check engine MERCEDES-BENZ ML500 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML500, Model: MERCEDES-BENZ ML500 1997Pages: 4133, PDF Size: 88.89 MB

Page 3489 of 4133

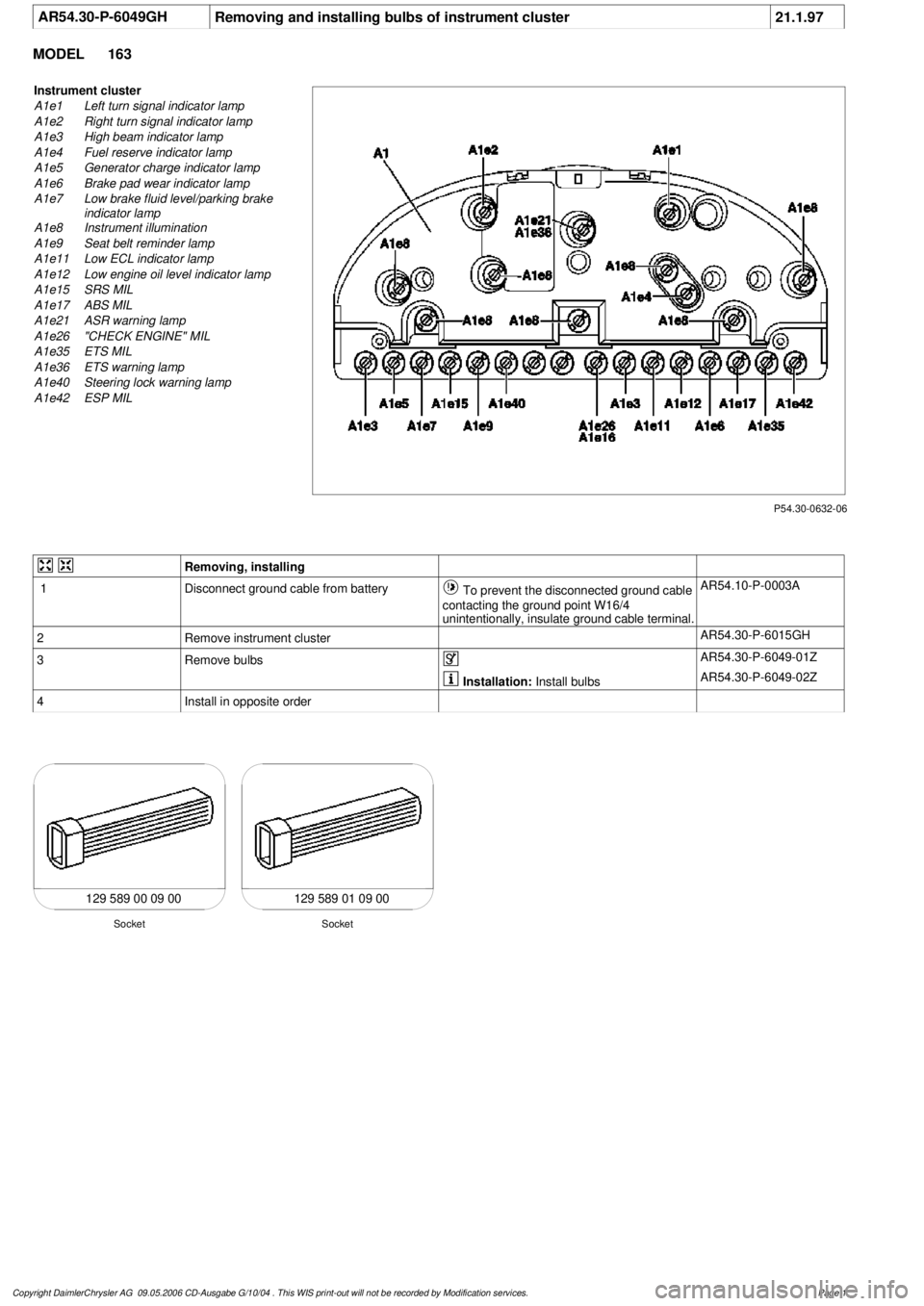

AR54.30-P-6049GH

Removing and installing bulbs of instrument cluster

21.1.97

MODEL

163

P54.30-0632-06

Instrument cluster

A1e1

Left turn signal indicator lamp

A1e2

Right turn signal indicator lamp

A1e3

High beam indicator lamp

A1e4

Fuel reserve indicator lamp

A1e5

Generator charge indicator lamp

A1e6

Brake pad wear indicator lamp

A1e7

Low brake fluid level/parking brake

indicator lamp

A1e8

Instrument illumination

A1e9

Seat belt reminder lamp

A1e11

Low ECL indicator lamp

A1e12

Low engine oil level indicator lamp

A1e15

SRS MIL

A1e17

ABS MIL

A1e21

ASR warning lamp

A1e26

"CHECK ENGINE" MIL

A1e35

ETS MIL

A1e36

ETS warning lamp

A1e40

Steering lock warning lamp

A1e42

ESP MIL

Removing, installing

1

Disconnect ground cable from battery

To prevent the disconnected ground cable

contacting the ground point W16/4

unintentionally, insulate ground cable terminal.

AR54.10-P-0003A

2

Remove instrument cluster

AR54.30-P-6015GH

3

Remove bulbs

AR54.30-P-6049-01Z

Installation:

Install bulbs

AR54.30-P-6049-02Z

4

Install in opposite order

129 589 00 09 00 129 589 01 09 00

Socket

Socket

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3498 of 4133

AF54.30-P-8400A

Instrument cluster indicates: Oil sensor defective, oil level below min. or oil level

above max. with engine running and at operating temperature. No DTC stored.

19.5.98

MODEL

129.0, 163.1, 202.0, 208.3 /4, 210.0 /2 /6, 220.0 /1 with ENGINE 112

MODEL

129.0, 163.1, 202.0, 208.3 /4, 210.0 /2, 220.0 /1 with ENGINE 113

Damage code

Cause

Remedy

54 201 90

Oil low, connector defective or coding error

1

Shut off engine and wait 2 min. (key

position 0)

Instrument cluster indicates oil sensor

defective, oil level below min. or oil level

above max. with engine warm and running.

No DTC stored in DTC memory!

2

Check oil level with oil dipstick

3

Check oil level on instrument cluster:

- Key in steering wheel lock position 2,

engine not running

- Wait until - - - - - - appears on

instrument cluster

- When this is displayed press the reset

button for the tripodometer twice within

1 sec. (display appears only after

expiration of a waiting time (max. 30

min.) depending on engine oil

temperature)

Oil level is at bottom mark on oil dipstick

and instrument cluster indicates:

-1L

, -

1,5L

or -2L

#

4

Add quantity of oil indicated on

instrument cluster display and repeat

test.

Oil level at upper mark on dipstick and

instrument cluster indicates either oil level

okay or -1L

, -

1,5L

, -2L

#

5

Recode instrument cluster

AF54.30-P-8600A

Problem still present

#

6

Check cable to oil sensor, oil sensor

connectors, control module and fuse

box (see wiring diagram) for good contact

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3740 of 4133

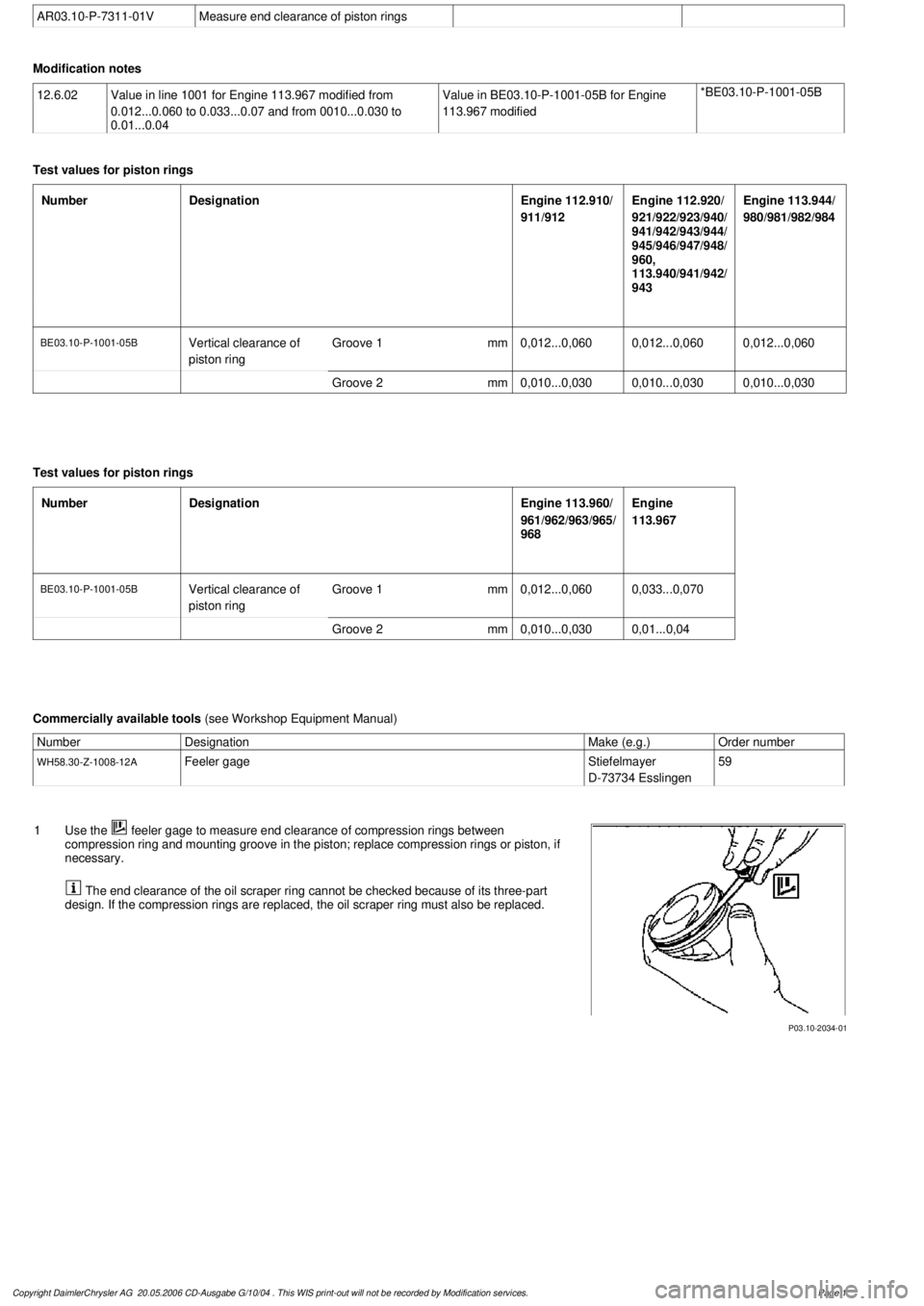

AR03.10-P-7311-01V

Measure end clearance of piston rings

Modification notes

12.6.02

Value in line 1001 for Engine 113.967 modified from

0.012...0.060 to 0.033...0.07 and from 0010...0.030 to

0.01...0.04

Value in BE03.10-P-1001-05B for Engine

113.967 modified

*BE03.10-P-1001-05B

Test values for piston rings

Number

Designation

Engine 112.910/

911/912

Engine 112.920/

921/922/923/940/

941/942/943/944/

945/946/947/948/

960,

113.940/941/942/

943

Engine 113.944/

980/981/982/984

BE03.10-P-1001-05B

Vertical clearance of

piston ring

Groove 1

mm

0,012...0,0600,012...0,0600,012...0,060

Groove 2

mm

0,010...0,0300,010...0,0300,010...0,030

Test values for piston rings

Number

Designation

Engine 113.960/

961/962/963/965/

968

Engine

113.967

BE03.10-P-1001-05B

Vertical clearance of

piston ring

Groove 1

mm

0,012...0,0600,033...0,070

Groove 2

mm

0,010...0,030

0,01...0,04

Commercially available tools

(see Workshop Equipment Manual)

Number

Designation

Make (e.g.)

Order number

WH58.30-Z-1008-12A

Feeler gage

Stiefelmayer

D-73734 Esslingen

59

P03.10-2034-01

1

Use the

feeler gage to measure end clearance of compression rings between

compression ring and mounting groove in the piston; replace compression rings or piston, if

necessary.

The end clearance of the oil scraper ring cannot be checked because of its three-part

design. If the compression rings are replaced, the oil scraper ring must also be replaced.

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3741 of 4133

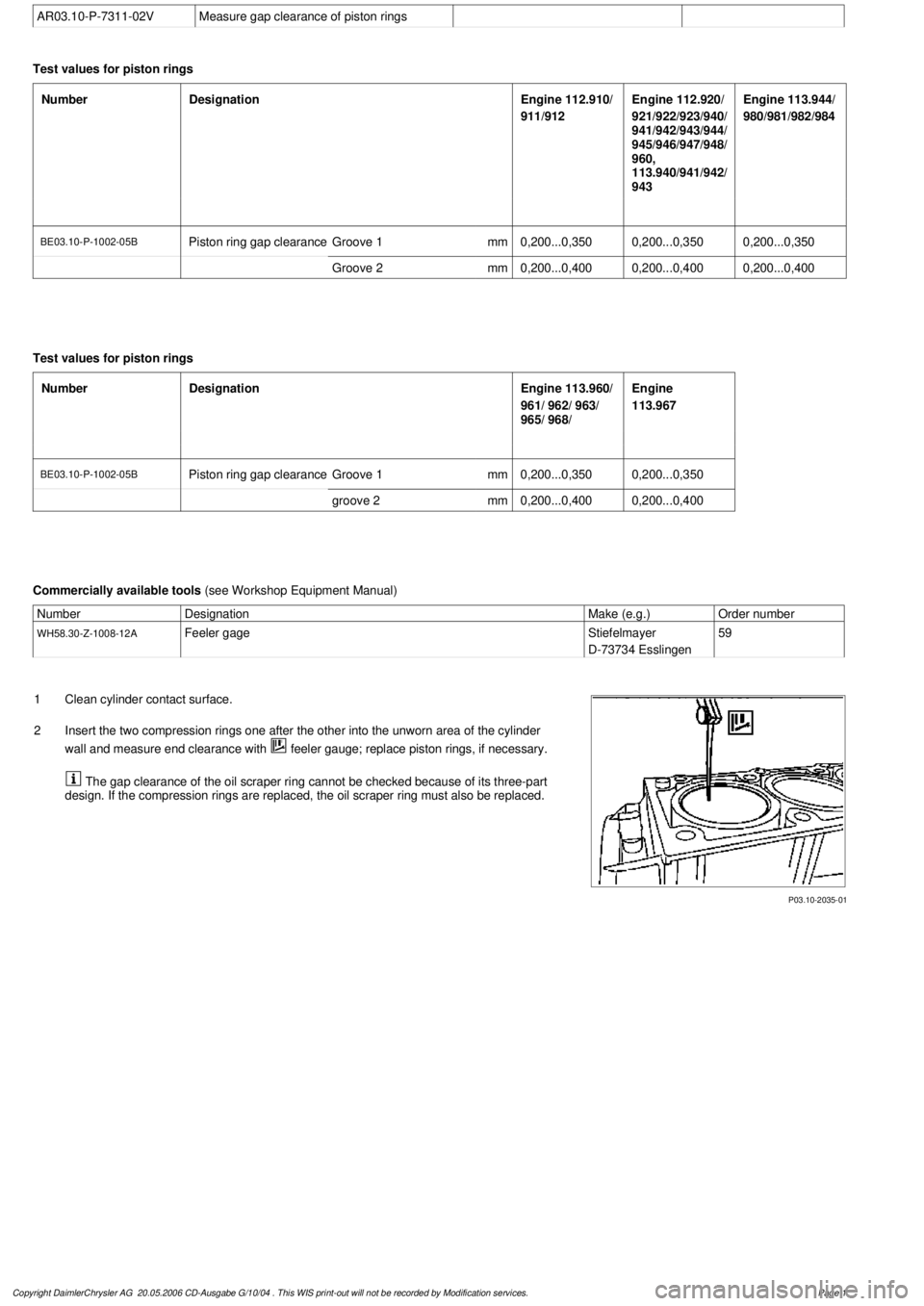

AR03.10-P-7311-02V

Measure gap clearance of piston rings

Test values for piston rings

Number

Designation

Engine 112.910/

911/912

Engine 112.920/

921/922/923/940/

941/942/943/944/

945/946/947/948/

960,

113.940/941/942/

943

Engine 113.944/

980/981/982/984

BE03.10-P-1002-05B

Piston ring gap clearance

Groove 1

mm

0,200...0,3500,200...0,3500,200...0,350

Groove 2

mm

0,200...0,4000,200...0,4000,200...0,400

Test values for piston rings

Number

Designation

Engine 113.960/

961/ 962/ 963/

965/ 968/

Engine

113.967

BE03.10-P-1002-05B

Piston ring gap clearance

Groove 1

mm

0,200...0,3500,200...0,350

groove 2

mm

0,200...0,4000,200...0,400

Commercially available tools

(see Workshop Equipment Manual)

Number

Designation

Make (e.g.)

Order number

WH58.30-Z-1008-12A

Feeler gage

Stiefelmayer

D-73734 Esslingen

59

P03.10-2035-01

1

Clean cylinder contact surface.

2

Insert the two compression rings one after the other into the unworn area of the cylinder

wall and measure end clearance with

feeler gauge; replace piston rings, if necessary.

The gap clearance of the oil scraper ring cannot be checked because of its three-part

design. If the compression rings are replaced, the oil scraper ring must also be replaced.

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3746 of 4133

11

Oil piston pin (2) and conrod bush

12

Assemble piston (3) and conrod (4)

Install piston (3) with arrow in direction of

travel.

13

Push in piston pin (2) by hand

14

Insert circlip (1) of piston pin (2) in the groove

on piston (3)

Do not damage piston (3). Place a clean

cloth underneath.

15

Oil cleaned parts (cylinder bore, conrod

bearing journal, conrod bearing shells and

pistons)

16

Fit on tensioning strap (10) and tension

Piston ring gaps must be offset 120°.

Tensioning strap

*000589041400

17

Install piston (3) with arrow pointing in

direction of travel

Rotate crankshaft far enough so that the

connecting rod when inserting piston into

cylinder bore does not line up at the

connecting rod journal!

18

Inspect conrod bolts (6)

AR03.10-P-6111-01BV

Thread and shank length

*BE03.10-P-1001-03A

19

Install conrod bearings and fit on conrod

bearing cap (5)

The connecting rod bearing shell (7) with

oil drilling (arrow) must be mounted in the

connecting rod, otherwise the piston pin (2) is

not lubricated.

The anti-twist locks (8) of the connecting rod

bearing shells (7) must be seated in the

grooves (9) in the conrods (4) and connecting

rod bearing caps (5).

AR03.10-P-6111-06AV

The connecting rod and connecting rod

bearing cap are cracked (broken) (arrow).

They must not be installed the wrong side

round!

20

Tighten conrod bolts (6)

AR03.10-P-6111-02BV

*BA03.10-P-1001-01E

21

Rotate crankshaft

To inspect ease of operation.

22

Install oil pump

-

Ensure oil return flow check valve is

correctly located.

-

Clean strainer of oil pump.

-

Fill oil pump with engine oil before

installing so that it pumps oil when first

started.

All except models 203, 209, 211.061/065/070,

220 without 4MATIC, 230.474 /475

AR18.10-P-6020B

Model 203 without 4MATIC, 209,

211.061/065/070

AR18.10-P-6020PV

Model 203 with 4MATIC, model 220 with

4MATIC

AR18.10-P-6020PW

Model 230.474/475

AR18.10-P-6020R

23

Fit on cylinder head

Models 463.206/ 209/ 232/ 233/ 240/ 241/

243/ 244/ 245/ 246/ 247/ 248/ 249/ 250/ 254

AR01.30-P-5800GV

Engine 112 in model 129 and engine 113 in

models 129, 202, 208, 210

AR01.30-P-5800B

Engine 112 in models 170, 202, 208, 210,

220 and engine 113 in models 220,

230.474 /475

AR01.30-P-5800BA

Model 163

AR01.30-P-5800MV

Models 203, 209 with engines 112, 113

Models 211.061/065/070

AR01.30-P-5800PV

24

Fit on top part of oil pan

Model 463

AR01.45-P-7500FG

Model 230.474/475

AR01.45-P-7500R

Model 220 without 4MATIC

AR01.45-P-7500I

Model 220 with 4MATIC

AR01.45-P-7500IW

Model 210 with 4MATIC

AR01.45-P-7500FA

Model 210 without 4MATIC

AR01.45-P-7500F

Models 202, 208

AR01.45-P-7500FC

Model 203 without 4MATIC, 209 with engines

112,113

AR01.45-P-7500PV

Model 203 with 4MATIC

AR01.45-P-7500PW

Model 211.061/065/070

AR01.45-P-7500TV

Model 170

AR01.45-P-7500SV

Model 163

AR01.45-P-7500FB

Model 129

AR01.45-P-7500FD

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 3752 of 4133

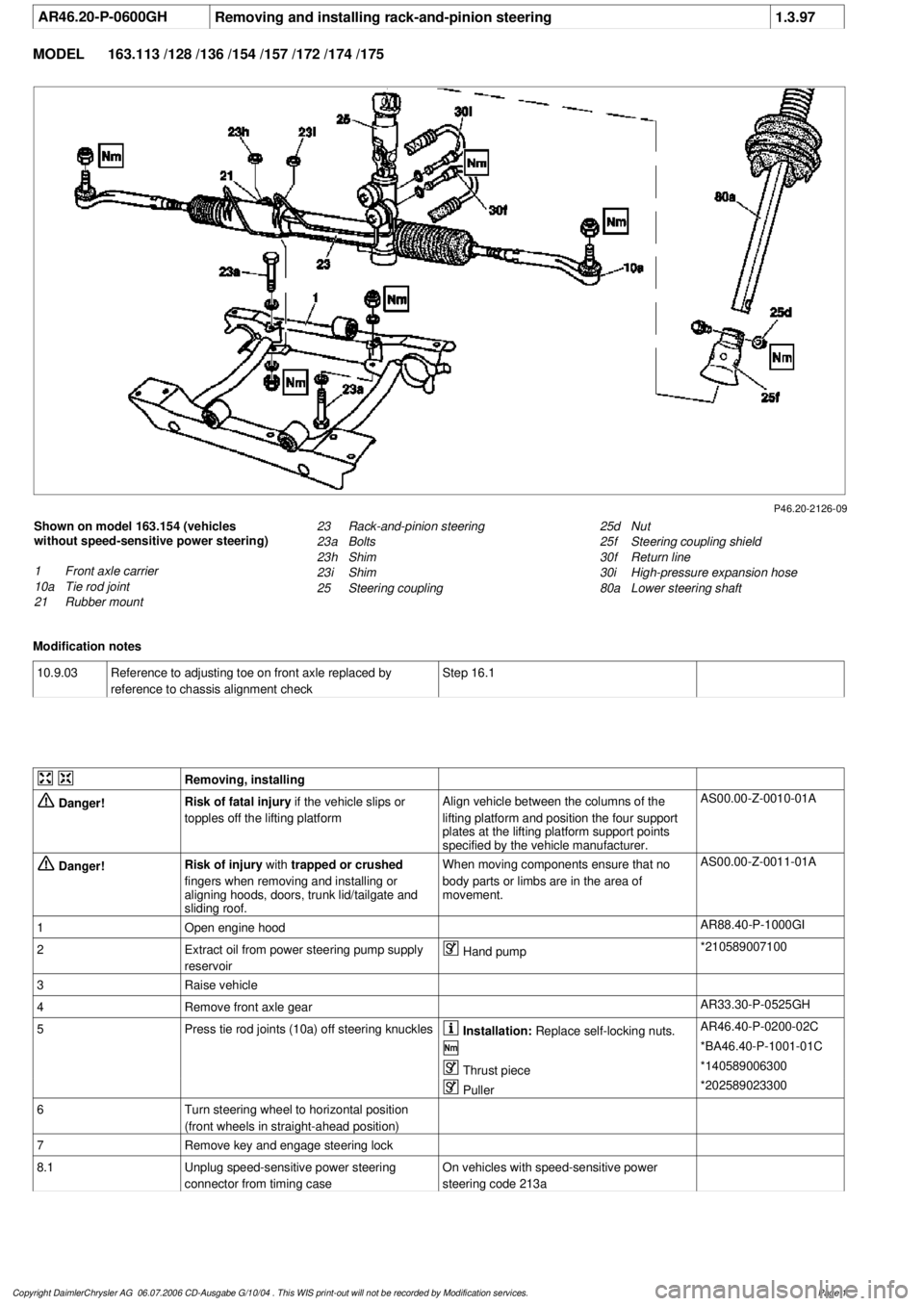

AR46.20-P-0600GH

Removing and installing rack-and-pinion steering

1.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.20-2126-09

Shown on model 163.154 (vehicles

without speed-sensitive power steering)

1

Front axle carrier

10a

Tie rod joint

21

Rubber mount

25d

Nut

25f

Steering coupling shield

30f

Return line

30i

High-pressure expansion hose

80a

Lower steering shaft

23

Rack-and-pinion steering

23a

Bolts

23h

Shim

23i

Shim

25

Steering coupling

Modification notes

10.9.03

Reference to adjusting toe on front axle replaced by

reference to chassis alignment check

Step 16.1

Removing, installing

Danger!

Risk of fatal injury

if the vehicle slips or

topples off the lifting platform

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Danger!

Risk of injury

with

trapped or crushed

fingers when removing and installing or

aligning hoods, doors, trunk lid/tailgate and

sliding roof.

When moving components ensure that no

body parts or limbs are in the area of

movement.

AS00.00-Z-0011-01A

1

Open engine hood

AR88.40-P-1000GI

2

Extract oil from power steering pump supply

reservoir

Hand pump

*210589007100

3

Raise vehicle

4

Remove front axle gear

AR33.30-P-0525GH

5

Press tie rod joints (10a) off steering knuckles

Installation:

Replace self-locking nuts.

AR46.40-P-0200-02C

*BA46.40-P-1001-01C

Thrust piece

*140589006300

Puller

*202589023300

6

Turn steering wheel to horizontal position

(front wheels in straight-ahead position)

7

Remove key and engage steering lock

8.1

Unplug speed-sensitive power steering

connector from timing case

On vehicles with speed-sensitive power

steering code 213a

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3753 of 4133

9

Detach return line (30f) and high-pressure

expansion hose (30i)

Connection fittings or banjo bolts

depending on the version. Seal off line

connections with plugs.

Installation:

Replace sealing rings.

Connection fitting, return line

*BA46.20-P-1001-01D

Connection fitting, high-pressure

expansion hose

*BA46.20-P-1002-01D

Banjo bolt, return line

*BA46.20-P-1004-01D

Banjo bolt, high-pressure expansion hose

*BA46.20-P-1005-01D

Plug

*129589009100

10

Detach nut (25d) and bolt from steering

coupling (25) and pull lower steering shaft

(80a) upwards out of steering coupling (25)

Do not use force as the corrugated tube is

sensitive to lateral forces. Enlarge clamping

groove a little with a screwdriver if necessary.

Installation:

Replace nut (25d).

Installation:

Turn rack-and-pinion

steering to center position and fit steering

coupling.

AR46.20-P-0600-01GH

*BA46.10-P-1001-01D

11

Detach rack-and-pinion steering (23) from

front axle carrier (1) by unscrewing bolts (23a)

The installed position of the shims (23h,

23i) on the right-hand side, between the

rubber mount and the front axle carrier, must

be observed as the shims are of different

thicknesses.

Installation:

Attach rack-and-pinion

steering to front axle carrier.

AR46.20-P-0600-03GH

Assessing condition of steering gear when

repairing accident vehicles

AH46.20-P-9409-01A

12

Check rubber mount (21) of rack-and-pinion

steering mounting for damage

Replace rubber mount if necessary:

#

Removing rubber mounts on rack-and-pinion

steering mounting

AR46.20-P-0600-02GH

13

Install in the reverse order

14

Fill and bleed power steering pump

Engines 112, 113

AR46.30-P-0010B

Engines 111, 612, 628

AR46.30-P-0010P

15

Check steering for function and leaks

There is a grease cushion under the cover

cap. A small amount of escaping grease is to

be regarded as normal and must not be

confused with leakage.

16.1

Check toe on front axle and adjust if necessary

When installing a new rack-and-pinion

steering, see:

#

Performing chassis alignment check

AR40.20-P-0200A

Steering shaft

Number

Designation

Model 163

BA46.10-P-1001-01D

Self-locking nut, steering coupling to steering shaft

and rack-and-pinion steering

Nm

28

Steering gear

Number

Designation

Model 163

BA46.20-P-1001-01D

Screwed connection fitting from return line

to rack-and-pinion steering

Nm

15

BA46.20-P-1002-01D

Screwed connection fitting from high-

pressure expansion hose to rack-and-pinion

steering

Nm

15

BA46.20-P-1003-01D

Bolted connection, rack-and-pinion steering

to front axle carrierNm

50

BA46.20-P-1004-01D

Banjo bolt, return line to rack-and-pinion

steering

Nm

30

BA46.20-P-1005-01D

Banjo bolt, high-pressure expansion hose to

rack-and-pinion steering

Nm

30

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3757 of 4133

3.1

Remove viscous fan (1)

Engine 112.942 /970 and 113.942.

Right-hand thread!

AR20.40-P-5660C

3.2

Remove electric fan

Only Engine 113.965 /981.

AR20.40-P-5000GH

4.1

Pull off plate clamps of fan shroud (2)

Only for Engine 112.942, from 5/98.

5.1

Remove fan shroud (3)

Only for Engine 112.942 /970 und

113.942. Unscrew the bolts at bottom of fan

shroud for this step

Installation:

If installing a new radiator

with integral power steering pump oil cooler, a

new fan shroud is required if a radiator

without integral oil cooler was previously

installed.

6

Remove headlamp (7).

AR82.10-P-4730GH

7

Remove radiator crossmember (8)

AR62.30-P-2300GH

8

Detach coolant line (4, 6) and expansion

reservoir coolant line (5) at the radiator

Installation:

Replace the hose clamps on

the radiator fitting for the coolant hose, as

they could cause damage to the screw/thread.

Hose clamp

*BA20.20-P-1004-01A

9

Remove the rubber seal on radiator (9)

10.1

Remove oil line (return line of radiator

!

power steering pump expansion reservoir)

(18) and oil line (feed line of steering gear

!

radiator) (19)

From 5/98 only, seal off the connections.

Set of plugs

*129589009100

11

Unscrew ATF lines (10) at the radiator

Seal off the connections.

*BA20.20-P-1001-01A

*BA20.20-P-1003-01A

Set of plugs

*129589009100

12.1

Detach the connector from the fan and

remove the fan grille (11)

Only for Engine 112.942 /970 and 113.942.

13

Unscrew the condenser from the radiator

Do not disconnect the lines.

14

Remove fasteners (20) and damper rubber

(21)

The damper rubber (21) is designed to

prevent possible vibrations between the

condenser and radiator (15) during off-road

driving.

15

Remove air conditioning system fluid

reservoir (14) from the radiator

Place aside with the lines connected.

Detach the condenser from the radiator.

16

Remove radiator (15)

When installing, the spigots on the

radiator must be inserted in the rubber

grommets in the bottom crossmember.

Installation:

On Model 163.154 with

Engine 112.942 before VIN end number

043553, when installing a new radiator with

integral power steering pump oil cooler,

additional operations are required, if they

have not already been carried out:

#

v

Retrofit the bracket for the oil cooler line of

the power steering pump

SM46.30-P-0002A

k

Radiator with integral oil cooler for the power

steering pump

BT20.20-P-0001-01A

17

Detach air guides (12)

Replace the clamps on air guides (13).

18

Install in the reverse order

19

Pour in coolant

AR20.00-P-1142HA

20

Check the headlamp setting and correct if

necessary

e

Check and adjust the headlamp setting

AP82.10-P-8260GH

Danger!

Risk of accident

caused by vehicle starting

off when engine is running.

Risk of injury

caused by contusions and burns when

working in engine during starting procedure

Secure the vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

21

Check the oil level in the automatic

transmission and correct if necessary

AR27.00-P-0101A

22

Check the cooling system for leaks

AR20.00-P-1010HA

Radiator, coolant hoses

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3762 of 4133

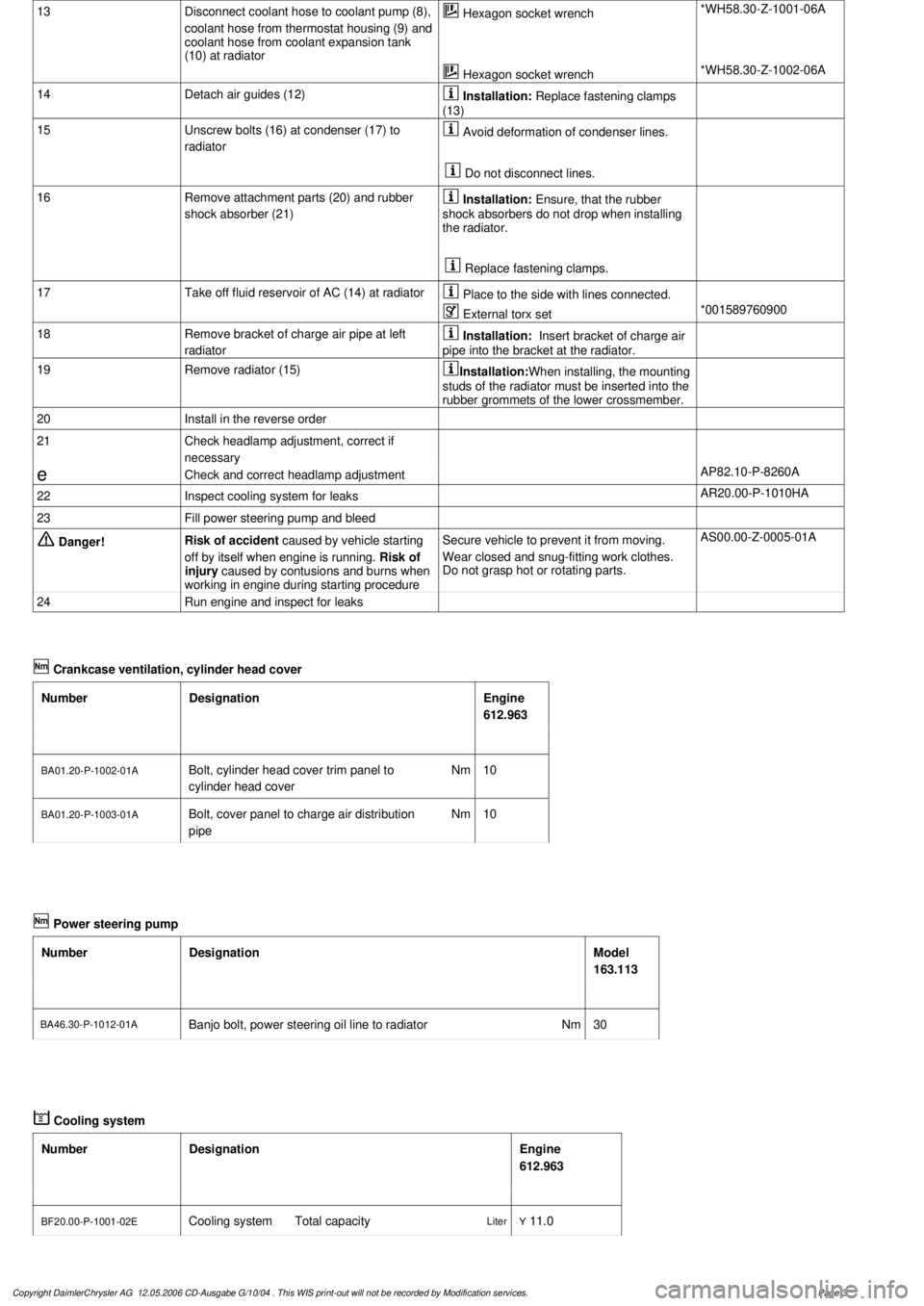

13

Disconnect coolant hose to coolant pump (8),

coolant hose from thermostat housing (9) and

coolant hose from coolant expansion tank

(10) at radiator

Hexagon socket wrench

*WH58.30-Z-1001-06A

Hexagon socket wrench

*WH58.30-Z-1002-06A

14

Detach air guides (12)

Installation:

Replace fastening clamps

(13)

15

Unscrew bolts (16) at condenser (17) to

radiator

Avoid deformation of condenser lines.

Do not disconnect lines.

16

Remove attachment parts (20) and rubber

shock absorber (21)

Installation:

Ensure, that the rubber

shock absorbers do not drop when installing

the radiator.

Replace fastening clamps.

17

Take off fluid reservoir of AC (14) at radiator

Place to the side with lines connected.

External torx set

*001589760900

18

Remove bracket of charge air pipe at left

radiator

Installation:

Insert bracket of charge air

pipe into the bracket at the radiator.

19

Remove radiator (15)

Installation:

When installing, the mounting

studs of the radiator must be inserted into the

rubber grommets of the lower crossmember.

20

Install in the reverse order

21

Check headlamp adjustment, correct if

necessary

e

Check and correct headlamp adjustment

AP82.10-P-8260A

22

Inspect cooling system for leaks

AR20.00-P-1010HA

23

Fill power steering pump and bleed

Danger!

Risk of accident

caused by vehicle starting

off by itself when engine is running.

Risk of

injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

24

Run engine and inspect for leaks

Crankcase ventilation, cylinder head cover

Number

Designation

Engine

612.963

BA01.20-P-1002-01A

Bolt, cylinder head cover trim panel to

cylinder head cover

Nm

10

BA01.20-P-1003-01A

Bolt, cover panel to charge air distribution

pipe

Nm

10

Power steering pump

Number

Designation

Model

163.113

BA46.30-P-1012-01A

Banjo bolt, power steering oil line to radiator

Nm

30

Cooling system

Number

Designation

Engine

612.963

BF20.00-P-1001-02E

Cooling system

Total capacity

Liter

Y

11.0

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 3832 of 4133

SI47.10-P-0004A

Service Information: Procedure when tank is filled with incorrect fuel

19.12.00

MODEL

202 with ENGINE 611

MODEL

203 with ENGINE 611, 612, 646

MODEL

210 with ENGINE 611, 612, 613

MODEL

220 with ENGINE 613, 628, 648

MODEL

163 with ENGINE 612, 628

MODEL

168 with ENGINE 668

MODEL

209 with ENGINE 612

MODEL

211 with ENGINE 628, 646, 647, 648

MODEL

463 with ENGINE 612, 628

Modification notes

26.7.04

Engines have been added and procedure has been updated

Incorrect refueling of diesel-power vehicles with a common rail

injection system. Please be aware that if the customer fills the fuel

tank with the wrong type of fuel, this is the customer's fault and

cannot be submitted as a warranty claim.

If the diesel-powered vehicle with a common rail injection system has

been refueled with gasoline, follow the steps below:

1.

If the engine was not started after fuel tank is filled with the wrong

type of fuel, then emptying the fuel tank and cleaning the fuel low-

pressure lines should be enough to solve the problem.

2.

If the engine was started after fuel tank was filled with wrong type

of fuel:

On engines 611, 612, 613, 668:

-

On the rail, open the low pressure connection of the high

pressure pump return (plastic connection in area of pressure

regulator valve) and check connecting point in rail for chips.

On engine 646, 647, 648, 628:

-

Disconnect Y-distributor unit (return line HDP/Rail) at the output

and, with ignition ON, collect the fuel in a clean container. Check

fuel for metal shavings.

If the high pressure pump is not damaged and there are no metal

shavings in the injection system:

-

As in step 1, empty fuel as per the guidelines and clean the fuel

low-pressure lines. In addition to this, remove/install/replace the

high-pressure pump and fuel filter.

If metal shavings are found in the fuel

system or the high pressure pump drive is

damaged:

#

b

Engine runs rough, surges or does not start

ENGINE 611 in MODEL 203, 202, 210

ENGINE 612 in MODEL 163, 203, 210, 209

ENGINE 613 in MODEL 210, 220

ENGINE 628 in MODEL 163, 220, 211

ENGINE 646 in MODEL 203, 211

ENGINE 647 in MODEL 211

ENGINE 648 in MODEL 220, 211

ENGINE 668 in MODEL 168

ENGINE 612, 628 in MODEL 463

AF07.00-P-9000B

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1