong fuel.

Otherwise, the fuel wil lenter the fuel system.

Even small amounts of the wrong fuel could

resul tind amage to the fuel system and the

engine. Notify aqualified specialist workshop

and have the fuel tank and fuel lines drained

completely.

!Only refuel using unleaded premiumg rade

gasoline with at least 91 AKI/95 RON.

!Only use the fuel recommended.O perating

the vehicle with other fuel scan leadtoe ngine

failure.

!Do not use the following:

RE85 (gasoline with 85% ethanol)

RE100 (100% ethanol)

RM15 (gasoline with 15% methanol)

RM30 (gasoline with 30% methanol)

RM85 (gasoline with 85% methanol)

RM100 (100% methanol)

RGasoline with metalliferous additives

RDiesel

Do not mix such fuel swith the fuel recom-

mended for you rvehicle.

!Filter the fuel beforet ransferring it to the

vehicle if you are refueling the vehicle from

barrels or containers.

This wil lprevent malfunctions in the fuel sys-

tem due to contaminated fuel.

iE10 fuel contains an admixture of up to 10%

bioethanol .Yourv ehicle is E10 compatible.

You can refue lyou rv ehicle with E10 fuel.

296Service products and capacities

Technical data

Page 302 of 310

Rear axle

Serviceproduct: transmission oil

Product name/numberMaintenance

interval

Mobilub eFE 75-W-85

Mobilube FE Plus NG

MB Shee tNo. 235.7—

Further information can be obtained at any

qualified specialist workshop.

Brake fluid

GWARNING

The brake fluid constantly absorbsm oisture

from the air. Thi slowers the boiling point of

the brake fluid .Ifthe boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. Thi swould impai rbraking efficiency.

There is ariskofana ccident.

Yo us houl dhavet he brake fluid renewe dat

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber .Ifp aint, plastic or rubber hasc ome into

contact with brake fluid ,rins ew ithw ater

immediately.

Whe nhandling, storing and disposing of brake

fluid ,pleas eobserve the relevant regulations

and the important safety notes for service prod-

ucts (

Ypage 295).

Overap eriodoft ime,the brake fluid absorbs

moistur efrom the air. Thi sreduce sits boiling

point.

Have the brake fluid renewe devery 2years at a

qualified specialist workshop.

iThere is usuall yanotice in the engine com-

partment to remind yo uwhent he next brake

fluid change is due.

Use only approved brake fluid sthat comply with

the Mercedes-Benz Specifications for Service

Products. Alway scheck for the identification

DOT 4plus.

Information abouta pproved brake fluid scan be

obtained:

Rat any qualified specialist workshop

Ron the Interne tat

http://bevo.merced es-benz.com.

Coolant

Important safety notes

GWARNING

If antifreezec omes intocontac twithh ot com-

ponents in th eenginec ompartment, it may

ignite .Thereisar iskoff irea nd injury.

Let th eenginec ooldown before you add anti-

freeze. Makes ure that antifreezeisn otspilled

next to th efille rneck. Thoroughlyc lean the

antifreezef romc omponents before starting

th ee ngine.

!Takec aren otto spill any coolant on painted

surfaces .You coul dotherwise damag ethe

paintwork.

When handling, storin gand disposingofc oolant

and antifreeze, please observ ethe relevan treg-

ulationsa nd theimportant safety note sfor ser-

vic ep roduct s(

Ypage 295).

Coolan tadditive with corrosion and

antifreeze protection

!Use only approved antifreeze/corrosion

inhibitor that complies withMBS pecification

300Service products and capacities

Technical data

for Service Products, Sheet Number 325.

Using other, non-approved antifreeze/corro-

sion inhibitors may causedamage to the cool-

ant system and reduce the engine' sservice

life

Page 303 of 310

.

The coolant is amixture of water and antifreeze

and corrosion inhibitor. It performs the following

tasks:

Rcorrosion protection

Rantifreeze protection

Rraises the boiling point

When the vehicl eisfirst delivered, it is filled with

ac oolant mixture that ensure sadequate anti-

freeze and corrosion protection. Coolant must

remai ninthe engine cooling system all year

round to ensure anti-corrosion protection and a

higher boiling point, even in countries with high

outside temperatures.

To prevent damage to the engine cooling sys-

tem, use only approved antifreeze and corrosion

inhibitor that complies with the Mercedes-Benz Specifications for Service Products.

Mercedes-Benz recommends an antifreeze and

corrosion inhibitor that meets the requirements

in the Mercedes-Benz Specifications for Service

Products Sheet Number 325.

Check the antifreeze/corrosio ninhibitor con-

centration in the coolant every six months.

The percentag eofcorrosion inhibitor/anti-

freeze additive in the engine cooling system

should:

Rbe at least 50%. This way, the engine cooling

system is protected against freezing downt o

approximately -35 ‡(-37 †).

Rnot exceed 55% (antifreeze protection down

to -49 ‡[-45 †]) .Otherwise, hea twilln ot be

dissipated as effectively.

If ther ehasbeen coolant loss, do not refill only

with water. If the vehicl ehaslost coolant, add

equa lparts water and antifreeze/corrosion

inhibitor. The water used as part of the coolant

mixture must fulfil lcertain requirements; these

are usuall yfulfille dbyd rinking water. If the

water quality is not sufficient, yo umusttrea tthe

water.

Mor einformatio ncan be obtaine datany qual i-

fi eds p

ecialist workshop.

Servic eproduct: coolant

Productn ame/number

Zerex G40-91, The Valvoline Company

MB SheetNo. 325.5

Maintenance interval

Hav ethe coolant renewe devery 15 years .

Capacities

Engine coolin gsystem

CoolantApprox. 11 US qt

(10.4l)

Clim ate control systemr efrigerants

Important safety notes

The climate control system of you rvehicle is fil-

led with the refrigerant R ‑134a.

The warning label for the refrigerant being used

can be found on the radiator cross member.

!Only the refrigerant R ‑134a and the PAG oil

approved by Mercedes-Benz may be used.

The approved PAG oil may not be mixed with

any other PAG oil that is not approved for

R-134a refrigerant. Otherwise ,the climate

control system may be damaged.

Maintenance work such as adding refrigerant or

replacing components may only be carried out

by aq ualified specialist workshop. All applicable

regulations thereto and the SAE standard J639

need to be respected.

All work on the climate control system should

always be carried out at qualified specialist

workshop.

Service products and capacities301

Technical data

Z

Page 304 of 310

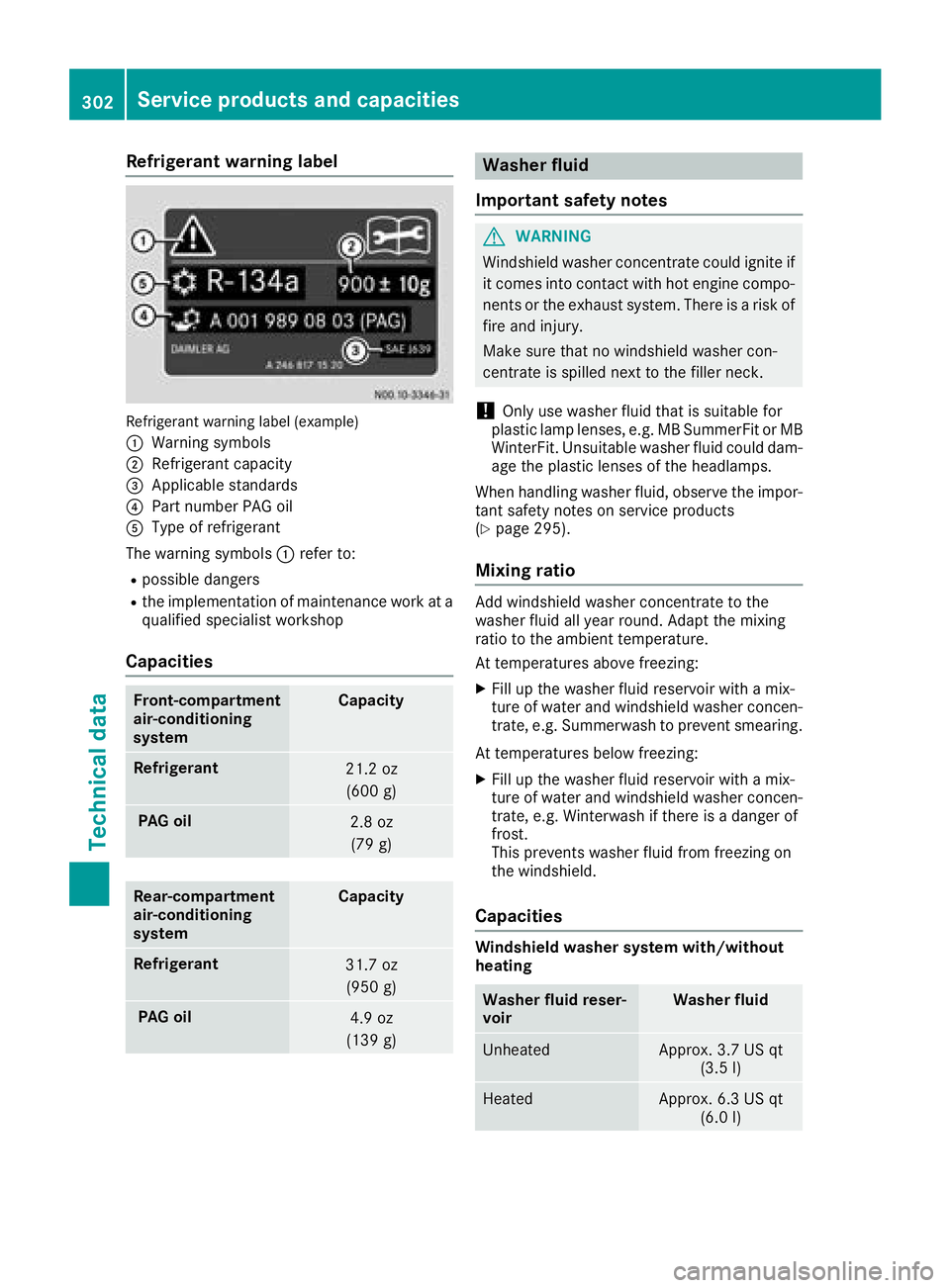

Refrigerant warninglabel

Refrigerant warning label (example)

:

Warning symbols

;Refrigerant capacity

=Applicabl estandards

?Part number PAG oil

AType of refrigerant

The warning symbols :refe rto:

Rpossible dangers

Rthe implementation of maintenance work at a

qualified specialist workshop

Capacities

Front-compartment

air-conditioning

systemCapacity

Refrigerant21.2 oz

(600 g)

PAGo il2.8 oz

(79 g)

Rear-compartment

air-conditioning

systemCapacity

Refrigerant31.7 oz

(950 g)

PAGo il4.9 oz

(139 g)

Washe rfluid

Important safety notes

GWARNING

Windshieldw asherc oncentrate could ignite if

it comesi nto contact with hot engine compo-

nents or the exhaus tsystem. There is arisko f

fire and injury.

Make sure that no windshield washerc on-

centrate is spilled next to the fille rneck.

!Only us ewasherf luid that is suitablef or

plasti clam plen ses, e.g. MB SummerFi torMB

WinterFit. Unsuitablew asherf luid could dam-

ag et he plasti clen ses of the headlamps.

Whe nhandling washerf luid,observe the impor-

tant safety notes on service products

(

Ypage 295).

Mixin gratio

Add windshield washerc oncentrate to the

washerf luid allyea rround. Adapt the mixing

rati otot he ambient temperature.

At temperatures above freezing:

XFil lupt he washerf luid reservoirw itham ix-

ture of water and windshield washerc oncen-

trate ,e.g. Summerwash to prevent smearing.

At temperatures below freezing:

XFil lupt he washerf luid reservoirw itham ix-

ture of water and windshield washerc oncen-

trate ,e.g. Winterwash if there is adanger of

frost.

Thisp revents washerf luid from freezing on

the windshield.

Capacities

Windshiel dwasher system with/without

heating

Washe rflui dr eser-

voirWashe rfluid

UnheatedApprox. 3.7 US qt

(3.5 l)

HeatedApprox. 6.3 US qt(6.0 l)

302Servic eproducts and capacities

Technical data

Page 306 of 310

Cargo tie-down points and carriersys-

tems

Cargo tie-down points

General notes

!Observ ethe informatio nonthemaximum

loadingc apacity of th eindividua lcargo tie-

down points.

If you use several cargo tie-down points to

secure aload, you must always tak ethe max-

imum loadingc apacity of theweakest cargo

tie-down pointi ntoa ccount.

If you brak ehard ,for example ,the forces act-

ing coul dbeuptos everal times th eweight

force of th eload. Always use multiple cargo

tie-down points in order to distribut ethe force

absorption.L oad theanchorages evenly.

You will fin dadditional informatio nabout cargo

tie-down points and cargo tie-down rings in the

"Securin gloads"s ection(

Ypage 234).

Cargo tie-down rings

The maximum tensile load of th ecargo tie-down

rings is:

Cargo tie-down

ringsPermissible nomi- nal tensile load

Passenger Vans786. 5lbf

(35 0daN)

Cargo Van1124.0 lbf

(50 0daN)

Guide/load rails

The maximum tensile load for th ecargo tie-

down points on aguide/load rail is:

Cargo tie-down

pointPermissible nomi-

nal tensile load

Guide rail786. 5lbf

(35 0daN)

Load rails on cargo

compartmen tfloor1124.0 lbf

(50 0daN)

Load rail on sidewall225. 0lbf

(10 0daN)

The values specifie dapply only to loads placed

on th ecargo compartmen tfloo rif:

Rth el oad is secured to two cargo tie-down

points on th erail and

Rthed istanc etotheneares tload-securing

pointont hesame rail is approximately 3ft

(1 m).

Roo fracks and rear racks

GWARNING

If yo uuseopenings in the bodywork or

detachabl eparts as steps, yo ucould:

Rslipa nd/or fall

Rdamag ethe vehicl eand cause yourselft o

fall.

There is ariskofi njury.

Alway susesecure climbing aids, e.g. asuita-

bl el adde r.

!Do not us ethe lowe rsliding doo rguide (car-

riage) as astep .Otherwise, yo ucould damage

the paneling and/or the sliding doo rmecha-

nism.

GWARNING

Whe nyou load the roof, the center of gravity

of the vehicl erises and the driving character-

istics change. If yo uexcee dthe maximum roof

load ,the driving characteristics, as well as

steering and braking, will be greatl yimpaired.

There is ariskofana ccident.

Neve rexcee dthe maximum roo floa da nd

adjust your driving style.

!The weight of any load carrie donthe roof,

including the roo fcarrier, mus tnot exceed

the maximum permissible roo fload.

The roo fcarrie rsuppo rts mus tbem ounted at

equal distances.

Install rai lcarriers in front of and behind the

middl eprop.

!For safety reasons,M ercedes-Benz recom-

mend sthat yo uonly us eroofcarrie rsystems

which have bee nteste dand approved for

Mercedes-Benz vehicles. Thi swillh elpt o

avoid damage.

304Vehicl edata

Technical data