MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1201 of 1232

SYMPTOMS DIAGNOSIS TABLE

Symptom Possible Causes

Smell of diesel fuel. Check heater system integration in vehicle's fuel system. Check fuel

lines for leakage, kinks or obstructions. If OK, Inspect the inlet muffler,

drain as necessary. Re-test the unit and re-inspect. Inspect the exhaust

tube and heater unit for the presence of external fuel. If a volume is

observed on the unit or in the exhaust tube or after draining and testing.

Remove heater unit from vehicle and repair or replace components as

required.

Heater does not achieve full load

operation.Check heater operation with DRBIIITscan tool and replace components

as required.

Continuous white smoke from heater

exhaust during combustion operation.Check heater operation with DRBIIITscan tool and replace components

as required. White smoke is typical in extreme weather conditions.

Heater can not be switched off. Check heater operation with DRBIIITscan tool and replace components

as required.

Heater does not operate. Diagnosis cabin heater control module using the DRBIIITscan tool and

the procedures listed in Vehicle Performance under Cabin Heater

Diagnosis in Group 18.

Loss of coolant (Leakage) or heater

develops smoke during combustion

operation and exhaust has an

extremely sweet smell.Inspect coolant hoses for leakage, kinks or loose hose connection.

Inspect the exhaust tube assembly for continuous flow, if OK there is an

internal heater leak and unit should be inspected and components

should be replaced as required.

Loss of fuel (dripping). Check heater system integration in vehicles fuel system. Check fuel line

connection for leakage. If OK there is an internal leak and unit should

be inspected and replaced as required.

EXHAUST TUBE

REMOVAL

WARNING: THERE IS A POTENTIAL DANGER OF

SKIN BURNS AS THE HEATER AND ITS COMPO-

NENTS MAY BE VERY HOT. MAKE SURE THE

HEATER IS ALLOWED TO COOL DOWN BEFORE

ANY SERVICE WORK ON THE CABIN HEATER SYS-

TEM IS ATTEMPTED.

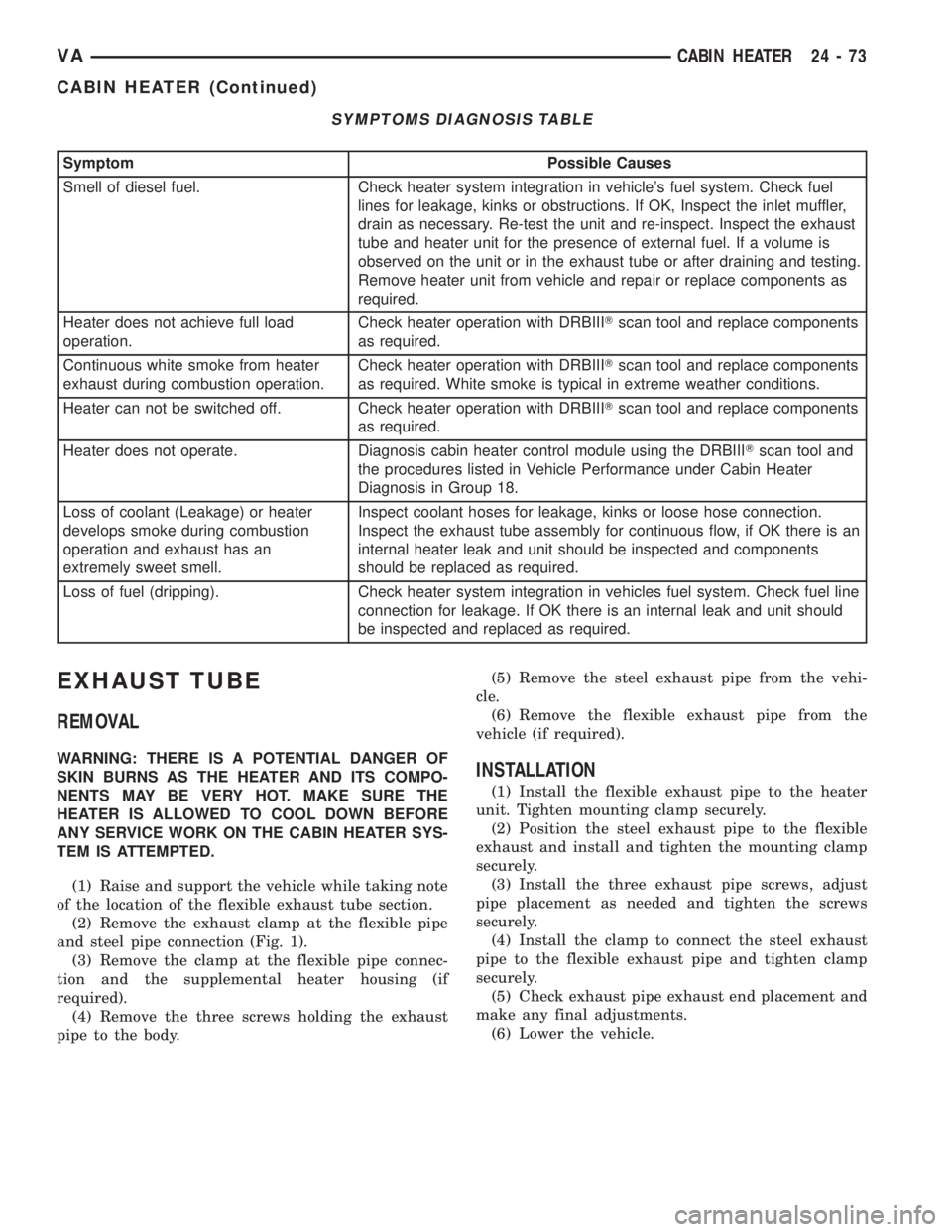

(1) Raise and support the vehicle while taking note

of the location of the flexible exhaust tube section.

(2) Remove the exhaust clamp at the flexible pipe

and steel pipe connection (Fig. 1).

(3) Remove the clamp at the flexible pipe connec-

tion and the supplemental heater housing (if

required).

(4) Remove the three screws holding the exhaust

pipe to the body.(5) Remove the steel exhaust pipe from the vehi-

cle.

(6) Remove the flexible exhaust pipe from the

vehicle (if required).INSTALLATION

(1) Install the flexible exhaust pipe to the heater

unit. Tighten mounting clamp securely.

(2) Position the steel exhaust pipe to the flexible

exhaust and install and tighten the mounting clamp

securely.

(3) Install the three exhaust pipe screws, adjust

pipe placement as needed and tighten the screws

securely.

(4) Install the clamp to connect the steel exhaust

pipe to the flexible exhaust pipe and tighten clamp

securely.

(5) Check exhaust pipe exhaust end placement and

make any final adjustments.

(6) Lower the vehicle.

VACABIN HEATER 24 - 73

CABIN HEATER (Continued)

Page 1202 of 1232

FUEL DOSING PUMP

DESCRIPTION

The dosing pump is a combined delivery, dosing

and shut-off system for the fuel supply to the supple-

mental heater from the vehicle fuel tank.

OPERATION

The dosing pump is an electrically operated pump

that receives its operation instructions from the sup-

plemental heater control module. The pump supplies

diesel fuel from the vehicle fuel tank to the supple-

mental heater.

REMOVAL

NOTE: The dosing pump is serviceable without

removing the component from the vehicle.

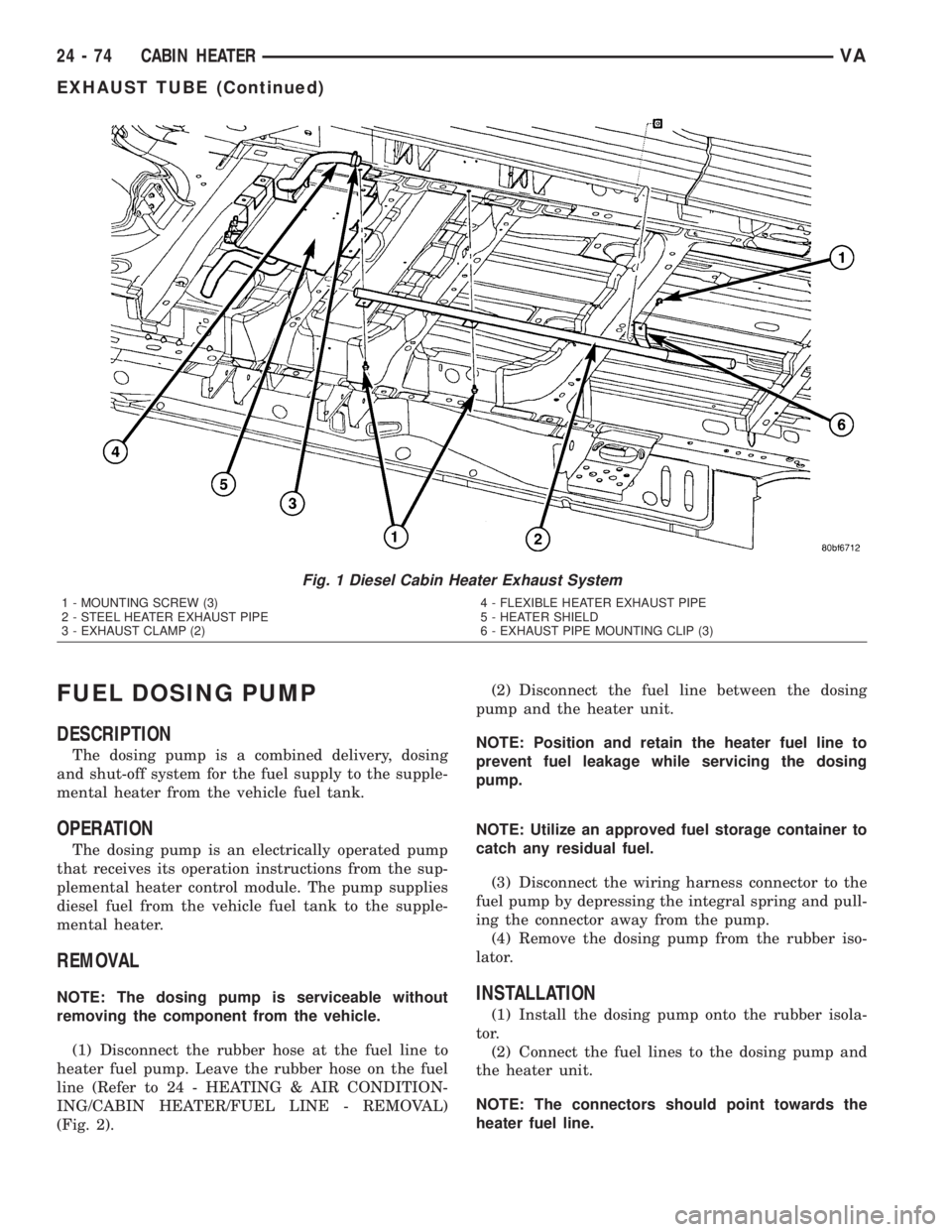

(1) Disconnect the rubber hose at the fuel line to

heater fuel pump. Leave the rubber hose on the fuel

line (Refer to 24 - HEATING & AIR CONDITION-

ING/CABIN HEATER/FUEL LINE - REMOVAL)

(Fig. 2).(2) Disconnect the fuel line between the dosing

pump and the heater unit.

NOTE: Position and retain the heater fuel line to

prevent fuel leakage while servicing the dosing

pump.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel.

(3) Disconnect the wiring harness connector to the

fuel pump by depressing the integral spring and pull-

ing the connector away from the pump.

(4) Remove the dosing pump from the rubber iso-

lator.INSTALLATION

(1) Install the dosing pump onto the rubber isola-

tor.

(2) Connect the fuel lines to the dosing pump and

the heater unit.

NOTE: The connectors should point towards the

heater fuel line.

Fig. 1 Diesel Cabin Heater Exhaust System

1 - MOUNTING SCREW (3)

2 - STEEL HEATER EXHAUST PIPE

3 - EXHAUST CLAMP (2)4 - FLEXIBLE HEATER EXHAUST PIPE

5 - HEATER SHIELD

6 - EXHAUST PIPE MOUNTING CLIP (3)

24 - 74 CABIN HEATERVA

EXHAUST TUBE (Continued)

Page 1203 of 1232

(3) Use aviation style clamps to attach the hose to

the fuel pump nipples (Refer to 24 - HEATING &

AIR CONDITIONING/CABIN HEATER/FUEL LINE

- INSTALLATION).

(4) Connect the wire harness connector to the fuel

pump by depressing the integral spring and pushing

the connector towards the dosing pump. Pull the con-

nector towards the heater to verify the installation.

(5) Verify function of the supplemental heater.

FUEL LINE

STANDARD PROCEDURE - CLEANING

(1) Remove the cabin heater fuel line (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/FUEL LINE - REMOVAL).

(2) With the cabin heater line removed from the

vehicle, place a shop cloth on the fuel tank end of the

fuel line to catch any residue, then apply a small

amount of air pressure to the other end of the fuel

line.

(3) Check to see if air pressure is coming from the

tank end of the line. If pressure is flowing unre-

stricted the line is clean.(4) If the line shows any signs of being restricted

after air pressure is applied, the fuel line should be

replaced.

(5) Install the cabin heater line (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/FUEL LINE - INSTALLATION).

(6) Verify function of the heater.

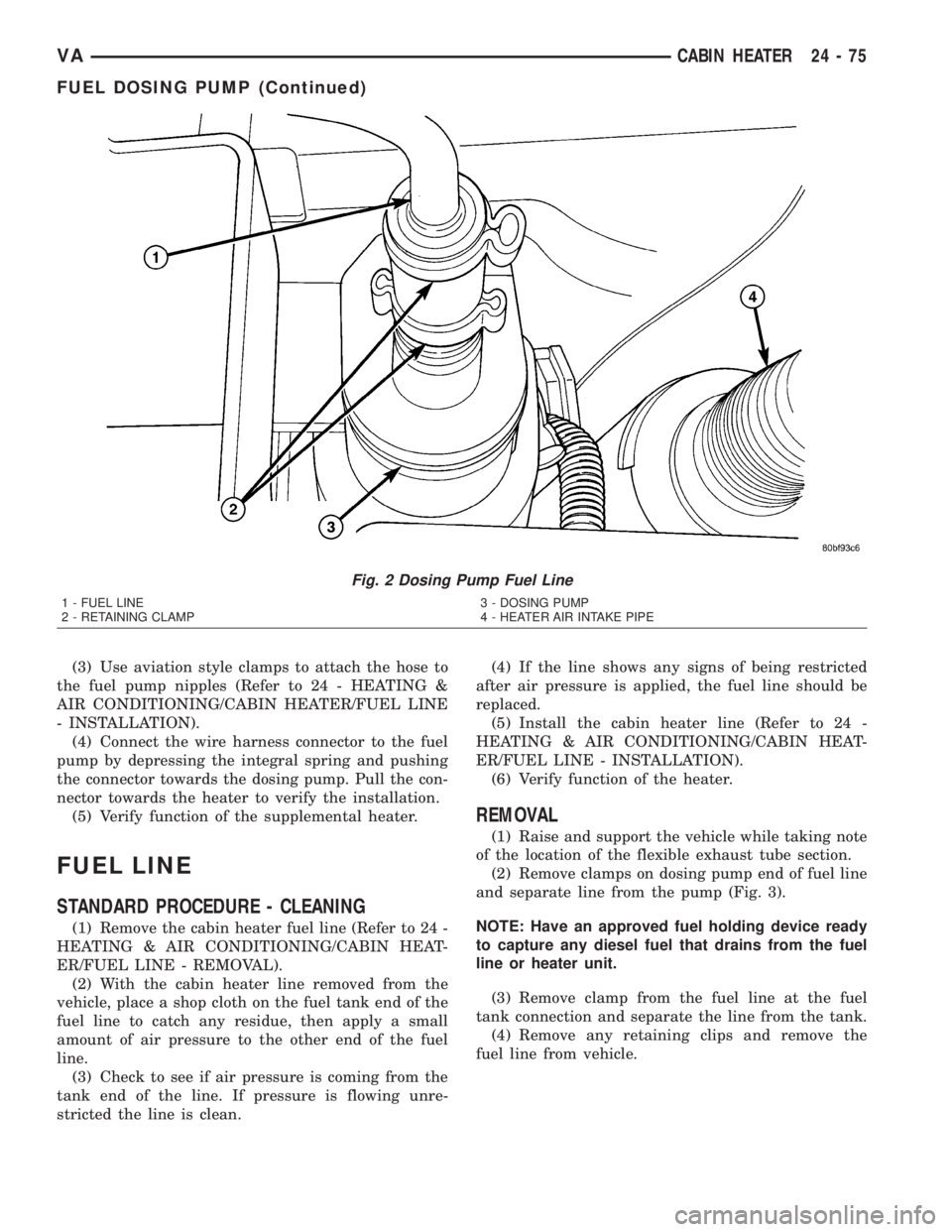

REMOVAL

(1) Raise and support the vehicle while taking note

of the location of the flexible exhaust tube section.

(2) Remove clamps on dosing pump end of fuel line

and separate line from the pump (Fig. 3).

NOTE: Have an approved fuel holding device ready

to capture any diesel fuel that drains from the fuel

line or heater unit.

(3) Remove clamp from the fuel line at the fuel

tank connection and separate the line from the tank.

(4) Remove any retaining clips and remove the

fuel line from vehicle.

Fig. 2 Dosing Pump Fuel Line

1 - FUEL LINE

2 - RETAINING CLAMP3 - DOSING PUMP

4 - HEATER AIR INTAKE PIPE

VACABIN HEATER 24 - 75

FUEL DOSING PUMP (Continued)

Page 1204 of 1232

INSTALLATION

WARNING: DO NOT OPERATE THE DCHA IN AN

ENCLOSED AREA SUCH AS A GARAGE THAT

DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA'S EXHAUST WHEN

OPERATING THE DCHA. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN PERSONAL

INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY.

WARNING: VERIFY THAT ALL DCHA FUEL LINES

ARE SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING THIS PRO-

CEDURE.

NOTE: Verify that there is more than 1/8 of a tank of

fuel in the vehicle's fuel tank before performing this

procedure. Add fuel, if necessary.(1) Install the heater fuel supply line into vehicle

and fuel line retainers.

(2) Install the fuel line connection at the fuel tank

and tighten the connection securely.

(3) Install the fuel line at the dosing pump and

tighten the connection securely.

(4) Lower the vehicle.

NOTE: Failure to prime the dosing pump after drain-

ing the DCHA fuel line will prevent DCHA heater

activation during the first attempt to start the

heater. This will also set a Diagnostic Trouble Code

(DCT) in the DCHA Control's memory. Do not per-

form the Dosing Pump Priming procedure if an

attempt was made to start the DCHA without prim-

ing the dosing pump first. This will put excess fuel

in the DCHA Heater Module and cause smoke to

emit from the DCHA exhaust pipe when heater acti-

vation occurs.

(5) Connect the DRBIIItscan tool to the Diagnos-

tic Link Connector.

(6) Turn the ignition to the ON position.

Fig. 3 Dosing Pump Fuel Line

1 - FUEL LINE

2 - RETAINING CLAMP3 - DOSING PUMP

4 - HEATER AIR INTAKE PIPE

24 - 76 CABIN HEATERVA

FUEL LINE (Continued)

Page 1205 of 1232

NOTE: Do not activate the Dosing Pump Prime

more than one time. This will put excess fuel in the

DCHA Heater Module an cause smoke to emit from

the DCHA exhaust pipe when heater activation

occurs.

NOTE: A clicking noise heard coming from the dos-

ing pump indicates that the pump is operational.

(7) With the DRBIIItscan tool in Cabin Heater,

select System Tests and Dosing Pump Prime. Allow

the dosing pump to run for the full 45 second cycle

time. When the 45 second cycle is complete, press

Page Back on the DRBIIItscan tool key pad to exit

the Dosing Pump Prime. The Dosing Pump Priming

procedure is now complete.

HEATER UNIT

REMOVAL

REMOVAL

WARNING: ALLOW THE SUPPLEMENTAL HEATER

TO COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR OR REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY.

WARNING: ALLOW THE EXHAUST SYSTEM TO

COOL BEFORE PERFORMING A COMPONENT

INSPECTION/REPAIR OR REPLACEMENT. FAILURE

TO FOLLOW THESE INSTRUCTION MAY RESULT IN

PERSONAL INJURY.

(1) Raise and support the vehicle. Take note of the

location of the flexible exhaust tube section.

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Carefully open one hose to the underbody tube

assembly and drain the remaining coolant. A salvage

hose is a good idea to control the residual coolant, as

flow will occur from both the heater and the hose and

tube assemblies.

(4) Remove the second hose from the underbody

hose and tube assembly.

(5) Loosen the hose and tube assembly from the

toe-board cross member at two locations.

(6) Disconnect the electrical connector from the

body harness near the toe-board cross member and

rail.(7) Remove the wiring harness from the toe-board

cross member (Refer to 24 - HEATING & AIR CON-

DITIONING/CABIN HEATER/HEATER UNIT -

REMOVAL).

(8) Open the fuel filler cap. Disconnect the rubber

fuel hose between the body tube assembly and the

fuel pump nipple at the body tube joint. A minimal

amount of fuel may flow from the open port.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel.

(9) Loosen the two fasteners at the rail. Take care

to notice that the exhaust tube bracket tab is on top

of the heater bracket and that there are two spacer

washers installed between the rubber grommets.

(10) Remove the heater exhaust tube flex section

from the exhaust tube by loosening the bolt of the

clamp assembly. Remove the hose from the exhaust

tube. Removal of the rail tube assembly may aid in

this service operation (Refer to 24 - HEATING & AIR

CONDITIONING/CABIN HEATER/EXHAUST TUBE

- REMOVAL).

(11) Remove seat hex nut at the heater mounting

flange to cross member.

(12) Loosen the remaining fasteners which mount

the exhaust tube assembly to the vehicle.

(a) Install a suitable cabin heater support device

under the cabin heater and secure the cabin heater

to the device.

(13) Loosen the remaining three fasteners to the

cross members.

(14) Remove the loosened fasteners that support

the heater while supporting the weight of the heater.

(15) Swing the unit mounting bracket from

between the exhaust bracket and rail mounting loca-

tion. Drain any residual coolant from the heater unit.

(16) Lower the cabin heater and remove from the

supporting device and place on a suitable work area.

REMOVAL

(1) Raise and support the vehicle while taking note

of the location of the flexible exhaust tube section.

(2) Unplug the wire harness connector from vehi-

cle wiring harness to cabin heater harness.

(3) Unplug the wire harness connector from cabin

heater harness to dosing pump connector.

(4) Unplug the two wire harness connectors from

cabin heater harness to cabin heater controller con-

nectors.

(5) Remove two wiring harness connectors from

underbody.

(6) Remove two wiring harness connectors from

cabin heater shield.

(7) Carefully route the cabin heater harness to the

left side between the cabin heater unit and the cabin

heater shield.

VACABIN HEATER 24 - 77

FUEL LINE (Continued)

Page 1206 of 1232

INSTALLATION

INSTALLATION

(1) Install the unit mounting bracket between the

exhaust bracket and the rail mounting location.

(2) Install the fasteners that support the heater

while supporting the weight of the heater.

(3) Install the three fasteners to the cross mem-

bers. Tighten the M6 fasteners to 7 N´m (62 in. lbs.).

(4) Position the two spacer washers between the

body and the rubber grommets for the two mounting

points on the rail.

(5) Tighten the remaining M6 fasteners to 7 N´m

(62 in. lbs.) and the M8 fasteners to 23 N´m (17 ft.

lbs.) which mount the exhaust tube assembly to the

vehicle.

(6) Install the seat hex nut at the heater mounting

flange to the cross members. Tighten the nut to 60

N´m (44 ft. lbs.)

(7) Install the heater exhaust tube flex section to

the exhaust tube by tightening the M6 bolt of the

clamp assembly. Install the hose to the exhaust tube.

(8) Tighten the two M8 fasteners at the rail to 23

N´m (17 ft. lbs.). Taking care so that the exhaust

tube bracket tab is on the top of the heater bracket.

(9) Install the wiring harness (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CABIN HEATER/

HEATER UNIT - INSTALLATION).

(10) Tighten the hose and tube assembly to the

toe-board cross member at two locations.

(11) Install the second hose to the underbody hose

and tube assembly.

(12) Connect the rubber fuel hose between the

body tube assembly and the fuel pump nipple at the

body tube joint. Close the fuel fill cap.

(13) Remove the heater unit support device from

under the vehicle.

(14) Lower the vehicle.

(15) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Verify function of the cabin heater.

INSTALLATION

(1) Carefully route the cabin heater harness from

the left side of the cabin heater between the cabin

heater unit and the cabin heater shield.(2) Install the two wiring harness retaining con-

nectors to the cabin heater shield.

(3) Route the wiring harness along the underside

of the vehicle and install the two wiring harness

retaining connectors.

(4) Plug the two connectors from the cabin heater

harness to the cabin heater controller.

(5) Plug the connector to the cabin heater harness

to the dosing pump connector.

(6) Plug the connector from the vehicle wiring har-

ness to the cabin heater harness.

(7) Lower the vehicle.

(8) Verify function of the cabin heater.

INLET HOSE

REMOVAL

NOTE: Heater air intake tube is part of an assembly

that includes the heater cooling intake and return

pipes. If heater air intake tube requires removal or

replacement the entire assembly will require remov-

al/replacement.

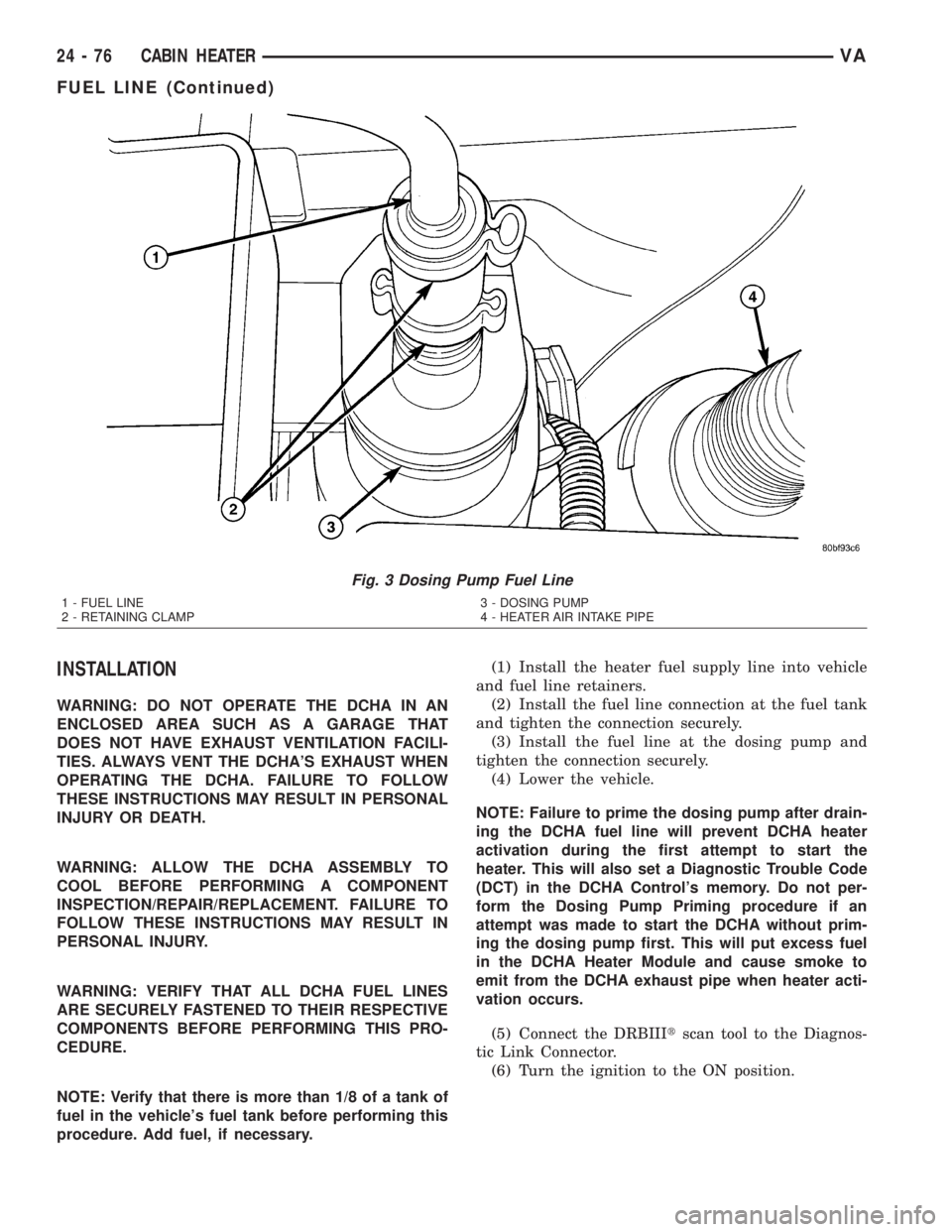

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(2) Remove clamps from the heater tubes at the

lower heater port and the lower EGR connector

which are located under the hood.

(3) Remove the retaining clamp at the heater air

intake muffler connection (Refer to 24 - HEATING &

AIR CONDITIONING/CABIN HEATER/INLET

MUFFLER - REMOVAL).

(4) Remove the clamp at the flexible tube to steel

tube connection (Fig. 4).

(5) Remove the two retaining screws and remove

pipe assembly (Fig. 5).

INSTALLATION

(1) Install the air intake pipe assembly and install

the two retaining screws. Tighten the screws to 7

N´m (62 in. lbs.).

(2) Attach the steel tube to the flexible tube and

position and then tighten the retaining clamp

securely.

(3) Install the flexible tube to the heater air intake

muffler and install and tighten the retaining clamp

securely.

24 - 78 CABIN HEATERVA

HEATER UNIT (Continued)

Page 1207 of 1232

(4) Install the heater tubes to the lower heater

connection and the lower EGR cooler connection and

tighten the retaining clamps.(5) Lower the vehicle.

(6) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(7) Verify function of the heater unit.

Fig. 4 Flexible Air Intake Line

1 - HEATER UNIT AND SPLASH SHIELD

2 - DOSING PUMP

3 - DOSING PUMP FUEL LINE

4 - FLEXIBLE INTAKE LINE

5 - CLAMP

6 - STEEL INTAKE PIPE

Fig. 5 Air Intake And Heater Pipe Assembly

1 - INTAKE TUBE AIR INTAKE

2 - INTAKE PIPE

3 - RETAINING SCREWS

4 - INTAKE HEATER LINE

5 - RETURN HEATER LINE

VACABIN HEATER 24 - 79

INLET HOSE (Continued)

Page 1208 of 1232

Page 1209 of 1232

EMISSIONS CONTROL

EXHAUST GAS RECIRCULATION

TABLE OF CONTENTS

page page

VA LV E

DESCRIPTION..........................1

OPERATION............................1REMOVAL.............................2

INSTALLATION..........................2

VA LV E

DESCRIPTION

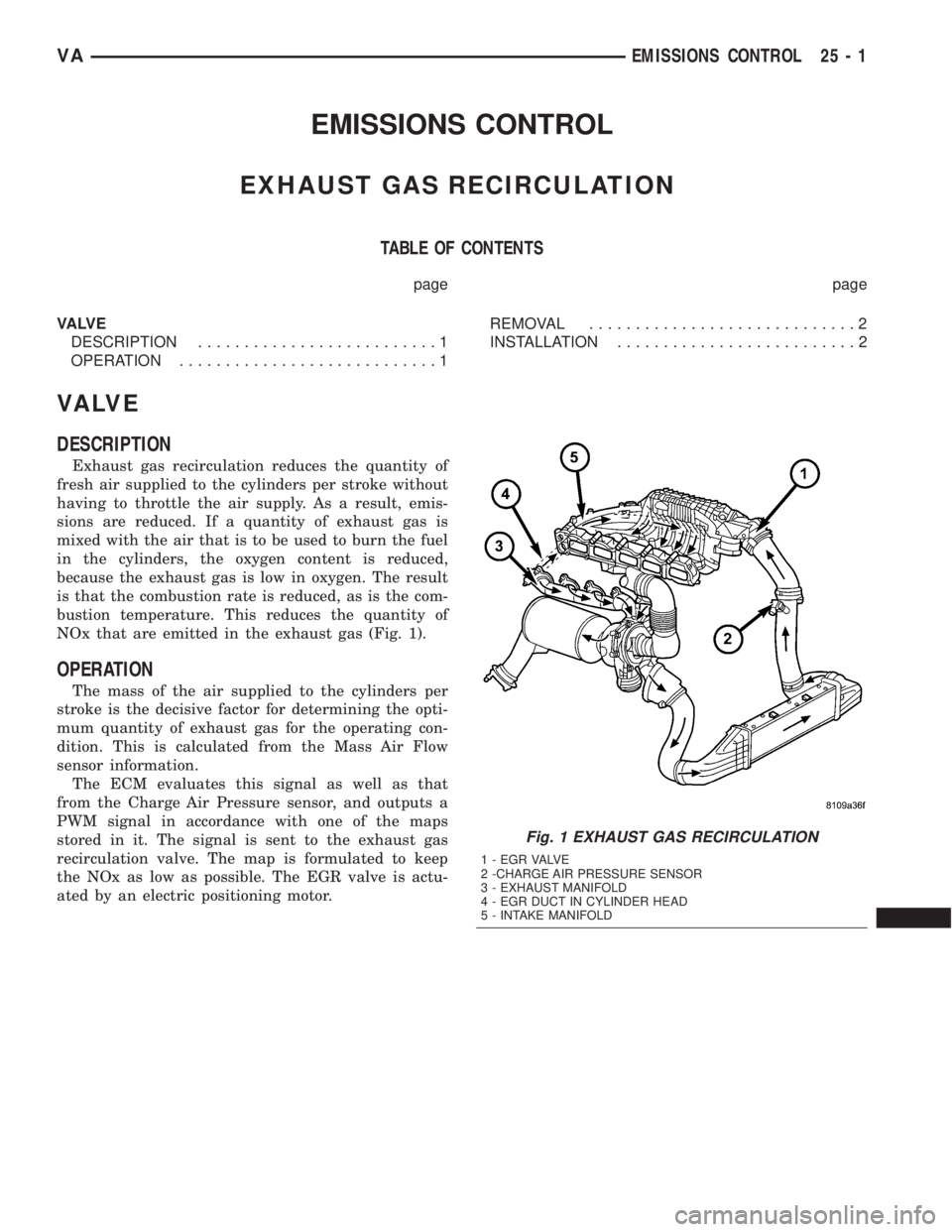

Exhaust gas recirculation reduces the quantity of

fresh air supplied to the cylinders per stroke without

having to throttle the air supply. As a result, emis-

sions are reduced. If a quantity of exhaust gas is

mixed with the air that is to be used to burn the fuel

in the cylinders, the oxygen content is reduced,

because the exhaust gas is low in oxygen. The result

is that the combustion rate is reduced, as is the com-

bustion temperature. This reduces the quantity of

NOx that are emitted in the exhaust gas (Fig. 1).

OPERATION

The mass of the air supplied to the cylinders per

stroke is the decisive factor for determining the opti-

mum quantity of exhaust gas for the operating con-

dition. This is calculated from the Mass Air Flow

sensor information.

The ECM evaluates this signal as well as that

from the Charge Air Pressure sensor, and outputs a

PWM signal in accordance with one of the maps

stored in it. The signal is sent to the exhaust gas

recirculation valve. The map is formulated to keep

the NOx as low as possible. The EGR valve is actu-

ated by an electric positioning motor.

Fig. 1 EXHAUST GAS RECIRCULATION

1 - E G R VA LV E

2 -CHARGE AIR PRESSURE SENSOR

3 - EXHAUST MANIFOLD

4 - EGR DUCT IN CYLINDER HEAD

5 - INTAKE MANIFOLD

VAEMISSIONS CONTROL 25 - 1

Page 1210 of 1232

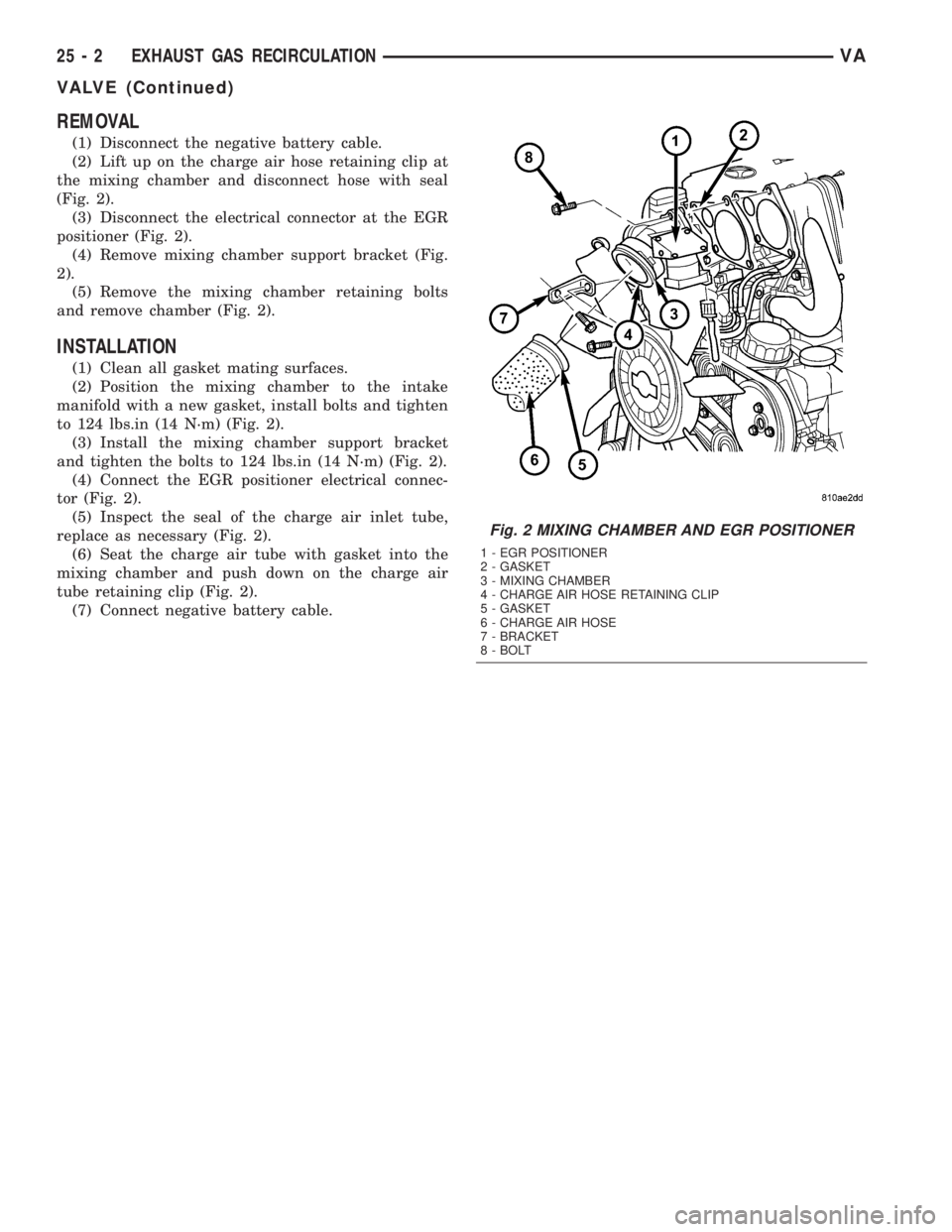

REMOVAL

(1) Disconnect the negative battery cable.

(2) Lift up on the charge air hose retaining clip at

the mixing chamber and disconnect hose with seal

(Fig. 2).

(3) Disconnect the electrical connector at the EGR

positioner (Fig. 2).

(4) Remove mixing chamber support bracket (Fig.

2).

(5) Remove the mixing chamber retaining bolts

and remove chamber (Fig. 2).

INSTALLATION

(1) Clean all gasket mating surfaces.

(2) Position the mixing chamber to the intake

manifold with a new gasket, install bolts and tighten

to 124 lbs.in (14 N´m) (Fig. 2).

(3) Install the mixing chamber support bracket

and tighten the bolts to 124 lbs.in (14 N´m) (Fig. 2).

(4) Connect the EGR positioner electrical connec-

tor (Fig. 2).

(5) Inspect the seal of the charge air inlet tube,

replace as necessary (Fig. 2).

(6) Seat the charge air tube with gasket into the

mixing chamber and push down on the charge air

tube retaining clip (Fig. 2).

(7) Connect negative battery cable.

Fig. 2 MIXING CHAMBER AND EGR POSITIONER

1 - EGR POSITIONER

2 - GASKET

3 - MIXING CHAMBER

4 - CHARGE AIR HOSE RETAINING CLIP

5 - GASKET

6 - CHARGE AIR HOSE

7 - BRACKET

8 - BOLT

25 - 2 EXHAUST GAS RECIRCULATIONVA

VALVE (Continued)