MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1061 of 1232

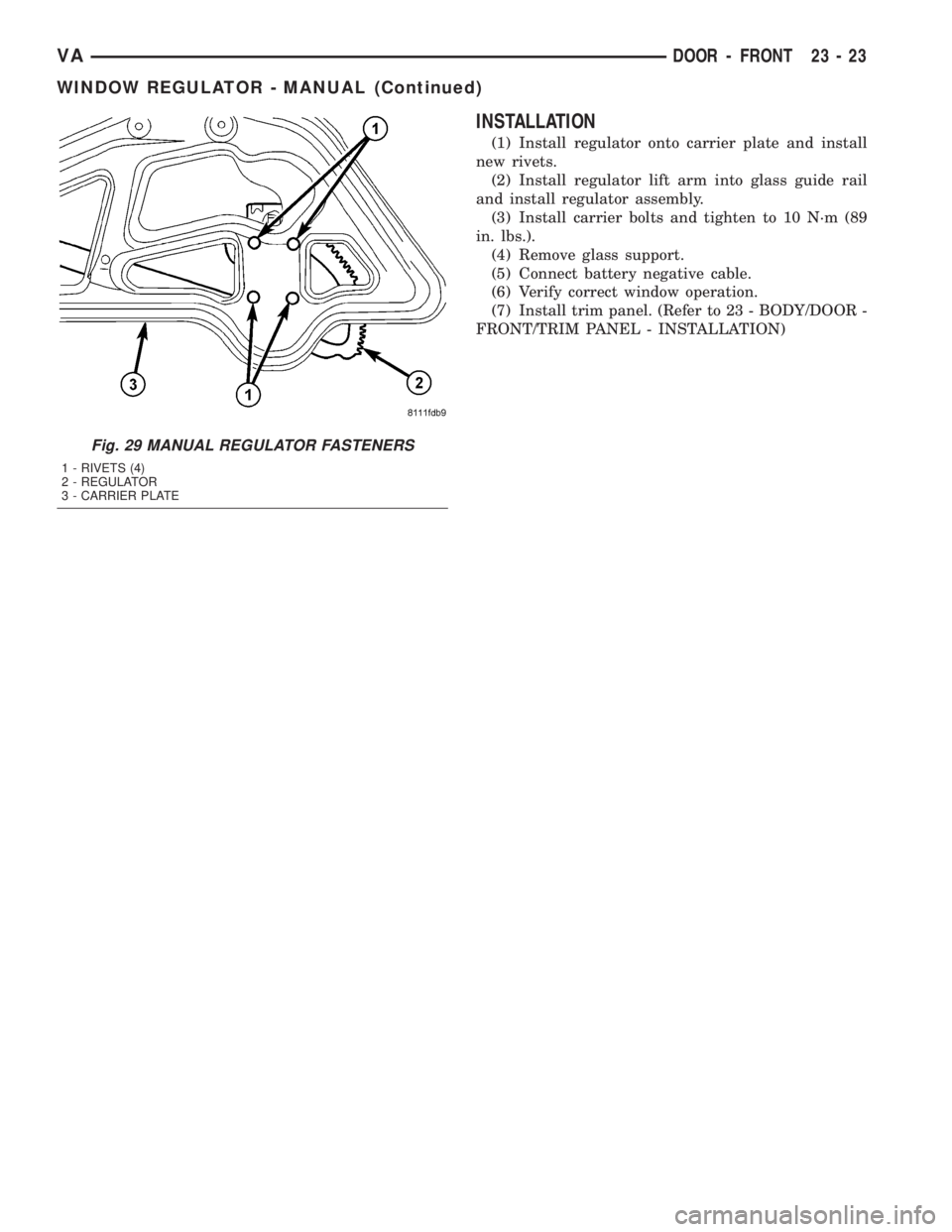

INSTALLATION

(1) Install regulator onto carrier plate and install

new rivets.

(2) Install regulator lift arm into glass guide rail

and install regulator assembly.

(3) Install carrier bolts and tighten to 10 N´m (89

in. lbs.).

(4) Remove glass support.

(5) Connect battery negative cable.

(6) Verify correct window operation.

(7) Install trim panel. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION)

Fig. 29 MANUAL REGULATOR FASTENERS

1 - RIVETS (4)

2 - REGULATOR

3 - CARRIER PLATE

VADOOR - FRONT 23 - 23

WINDOW REGULATOR - MANUAL (Continued)

Page 1062 of 1232

DOORS - REAR

TABLE OF CONTENTS

page page

CHECK

REMOVAL.............................24

INSTALLATION.........................24

DOOR

REMOVAL.............................25

DISASSEMBLY.........................26

ASSEMBLY............................28

INSTALLATION.........................30

ADJUSTMENTS

ADJUSTMENT........................30

DOOR GLASS

REMOVAL.............................31

INSTALLATION.........................31

EXTERIOR HANDLE

REMOVAL.............................32INSTALLATION.........................33

HINGE

REMOVAL.............................34

INSTALLATION.........................34

INSIDE HANDLE ACTUATOR

REMOVAL.............................34

INSTALLATION.........................34

LATCH

REMOVAL.............................34

INSTALLATION.........................35

TRIM PANEL

REMOVAL.............................35

INSTALLATION.........................35

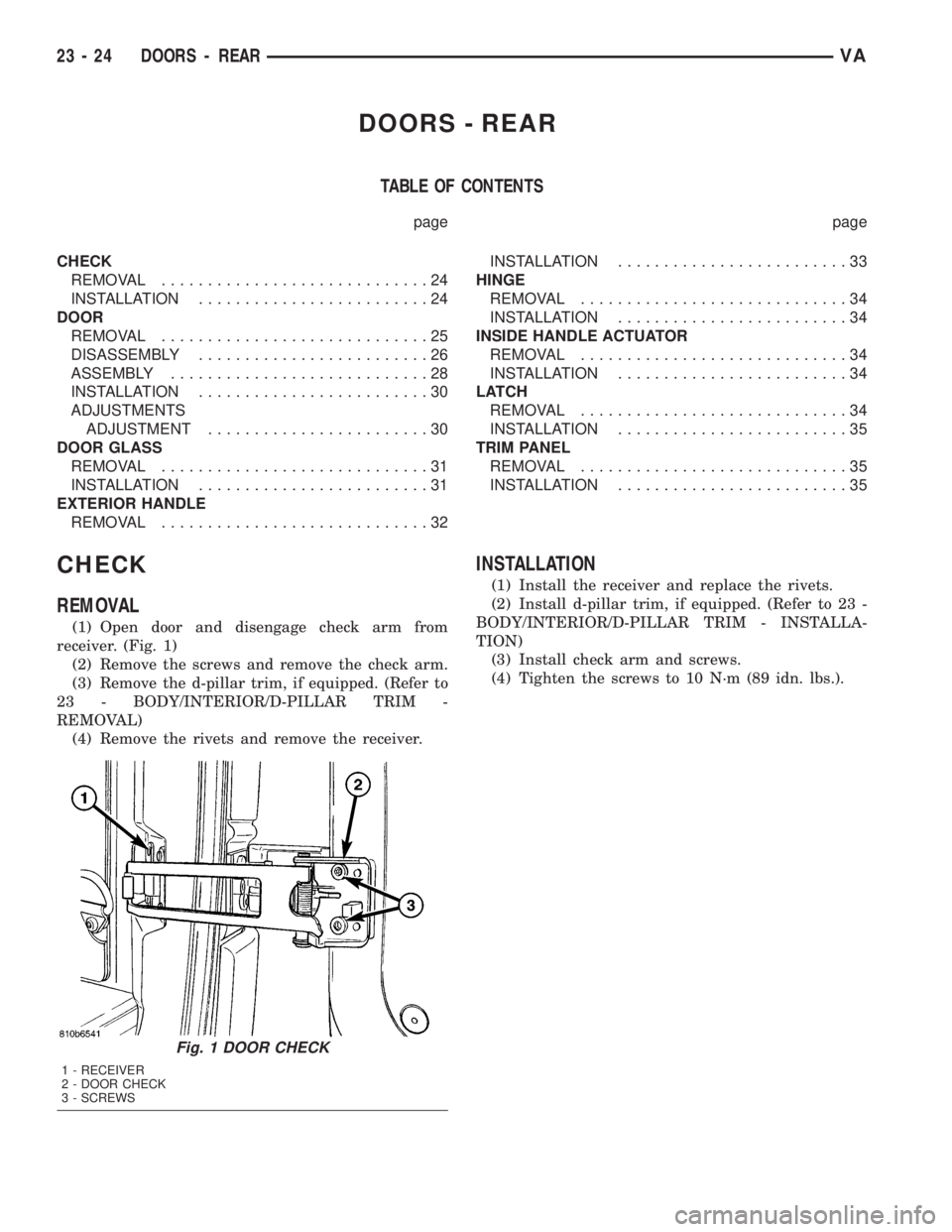

CHECK

REMOVAL

(1) Open door and disengage check arm from

receiver. (Fig. 1)

(2) Remove the screws and remove the check arm.

(3) Remove the d-pillar trim, if equipped. (Refer to

23 - BODY/INTERIOR/D-PILLAR TRIM -

REMOVAL)

(4) Remove the rivets and remove the receiver.

INSTALLATION

(1) Install the receiver and replace the rivets.

(2) Install d-pillar trim, if equipped. (Refer to 23 -

BODY/INTERIOR/D-PILLAR TRIM - INSTALLA-

TION)

(3) Install check arm and screws.

(4) Tighten the screws to 10 N´m (89 idn. lbs.).

Fig. 1 DOOR CHECK

1 - RECEIVER

2 - DOOR CHECK

3 - SCREWS

23 - 24 DOORS - REARVA

Page 1063 of 1232

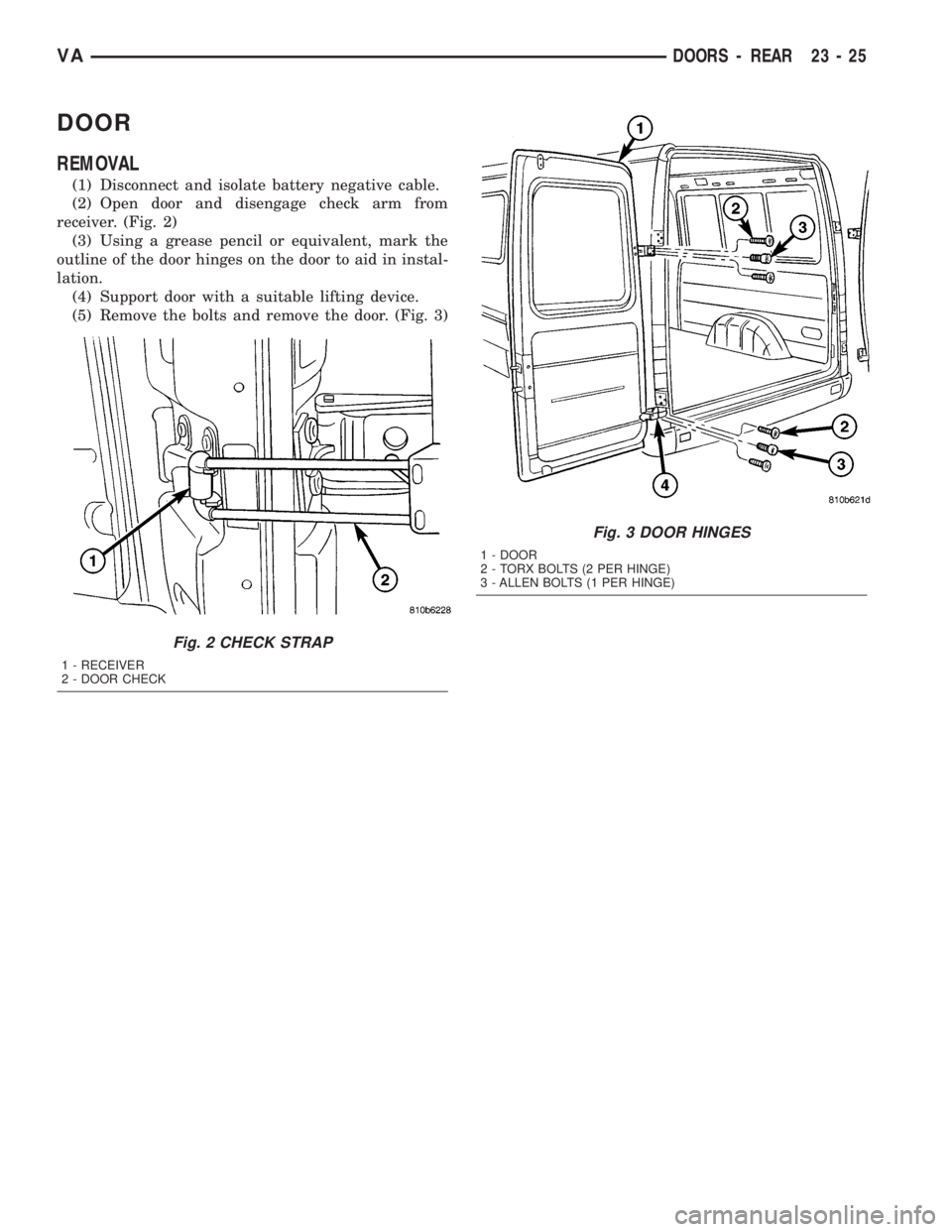

DOOR

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Open door and disengage check arm from

receiver. (Fig. 2)

(3) Using a grease pencil or equivalent, mark the

outline of the door hinges on the door to aid in instal-

lation.

(4) Support door with a suitable lifting device.

(5) Remove the bolts and remove the door. (Fig. 3)

Fig. 2 CHECK STRAP

1 - RECEIVER

2 - DOOR CHECK

Fig. 3 DOOR HINGES

1 - DOOR

2 - TORX BOLTS (2 PER HINGE)

3 - ALLEN BOLTS (1 PER HINGE)

VADOORS - REAR 23 - 25

Page 1064 of 1232

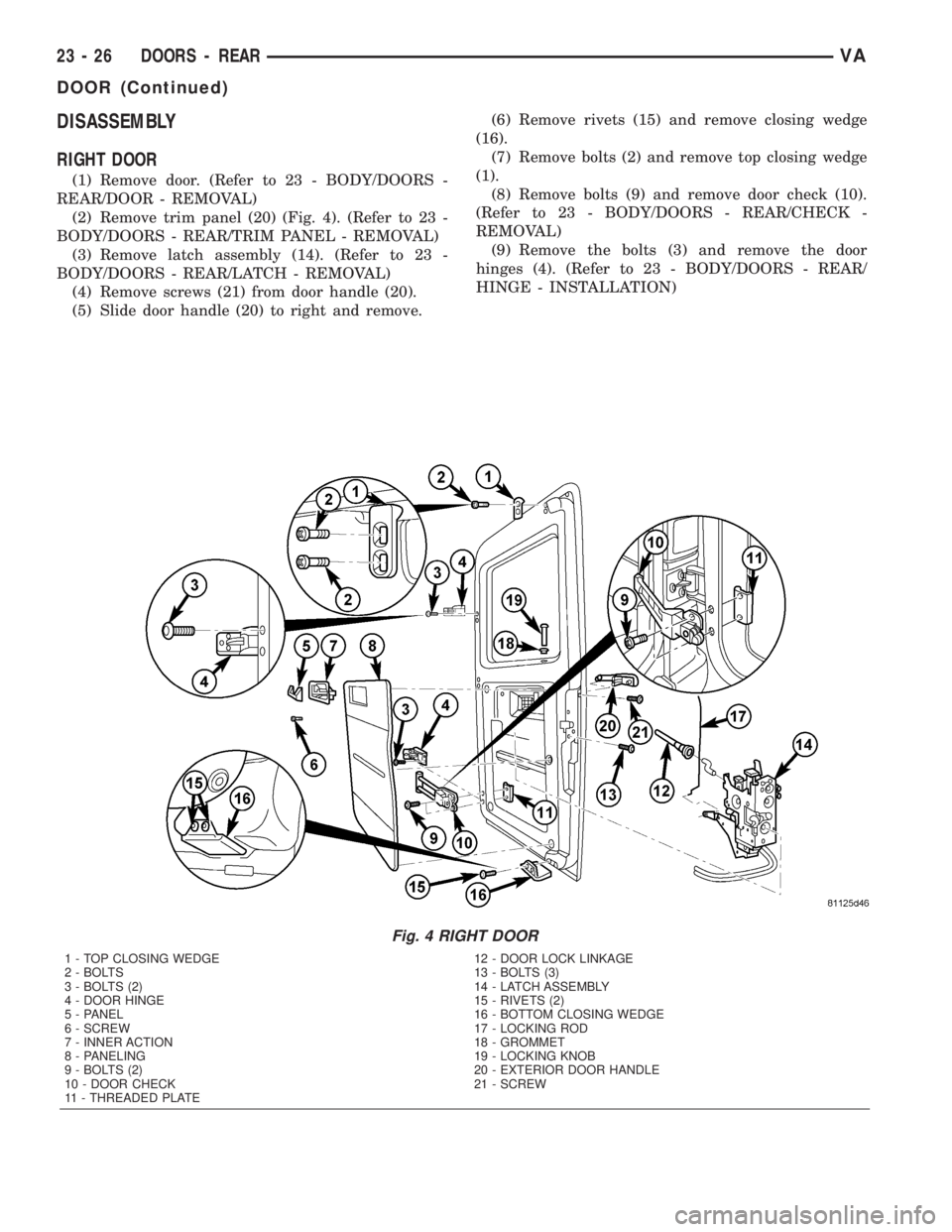

DISASSEMBLY

RIGHT DOOR

(1) Remove door. (Refer to 23 - BODY/DOORS -

REAR/DOOR - REMOVAL)

(2) Remove trim panel (20) (Fig. 4). (Refer to 23 -

BODY/DOORS - REAR/TRIM PANEL - REMOVAL)

(3) Remove latch assembly (14). (Refer to 23 -

BODY/DOORS - REAR/LATCH - REMOVAL)

(4) Remove screws (21) from door handle (20).

(5) Slide door handle (20) to right and remove.(6) Remove rivets (15) and remove closing wedge

(16).

(7) Remove bolts (2) and remove top closing wedge

(1).

(8) Remove bolts (9) and remove door check (10).

(Refer to 23 - BODY/DOORS - REAR/CHECK -

REMOVAL)

(9) Remove the bolts (3) and remove the door

hinges (4). (Refer to 23 - BODY/DOORS - REAR/

HINGE - INSTALLATION)

Fig. 4 RIGHT DOOR

1 - TOP CLOSING WEDGE 12 - DOOR LOCK LINKAGE

2 - BOLTS 13 - BOLTS (3)

3 - BOLTS (2) 14 - LATCH ASSEMBLY

4 - DOOR HINGE 15 - RIVETS (2)

5 - PANEL 16 - BOTTOM CLOSING WEDGE

6 - SCREW 17 - LOCKING ROD

7 - INNER ACTION 18 - GROMMET

8 - PANELING 19 - LOCKING KNOB

9 - BOLTS (2) 20 - EXTERIOR DOOR HANDLE

10 - DOOR CHECK 21 - SCREW

11 - THREADED PLATE

23 - 26 DOORS - REARVA

DOOR (Continued)

Page 1065 of 1232

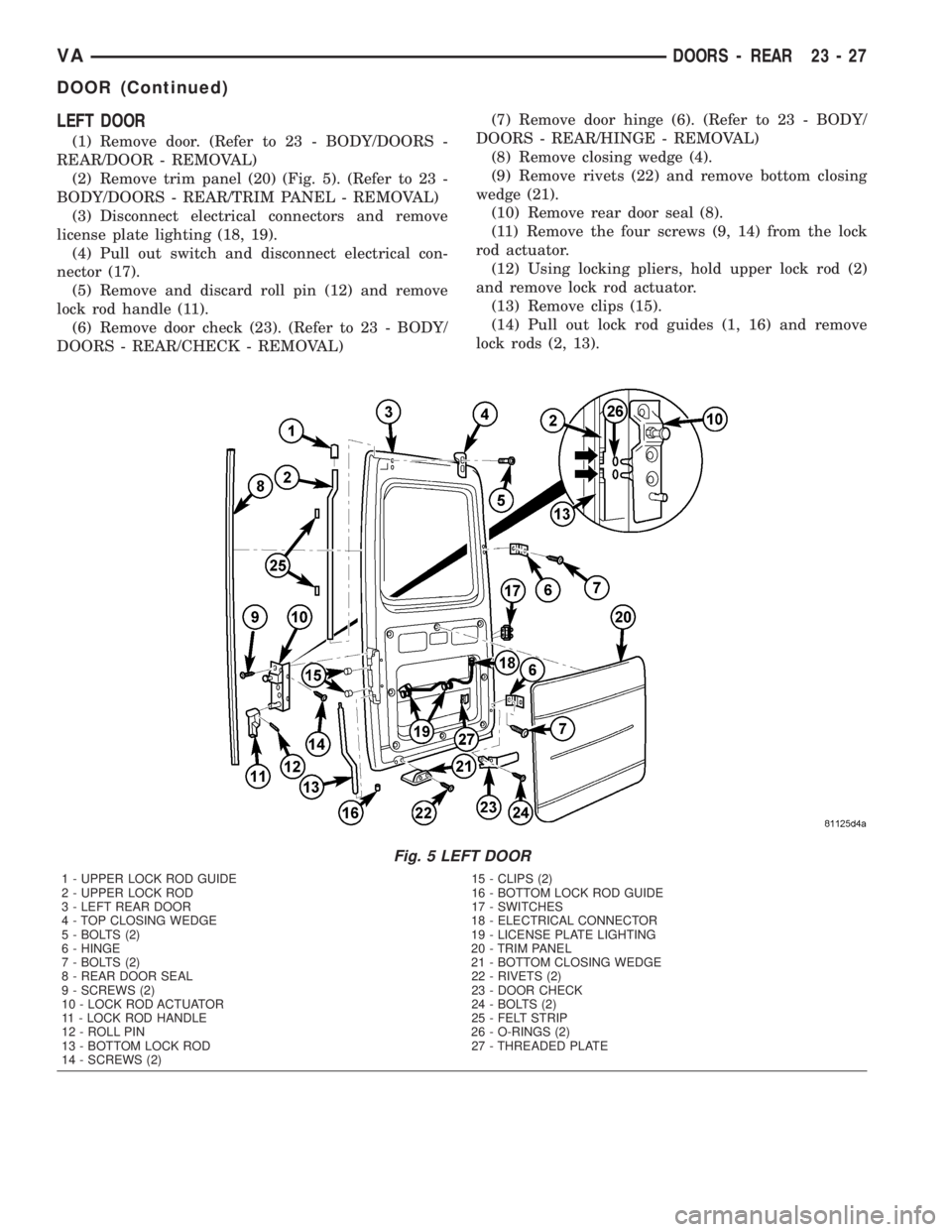

LEFT DOOR

(1) Remove door. (Refer to 23 - BODY/DOORS -

REAR/DOOR - REMOVAL)

(2) Remove trim panel (20) (Fig. 5). (Refer to 23 -

BODY/DOORS - REAR/TRIM PANEL - REMOVAL)

(3) Disconnect electrical connectors and remove

license plate lighting (18, 19).

(4) Pull out switch and disconnect electrical con-

nector (17).

(5) Remove and discard roll pin (12) and remove

lock rod handle (11).

(6) Remove door check (23). (Refer to 23 - BODY/

DOORS - REAR/CHECK - REMOVAL)(7) Remove door hinge (6). (Refer to 23 - BODY/

DOORS - REAR/HINGE - REMOVAL)

(8) Remove closing wedge (4).

(9) Remove rivets (22) and remove bottom closing

wedge (21).

(10) Remove rear door seal (8).

(11) Remove the four screws (9, 14) from the lock

rod actuator.

(12) Using locking pliers, hold upper lock rod (2)

and remove lock rod actuator.

(13) Remove clips (15).

(14) Pull out lock rod guides (1, 16) and remove

lock rods (2, 13).

Fig. 5 LEFT DOOR

1 - UPPER LOCK ROD GUIDE 15 - CLIPS (2)

2 - UPPER LOCK ROD 16 - BOTTOM LOCK ROD GUIDE

3 - LEFT REAR DOOR 17 - SWITCHES

4 - TOP CLOSING WEDGE 18 - ELECTRICAL CONNECTOR

5 - BOLTS (2) 19 - LICENSE PLATE LIGHTING

6 - HINGE 20 - TRIM PANEL

7 - BOLTS (2) 21 - BOTTOM CLOSING WEDGE

8 - REAR DOOR SEAL 22 - RIVETS (2)

9 - SCREWS (2) 23 - DOOR CHECK

10 - LOCK ROD ACTUATOR 24 - BOLTS (2)

11 - LOCK ROD HANDLE 25 - FELT STRIP

12 - ROLL PIN 26 - O-RINGS (2)

13 - BOTTOM LOCK ROD 27 - THREADED PLATE

14 - SCREWS (2)

VADOORS - REAR 23 - 27

DOOR (Continued)

Page 1066 of 1232

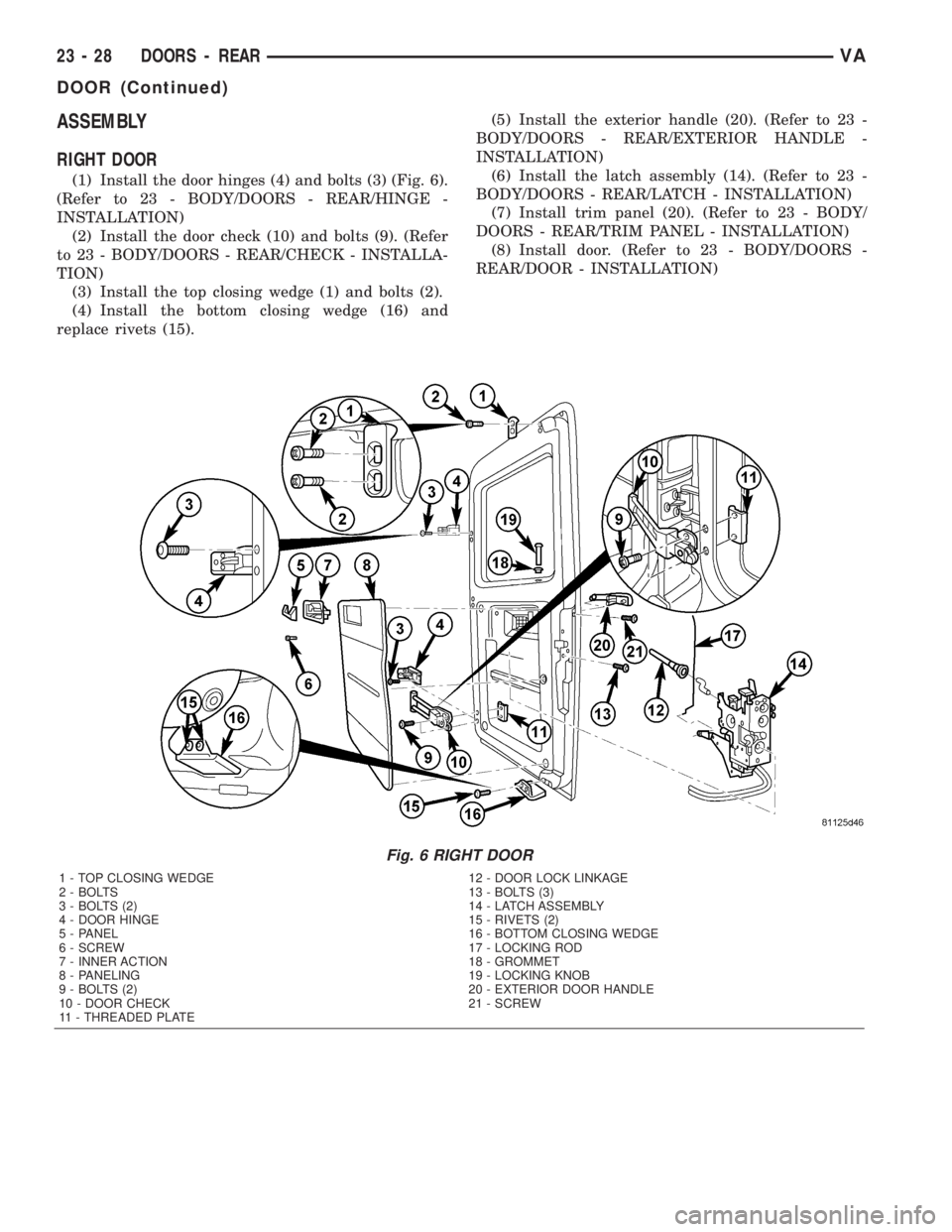

ASSEMBLY

RIGHT DOOR

(1) Install the door hinges (4) and bolts (3) (Fig. 6).

(Refer to 23 - BODY/DOORS - REAR/HINGE -

INSTALLATION)

(2) Install the door check (10) and bolts (9). (Refer

to 23 - BODY/DOORS - REAR/CHECK - INSTALLA-

TION)

(3) Install the top closing wedge (1) and bolts (2).

(4) Install the bottom closing wedge (16) and

replace rivets (15).(5) Install the exterior handle (20). (Refer to 23 -

BODY/DOORS - REAR/EXTERIOR HANDLE -

INSTALLATION)

(6) Install the latch assembly (14). (Refer to 23 -

BODY/DOORS - REAR/LATCH - INSTALLATION)

(7) Install trim panel (20). (Refer to 23 - BODY/

DOORS - REAR/TRIM PANEL - INSTALLATION)

(8) Install door. (Refer to 23 - BODY/DOORS -

REAR/DOOR - INSTALLATION)

Fig. 6 RIGHT DOOR

1 - TOP CLOSING WEDGE 12 - DOOR LOCK LINKAGE

2 - BOLTS 13 - BOLTS (3)

3 - BOLTS (2) 14 - LATCH ASSEMBLY

4 - DOOR HINGE 15 - RIVETS (2)

5 - PANEL 16 - BOTTOM CLOSING WEDGE

6 - SCREW 17 - LOCKING ROD

7 - INNER ACTION 18 - GROMMET

8 - PANELING 19 - LOCKING KNOB

9 - BOLTS (2) 20 - EXTERIOR DOOR HANDLE

10 - DOOR CHECK 21 - SCREW

11 - THREADED PLATE

23 - 28 DOORS - REARVA

DOOR (Continued)

Page 1067 of 1232

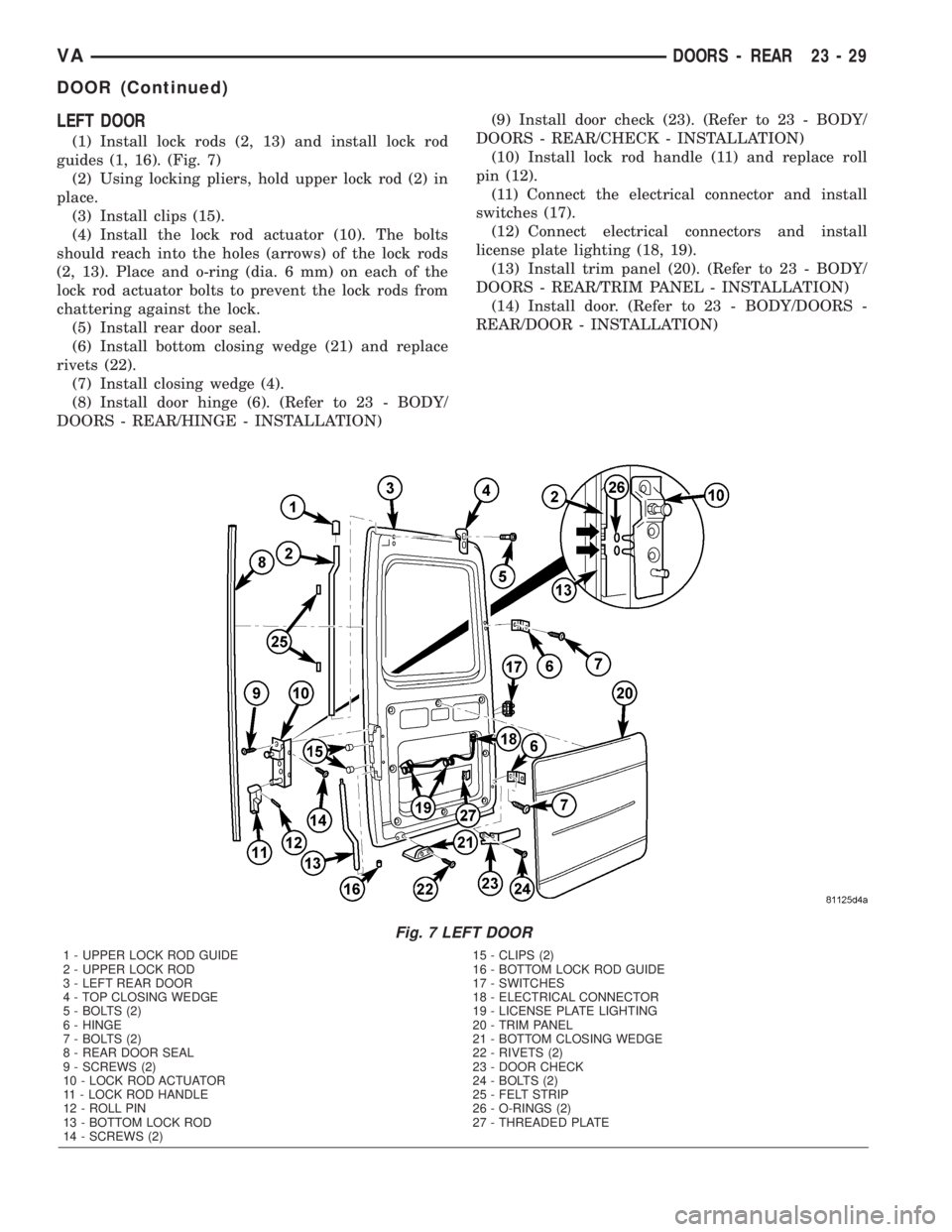

LEFT DOOR

(1) Install lock rods (2, 13) and install lock rod

guides (1, 16). (Fig. 7)

(2) Using locking pliers, hold upper lock rod (2) in

place.

(3) Install clips (15).

(4) Install the lock rod actuator (10). The bolts

should reach into the holes (arrows) of the lock rods

(2, 13). Place and o-ring (dia. 6 mm) on each of the

lock rod actuator bolts to prevent the lock rods from

chattering against the lock.

(5) Install rear door seal.

(6) Install bottom closing wedge (21) and replace

rivets (22).

(7) Install closing wedge (4).

(8) Install door hinge (6). (Refer to 23 - BODY/

DOORS - REAR/HINGE - INSTALLATION)(9) Install door check (23). (Refer to 23 - BODY/

DOORS - REAR/CHECK - INSTALLATION)

(10) Install lock rod handle (11) and replace roll

pin (12).

(11) Connect the electrical connector and install

switches (17).

(12) Connect electrical connectors and install

license plate lighting (18, 19).

(13) Install trim panel (20). (Refer to 23 - BODY/

DOORS - REAR/TRIM PANEL - INSTALLATION)

(14) Install door. (Refer to 23 - BODY/DOORS -

REAR/DOOR - INSTALLATION)

Fig. 7 LEFT DOOR

1 - UPPER LOCK ROD GUIDE 15 - CLIPS (2)

2 - UPPER LOCK ROD 16 - BOTTOM LOCK ROD GUIDE

3 - LEFT REAR DOOR 17 - SWITCHES

4 - TOP CLOSING WEDGE 18 - ELECTRICAL CONNECTOR

5 - BOLTS (2) 19 - LICENSE PLATE LIGHTING

6 - HINGE 20 - TRIM PANEL

7 - BOLTS (2) 21 - BOTTOM CLOSING WEDGE

8 - REAR DOOR SEAL 22 - RIVETS (2)

9 - SCREWS (2) 23 - DOOR CHECK

10 - LOCK ROD ACTUATOR 24 - BOLTS (2)

11 - LOCK ROD HANDLE 25 - FELT STRIP

12 - ROLL PIN 26 - O-RINGS (2)

13 - BOTTOM LOCK ROD 27 - THREADED PLATE

14 - SCREWS (2)

VADOORS - REAR 23 - 29

DOOR (Continued)

Page 1068 of 1232

INSTALLATION

CAUTION: If the door is being replaced a suitable

seam sealer must be used prior to painting.

(1) Support the door with a suitable lifting device,

install door and install the hinge bolts.

(2) Tighten bolts to 25 N´m (18 ft. lbs.).

(3) Engage check arm into receiver.

(4) Adjust the door as necessary. (Refer to 23 -

BODY/DOORS - REAR/DOOR - ADJUSTMENTS)

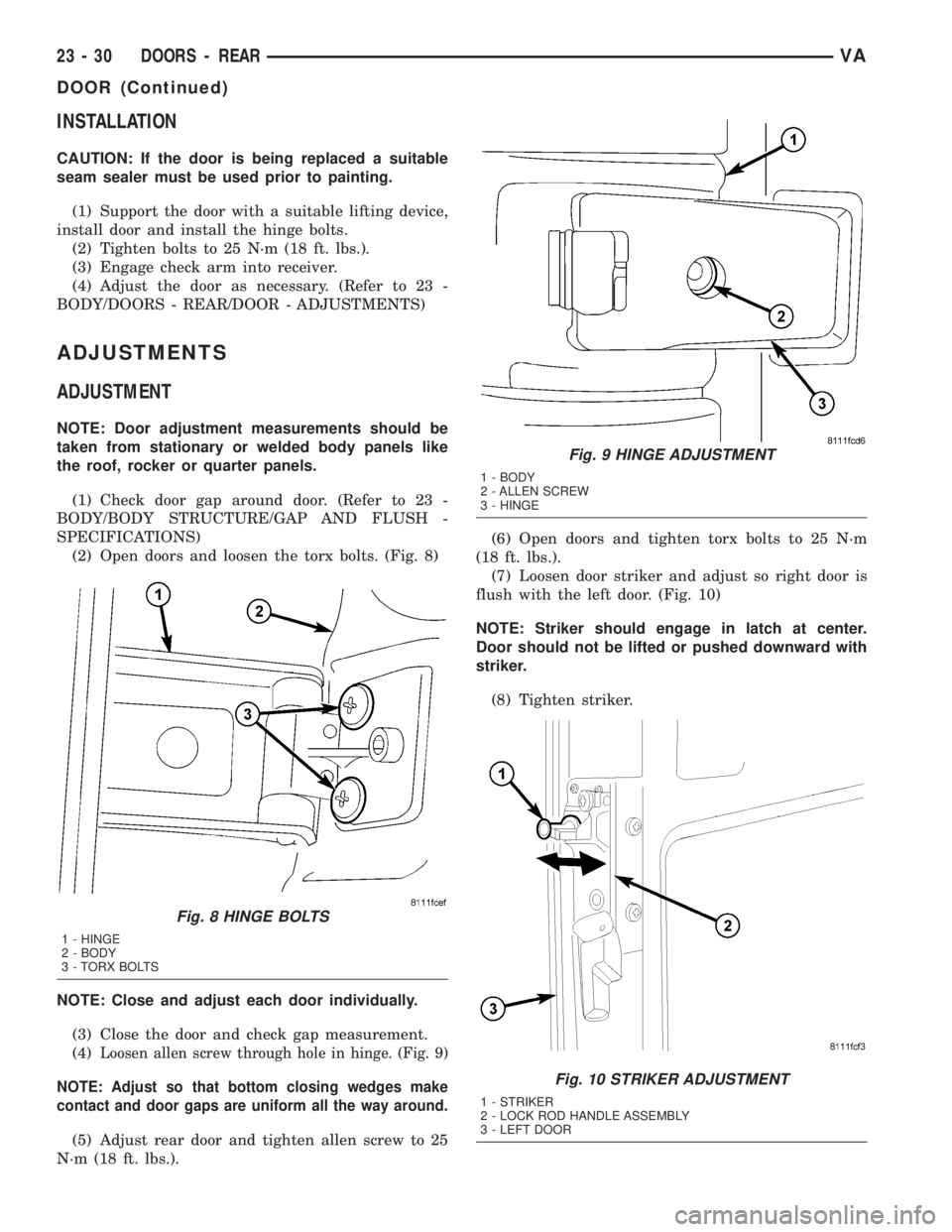

ADJUSTMENTS

ADJUSTMENT

NOTE: Door adjustment measurements should be

taken from stationary or welded body panels like

the roof, rocker or quarter panels.

(1) Check door gap around door. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

(2) Open doors and loosen the torx bolts. (Fig. 8)

NOTE: Close and adjust each door individually.

(3) Close the door and check gap measurement.

(4)

Loosen allen screw through hole in hinge. (Fig. 9)

NOTE: Adjust so that bottom closing wedges make

contact and door gaps are uniform all the way around.

(5) Adjust rear door and tighten allen screw to 25

N´m (18 ft. lbs.).(6) Open doors and tighten torx bolts to 25 N´m

(18 ft. lbs.).

(7) Loosen door striker and adjust so right door is

flush with the left door. (Fig. 10)

NOTE: Striker should engage in latch at center.

Door should not be lifted or pushed downward with

striker.

(8) Tighten striker.

Fig. 8 HINGE BOLTS

1 - HINGE

2 - BODY

3 - TORX BOLTS

Fig. 9 HINGE ADJUSTMENT

1 - BODY

2 - ALLEN SCREW

3 - HINGE

Fig. 10 STRIKER ADJUSTMENT

1 - STRIKER

2 - LOCK ROD HANDLE ASSEMBLY

3 - LEFT DOOR

23 - 30 DOORS - REARVA

DOOR (Continued)

Page 1069 of 1232

CAUTION: Since the rear doors are components

with static functions it is very important that they

are fastened while driving. This prevents excessive

torsion of the vehicle and leaky rear doors. The rear

doors are fastened by adjusting the closing

wedges.

(9) Closing wedges at bottom must be resting free

of play on plastic closing plates when rear doors are

closed. To adjust, loosen door hinges and raise or

lower complete doors.

(10) Loosen upper closing wedge screws and move

top closing wedge up against plastic closing plate free

of play with rear door closed and tighten screws to 10

N´m (89 in. lbs.).

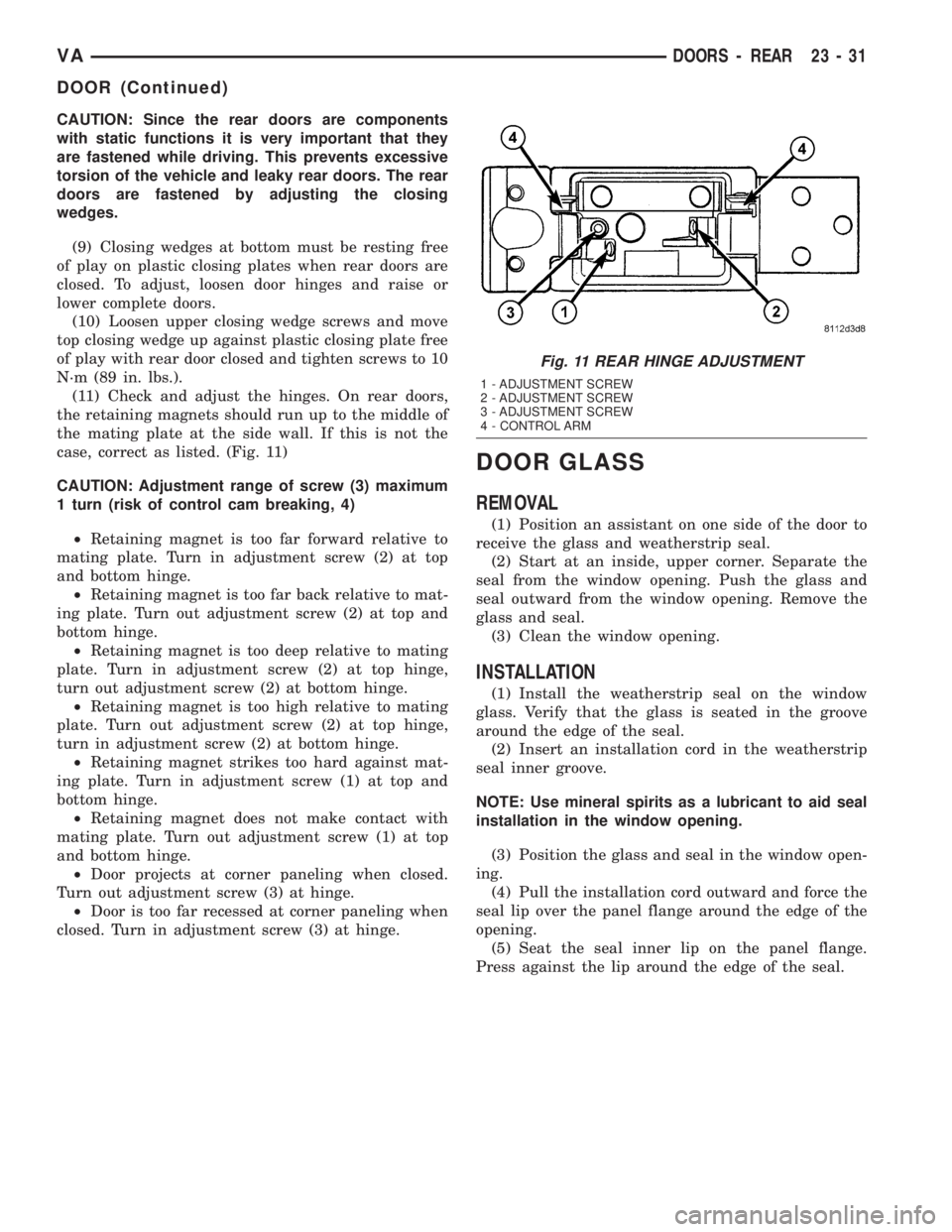

(11) Check and adjust the hinges. On rear doors,

the retaining magnets should run up to the middle of

the mating plate at the side wall. If this is not the

case, correct as listed. (Fig. 11)

CAUTION: Adjustment range of screw (3) maximum

1 turn (risk of control cam breaking, 4)

²Retaining magnet is too far forward relative to

mating plate. Turn in adjustment screw (2) at top

and bottom hinge.

²Retaining magnet is too far back relative to mat-

ing plate. Turn out adjustment screw (2) at top and

bottom hinge.

²Retaining magnet is too deep relative to mating

plate. Turn in adjustment screw (2) at top hinge,

turn out adjustment screw (2) at bottom hinge.

²Retaining magnet is too high relative to mating

plate. Turn out adjustment screw (2) at top hinge,

turn in adjustment screw (2) at bottom hinge.

²Retaining magnet strikes too hard against mat-

ing plate. Turn in adjustment screw (1) at top and

bottom hinge.

²Retaining magnet does not make contact with

mating plate. Turn out adjustment screw (1) at top

and bottom hinge.

²Door projects at corner paneling when closed.

Turn out adjustment screw (3) at hinge.

²Door is too far recessed at corner paneling when

closed. Turn in adjustment screw (3) at hinge.

DOOR GLASS

REMOVAL

(1) Position an assistant on one side of the door to

receive the glass and weatherstrip seal.

(2) Start at an inside, upper corner. Separate the

seal from the window opening. Push the glass and

seal outward from the window opening. Remove the

glass and seal.

(3) Clean the window opening.

INSTALLATION

(1) Install the weatherstrip seal on the window

glass. Verify that the glass is seated in the groove

around the edge of the seal.

(2) Insert an installation cord in the weatherstrip

seal inner groove.

NOTE: Use mineral spirits as a lubricant to aid seal

installation in the window opening.

(3) Position the glass and seal in the window open-

ing.

(4) Pull the installation cord outward and force the

seal lip over the panel flange around the edge of the

opening.

(5) Seat the seal inner lip on the panel flange.

Press against the lip around the edge of the seal.

Fig. 11 REAR HINGE ADJUSTMENT

1 - ADJUSTMENT SCREW

2 - ADJUSTMENT SCREW

3 - ADJUSTMENT SCREW

4 - CONTROL ARM

VADOORS - REAR 23 - 31

DOOR (Continued)

Page 1070 of 1232

NOTE: Remove any mineral spirits with a clean

cloth after glass installation.

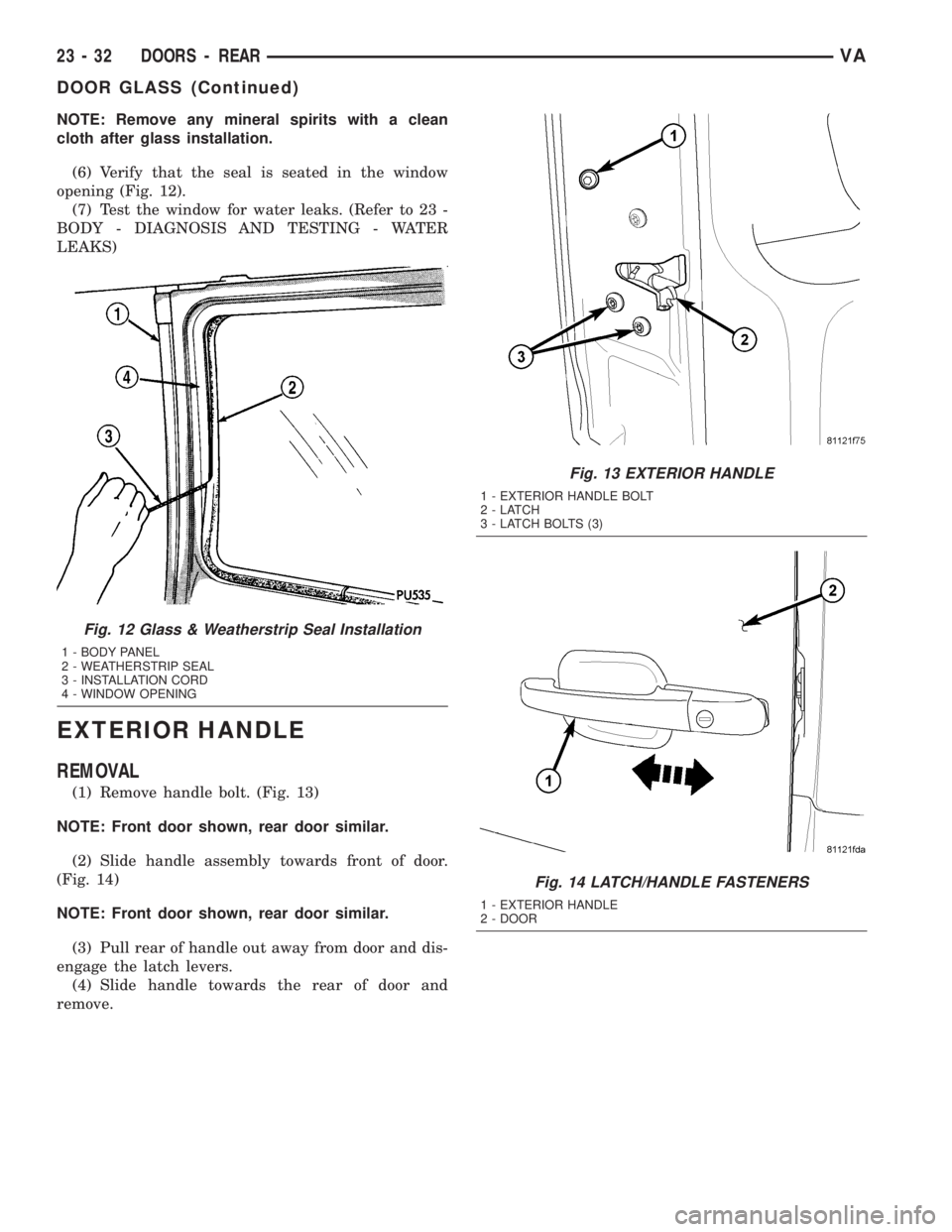

(6) Verify that the seal is seated in the window

opening (Fig. 12).

(7) Test the window for water leaks. (Refer to 23 -

BODY - DIAGNOSIS AND TESTING - WATER

LEAKS)

EXTERIOR HANDLE

REMOVAL

(1) Remove handle bolt. (Fig. 13)

NOTE: Front door shown, rear door similar.

(2) Slide handle assembly towards front of door.

(Fig. 14)

NOTE: Front door shown, rear door similar.

(3) Pull rear of handle out away from door and dis-

engage the latch levers.

(4) Slide handle towards the rear of door and

remove.

Fig. 12 Glass & Weatherstrip Seal Installation

1 - BODY PANEL

2 - WEATHERSTRIP SEAL

3 - INSTALLATION CORD

4 - WINDOW OPENING

Fig. 13 EXTERIOR HANDLE

1 - EXTERIOR HANDLE BOLT

2-LATCH

3 - LATCH BOLTS (3)

Fig. 14 LATCH/HANDLE FASTENERS

1 - EXTERIOR HANDLE

2 - DOOR

23 - 32 DOORS - REARVA

DOOR GLASS (Continued)