check engine MERCEDES-BENZ ML500 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML500, Model: MERCEDES-BENZ ML500 1997Pages: 4133, PDF Size: 88.89 MB

Page 3429 of 4133

1. Start vehicle engine and switch on air conditioning system.

2. Check entire air conditioning circuit using leak detector probe (1).

Remain for some time in areas where leaks are suspected.

Since refrigerant is heavier than air and sinks, always guide leak detector probe (1) underneath the locations

where leaks are suspected.

Line connections, screwed pipe connections, condensers and evaporators are the most frequent cause of

refrigerant leaks.

Fig. 155: Identifying Air Conditioning System Leak Detector Probe

CARRY OUT QUICK TEST ON AIR CONDITIONING SYSTEM - AR83.30-D-1209A

MODEL 163 with CODE (580) Air conditioning or Tempmatic for USA

MODELS 901.0/3 /4, 902.0/3 /4, 903.0/3 /4, 904.0/3 /4 with CODE (H06) Air conditioning

WE58.40-Z-1002-20AAir conditioning leak detector

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 185 © 2006 Mitchell Repair Information Company, LLC.

Page 3430 of 4133

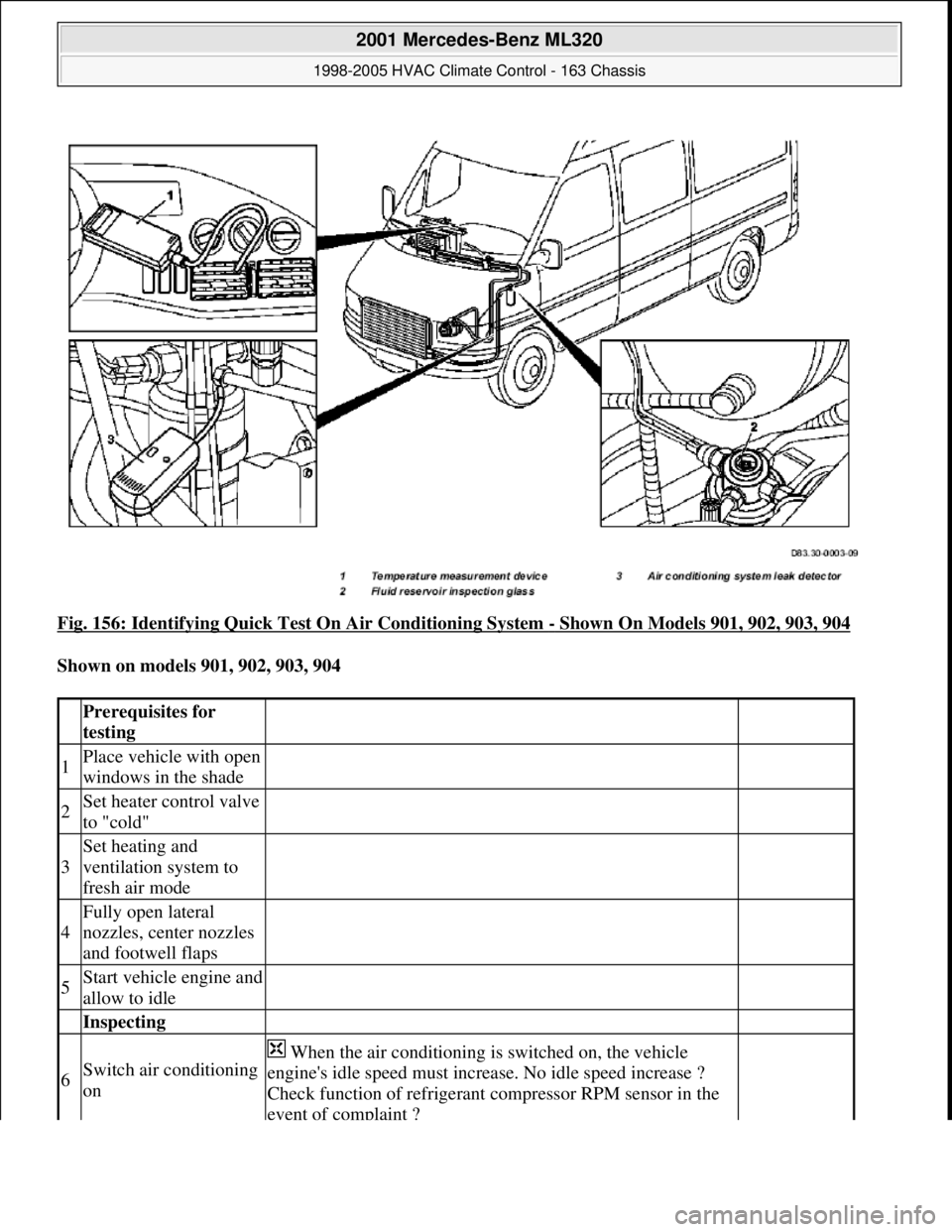

Fig. 156: Identifying Quick Test On Air Conditioning System - Shown On Models 901, 902, 903, 904

Shown on models 901, 902, 903, 904

Prerequisites for

testing

1Place vehicle with open

windows in the shade

2Set heater control valve

to "cold"

3

Set heating and

ventilation system to

fresh air mode

4

Fully open lateral

nozzles, center nozzles

and footwell flaps

5Start vehicle engine and

allow to idle

Inspecting

6Switch air conditioning

on

When the air conditioning is switched on, the vehicle

engine's idle speed must increase. No idle speed increase ?

Check function of refrigerant compressor RPM sensor in the

event of complaint ?

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 186 © 2006 Mitchell Repair Information Company, LLC.

Page 3431 of 4133

Commercially available tools

Workshop equipment

DRAINING, EVACUATING AND REFILLING AIR CONDITIONING, CHECKING FUNCTION AND CHECKING FOR

LEAKS - AR83.30-P-1760GH

MODELS 163.113 /128 /136 /154 /157 /172 /174 /175 with CODE (580) Air conditioning or Tempmatic for

USA

Replace refrigerant compressor RPM sensor

Models 901-904

Not in model 163AR83.55-D-

5320A

7

Set blower rotary

switch to maximum

blower setting

8Check that refrigerant

flows free of bubbles

If the system is filled sufficiently, the refrigerant must flow

through the inspection glass (2) free of bubbles. A newly-

filled system may initially reveal bubbles. In this case, wait

for approx. 10 min. and check inspection glass again.

Does not reveal bubble-free flow ?

Check entire air conditioning circuit for leaks using leak

detector (3).AR83.30-D-

1209-01A

Air conditioning system leak detector*WE58.40-Z-

1002-20A

9Determine air outlet

temperature

Switch blower rotary switch to stage "1".

Insert sensor of temperature measurement device (1) into the

air outlet of the center nozzles.

After running for a period of 5 min., the air outlet temperature

must not be less than 2°C and more than 12°C. After 5 min., at

the latest, the refrigerant compressor must also be connected

and disconnected.

If the refrigerant compressor is disconnected at below 2°C ?

Check evaporator temperature switch. If the air outlet

temperature is not achieved ?

Check the connection and disconnection of the refrigerant

compressor or the refrigerant pressure upstream and

downstream of the refrigerant compressor.

*WH58.30-Z-

1005-08A

10

Switch air conditioning

off and shut vehicle

engine off

NumberDesignation

WH58.30-Z-1005-08ATemperature measuring device

WE58.40-Z-1002-20AAir conditioning leak detector

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 187 © 2006 Mitchell Repair Information Company, LLC.

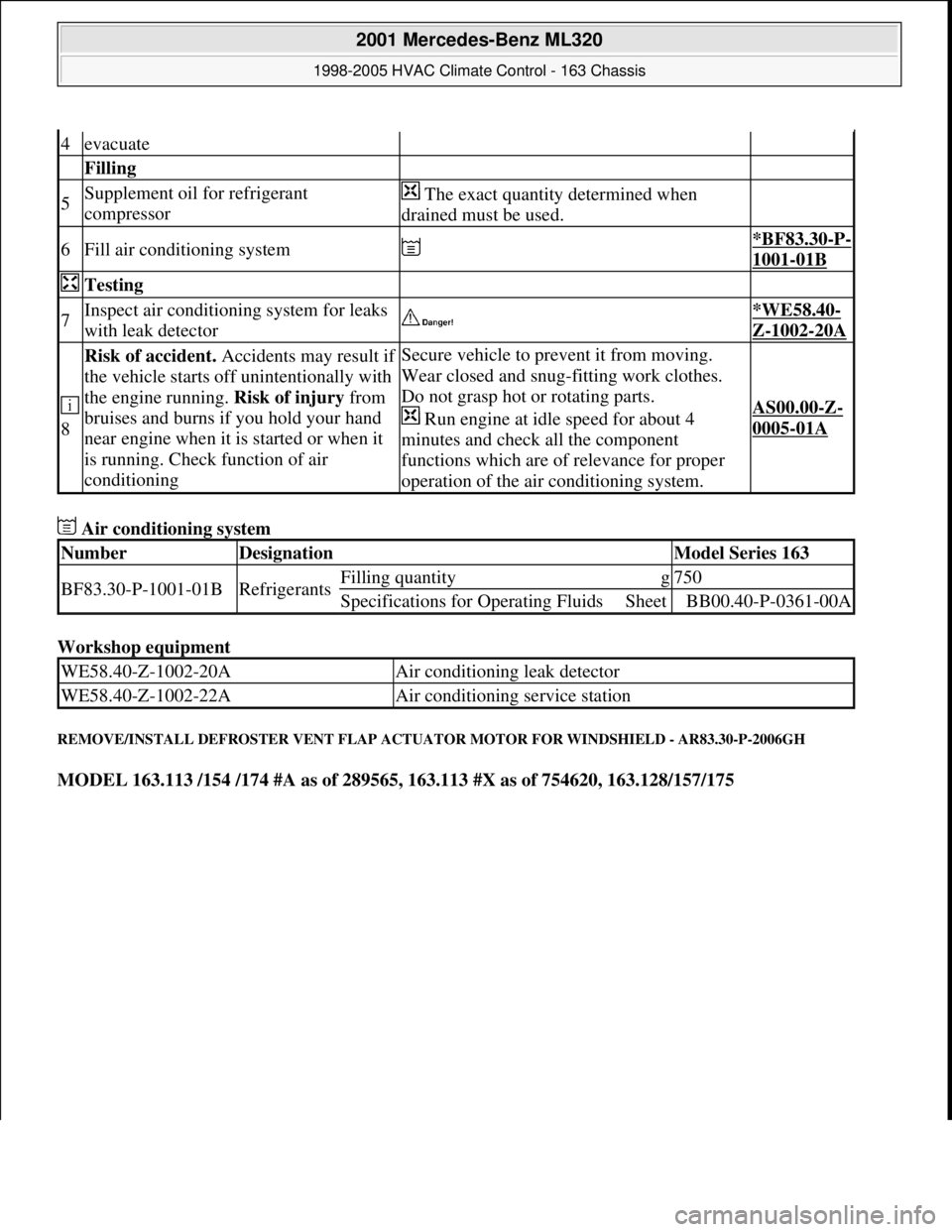

Page 3433 of 4133

Air conditioning system

Workshop equipment

REMOVE/INSTALL DEFROSTER VENT FLAP ACTUATOR MOTOR FOR WINDSHIELD - AR83.30-P-2006GH

MODEL 163.113 /154 /174 #A as of 289565, 163.113 #X as of 754620, 163.128/157/175

4evacuate

Filling

5Supplement oil for refrigerant

compressor The exact quantity determined when

drained must be used.

6Fill air conditioning system *BF83.30-P-

1001-01B

Testing

7Inspect air conditioning system for leaks

with leak detector *WE58.40-

Z-1002-20A

8

Risk of accident. Accidents may result if

the vehicle starts off unintentionally with

the engine running. Risk of injury from

bruises and burns if you hold your hand

near engine when it is started or when it

is running. Check function of air

conditioningSecure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

Run engine at idle speed for about 4

minutes and check all the component

functions which are of relevance for proper

operation of the air conditioning system.

AS00.00-Z-

0005-01A

NumberDesignationModel Series 163

BF83.30-P-1001-01BRefrigerantsFilling quantityg750

Specifications for Operating FluidsSheetBB00.40-P-0361-00A

WE58.40-Z-1002-20AAir conditioning leak detector

WE58.40-Z-1002-22AAir conditioning service station

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 189 © 2006 Mitchell Repair Information Company, LLC.

Page 3441 of 4133

poisoning from swallowing

coolant.Wear protective gloves, protective

clothing and eye protection.

1Drain coolantEngine 111 in MODEL 163.AR20.00-P-

1142HG

Engines 112 /113 in MODEL 163.AR20.00-

P-1142HA

Engine 628.963 in MODEL 163.128.AR20.00-P-

1142HB

Engine 612.963 in MODEL 163.113.AR20.00-P-

1142M

2.1 Detach

brake line

from the

front end of

the radiator

Only required for right-hand steering.

3.1 Detach

ignition

cable from

the front end

of the

radiator

Only required on right-hand drive vehicles

with ENGINES 111 /112/113.

4Release coolant overflow from

battery shield

5Disconnect upper coolant hose

from the electric coolant pump Detach hose clamp from the upper

coolant hose.

6Unscrew nuts from expansion

reservoir at firewall

7Remove expansion reservoir from

the firewall and lay aside

8Disconnect coolant delivery/return

hoses for heat exchanger (17) Detach hose clamps from coolant

delivery/ return hoses for heat exchanger.

9Discharge air conditioning system

Installation: Evacuate air

conditioning, refill and check for proper

operation and leaktightness.AR83.30-

P-1760GH

10Unscrew self-locking nut (16) at

the expansion valve (15) Replace self-locking nut.

*BA83.30-

P-1003-01B

11

Detach low-pressure refrigerant

line (13) and high-pressure

refrigerant line (14) from expansion

valve (15)

Installation: Install new sealing rings

and moisten with compressor oil.

12Remove instrument panel carrier

(4) AR68.10-

P-1111GH

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 197 © 2006 Mitchell Repair Information Company, LLC.

Page 3446 of 4133

conditioning (Automatic) A/C compressor 7SB16

MODEL 210 with CODE (580) Air conditioning or Tempmatic for USA with CODE (581a) Air

conditioning (Automatic) A/C compressor 7SB16

MODELS 215,220 A/C compressor 7SE16

A/C compressor

Correct oil level

Carry out work quickly, compressor oil is

hygroscopic

When evacuating refrigerant, the quantity of

compressor oil evacuated must be added again

to refrigerant circuit when refilling air

conditioning (new oil)

1Replace A/C compressor, additionally fill with

new compressor oil *BF83.55-P-

1008-01A

2Replace condenser and additionally fill with new

compressor oil *BF83.55-P-

1003-01A

3Replace evaporator and additionally fill with

compressor oil *BF83.55-P-

1004-01A

4Replace fluid reservoir and additionally fill with

compressor oil *BF83.55-P-

1005-01A

5

Replace suction pipe from evaporator to A/C

compressor and additionally fill with new

compressor oil

*BF83.55-P-

1006-01A

6

Replace pressure pipe from A/C compressor to

condenser and additionally fill with new

compressor oil

*BF83.55-P-

1007-01A

7Additional oil quantity when replacing

evaporator, rear air conditioning Model 220*BF83.55-P-

1010-01A

8Additional oil quantity when replacing rear air

conditioning lines Model 220*BF83.55-P-

1011-01A

9Switch on air conditioning and allow engine to

run at idle speed for approx. 4 minutes

Turn temperature thumb wheel of

center nozzles to stop in blue range, or

on automatic air conditioning to "Lo"

Blower at max.

10Check function of air conditioning

Air output temperature at center

nozzle must not fall below + 5

0 C, if

necessary ? Carry out diagnosis

NumberDesignationA/C

compressor

7SB16 in A/C

compressor

7SB16 A/C

compressor

ND6CA17 in

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 202 © 2006 Mitchell Repair Information Company, LLC.

Page 3457 of 4133

Air conditioning system

Refrigerant compressor

Fig. 172: Identifying External Torx Set (001 589 76 09 00)

3.1Remove mass air flow sensor on left

behind the charge air cooler On Model 163.113 only: between the air

hose of the charge air cooler and engine.

4Discharge air conditioning system

Installation: Evacuate air conditioning,

refill and check for proper operation and

leaktightness.AR83.30-P-

1760GH

5

Unscrew screw (3) for refrigerant

line (6) to the expansion valve and

screw (4) for refrigerant line (5) from

the condenser at the fluid reservoir

(8)

*BA83.30-

P-1001-01B

6

Remove refrigerant line (5) from

condenser and refrigerant line (6) to

the expansion valve at the fluid

reservoir (8)

Installation: Install new sealing rings

and moisten with compressor oil.

7Release external Torx drive bolt (7)

at fluid reservoir clamp External torx setFig. 172

8Remove fluid reservoir (8) Installation: Note additional oil filling

capacity when replacing the fluid reservoir.*BF83.55-

P-1005-

01A

9Install in the reverse order

NumberDesignationModel Series 163

BA83.30-P-1001-01BHexagon bolt securing refrigerant line to fluid reservoirNM10

NumberDesignationRefrigerant

compressor 7SB16,

refrigerant R134a

in model 163

BF83.55-P-1005-

01AAdditional oil filling

capacity when

replacing fluid

reservoirCompressor oilcm3 10

Specifications for

Operating FluidsSheetBB00.40-P-0362-

00A

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 213 © 2006 Mitchell Repair Information Company, LLC.

Page 3459 of 4133

Notes on handling refrigerant

R134aAll models fitted with air conditioning

AH83.30-

N-0003-

01A

1.1

Remove

additional

fan (M4)

Models 163.136 /154/157 /172 with air

conditioning or for USA Tempmatic, code

580.AR83.30-

P-5600GH

2.1Remove intercooler Only models 163.113/ 128.

Model 163.113AR09.41-P-

6817MM

Model 163.128AR09.41-P-

6817CD

3Discharge air conditioning system

Installation: Evacuate, refill air

conditioning system and check for proper

operation and tightness.AR83.30-

P-1760GH

4.1Detach lower engine compartment

panelingModel 163.172/174/175AR61.20-

P-1105GH

4.2Remove noise encapsulation Removal: Only remove front part.

Model 163.113/128AR94.30-P-

5400GH

5.1Remove air guide Only if present Located at front

crossmember, in center behind front bumper.

6Unscrew bolts at bottom of

electric fan or fan shroud. Also remove sheet metal nuts.

7Remove attachment parts (20) and

rubber shock absorber(21) Removal: Lower attaching parts and

damper rubber.

Installation: Replace attaching parts.

8Unscrew screw (2) for refrigerant

line at fluid reservoir

*BA83.30-

P-1001-

01B

9Detach refrigerant line from fluid

reservoir Installation: Replace sealing rings and

moisten with compressor oil.

10Unscrew screw (6) for refrigerant

line at condenser(5)

*BA83.30-

P-1002-

01B

11Detach refrigerant line from

condenser (5) Installation: Replace sealing rings and

moisten with compressor oil.

12Detach rubber seal (4) from

radiator (7)

13Remove screws (3)

14.1Remove attachment parts (20) and

rubber shock absorber(21)Model 163.113/128

Upper attaching parts and damper rubber.

Installation: Replace attaching parts.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 215 © 2006 Mitchell Repair Information Company, LLC.

Page 3464 of 4133

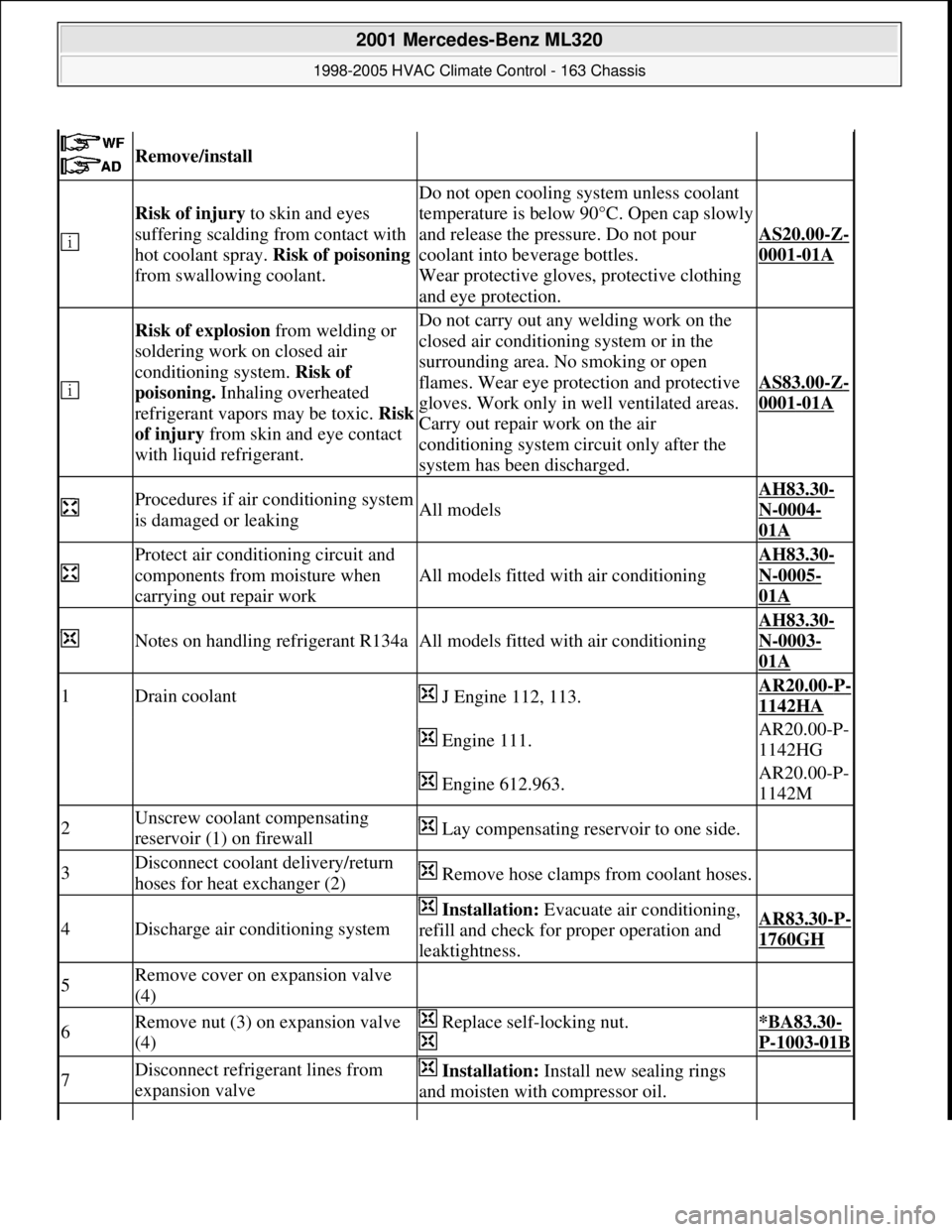

Remove/install

Risk of injury to skin and eyes

suffering scalding from contact with

hot coolant spray. Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90°C. Open cap slowly

and release the pressure. Do not pour

coolant into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-

0001-01A

Risk of explosion from welding or

soldering work on closed air

conditioning system. Risk of

poisoning. Inhaling overheated

refrigerant vapors may be toxic. Risk

of injury from skin and eye contact

with liquid refrigerant.Do not carry out any welding work on the

closed air conditioning system or in the

surrounding area. No smoking or open

flames. Wear eye protection and protective

gloves. Work only in well ventilated areas.

Carry out repair work on the air

conditioning system circuit only after the

system has been discharged.

AS83.00-Z-

0001-01A

Procedures if air conditioning system

is damaged or leakingAll models

AH83.30-

N-0004-

01A

Protect air conditioning circuit and

components from moisture when

carrying out repair work

All models fitted with air conditioning

AH83.30-

N-0005-

01A

Notes on handling refrigerant R134aAll models fitted with air conditioning

AH83.30-

N-0003-

01A

1Drain coolant J Engine 112, 113.AR20.00-P-

1142HA

Engine 111.AR20.00-P-

1142HG

Engine 612.963.AR20.00-P-

1142M

2Unscrew coolant compensating

reservoir (1) on firewall Lay compensating reservoir to one side.

3Disconnect coolant delivery/return

hoses for heat exchanger (2) Remove hose clamps from coolant hoses.

4Discharge air conditioning system

Installation: Evacuate air conditioning,

refill and check for proper operation and

leaktightness.AR83.30-P-

1760GH

5Remove cover on expansion valve

(4)

6Remove nut (3) on expansion valve

(4) Replace self-locking nut.

*BA83.30-

P-1003-01B

7Disconnect refrigerant lines from

expansion valve Installation: Install new sealing rings

and moisten with compressor oil.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:19 PMPage 220 © 2006 Mitchell Repair Information Company, LLC.

Page 3482 of 4133

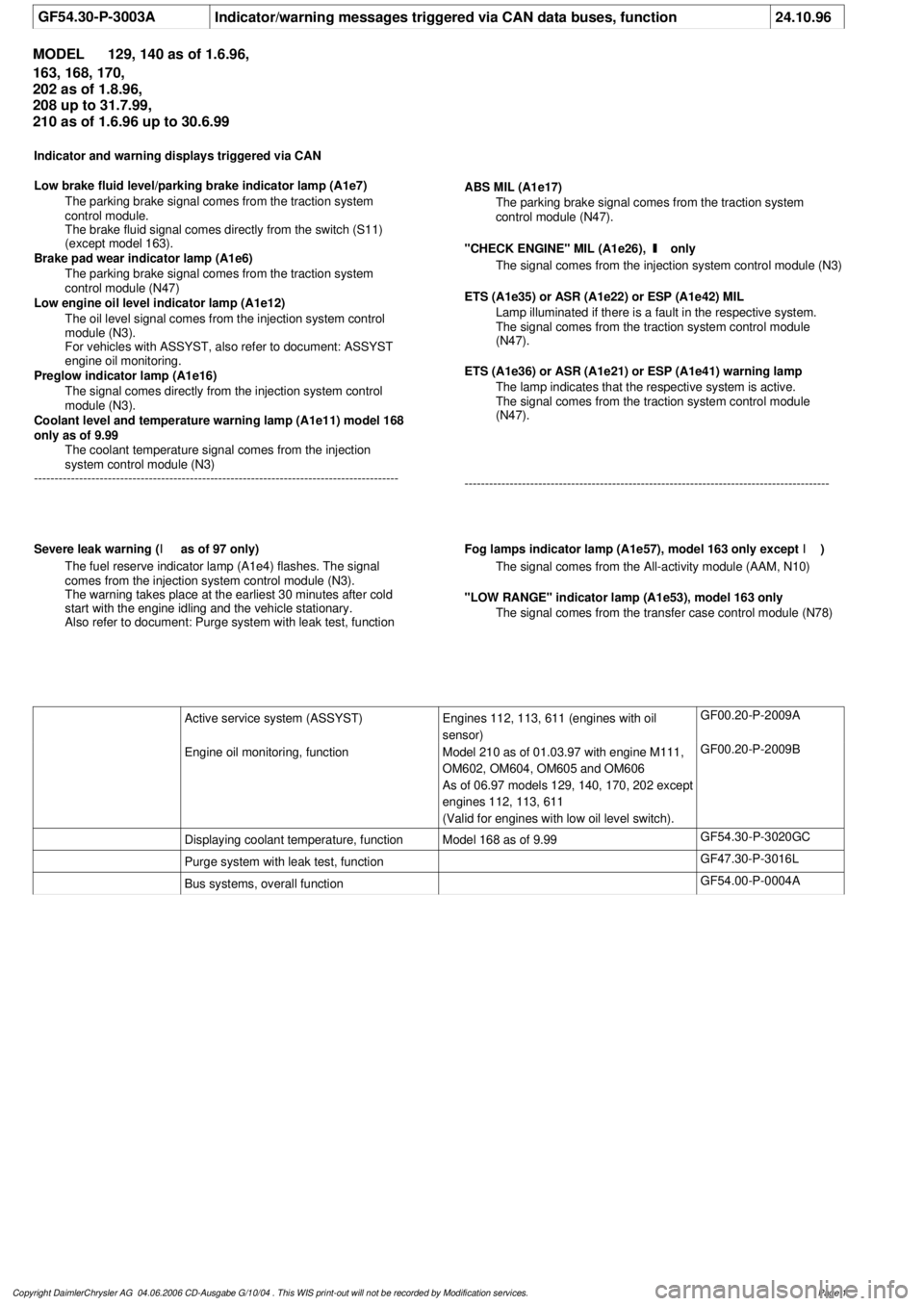

GF54.30-P-3003A

Indicator/warning messages triggered via CAN data buses, function

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

Indicator and warning displays triggered via CAN

Low brake fluid level/parking brake indicator lamp (A1e7)

The parking brake signal comes from the traction system

control module.

The brake fluid signal comes directly from the switch (S11)

(except model 163).

Brake pad wear indicator lamp (A1e6)

The parking brake signal comes from the traction system

control module (N47)

Low engine oil level indicator lamp (A1e12)

The oil level signal comes from the injection system control

module (N3).

For vehicles with ASSYST, also refer to document: ASSYST

engine oil monitoring.

Preglow indicator lamp (A1e16)

The signal comes directly from the injection system control

module (N3).

Coolant level and temperature warning lamp (A1e11) model 168

only as of 9.99

The coolant temperature signal comes from the injection

system control module (N3)

-----------------------------------------------------------------------------------------

ABS MIL (A1e17)

The parking brake signal comes from the traction system

control module (N47).

"CHECK ENGINE" MIL (A1e26),

I

only

The signal comes from the injection system control module (N3)

ETS (A1e35) or ASR (A1e22) or ESP (A1e42) MIL

Lamp illuminated if there is a fault in the respective system.

The signal comes from the traction system control module

(N47).

ETS (A1e36) or ASR (A1e21) or ESP (A1e41) warning lamp

The lamp indicates that the respective system is active.

The signal comes from the traction system control module

(N47).

-----------------------------------------------------------------------------------------

Severe leak warning (

I

as of 97 only)

The fuel reserve indicator lamp (A1e4) flashes. The signal

comes from the injection system control module (N3).

The warning takes place at the earliest 30 minutes after cold

start with the engine idling and the vehicle stationary.

Also refer to document: Purge system with leak test, function

Fog lamps indicator lamp (A1e57), model 163 only except

I

)

The signal comes from the All-activity module (AAM, N10)

"LOW RANGE" indicator lamp (A1e53), model 163 only

The signal comes from the transfer case control module (N78)

Active service system (ASSYST)

Engines 112, 113, 611 (engines with oil

sensor)

GF00.20-P-2009A

Engine oil monitoring, function

Model 210 as of 01.03.97 with engine M111,

OM602, OM604, OM605 and OM606

As of 06.97 models 129, 140, 170, 202 except

engines 112, 113, 611

(Valid for engines with low oil level switch).

GF00.20-P-2009B

Displaying coolant temperature, function

Model 168 as of 9.99

GF54.30-P-3020GC

Purge system with leak test, function

GF47.30-P-3016L

Bus systems, overall function

GF54.00-P-0004A

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1