MERCEDES-BENZ R-CLASS FAMILY TOURER 2012 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: R-CLASS FAMILY TOURER, Model: MERCEDES-BENZ R-CLASS FAMILY TOURER 2012Pages: 368, PDF Size: 29.05 MB

Page 301 of 368

Flat tire

Preparing the vehicle

Your vehicle may be equipped with a

collapsible spare wheel or MOExtended tires

(tires with run-flat properties) ( Y page 309).

i Vehicle preparation is not necessary on

vehicles with MOExtended tires.

i Vehicles equipped with MOExtended tires

are not equipped with a TIREFIT kit at the

factory. It is therefore recommended that

you additionally equip your vehicle with a

TIREFIT kit if you mount tires that do not

feature run-flat properties, e.g. winter tires.

A TIREFIT kit can be obtained from an

authorized Mercedes-Benz Center.

XVehicles with the AIRMATIC package: make

sure that highway level is selected

( Y page 180).XStop the vehicle as far away as possible

from traffic on solid, non-slippery and level

ground.XSwitch on the hazard warning lamps.XFirmly depress the parking brake.XBring the front wheels into the straight-

ahead position.XMove the DIRECT SELECT lever to P.XSwitch off the engine.XVehicles without KEYLESS-GO: remove

the SmartKey from the ignition lock.XVehicles with KEYLESS-GO: open the

driver's door.

The on-board electronics have status 0,

which is the same as the SmartKey having

been removed.XVehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

( Y page 145).XAll occupants must get out of the vehicle.

Make sure that they are not endangered as

they do so.XMake sure that no one is near the danger

area while a wheel is being changed.Anyone who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.XGet out of the vehicle. Pay attention to

traffic conditions when doing so.XClose the driver's door.

i Only operate the tire inflation compressor

using the socket in the footwell of the

second row of seats ( Y page 268), even if

the ignition is turned off.

An emergency cut-off ensures that the on-

board electrical system voltage does not

drop too low. If the on-board electrical

system voltage is too low, power to the

sockets is automatically cut off. This

ensures that there is sufficient power to

start the engine.

TIREFIT kit

Using the TIREFIT kit

You can use the TIREFIT kit to seal small

punctures, particularly those in the tire tread.

You can use TIREFIT at outside temperatures

down to -4 ‡ (-20 †).

GWARNING

TIREFIT is a limited repair device. TIREFIT

cannot be used for cuts or punctures larger

than approximately 0.16 in (4 mm) and tire

damage caused by driving with extremely low

tire inflation pressure, or on a flat tire, or a

damaged wheel.

Do not drive the vehicle under such

circumstances.

Contact the nearest authorized Mercedes-

Benz Center for assistance or call Roadside

Assistance.

XDo not remove any foreign objects which

have penetrated the tire, e.g. screws or

nails.XRemove the tire sealant bottle, the

accompanying "max. 80 km/h" sticker and

the tire inflation compressor from theFlat tire299Breakdown assistanceZ

Page 302 of 368

stowage well underneath the trunk floor

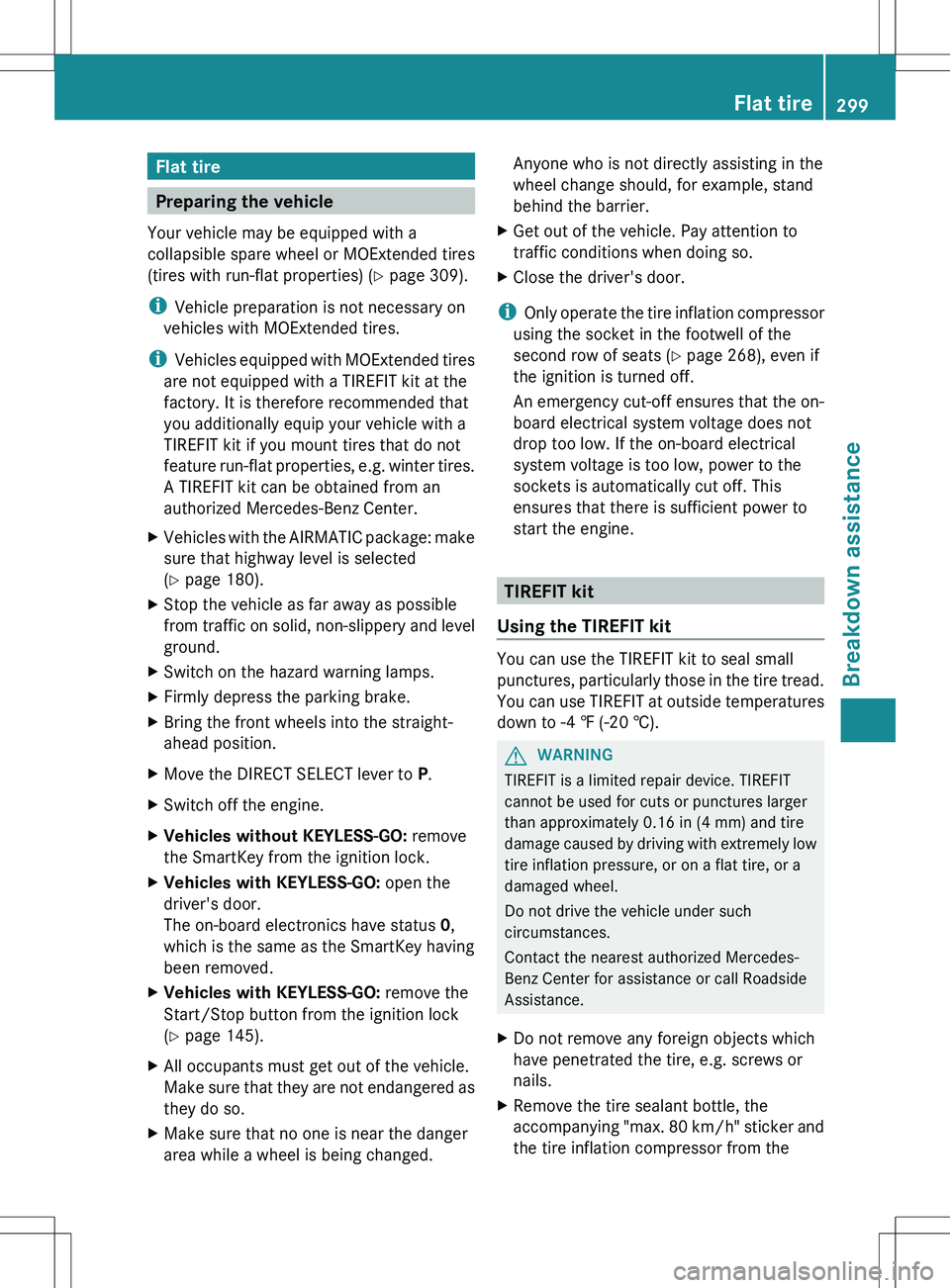

( Y page 296).XAffix part : of the sticker within the

driver's field of vision.XAffix part ; of the sticker near the valve

on the wheel with the defective tire.GWARNING

Take care not to allow the contents of TIREFIT

to come in contact with hair, eyes or clothing.

TIREFIT is harmful if inhaled, swallowed or

absorbed through the skin - causes skin, eye

and respiratory irritation.

Any contact with eyes or skin should be

flushed immediately with plenty of water.

If clothing comes in contact with TIREFIT,

change clothing as soon as possible.

In case of allergic reaction or rash, consult a

physician immediately.

GWARNING

Keep TIREFIT away from children. If

swallowed, rinse mouth immediately with

plenty of water and drink plenty of water.

Do not induce vomiting.

Consult a doctor immediately.

Keep away from open flame or heat source.

i If TIREFIT leaks out, allow it to dry. It can

then be removed like a layer of film.

If you get TIREFIT on your clothing, have it

cleaned as soon as possible with

perchloroethylene.

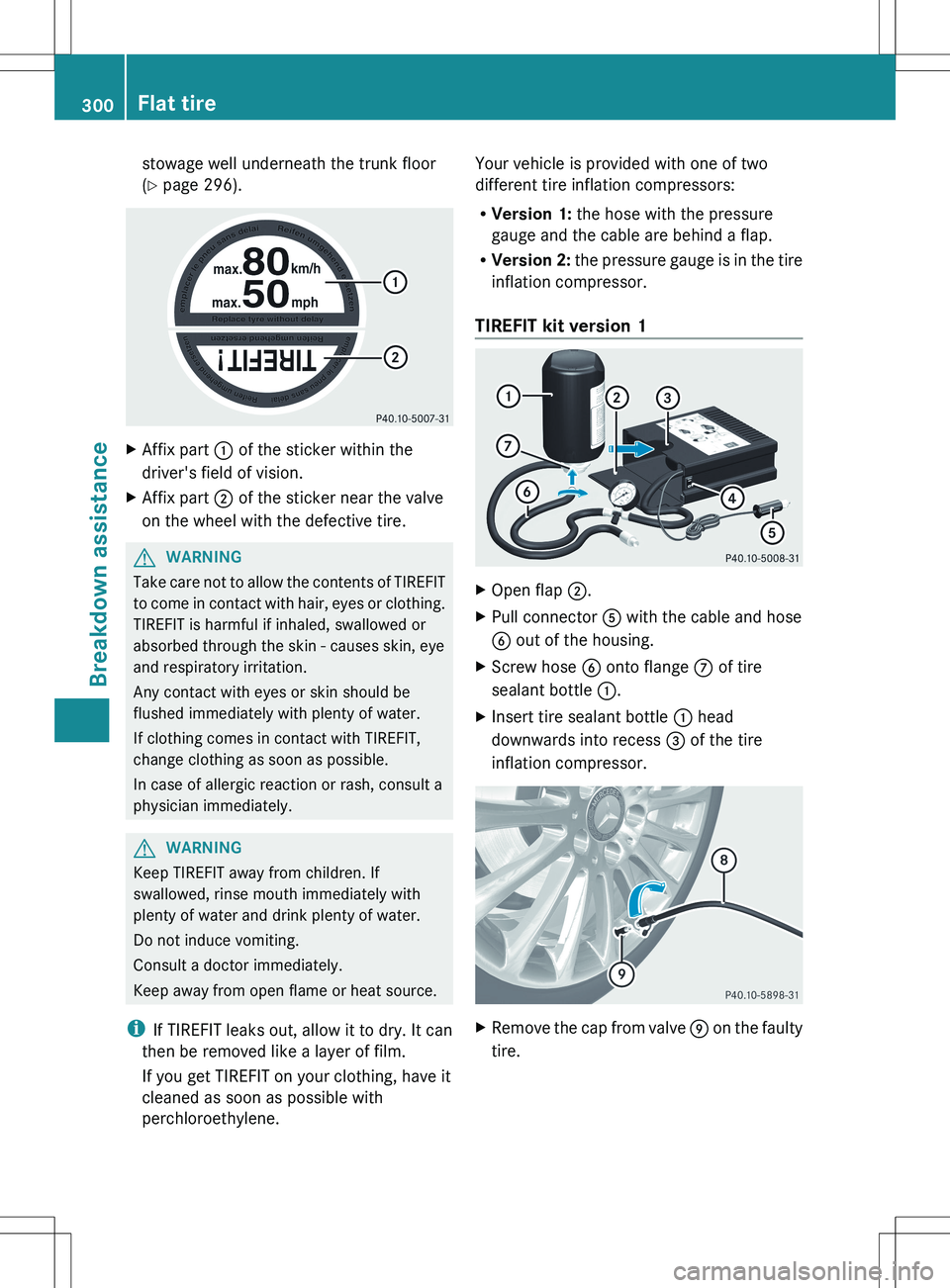

Your vehicle is provided with one of two

different tire inflation compressors:

R Version 1: the hose with the pressure

gauge and the cable are behind a flap.

R Version 2: the pressure gauge is in the tire

inflation compressor.

TIREFIT kit version 1XOpen flap ;.XPull connector A with the cable and hose

B out of the housing.XScrew hose B onto flange C of tire

sealant bottle :.XInsert tire sealant bottle : head

downwards into recess = of the tire

inflation compressor.XRemove the cap from valve E on the faulty

tire.300Flat tireBreakdown assistance

Page 303 of 368

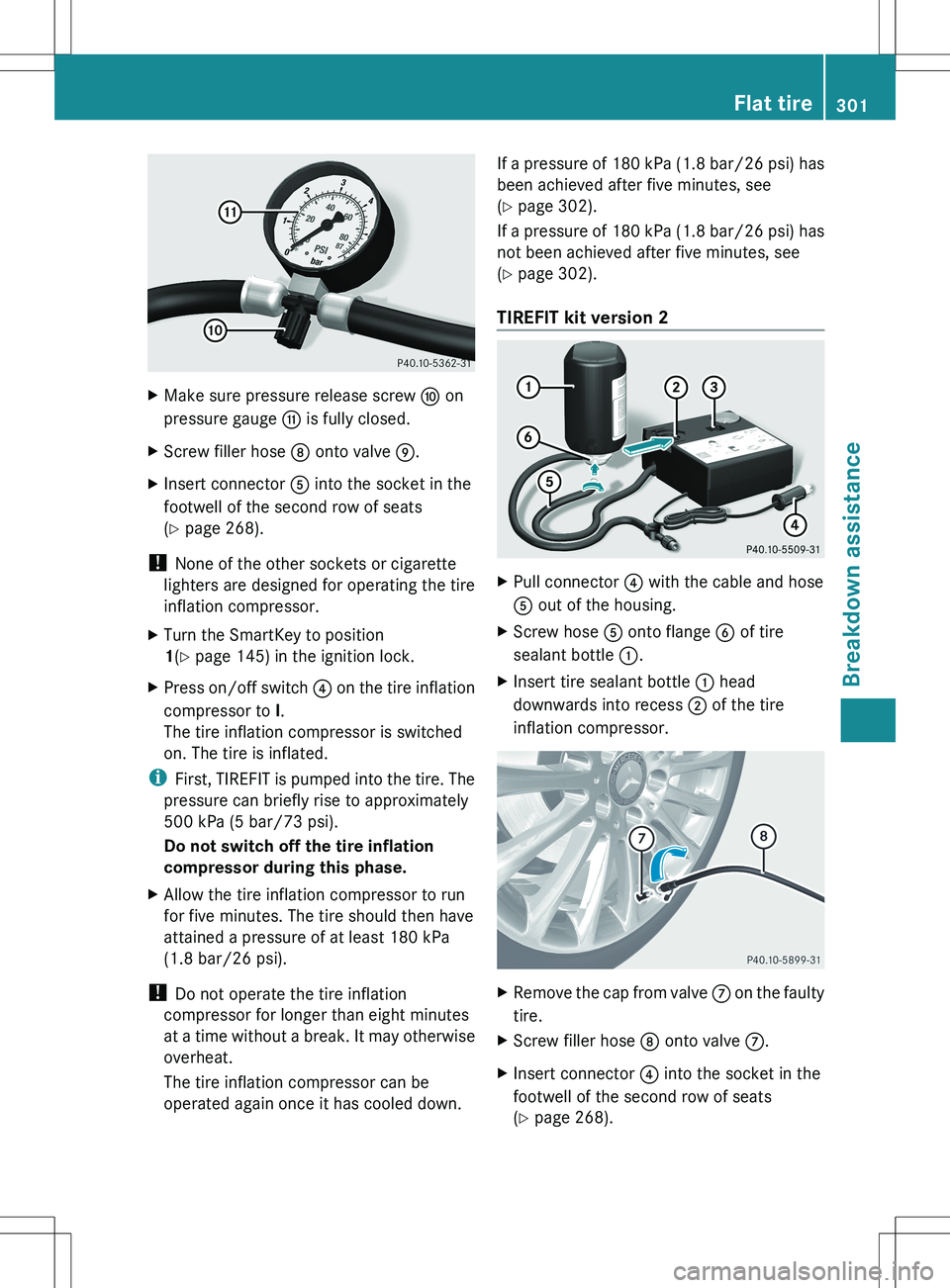

XMake sure pressure release screw F on

pressure gauge G is fully closed.XScrew filler hose D onto valve E.XInsert connector A into the socket in the

footwell of the second row of seats

( Y page 268).

!

None of the other sockets or cigarette

lighters are designed for operating the tire

inflation compressor.

XTurn the SmartKey to position

1 (Y page 145) in the ignition lock.XPress on/off switch ? on the tire inflation

compressor to I.

The tire inflation compressor is switched

on. The tire is inflated.

i First, TIREFIT is pumped into the tire. The

pressure can briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tire inflation

compressor during this phase.

XAllow the tire inflation compressor to run

for five minutes. The tire should then have

attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

! Do not operate the tire inflation

compressor for longer than eight minutes

at a time without a break. It may otherwise

overheat.

The tire inflation compressor can be

operated again once it has cooled down.

If a pressure of 180 kPa (1.8 bar/26 psi) has

been achieved after five minutes, see

( Y page 302).

If a pressure of 180 kPa (1.8 bar/26 psi) has

not been achieved after five minutes, see

( Y page 302).

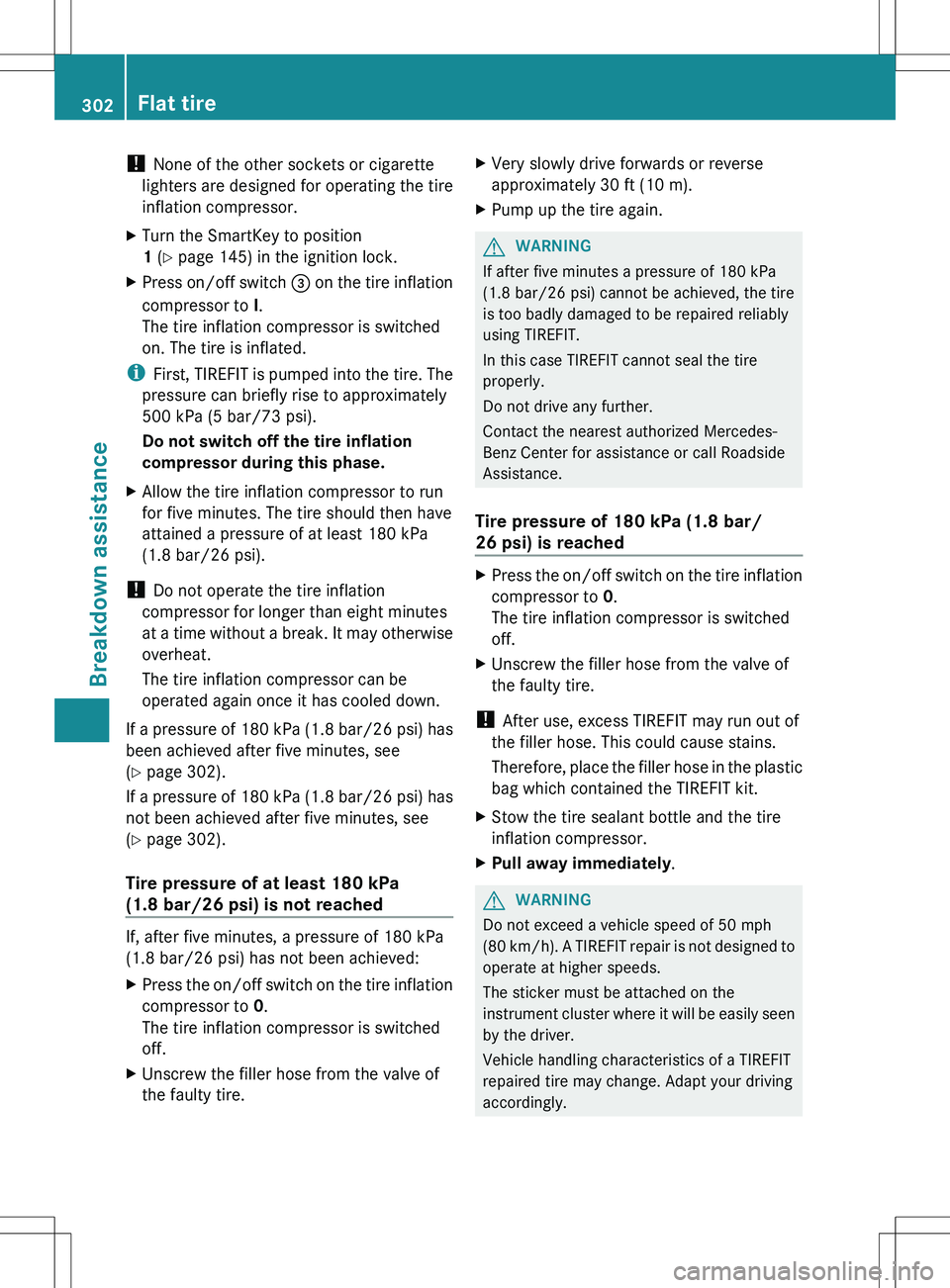

TIREFIT kit version 2XPull connector ? with the cable and hose

A out of the housing.XScrew hose A onto flange B of tire

sealant bottle :.XInsert tire sealant bottle : head

downwards into recess ; of the tire

inflation compressor.XRemove the cap from valve C on the faulty

tire.XScrew filler hose D onto valve C.XInsert connector ? into the socket in the

footwell of the second row of seats

( Y page 268).Flat tire301Breakdown assistanceZ

Page 304 of 368

! None of the other sockets or cigarette

lighters are designed for operating the tire

inflation compressor.XTurn the SmartKey to position

1 (Y page 145) in the ignition lock.XPress on/off switch = on the tire inflation

compressor to I.

The tire inflation compressor is switched

on. The tire is inflated.

i First, TIREFIT is pumped into the tire. The

pressure can briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tire inflation

compressor during this phase.

XAllow the tire inflation compressor to run

for five minutes. The tire should then have

attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

! Do not operate the tire inflation

compressor for longer than eight minutes

at a time without a break. It may otherwise

overheat.

The tire inflation compressor can be

operated again once it has cooled down.

If a pressure of 180 kPa (1.8 bar/26 psi) has

been achieved after five minutes, see

( Y page 302).

If a pressure of 180 kPa (1.8 bar/26 psi) has

not been achieved after five minutes, see

( Y page 302).

Tire pressure of at least 180 kPa

(1.8 bar/26 psi) is not reached

If, after five minutes, a pressure of 180 kPa

(1.8 bar/26 psi) has not been achieved:

XPress the on/off switch on the tire inflation

compressor to 0.

The tire inflation compressor is switched

off.XUnscrew the filler hose from the valve of

the faulty tire.XVery slowly drive forwards or reverse

approximately 30 ft (10 m).XPump up the tire again.GWARNING

If after five minutes a pressure of 180 kPa

(1.8 bar/26 psi) cannot be achieved, the tire

is too badly damaged to be repaired reliably

using TIREFIT.

In this case TIREFIT cannot seal the tire

properly.

Do not drive any further.

Contact the nearest authorized Mercedes-

Benz Center for assistance or call Roadside

Assistance.

Tire pressure of 180 kPa (1.8 bar/

26 psi) is reached

XPress the on/off switch on the tire inflation

compressor to 0.

The tire inflation compressor is switched

off.XUnscrew the filler hose from the valve of

the faulty tire.

! After use, excess TIREFIT may run out of

the filler hose. This could cause stains.

Therefore, place the filler hose in the plastic

bag which contained the TIREFIT kit.

XStow the tire sealant bottle and the tire

inflation compressor.XPull away immediately .GWARNING

Do not exceed a vehicle speed of 50 mph

(80 km/h ). A TIREFIT repair is not designed to

operate at higher speeds.

The sticker must be attached on the

instrument cluster where it will be easily seen

by the driver.

Vehicle handling characteristics of a TIREFIT

repaired tire may change. Adapt your driving

accordingly.

302Flat tireBreakdown assistance

Page 305 of 368

XStop after driving for approximately ten

minutes and check the tire pressure with

the tire inflation compressor.GWARNING

If tire inflation pressure has fallen below

130 kPa (1.3 bar/26 psi) do not continue to

drive the vehicle.

Park your vehicle safely away from the

roadway and contact the nearest authorized

Mercedes-Benz Center or Roadside

Assistance.

Have the damaged tire replaced.

XCorrect the tire pressure if it is at least

130 kPa (1.3 bar/20 psi) (for the required

values, see the Tire and Loading

Information placard on the driver's side

B-pillar or the tire pressure table inside the

fuel filler flap).XTo increase the tire pressure: switch on

the tire inflation compressor.

TIREFIT kit version 1

XTo reduce the tire pressure (version 1):

open pressure release screw F on

pressure gauge G.

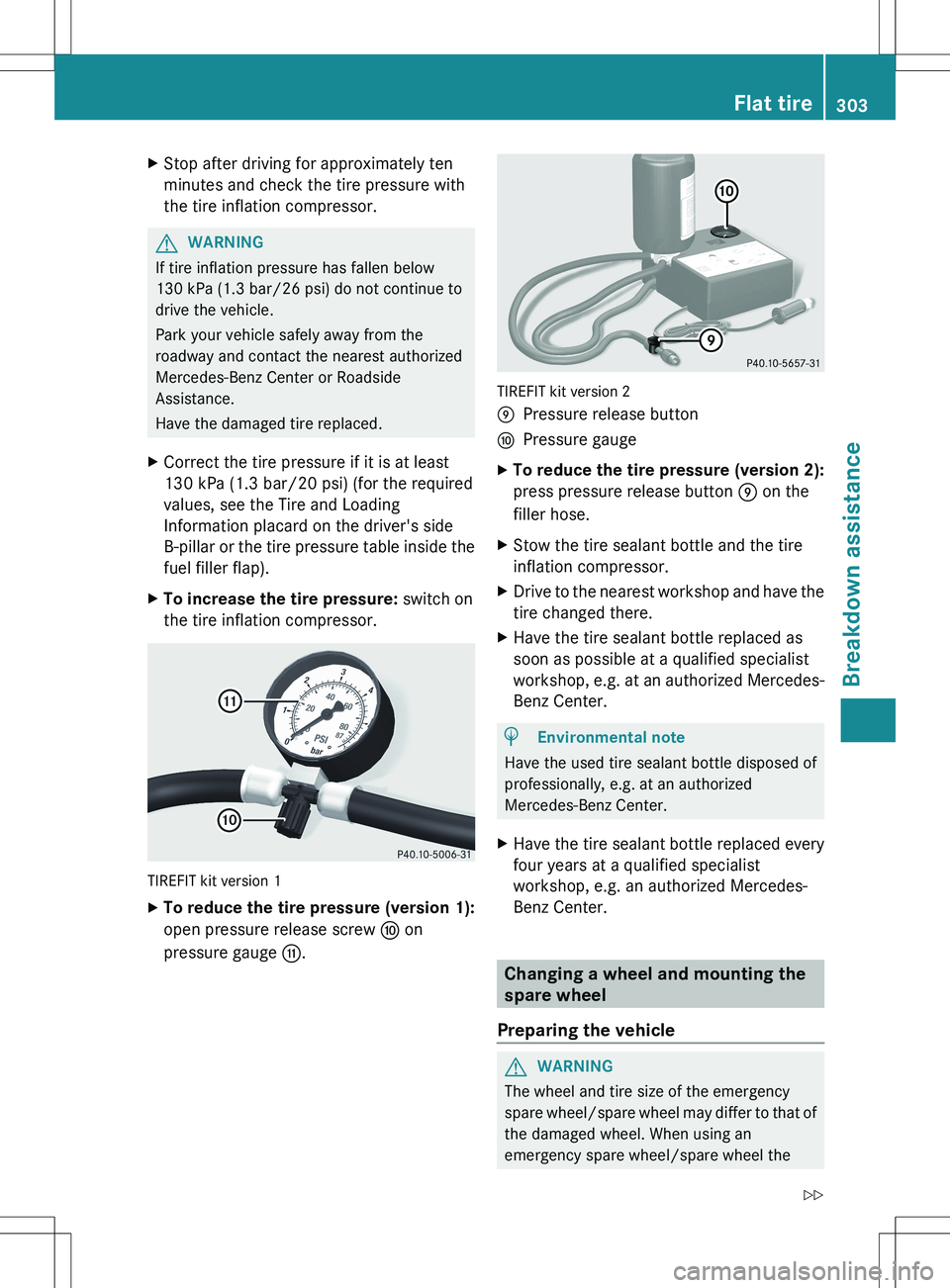

TIREFIT kit version 2

EPressure release buttonFPressure gaugeXTo reduce the tire pressure (version 2):

press pressure release button E on the

filler hose.XStow the tire sealant bottle and the tire

inflation compressor.XDrive to the nearest workshop and have the

tire changed there.XHave the tire sealant bottle replaced as

soon as possible at a qualified specialist

workshop, e.g. at an authorized Mercedes-

Benz Center.HEnvironmental note

Have the used tire sealant bottle disposed of

professionally, e.g. at an authorized

Mercedes-Benz Center.

XHave the tire sealant bottle replaced every

four years at a qualified specialist

workshop, e.g. an authorized Mercedes-

Benz Center.

Changing a wheel and mounting the

spare wheel

Preparing the vehicle

GWARNING

The wheel and tire size of the emergency

spare wheel/spare wheel may differ to that of

the damaged wheel. When using an

emergency spare wheel/spare wheel the

Flat tire303Breakdown assistanceZ

Page 306 of 368

handling characteristics of the vehicle may

change.

Adapt your style of driving accordingly.

Never operate the vehicle with more than one

emergency spare wheel/spare wheel that

differs in size.

Only use an emergency spare wheel/spare

wheel of a differing size briefly and do not

switch off ESP ®

.

When using an emergency spare wheel, you

must not exceed the maximum speed of

50 mph (80 km/h).GWARNING

Have the emergency spare wheel/spare

wheel replaced with a new wheel as soon as

possible at a qualified specialist workshop

which has the necessary specialist knowledge

and tools to carry out the work required.

Mercedes-Benz recommends that you use an

authorized Mercedes-Benz Center for this

purpose. In particular, work relevant to safety

or on safety-related systems must be carried

out at a qualified specialist workshop.

i Vehicles without a spare wheel/

emergency spare wheel are not equipped

with a tire-change tool kit at the factory. For

more information on which tools are

required to perform a wheel change on your

vehicle, e.g. wheel chock, lug wrench or

alignment bolt, consult an authorized

Mercedes-Benz Center.

XPrepare the vehicle as described

( Y page 299).XIf a trailer is coupled to the vehicle,

uncouple it.XRemove the following items (depending on

the vehicle's equipment) from the stowage

well under the trunk floor:

R the emergency spare wheel 35

R the wheel bolts for the emergency spare

wheel 35

R the jackRthe ratchet wrench

R the lug wrench

R the folding wheel chock

R the alignment bolt

R the tire inflation compressor 35XSecure the vehicle to prevent it from rolling

away.

Securing the vehicle to prevent it from

rolling away

GWARNING

Only jack up the vehicle on level ground or on

slight inclines/declines. The vehicle could

otherwise fall off the jack and injure you or

others.

If your vehicle is equipped with a wheel chock,

it can be found in the vehicle tool kit

( Y page 296).

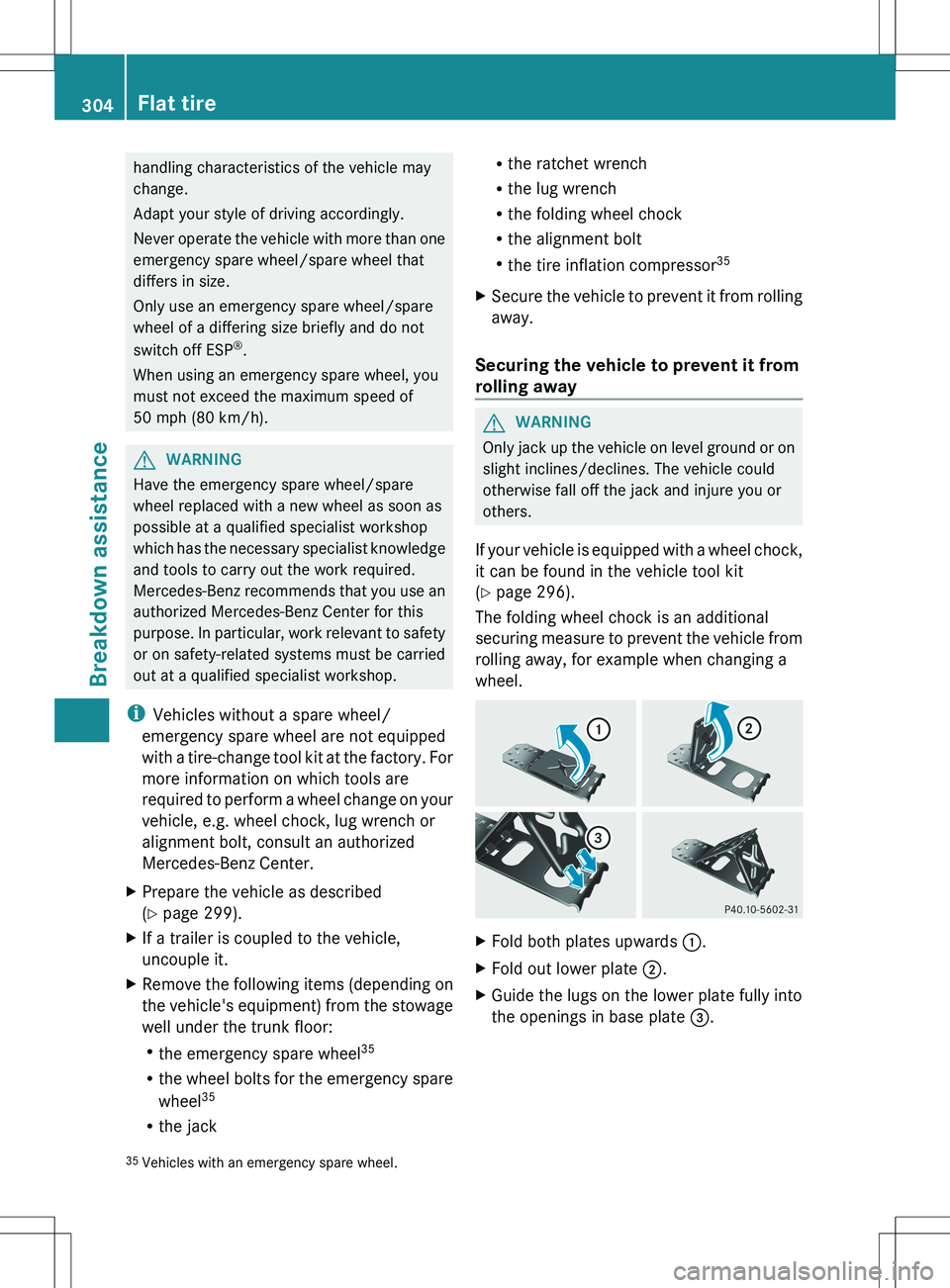

The folding wheel chock is an additional

securing measure to prevent the vehicle from

rolling away, for example when changing a

wheel.

XFold both plates upwards :.XFold out lower plate ;.XGuide the lugs on the lower plate fully into

the openings in base plate =.35

Vehicles with an emergency spare wheel.304Flat tireBreakdown assistance

Page 307 of 368

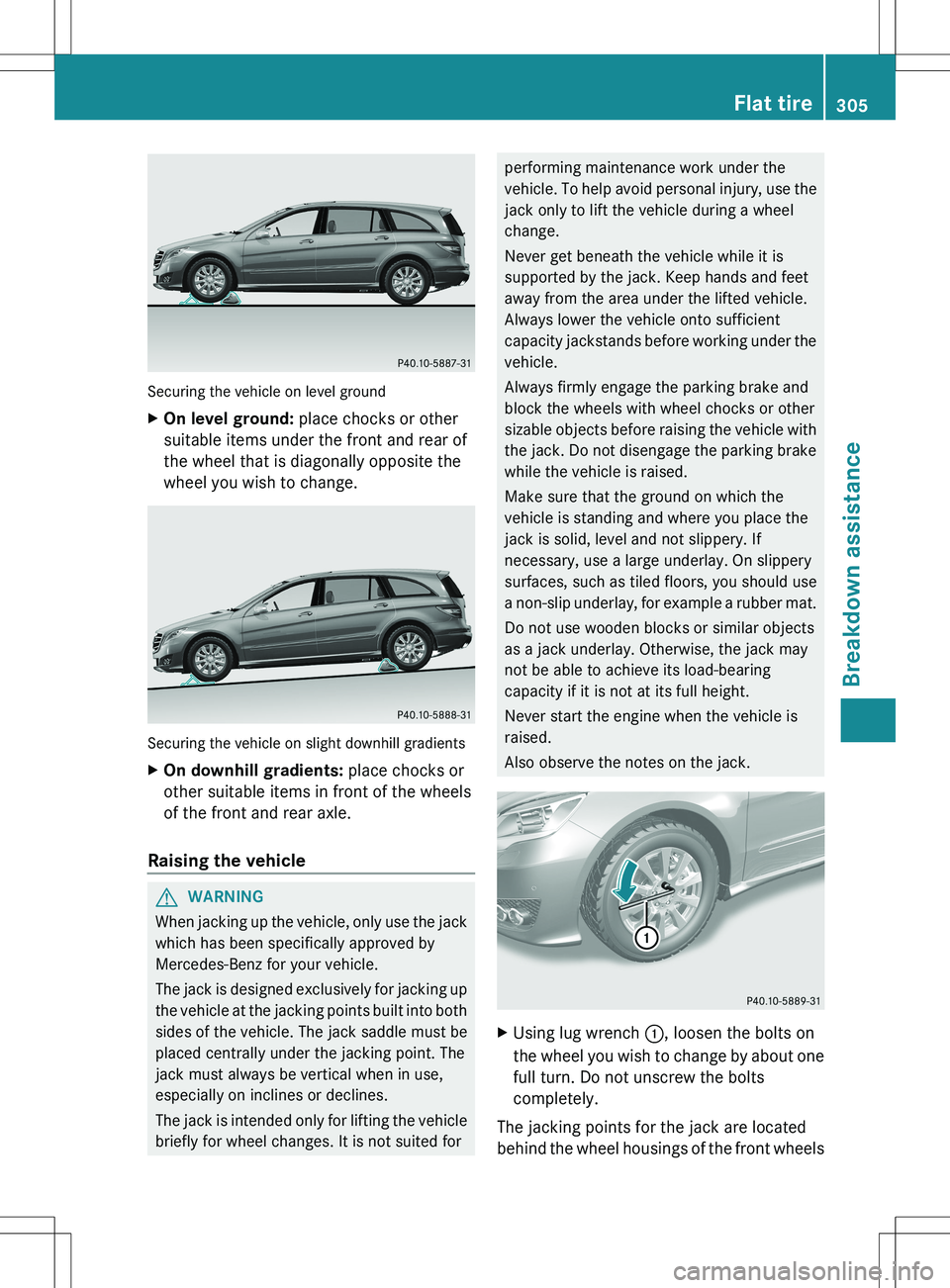

Securing the vehicle on level ground

XOn level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change.

Securing the vehicle on slight downhill gradients

XOn downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle.

Raising the vehicle

GWARNING

When jacking up the vehicle, only use the jack

which has been specifically approved by

Mercedes-Benz for your vehicle.

The jack is designed exclusively for jacking up

the vehicle at the jacking points built into both

sides of the vehicle. The jack saddle must be

placed centrally under the jacking point. The

jack must always be vertical when in use,

especially on inclines or declines.

The jack is intended only for lifting the vehicle

briefly for wheel changes. It is not suited for

performing maintenance work under the

vehicle. To help avoid personal injury, use the

jack only to lift the vehicle during a wheel

change.

Never get beneath the vehicle while it is

supported by the jack. Keep hands and feet

away from the area under the lifted vehicle.

Always lower the vehicle onto sufficient

capacity jackstands before working under the

vehicle.

Always firmly engage the parking brake and

block the wheels with wheel chocks or other

sizable objects before raising the vehicle with

the jack. Do not disengage the parking brake

while the vehicle is raised.

Make sure that the ground on which the

vehicle is standing and where you place the

jack is solid, level and not slippery. If

necessary, use a large underlay. On slippery

surfaces, such as tiled floors, you should use

a non-slip underlay, for example a rubber mat.

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack may

not be able to achieve its load-bearing

capacity if it is not at its full height.

Never start the engine when the vehicle is

raised.

Also observe the notes on the jack.XUsing lug wrench :, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts

completely.

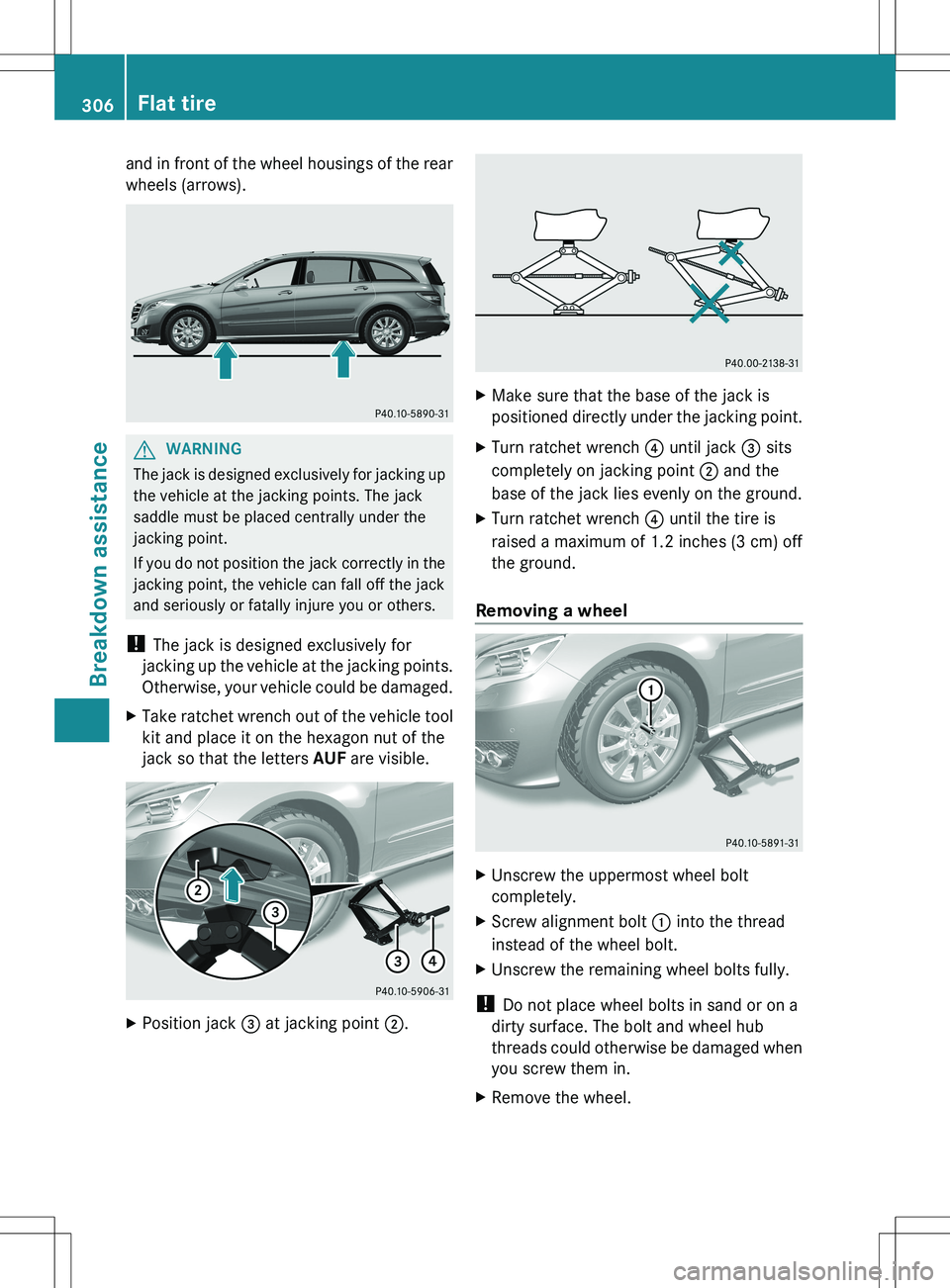

The jacking points for the jack are located

behind the wheel housings of the front wheels

Flat tire305Breakdown assistanceZ

Page 308 of 368

and in front of the wheel housings of the rear

wheels (arrows).GWARNING

The jack is designed exclusively for jacking up

the vehicle at the jacking points. The jack

saddle must be placed centrally under the

jacking point.

If you do not position the jack correctly in the

jacking point, the vehicle can fall off the jack

and seriously or fatally injure you or others.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged.

XTake ratchet wrench out of the vehicle tool

kit and place it on the hexagon nut of the

jack so that the letters AUF are visible.XPosition jack = at jacking point ;.XMake sure that the base of the jack is

positioned directly under the jacking point.XTurn ratchet wrench ? until jack = sits

completely on jacking point ; and the

base of the jack lies evenly on the ground.XTurn ratchet wrench ? until the tire is

raised a maximum of 1.2 inches (3 cm) off

the ground.

Removing a wheel

XUnscrew the uppermost wheel bolt

completely.XScrew alignment bolt : into the thread

instead of the wheel bolt.XUnscrew the remaining wheel bolts fully.

! Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in.

XRemove the wheel.306Flat tireBreakdown assistance

Page 309 of 368

Mounting a new wheelGWARNING

Always replace wheel bolts that are damaged

or rusted.

Never apply oil or grease to wheel bolts.

Damaged wheel hub threads should be

repaired immediately. Do not continue to

drive under these circumstances! Contact an

authorized Mercedes-Benz Center or call

Roadside Assistance.

Incorrect wheel bolts or improperly tightened

wheel bolts can cause the wheel to come off.

This could cause an accident. Make sure to

use the correct wheel bolts.

GWARNING

Only use genuine Mercedes-Benz wheel bolts.

Other wheel bolts may come loose.

Do not tighten the wheel bolts when the

vehicle is raised. Otherwise, the vehicle could

fall off the jack.

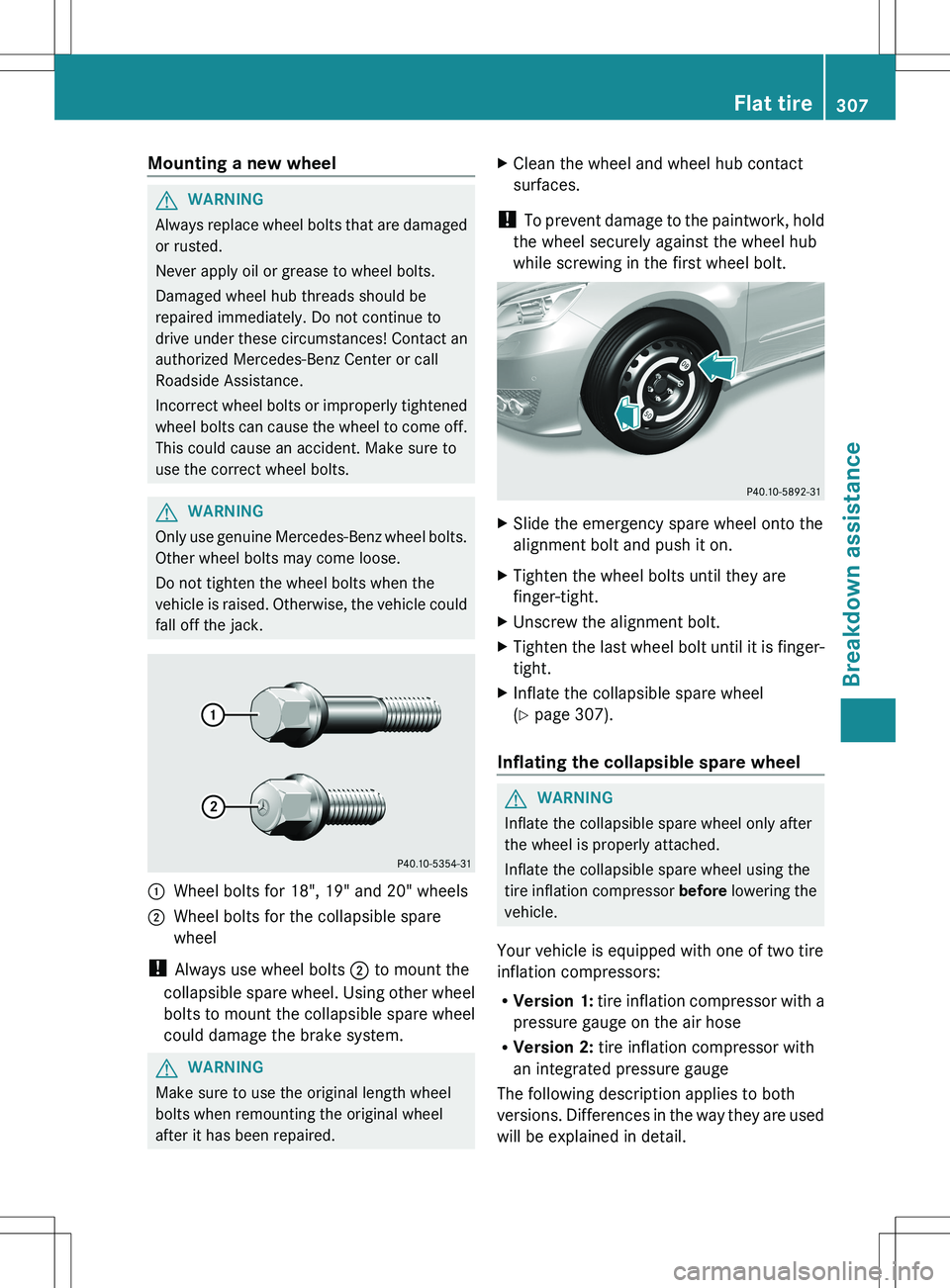

:Wheel bolts for 18", 19" and 20" wheels2Wheel bolts for the collapsible spare

wheel

! Always use wheel bolts ; to mount the

collapsible spare wheel. Using other wheel

bolts to mount the collapsible spare wheel

could damage the brake system.

GWARNING

Make sure to use the original length wheel

bolts when remounting the original wheel

after it has been repaired.

XClean the wheel and wheel hub contact

surfaces.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

XSlide the emergency spare wheel onto the

alignment bolt and push it on.XTighten the wheel bolts until they are

finger-tight.XUnscrew the alignment bolt.XTighten the last wheel bolt until it is finger-

tight.XInflate the collapsible spare wheel

( Y page 307).

Inflating the collapsible spare wheel

GWARNING

Inflate the collapsible spare wheel only after

the wheel is properly attached.

Inflate the collapsible spare wheel using the

tire inflation compressor before lowering the

vehicle.

Your vehicle is equipped with one of two tire

inflation compressors:

R Version 1: tire inflation compressor with a

pressure gauge on the air hose

R Version 2: tire inflation compressor with

an integrated pressure gauge

The following description applies to both

versions. Differences in the way they are used

will be explained in detail.

Flat tire307Breakdown assistanceZ

Page 310 of 368

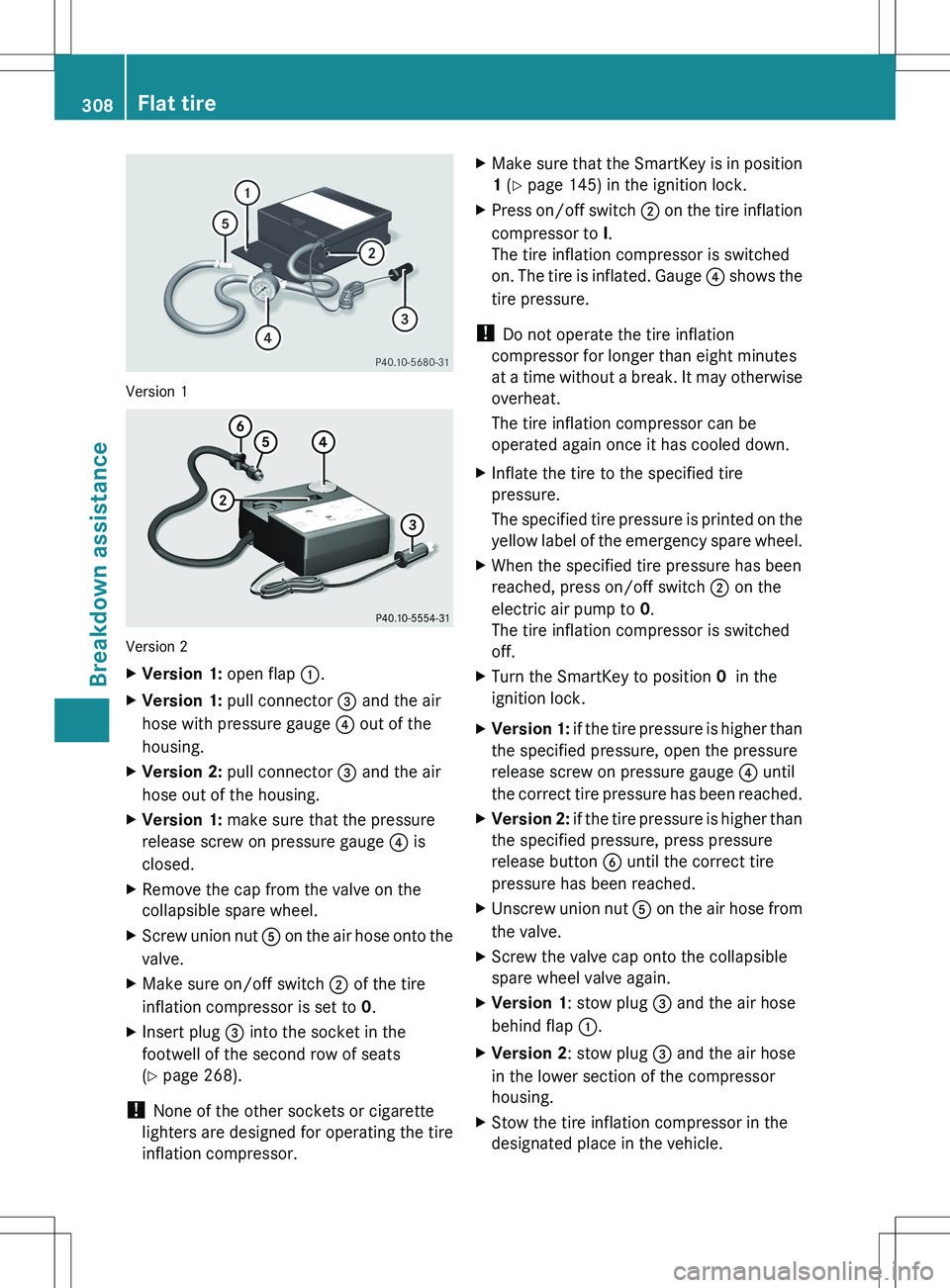

Version 1

Version 2

XVersion 1: open flap :.XVersion 1: pull connector = and the air

hose with pressure gauge ? out of the

housing.XVersion 2: pull connector = and the air

hose out of the housing.XVersion 1: make sure that the pressure

release screw on pressure gauge ? is

closed.XRemove the cap from the valve on the

collapsible spare wheel.XScrew union nut A on the air hose onto the

valve.XMake sure on/off switch ; of the tire

inflation compressor is set to 0.XInsert plug 3 into the socket in the

footwell of the second row of seats

( Y page 268).

!

None of the other sockets or cigarette

lighters are designed for operating the tire

inflation compressor.

XMake sure that the SmartKey is in position

1 (Y page 145) in the ignition lock.XPress on/off switch ; on the tire inflation

compressor to I.

The tire inflation compressor is switched

on. The tire is inflated. Gauge ? shows the

tire pressure.

! Do not operate the tire inflation

compressor for longer than eight minutes

at a time without a break. It may otherwise

overheat.

The tire inflation compressor can be

operated again once it has cooled down.

XInflate the tire to the specified tire

pressure.

The specified tire pressure is printed on the

yellow label of the emergency spare wheel.XWhen the specified tire pressure has been

reached, press on/off switch 2 on the

electric air pump to 0.

The tire inflation compressor is switched

off.XTurn the SmartKey to position 0 in the

ignition lock.XVersion 1: if the tire pressure is higher than

the specified pressure, open the pressure

release screw on pressure gauge 4 until

the correct tire pressure has been reached.XVersion 2: if the tire pressure is higher than

the specified pressure, press pressure

release button 6 until the correct tire

pressure has been reached.XUnscrew union nut A on the air hose from

the valve.XScrew the valve cap onto the collapsible

spare wheel valve again.XVersion 1 : stow plug = and the air hose

behind flap :.XVersion 2 : stow plug = and the air hose

in the lower section of the compressor

housing.XStow the tire inflation compressor in the

designated place in the vehicle.308Flat tireBreakdown assistance