lock MERCEDES-BENZ SPRINTER 2005 Service User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 27 of 1232

NOTE: In order to remove tension from the strut,

Raise the lower control arm approximately 10 mm

with a jack.

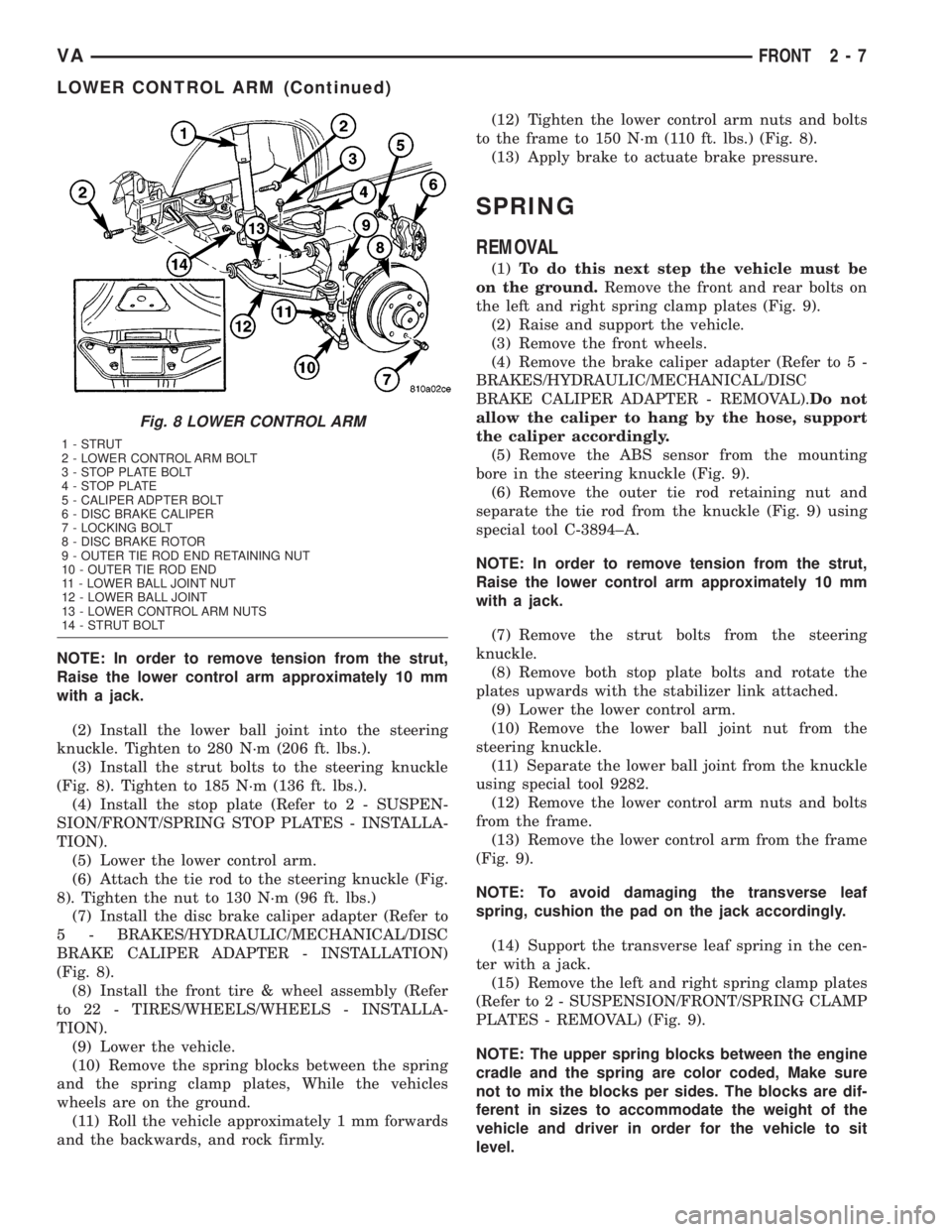

(2) Install the lower ball joint into the steering

knuckle. Tighten to 280 N´m (206 ft. lbs.).

(3) Install the strut bolts to the steering knuckle

(Fig. 8). Tighten to 185 N´m (136 ft. lbs.).

(4) Install the stop plate (Refer to 2 - SUSPEN-

SION/FRONT/SPRING STOP PLATES - INSTALLA-

TION).

(5) Lower the lower control arm.

(6) Attach the tie rod to the steering knuckle (Fig.

8). Tighten the nut to 130 N´m (96 ft. lbs.)

(7) Install the disc brake caliper adapter (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION)

(Fig. 8).

(8) Install the front tire & wheel assembly (Refer

to 22 - TIRES/WHEELS/WHEELS - INSTALLA-

TION).

(9) Lower the vehicle.

(10) Remove the spring blocks between the spring

and the spring clamp plates, While the vehicles

wheels are on the ground.

(11) Roll the vehicle approximately 1 mm forwards

and the backwards, and rock firmly.(12) Tighten the lower control arm nuts and bolts

to the frame to 150 N´m (110 ft. lbs.) (Fig. 8).

(13) Apply brake to actuate brake pressure.

SPRING

REMOVAL

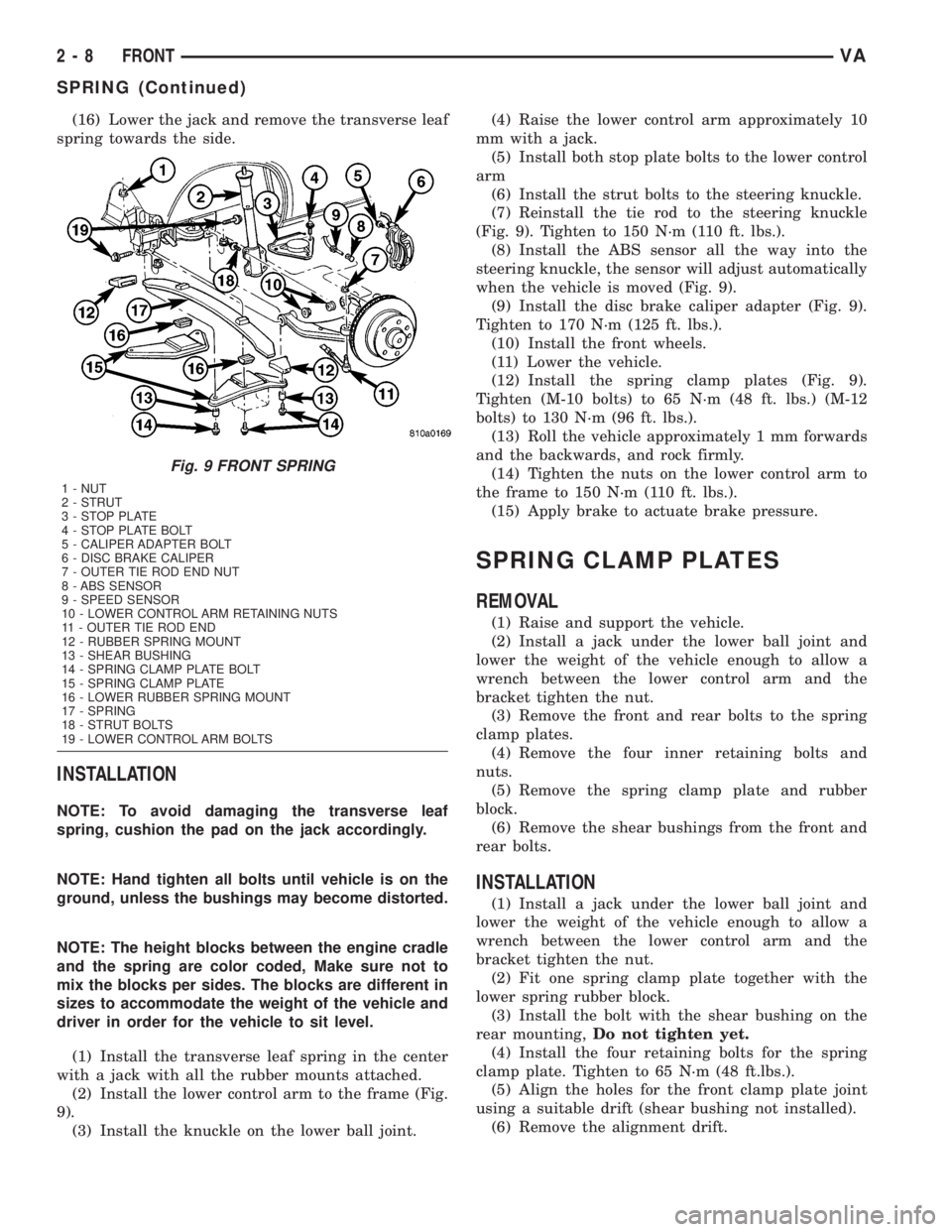

(1)To do this next step the vehicle must be

on the ground.Remove the front and rear bolts on

the left and right spring clamp plates (Fig. 9).

(2) Raise and support the vehicle.

(3) Remove the front wheels.

(4) Remove the brake caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).Do not

allow the caliper to hang by the hose, support

the caliper accordingly.

(5) Remove the ABS sensor from the mounting

bore in the steering knuckle (Fig. 9).

(6) Remove the outer tie rod retaining nut and

separate the tie rod from the knuckle (Fig. 9) using

special tool C-3894±A.

NOTE: In order to remove tension from the strut,

Raise the lower control arm approximately 10 mm

with a jack.

(7) Remove the strut bolts from the steering

knuckle.

(8) Remove both stop plate bolts and rotate the

plates upwards with the stabilizer link attached.

(9) Lower the lower control arm.

(10) Remove the lower ball joint nut from the

steering knuckle.

(11) Separate the lower ball joint from the knuckle

using special tool 9282.

(12) Remove the lower control arm nuts and bolts

from the frame.

(13) Remove the lower control arm from the frame

(Fig. 9).

NOTE: To avoid damaging the transverse leaf

spring, cushion the pad on the jack accordingly.

(14) Support the transverse leaf spring in the cen-

ter with a jack.

(15) Remove the left and right spring clamp plates

(Refer to 2 - SUSPENSION/FRONT/SPRING CLAMP

PLATES - REMOVAL) (Fig. 9).

NOTE: The upper spring blocks between the engine

cradle and the spring are color coded, Make sure

not to mix the blocks per sides. The blocks are dif-

ferent in sizes to accommodate the weight of the

vehicle and driver in order for the vehicle to sit

level.

Fig. 8 LOWER CONTROL ARM

1 - STRUT

2 - LOWER CONTROL ARM BOLT

3 - STOP PLATE BOLT

4 - STOP PLATE

5 - CALIPER ADPTER BOLT

6 - DISC BRAKE CALIPER

7 - LOCKING BOLT

8 - DISC BRAKE ROTOR

9 - OUTER TIE ROD END RETAINING NUT

10 - OUTER TIE ROD END

11 - LOWER BALL JOINT NUT

12 - LOWER BALL JOINT

13 - LOWER CONTROL ARM NUTS

14 - STRUT BOLT

VAFRONT 2 - 7

LOWER CONTROL ARM (Continued)

Page 28 of 1232

(16) Lower the jack and remove the transverse leaf

spring towards the side.

INSTALLATION

NOTE: To avoid damaging the transverse leaf

spring, cushion the pad on the jack accordingly.

NOTE: Hand tighten all bolts until vehicle is on the

ground, unless the bushings may become distorted.

NOTE: The height blocks between the engine cradle

and the spring are color coded, Make sure not to

mix the blocks per sides. The blocks are different in

sizes to accommodate the weight of the vehicle and

driver in order for the vehicle to sit level.

(1) Install the transverse leaf spring in the center

with a jack with all the rubber mounts attached.

(2) Install the lower control arm to the frame (Fig.

9).

(3) Install the knuckle on the lower ball joint.(4) Raise the lower control arm approximately 10

mm with a jack.

(5) Install both stop plate bolts to the lower control

arm

(6) Install the strut bolts to the steering knuckle.

(7) Reinstall the tie rod to the steering knuckle

(Fig. 9). Tighten to 150 N´m (110 ft. lbs.).

(8) Install the ABS sensor all the way into the

steering knuckle, the sensor will adjust automatically

when the vehicle is moved (Fig. 9).

(9) Install the disc brake caliper adapter (Fig. 9).

Tighten to 170 N´m (125 ft. lbs.).

(10) Install the front wheels.

(11) Lower the vehicle.

(12) Install the spring clamp plates (Fig. 9).

Tighten (M-10 bolts) to 65 N´m (48 ft. lbs.) (M-12

bolts) to 130 N´m (96 ft. lbs.).

(13) Roll the vehicle approximately 1 mm forwards

and the backwards, and rock firmly.

(14) Tighten the nuts on the lower control arm to

the frame to 150 N´m (110 ft. lbs.).

(15) Apply brake to actuate brake pressure.

SPRING CLAMP PLATES

REMOVAL

(1) Raise and support the vehicle.

(2) Install a jack under the lower ball joint and

lower the weight of the vehicle enough to allow a

wrench between the lower control arm and the

bracket tighten the nut.

(3) Remove the front and rear bolts to the spring

clamp plates.

(4) Remove the four inner retaining bolts and

nuts.

(5) Remove the spring clamp plate and rubber

block.

(6) Remove the shear bushings from the front and

rear bolts.

INSTALLATION

(1) Install a jack under the lower ball joint and

lower the weight of the vehicle enough to allow a

wrench between the lower control arm and the

bracket tighten the nut.

(2) Fit one spring clamp plate together with the

lower spring rubber block.

(3) Install the bolt with the shear bushing on the

rear mounting,Do not tighten yet.

(4) Install the four retaining bolts for the spring

clamp plate. Tighten to 65 N´m (48 ft.lbs.).

(5) Align the holes for the front clamp plate joint

using a suitable drift (shear bushing not installed).

(6) Remove the alignment drift.

Fig. 9 FRONT SPRING

1 - NUT

2 - STRUT

3 - STOP PLATE

4 - STOP PLATE BOLT

5 - CALIPER ADAPTER BOLT

6 - DISC BRAKE CALIPER

7 - OUTER TIE ROD END NUT

8 - ABS SENSOR

9 - SPEED SENSOR

10 - LOWER CONTROL ARM RETAINING NUTS

11 - OUTER TIE ROD END

12 - RUBBER SPRING MOUNT

13 - SHEAR BUSHING

14 - SPRING CLAMP PLATE BOLT

15 - SPRING CLAMP PLATE

16 - LOWER RUBBER SPRING MOUNT

17 - SPRING

18 - STRUT BOLTS

19 - LOWER CONTROL ARM BOLTS

2 - 8 FRONTVA

SPRING (Continued)

Page 30 of 1232

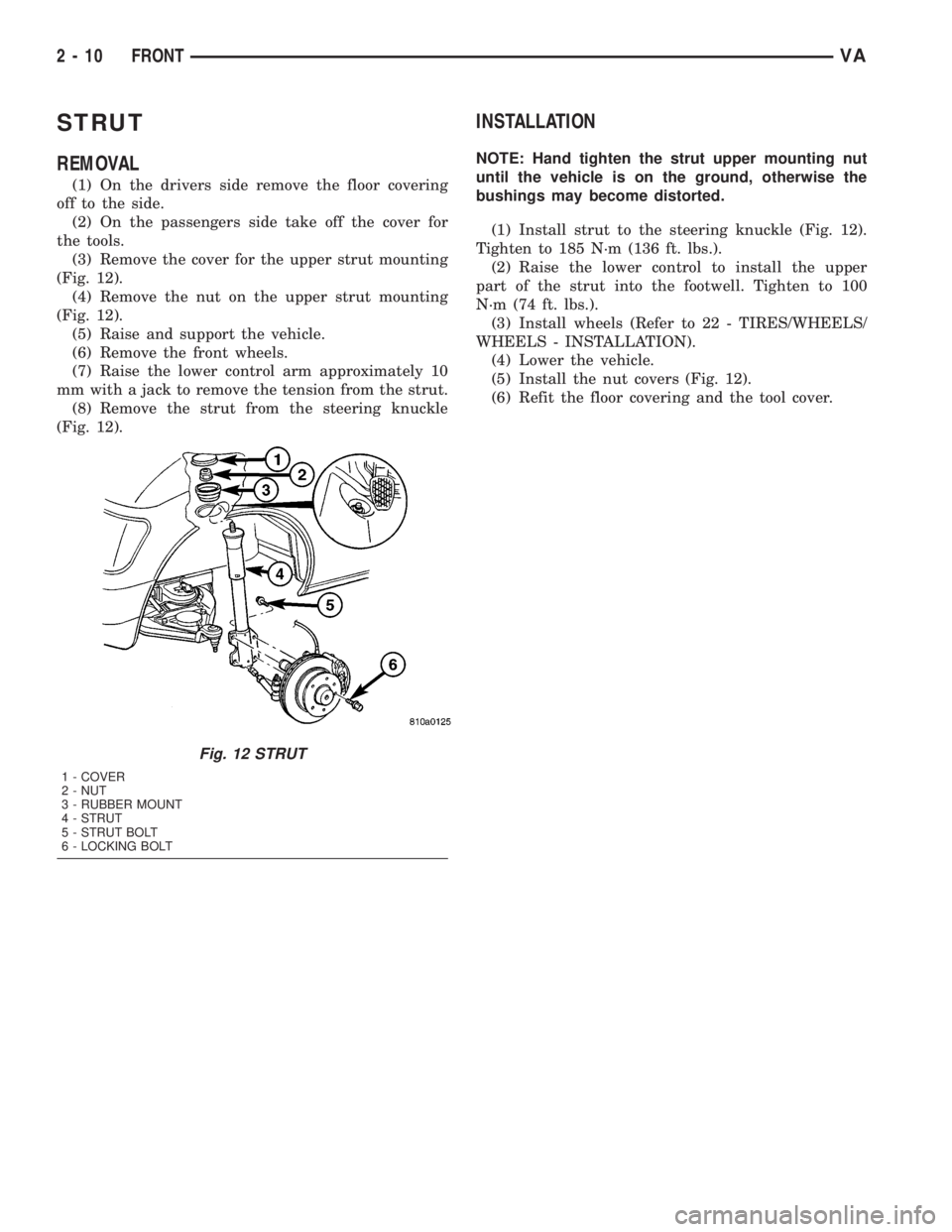

STRUT

REMOVAL

(1) On the drivers side remove the floor covering

off to the side.

(2) On the passengers side take off the cover for

the tools.

(3) Remove the cover for the upper strut mounting

(Fig. 12).

(4) Remove the nut on the upper strut mounting

(Fig. 12).

(5) Raise and support the vehicle.

(6) Remove the front wheels.

(7) Raise the lower control arm approximately 10

mm with a jack to remove the tension from the strut.

(8) Remove the strut from the steering knuckle

(Fig. 12).

INSTALLATION

NOTE: Hand tighten the strut upper mounting nut

until the vehicle is on the ground, otherwise the

bushings may become distorted.

(1) Install strut to the steering knuckle (Fig. 12).

Tighten to 185 N´m (136 ft. lbs.).

(2) Raise the lower control to install the upper

part of the strut into the footwell. Tighten to 100

N´m (74 ft. lbs.).

(3) Install wheels (Refer to 22 - TIRES/WHEELS/

WHEELS - INSTALLATION).

(4) Lower the vehicle.

(5) Install the nut covers (Fig. 12).

(6) Refit the floor covering and the tool cover.

Fig. 12 STRUT

1 - COVER

2 - NUT

3 - RUBBER MOUNT

4 - STRUT

5 - STRUT BOLT

6 - LOCKING BOLT

2 - 10 FRONTVA

Page 55 of 1232

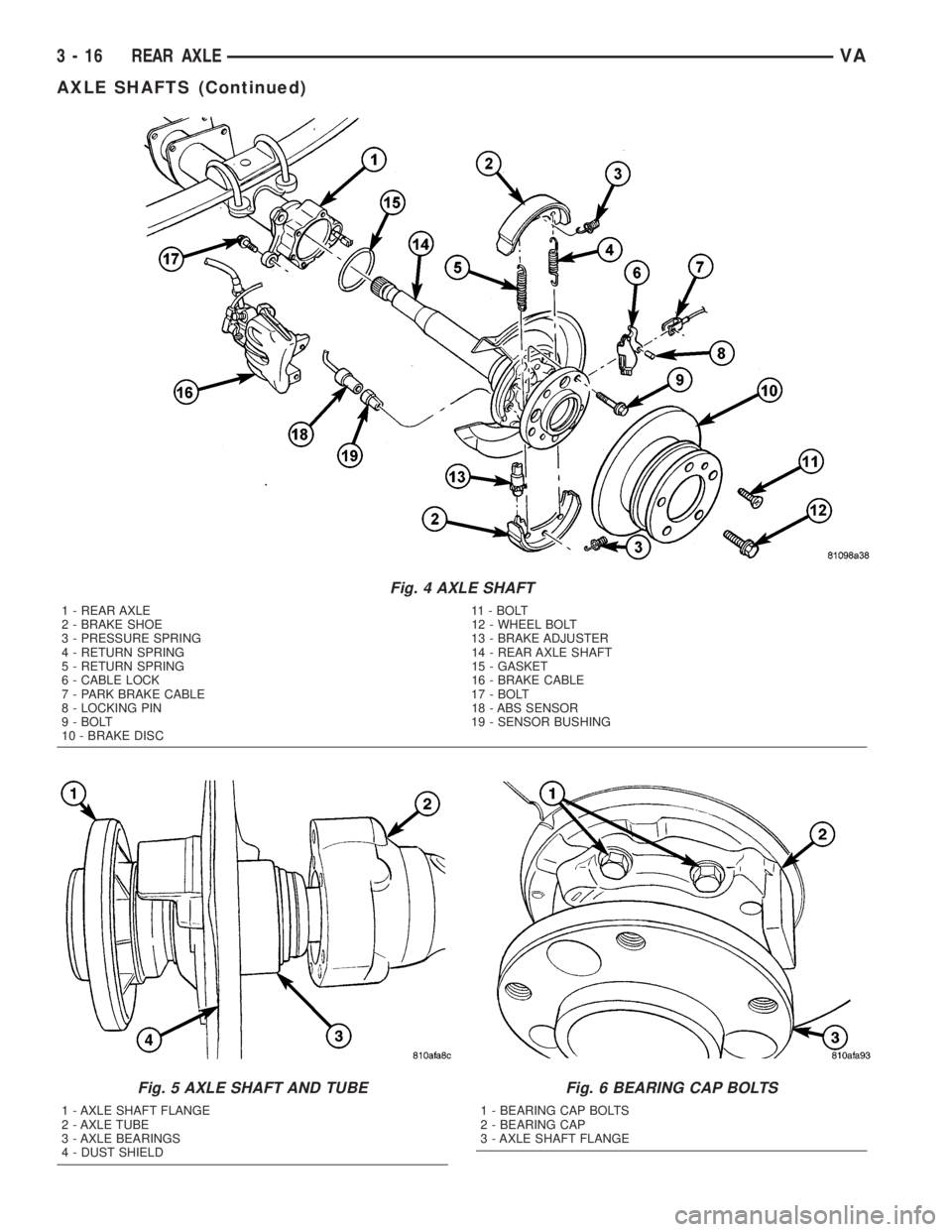

AXLE SHAFTS

REMOVAL

(1) Remove wheels.

(2) Detach front brake cable.

(3) Pull ABS sensor together with clamp bushing

out of bearing cap (Fig. 4).

(4) Remove brake disk at rear axle. Attach brake

caliper with lines connected in wheel house.

(5) Remove brake shoes of parking brake.

(6) Remove brake control cable lock.

(7) Remove bearing cap bolts and pull axle shaft

out of axle tube (Fig. 4).

(8) Remove seal/gasket.

INSTALLATION

(1) Install sealing ring.

(2) Install rear axle shaft in the axle tube (Fig. 5).

(3) Installnewbearing cap bolts and tighten to 72

N´m (53 ft. lbs.) (Fig. 6).

NOTE: Tighten bolts diagonally across.

(4) Install brake control cable lock.

(5) Install parking brake shoes.

(6) Install brake disk and calipers.

(7) Coat clamping bush with acid-free grease.

Insert ABS sensor with clamping bush fully into the

mounting hole.

(8) Install front brake cable.

(9) Operate brake pedal several times until brake

pads contact brake discs (brake pressure built up).

(10) Install wheels.

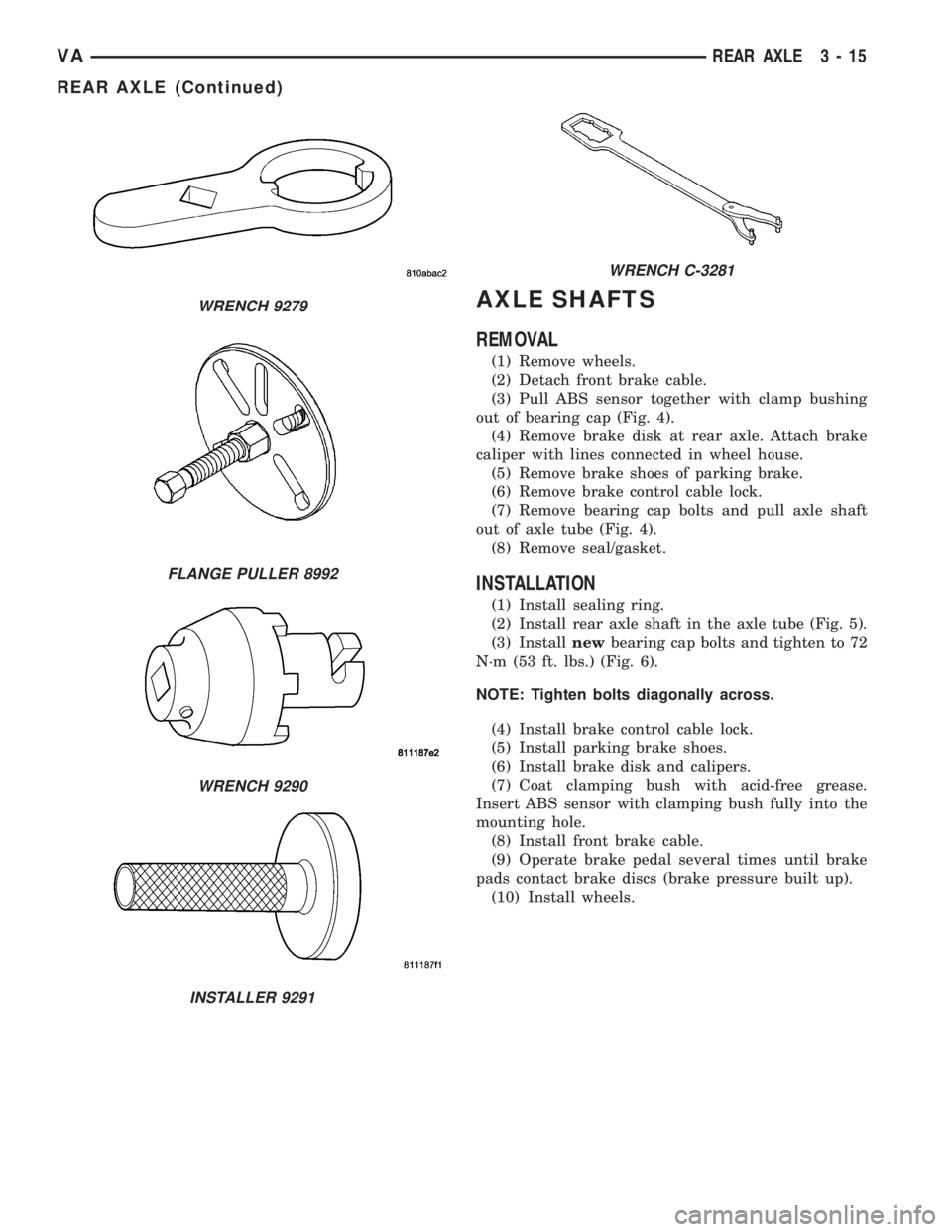

WRENCH 9279

FLANGE PULLER 8992

WRENCH 9290

INSTALLER 9291

WRENCH C-3281

VAREAR AXLE 3 - 15

REAR AXLE (Continued)

Page 56 of 1232

Fig. 4 AXLE SHAFT

1 - REAR AXLE 11 - BOLT

2 - BRAKE SHOE 12 - WHEEL BOLT

3 - PRESSURE SPRING 13 - BRAKE ADJUSTER

4 - RETURN SPRING 14 - REAR AXLE SHAFT

5 - RETURN SPRING 15 - GASKET

6 - CABLE LOCK 16 - BRAKE CABLE

7 - PARK BRAKE CABLE 17 - BOLT

8 - LOCKING PIN 18 - ABS SENSOR

9 - BOLT 19 - SENSOR BUSHING

10 - BRAKE DISC

Fig. 5 AXLE SHAFT AND TUBE

1 - AXLE SHAFT FLANGE

2 - AXLE TUBE

3 - AXLE BEARINGS

4 - DUST SHIELD

Fig. 6 BEARING CAP BOLTS

1 - BEARING CAP BOLTS

2 - BEARING CAP

3 - AXLE SHAFT FLANGE

3 - 16 REAR AXLEVA

AXLE SHAFTS (Continued)

Page 57 of 1232

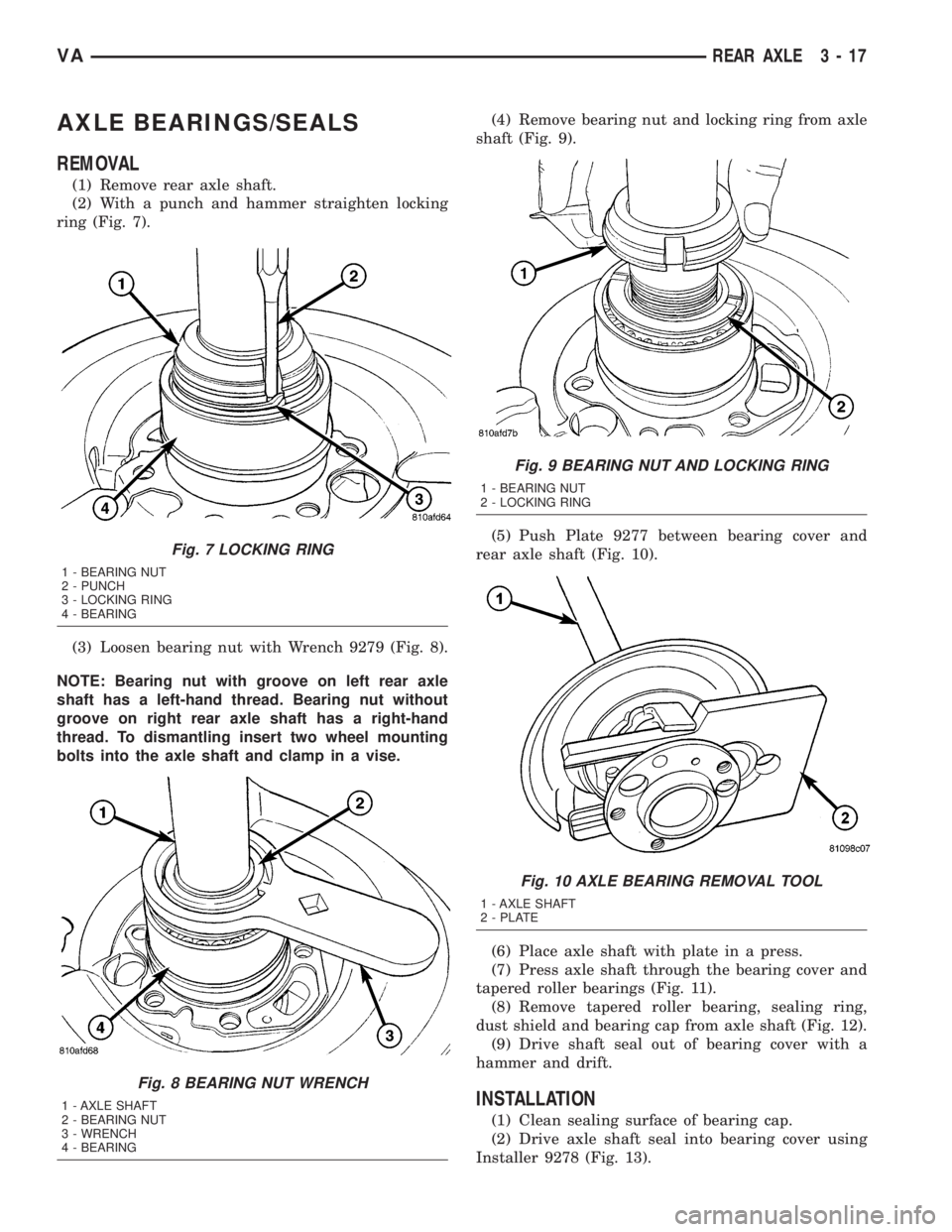

AXLE BEARINGS/SEALS

REMOVAL

(1) Remove rear axle shaft.

(2) With a punch and hammer straighten locking

ring (Fig. 7).

(3) Loosen bearing nut with Wrench 9279 (Fig. 8).

NOTE: Bearing nut with groove on left rear axle

shaft has a left-hand thread. Bearing nut without

groove on right rear axle shaft has a right-hand

thread. To dismantling insert two wheel mounting

bolts into the axle shaft and clamp in a vise.(4) Remove bearing nut and locking ring from axle

shaft (Fig. 9).

(5) Push Plate 9277 between bearing cover and

rear axle shaft (Fig. 10).

(6) Place axle shaft with plate in a press.

(7) Press axle shaft through the bearing cover and

tapered roller bearings (Fig. 11).

(8) Remove tapered roller bearing, sealing ring,

dust shield and bearing cap from axle shaft (Fig. 12).

(9) Drive shaft seal out of bearing cover with a

hammer and drift.

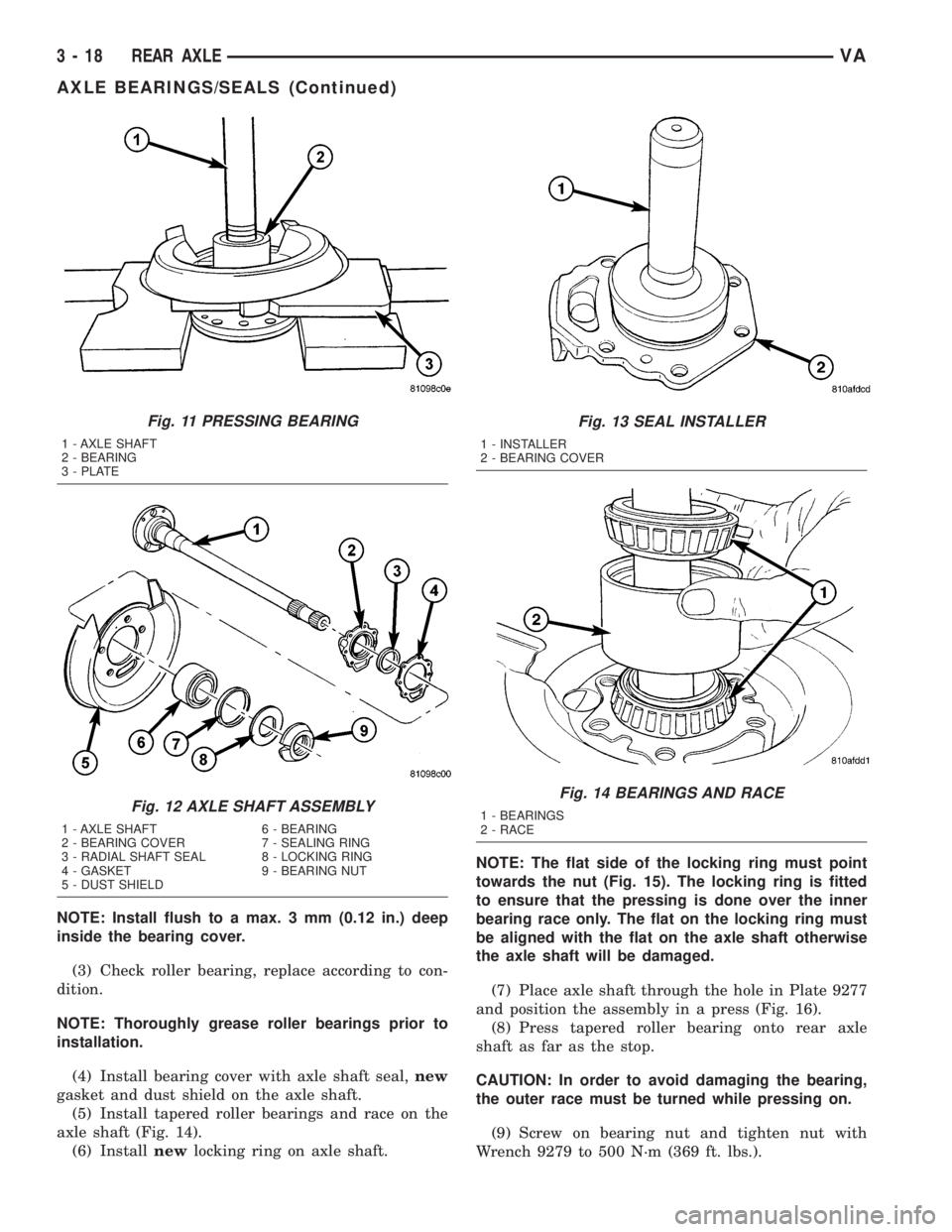

INSTALLATION

(1) Clean sealing surface of bearing cap.

(2) Drive axle shaft seal into bearing cover using

Installer 9278 (Fig. 13).

Fig. 7 LOCKING RING

1 - BEARING NUT

2 - PUNCH

3 - LOCKING RING

4 - BEARING

Fig. 8 BEARING NUT WRENCH

1 - AXLE SHAFT

2 - BEARING NUT

3 - WRENCH

4 - BEARING

Fig. 9 BEARING NUT AND LOCKING RING

1 - BEARING NUT

2 - LOCKING RING

Fig. 10 AXLE BEARING REMOVAL TOOL

1 - AXLE SHAFT

2 - PLATE

VAREAR AXLE 3 - 17

Page 58 of 1232

NOTE: Install flush to a max. 3 mm (0.12 in.) deep

inside the bearing cover.

(3) Check roller bearing, replace according to con-

dition.

NOTE: Thoroughly grease roller bearings prior to

installation.

(4) Install bearing cover with axle shaft seal,new

gasket and dust shield on the axle shaft.

(5) Install tapered roller bearings and race on the

axle shaft (Fig. 14).

(6) Installnewlocking ring on axle shaft.NOTE: The flat side of the locking ring must point

towards the nut (Fig. 15). The locking ring is fitted

to ensure that the pressing is done over the inner

bearing race only. The flat on the locking ring must

be aligned with the flat on the axle shaft otherwise

the axle shaft will be damaged.

(7) Place axle shaft through the hole in Plate 9277

and position the assembly in a press (Fig. 16).

(8) Press tapered roller bearing onto rear axle

shaft as far as the stop.

CAUTION: In order to avoid damaging the bearing,

the outer race must be turned while pressing on.

(9) Screw on bearing nut and tighten nut with

Wrench 9279 to 500 N´m (369 ft. lbs.).

Fig. 11 PRESSING BEARING

1 - AXLE SHAFT

2 - BEARING

3 - PLATE

Fig. 12 AXLE SHAFT ASSEMBLY

1 - AXLE SHAFT 6 - BEARING

2 - BEARING COVER 7 - SEALING RING

3 - RADIAL SHAFT SEAL 8 - LOCKING RING

4 - GASKET 9 - BEARING NUT

5 - DUST SHIELD

Fig. 13 SEAL INSTALLER

1 - INSTALLER

2 - BEARING COVER

Fig. 14 BEARINGS AND RACE

1 - BEARINGS

2 - RACE

3 - 18 REAR AXLEVA

AXLE BEARINGS/SEALS (Continued)

Page 59 of 1232

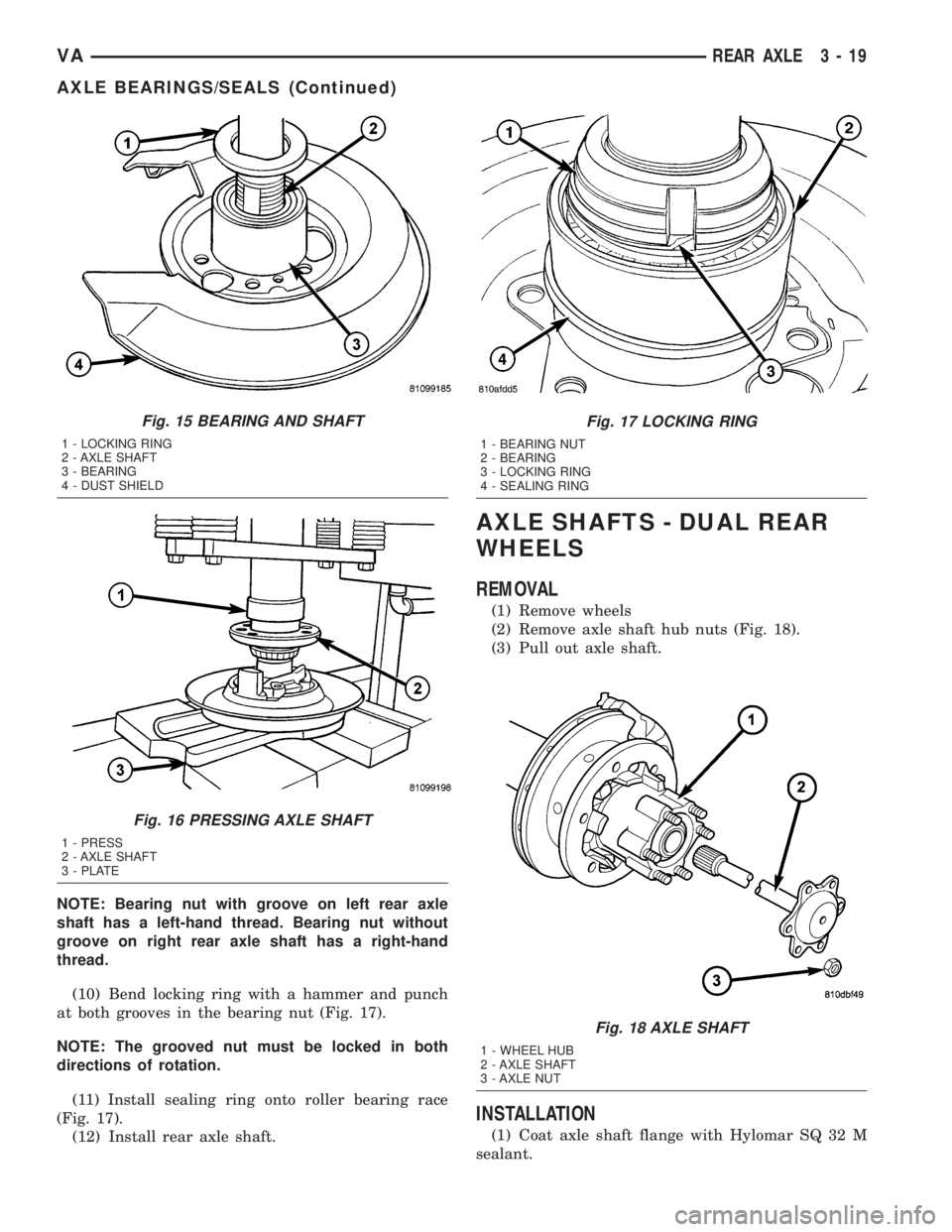

NOTE: Bearing nut with groove on left rear axle

shaft has a left-hand thread. Bearing nut without

groove on right rear axle shaft has a right-hand

thread.

(10) Bend locking ring with a hammer and punch

at both grooves in the bearing nut (Fig. 17).

NOTE: The grooved nut must be locked in both

directions of rotation.

(11) Install sealing ring onto roller bearing race

(Fig. 17).

(12) Install rear axle shaft.

AXLE SHAFTS - DUAL REAR

WHEELS

REMOVAL

(1) Remove wheels

(2) Remove axle shaft hub nuts (Fig. 18).

(3) Pull out axle shaft.

INSTALLATION

(1) Coat axle shaft flange with Hylomar SQ 32 M

sealant.

Fig. 15 BEARING AND SHAFT

1 - LOCKING RING

2 - AXLE SHAFT

3 - BEARING

4 - DUST SHIELD

Fig. 16 PRESSING AXLE SHAFT

1 - PRESS

2 - AXLE SHAFT

3 - PLATE

Fig. 17 LOCKING RING

1 - BEARING NUT

2 - BEARING

3 - LOCKING RING

4 - SEALING RING

Fig. 18 AXLE SHAFT

1 - WHEEL HUB

2 - AXLE SHAFT

3 - AXLE NUT

VAREAR AXLE 3 - 19

AXLE BEARINGS/SEALS (Continued)

Page 60 of 1232

(2) Slide axle shaft into axle tube.

(3) Install axle shaft hub nuts and tighten to N´m

65 (48 ft. lbs.).

(4) Install wheels.

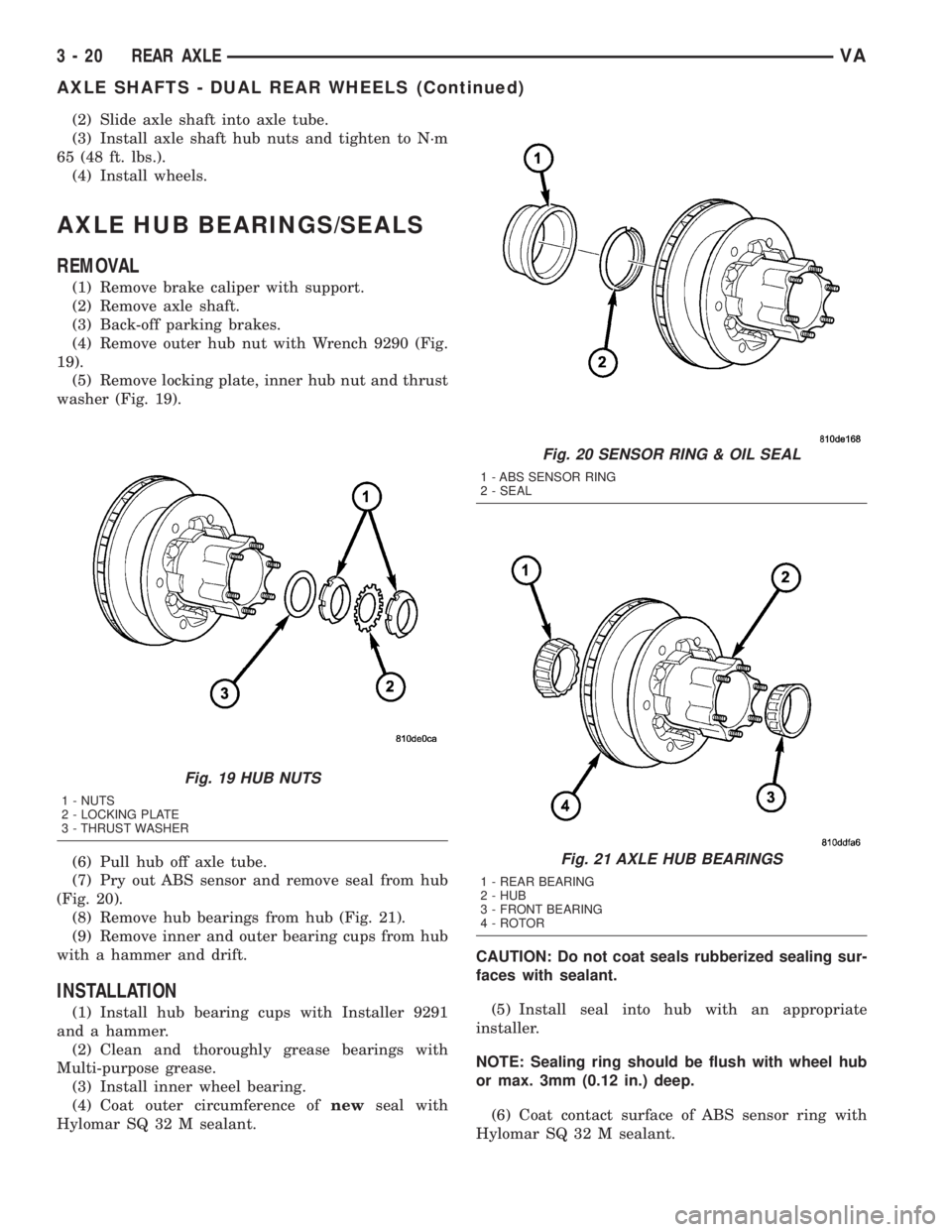

AXLE HUB BEARINGS/SEALS

REMOVAL

(1) Remove brake caliper with support.

(2) Remove axle shaft.

(3) Back-off parking brakes.

(4) Remove outer hub nut with Wrench 9290 (Fig.

19).

(5) Remove locking plate, inner hub nut and thrust

washer (Fig. 19).

(6) Pull hub off axle tube.

(7) Pry out ABS sensor and remove seal from hub

(Fig. 20).

(8) Remove hub bearings from hub (Fig. 21).

(9) Remove inner and outer bearing cups from hub

with a hammer and drift.

INSTALLATION

(1) Install hub bearing cups with Installer 9291

and a hammer.

(2) Clean and thoroughly grease bearings with

Multi-purpose grease.

(3) Install inner wheel bearing.

(4) Coat outer circumference ofnewseal with

Hylomar SQ 32 M sealant.CAUTION: Do not coat seals rubberized sealing sur-

faces with sealant.

(5) Install seal into hub with an appropriate

installer.

NOTE: Sealing ring should be flush with wheel hub

or max. 3mm (0.12 in.) deep.

(6) Coat contact surface of ABS sensor ring with

Hylomar SQ 32 M sealant.

Fig. 19 HUB NUTS

1 - NUTS

2 - LOCKING PLATE

3 - THRUST WASHER

Fig. 20 SENSOR RING & OIL SEAL

1 - ABS SENSOR RING

2 - SEAL

Fig. 21 AXLE HUB BEARINGS

1 - REAR BEARING

2 - HUB

3 - FRONT BEARING

4 - ROTOR

3 - 20 REAR AXLEVA

AXLE SHAFTS - DUAL REAR WHEELS (Continued)

Page 61 of 1232

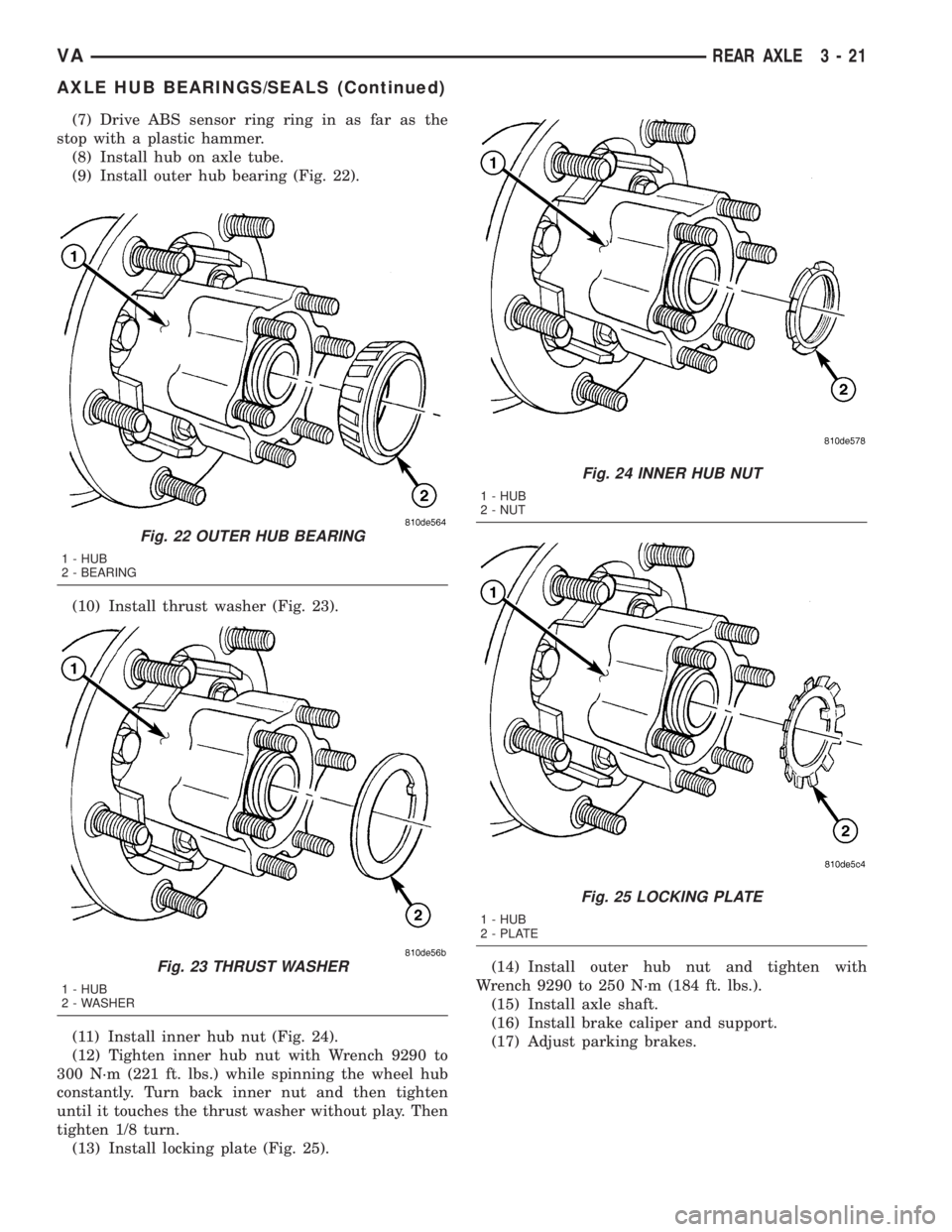

(7) Drive ABS sensor ring ring in as far as the

stop with a plastic hammer.

(8) Install hub on axle tube.

(9) Install outer hub bearing (Fig. 22).

(10) Install thrust washer (Fig. 23).

(11) Install inner hub nut (Fig. 24).

(12) Tighten inner hub nut with Wrench 9290 to

300 N´m (221 ft. lbs.) while spinning the wheel hub

constantly. Turn back inner nut and then tighten

until it touches the thrust washer without play. Then

tighten 1/8 turn.

(13) Install locking plate (Fig. 25).(14) Install outer hub nut and tighten with

Wrench 9290 to 250 N´m (184 ft. lbs.).

(15) Install axle shaft.

(16) Install brake caliper and support.

(17) Adjust parking brakes.

Fig. 22 OUTER HUB BEARING

1 - HUB

2 - BEARING

Fig. 23 THRUST WASHER

1 - HUB

2 - WASHER

Fig. 24 INNER HUB NUT

1 - HUB

2 - NUT

Fig. 25 LOCKING PLATE

1 - HUB

2 - PLATE

VAREAR AXLE 3 - 21

AXLE HUB BEARINGS/SEALS (Continued)